Automatic brick setting machine

A technology for coded bricks and bricks, which is applied in the field of lifting mechanisms, can solve the problems of short service life of screw, high power of motor, large power consumption, etc., and achieve the effects of prolonging service life, reducing load and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

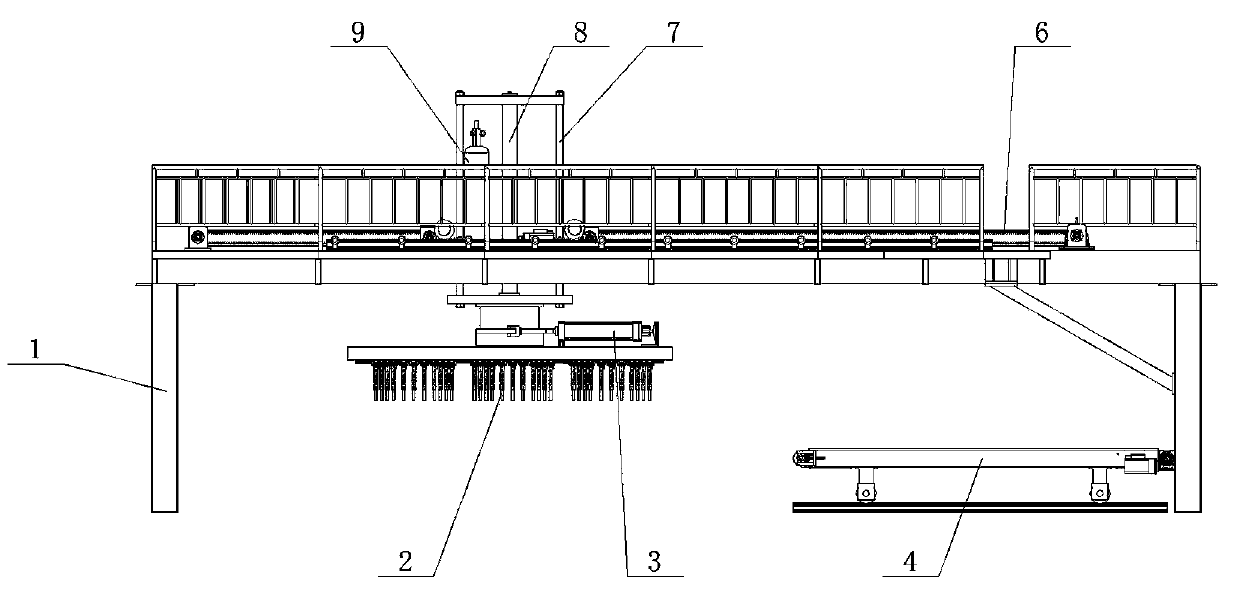

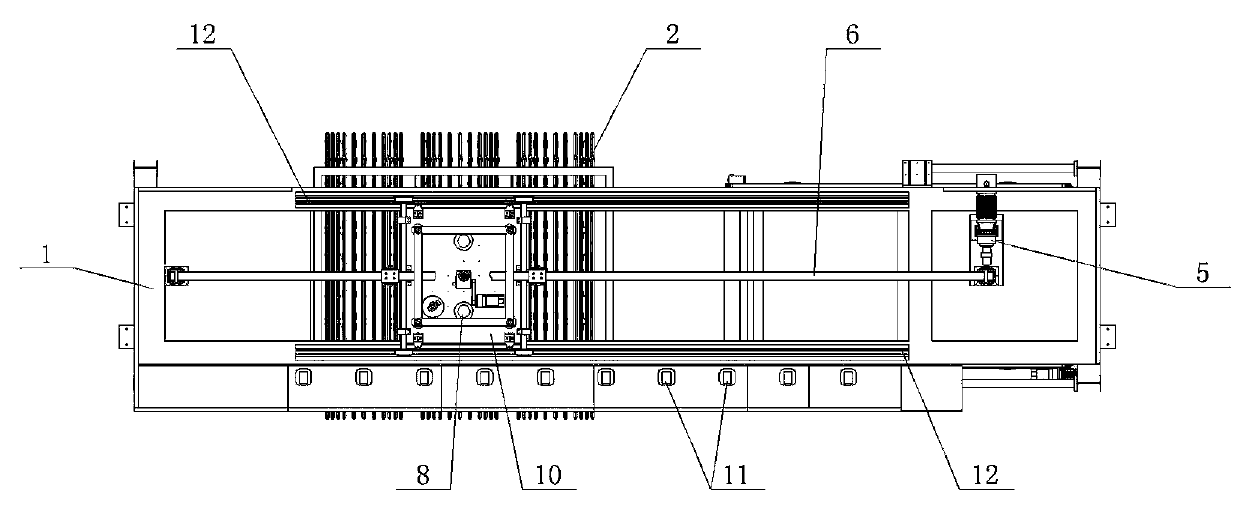

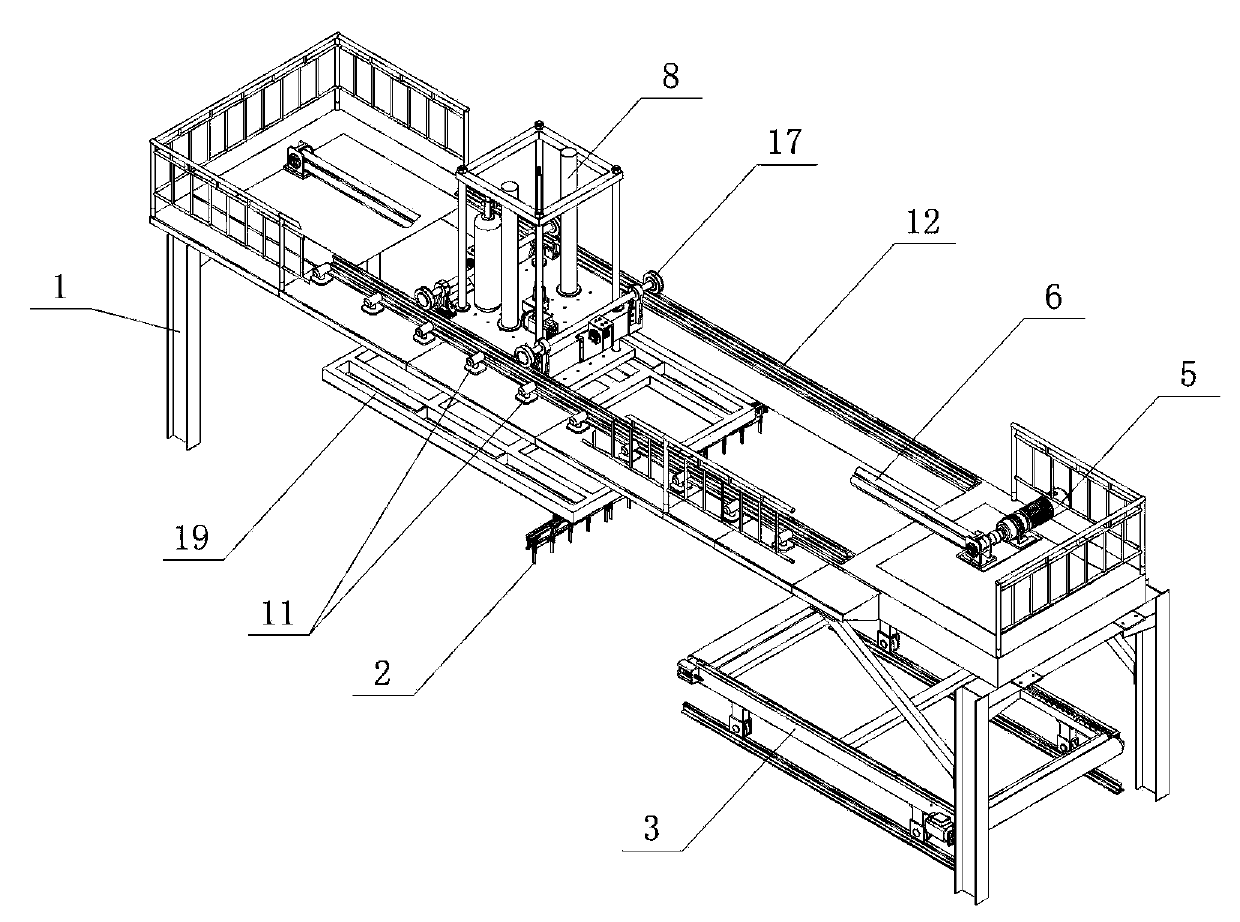

[0032] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention purpose, the structure and working process of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0033] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 Shown is one of the embodiments of the present invention, in this embodiment, the automatic adobe stacking machine is provided with a gantry frame 1, and the gantry frame 1 is provided with a slidable lifting mechanism, and the lifting mechanism consists of a sliding platform 10 and a lifting platform 13 Composition, the lifting platform 13 is installed below the sliding platform 10, several groups of adobe fixtures 2 are arranged below the lifting platform 13, and the vertical lead screw 16 is arranged on the sliding platform 10, and the lifting platform 13 is lifted by the leading screw 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com