Double girder overhead viaduct type crane

A viaduct and crane technology, which is applied in the direction of cranes, trolley cranes, transportation and packaging, etc., can solve the problems of port wharf extension, etc., and achieve the effect of increasing throughput, increasing loading and unloading speed, and reducing intermediate operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

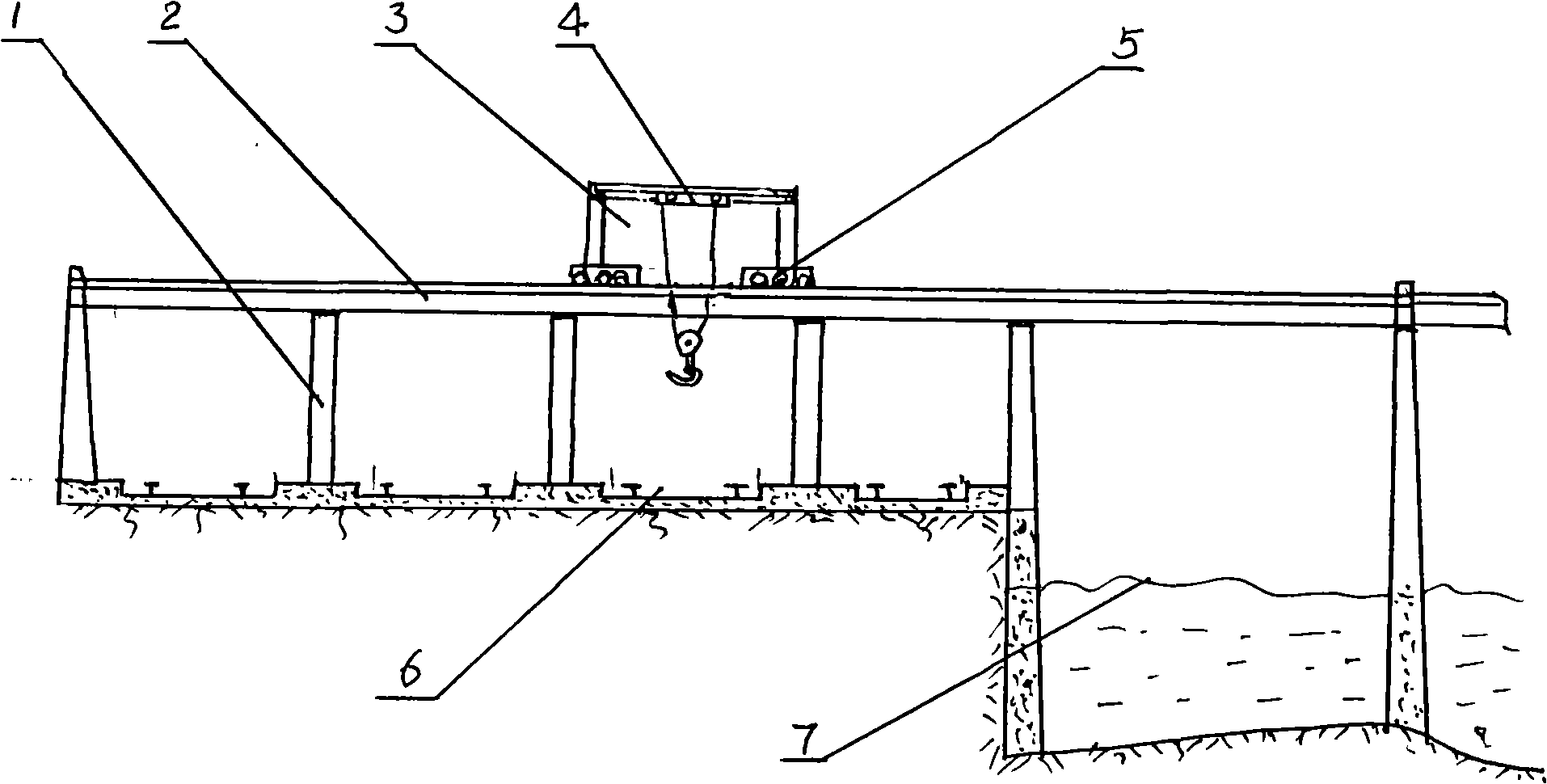

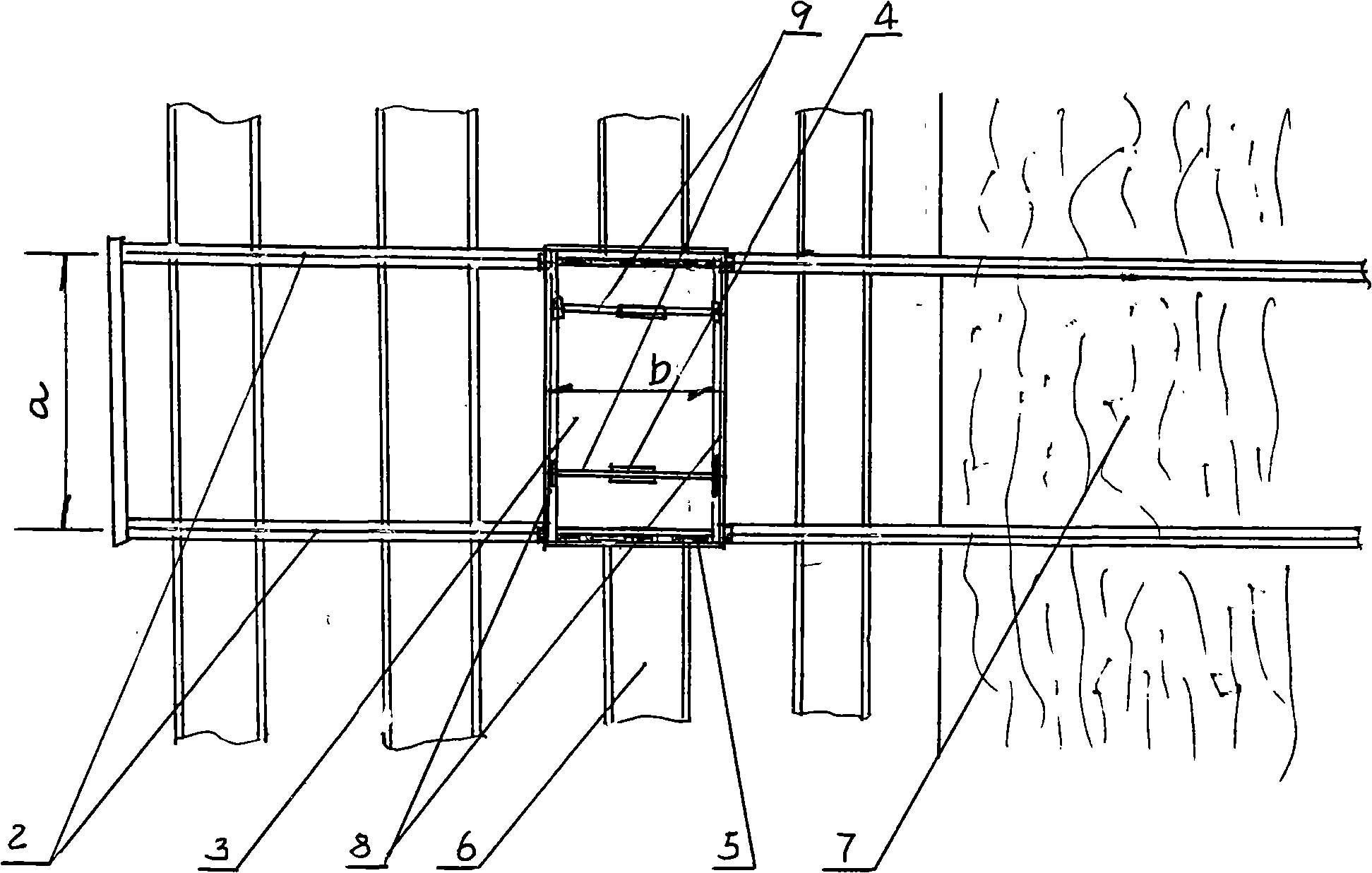

