Pneumatic crawler-type forklift and method

A crawler type, forklift technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system component, lifting device, etc., can solve the problems of low work efficiency, affecting personnel safety, high labor intensity, etc., to reduce labor intensity, The effect of guaranteeing personal safety, guaranteeing walking and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

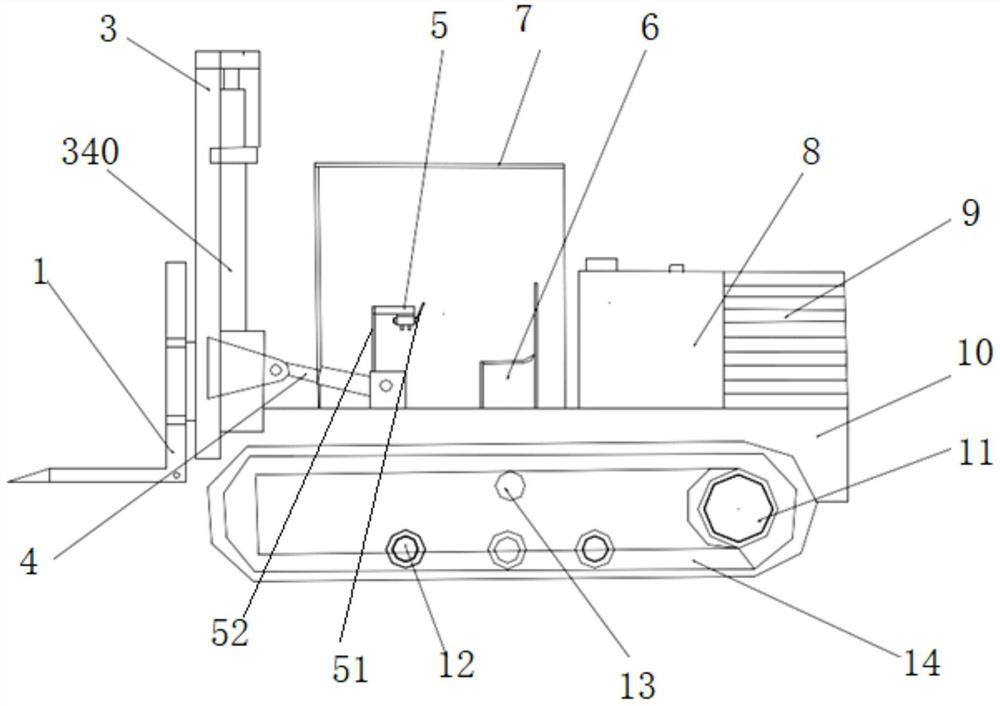

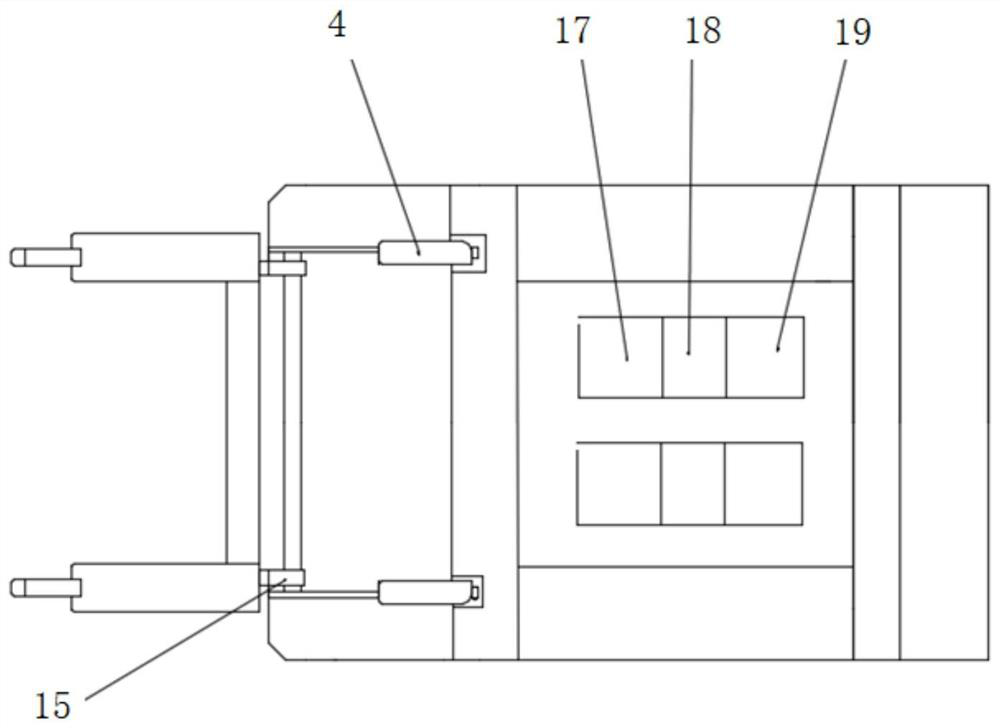

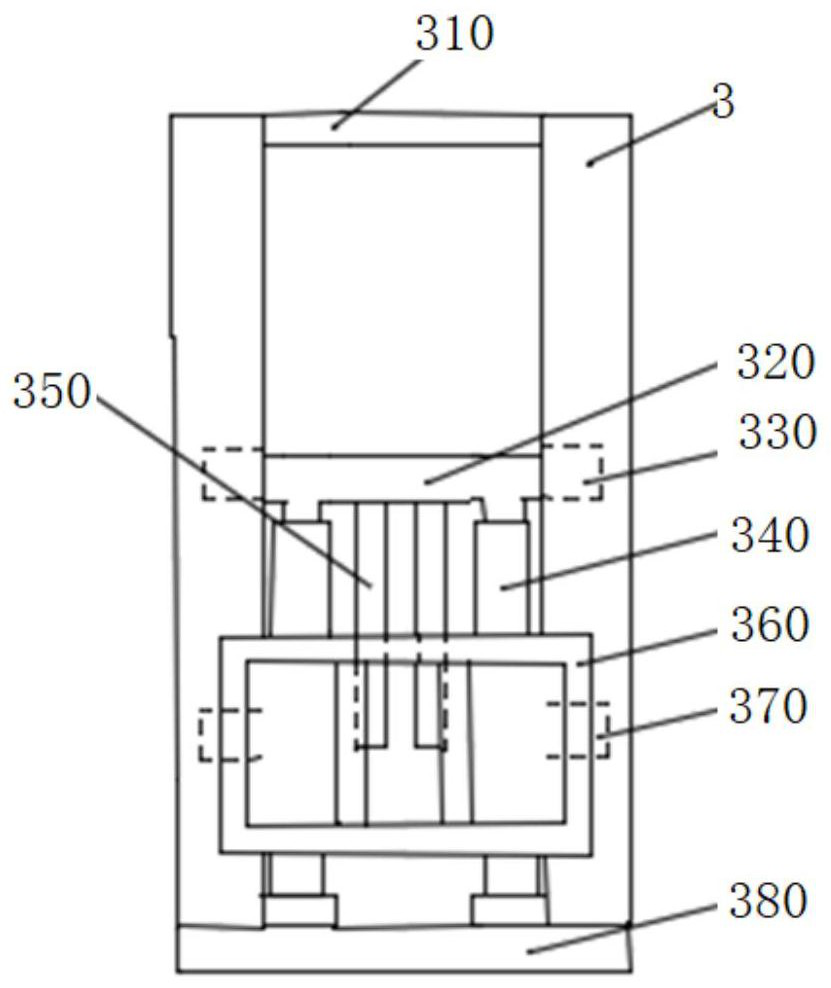

[0044] Such as figure 1 and 2 As shown, a pneumatic crawler forklift includes a walking track assembly, a forklift mast assembly, a vehicle chassis 10 and an operating console 5; the operating console 5 is located above the front of the vehicle chassis 10, and the rear side of the operating console 5 is provided with a Seat 6, the driver's head protection device 7 is arranged on the driver's seat 6, and the rear part above the vehicle chassis 10 is provided with a counterweight 9. The vehicle chassis 10 is installed on the walking track assembly. The air motor 19 and the gear oil pump 17 are installed in the vehicle chassis 10. The output shaft of the air motor 19 and the input shaft of the gear oil pump 17 are connected by a flat key or a spline, and the connection is made of cast iron. The shroud acts as a rotation guard 18, and the exhaust port of the air motor 19 is equipped with a muffler. The walking track assembly comprises a walking frame, a traveling motor 37, a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com