Method for manufacturing or transforming main beams of crane

A crane and main beam technology, which is applied in the field of crane manufacturing technology, can solve the problems of lower deflection of the main beam of the crane, lower lifting capacity, easy occurrence of accidents, etc., and achieves the effects of increasing cutting area, low cost, and increasing lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

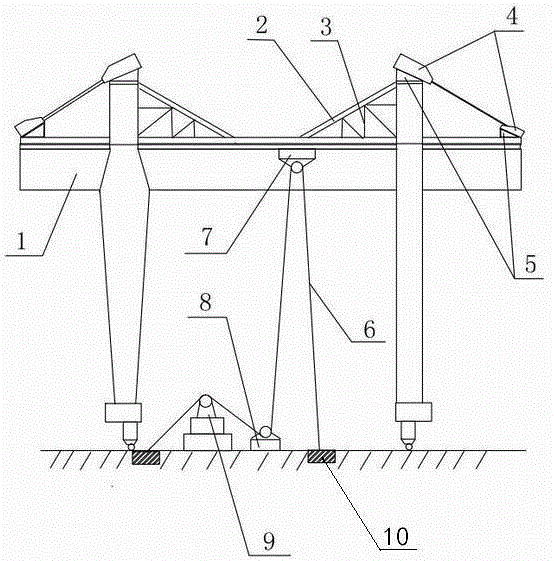

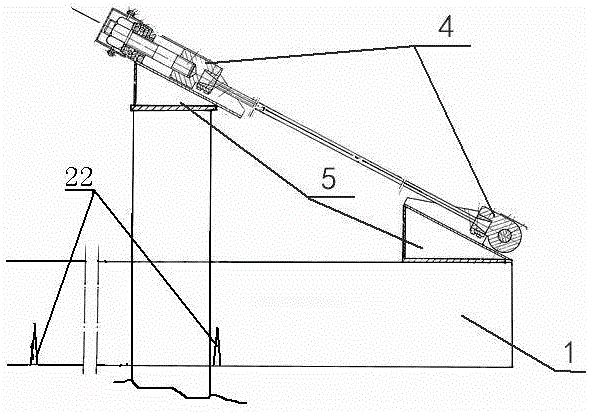

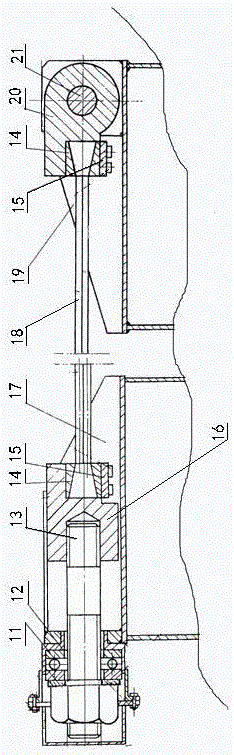

[0012] A method for manufacturing a crane girder, characterized in that: 1. The camber of the girder at the span of the main girder satisfies condition, L K For the span of the crane, the I-shaped steel bracket 2 is welded between the main girder mid-span beam and the support frame, the I-shaped steel bracket 2 and the main girder mid-span beam, and the support frame are provided with reinforcement bars 3, and the I-shaped steel bracket 2 is connected to the main girder span The included angle of the middle beam is 50-60°; 2. Under the condition that the cantilever of the main beam satisfies the condition that the upwarp of the cantilever at the effective cantilever is 0.9 / 350-1.4 / 350, the top of the support frame and the end of the cantilever of the main beam are installed through the connecting seat 5. Tensioner 4, and tensioner 4 is tensioned by a tensioning system.

[0013] A method for crane girder transformation is characterized in that: 1. At first, the lower cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com