Circular high-accuracy crane and control method thereof

A high-precision, crane technology, used in cranes, trolley cranes, traveling mechanisms, etc., can solve the problems of easy accidents and low efficiency, and achieve the effect of improving the working range, simple principles, and reducing production accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

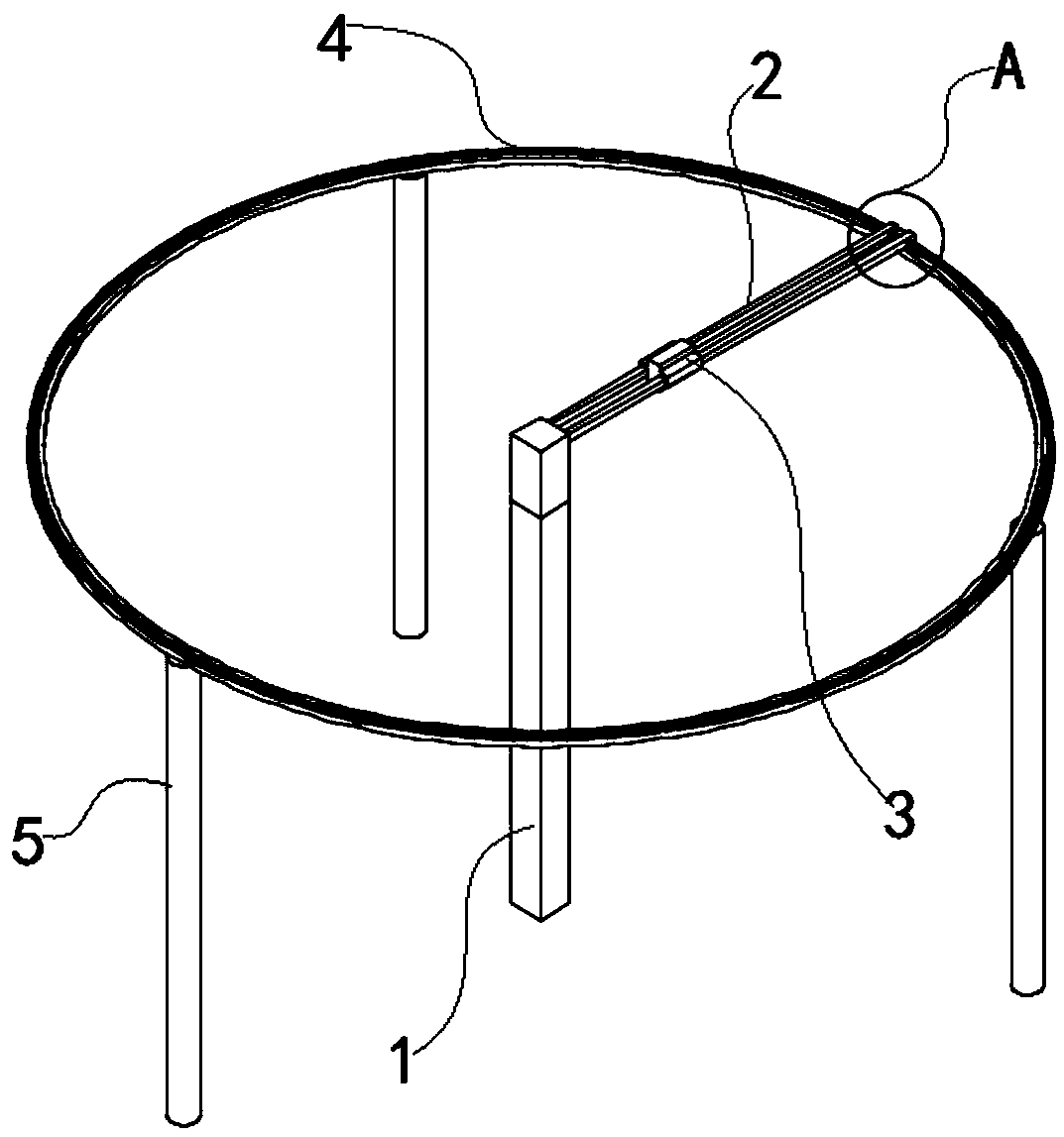

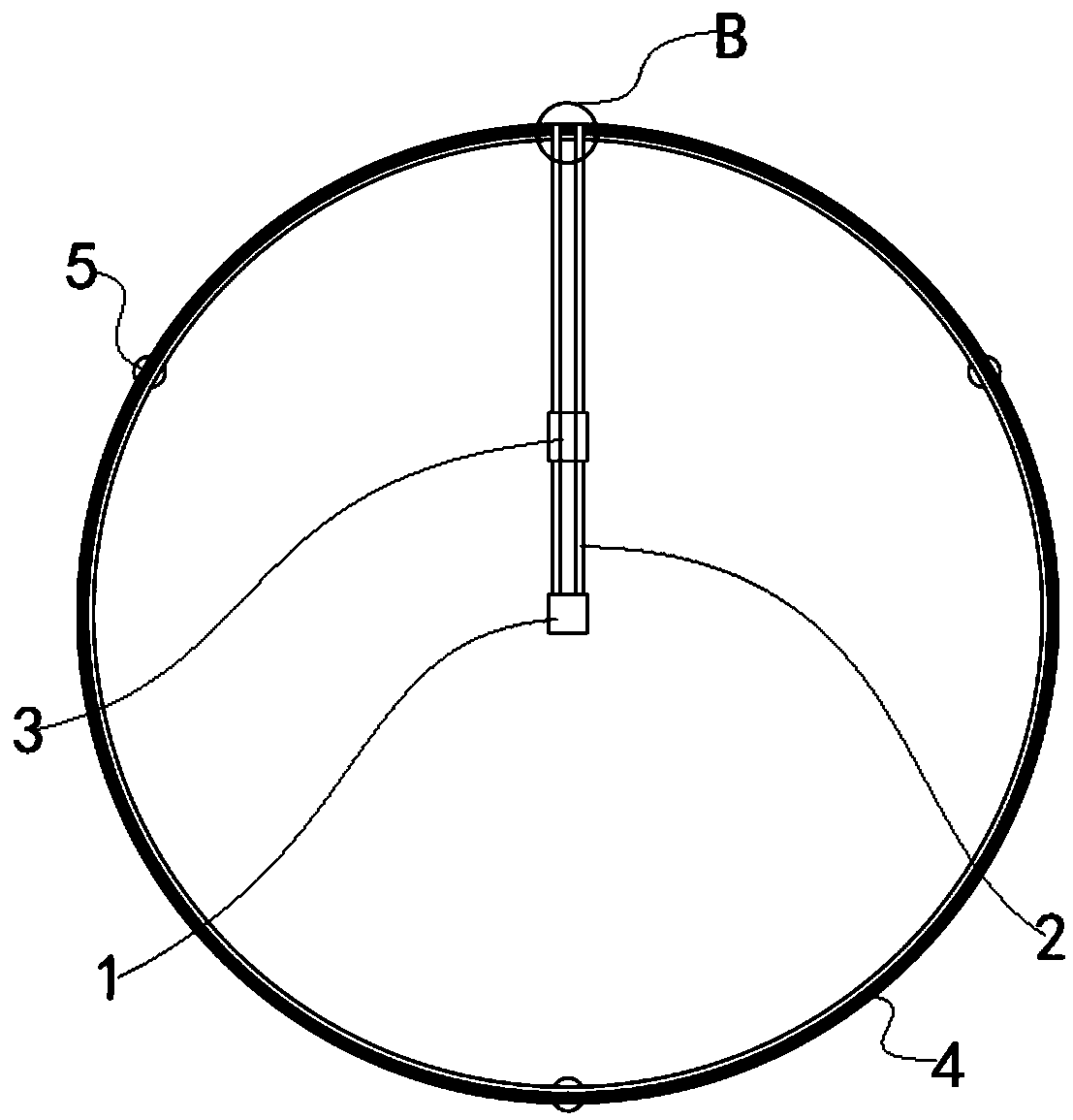

[0040] see Figure 1-10 As shown, the present invention is a circular high-precision crane, including a main frame 1, a slide bar 2, an electric hoist 3, a guide rail 4 and a sub-frame 5; the main frame 1 includes a rotary table 101 and a fixed frame 102; one end of the fixed frame 102 Connected with the rotary table 101; one surface of the rotary table 101 is connected with the slide bar 2, and the rotary table 101 drives the slide bar 2 to rotate; the slide bar 2 is provided with a matching electric hoist 3; one end of the slide bar 2 is connected with the guide rail 4; the guide rail 4 One surface is connected with several sub-frames 5 .