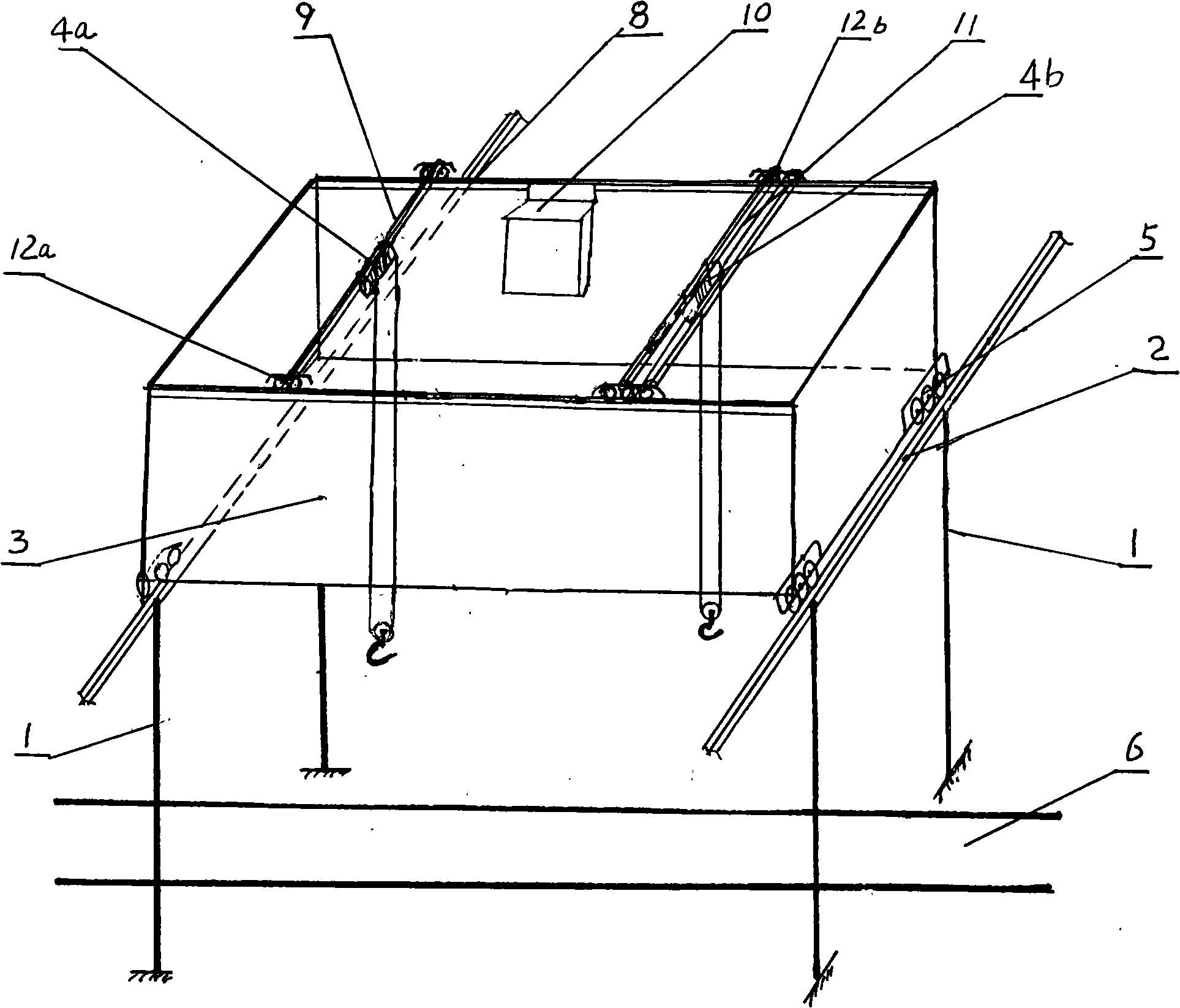

[0020] Such as figure 1 , figure 2 As shown, the double-girder viaduct crane of the present invention is composed of two rail girders 2 arranged in parallel, a large vehicle frame 3 composed of two rail beams 8, a large vehicle operating mechanism 5 fixed at both ends of the large vehicle frame 3, and arranged The track trolley 4 on the big vehicle frame 3, the hoisting mechanism (such as an electric hoist) fixed on the track trolley 4, and the operating room 10 and the electric control equipment fixed on the large vehicle frame 3 are formed. in:

[0021] Two parallel track main girders 2 are each supported by a row of support columns 1, spanning from the top of the railway 6 and extending to the ship berth 7 in the sea to form a viaduct structure; if it is only used for land goods such as trains and cars For loading and unloading, the viaduct structure extends over ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com