Electric steel wire rope balancing device and lifting method for vertical full-balance steel wire rope hoisting winch

A technology for balancing steel wire ropes and vertical hoists, which is applied in vertical lifting of ship machinery, boat lifting devices, elevators, etc., can solve the problems of inability to obtain dynamic response, complicated maintenance work, and influence on driving stability, and achieves high hoisting weight. Easy maintenance and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

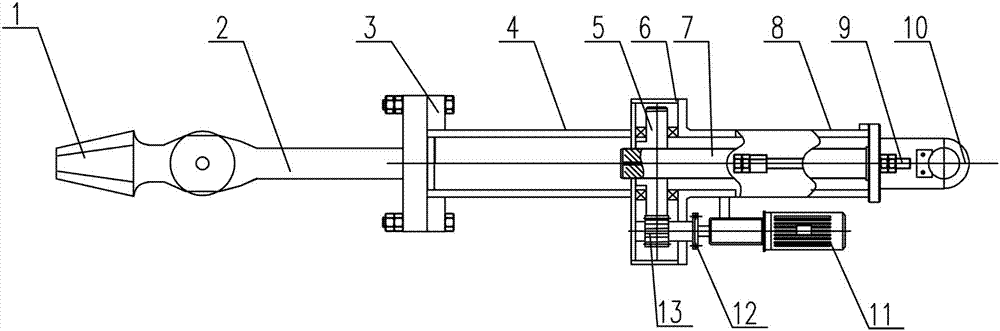

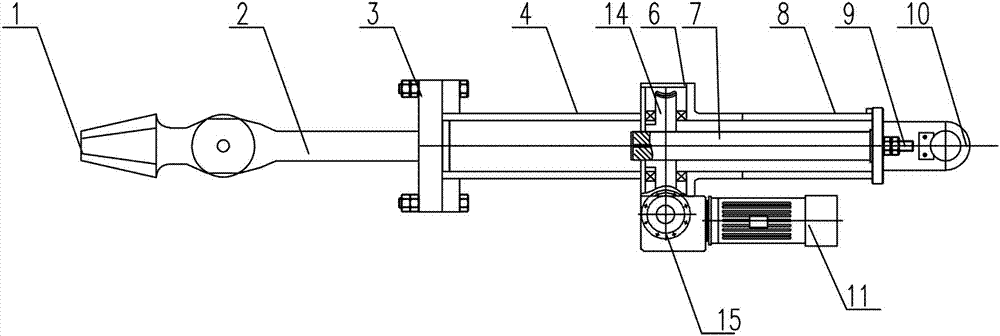

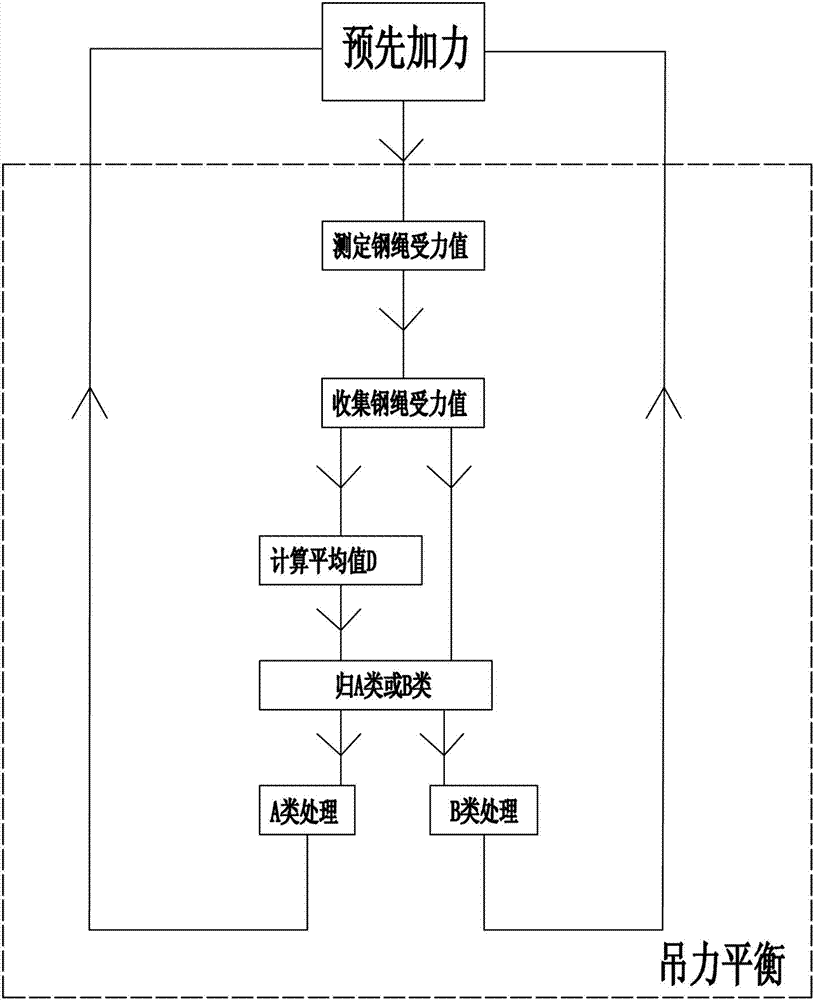

[0024] Such as figure 1 , a wire rope electric balancing device applied to a fully balanced wire rope winch vertical hoist. The fully balanced wire rope winch vertical hoist includes hoisting equipment and hoisting wire ropes. One end of the hoisting wire rope is wound around the hoisting equipment, and the other end is connected to the lifting object. , the wire rope electric balancing device connects the disconnected two-section steel wire rope into a lifting wire rope, and the electric balancing device includes a cone sleeve 1, a connecting rod 2, a housing, a driving device, a screw rod 7, and a reducer motor 11 for fixing the lifting wire rope;

[0025] The housing includes a first circular support 4, a second circular support 8, and a casing 6. The first circular support 4 and the second circular support 8 are connected by the casing 6. The first circular support 4, the casing 6, and the second circular support 4 are connected by the casing 6. The inside of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com