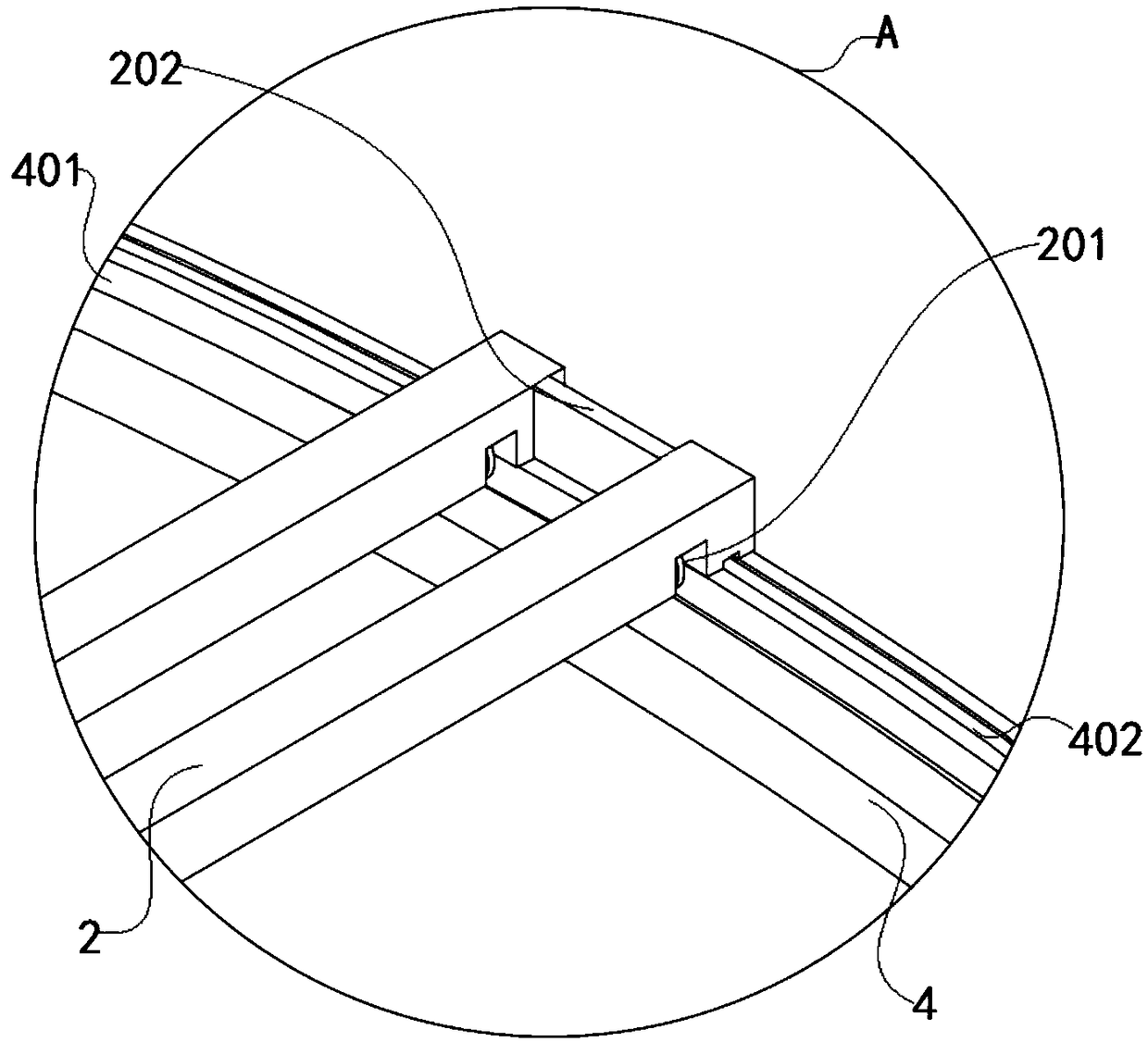

[0041] Such as figure 2 , 4 , 6, and 8, one end of the slide bar 2 is provided with a slot 201; a pulley 203 is fixed in the slot 201 to reduce the frictional resistance between the slide bar 2 and the guide rail 4, and reduce energy consumption; one end of the slide bar 2 is fixed with a fixed plate 202 One surface of the fixed plate...

Embodiment 2

[0049] see Figure 12As shown, a control method of a circular high-precision crane includes the following steps:

[0050] SS01: After power-on, the angle positioning sensor 403 positions the direction of the slide bar 2 and sets it as the initial direction, and the distance positioning sensor 206 positions the distance between the electric hoist 3 and the rotary table 101 and sets it as the initial distance;

[0051] SS02: Input the position of the heavy object to be lifted, the distance between the heavy object to be lifted and the rotary table 101 is the end distance, the end distance minus the initial distance is the moving distance, and the direction of the line between the rotary table 101 and the heavy object to be lifted is End direction, the clockwise angle from the initial direction to the end direction is the rotation angle;

[0052] SS03: The rotary table 101 drives the slide bar 2 to rotate clockwise at the rotation angle;

[0053] SS04: The electric hoist 3 slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com