Patents

Literature

203results about How to "Reduce production accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of active calcium silicate

InactiveCN103145136AEfficient removalReduce shipping costsAlkaline-earth metal silicatesAluminium oxides/hydroxidesCalcium silicateSlag

The invention provides a production method of active calcium silicate. The production method of the active calcium silicate is characterized by comprising the following steps of calcining limestone, cooling the limestone, screening the limestone to collect calcium oxide particles with the particle size of over 10 mm, conducting incineration to manufacture lime milk, wherein the concentration of the lime milk is 140-190g / L, conducting centrifugal sedimentation on the manufactured lime milk, collecting refined lime milk with the particle size less than 75 mu, filtering sodium silicate feed liquid of pre-desilication, wherein the content of seston in the sodium silicate feed liquid is enabled to be less than 0.1g / L, obtaining sodium silicate fine liquid, conducting a hydrothermal reaction on the manufactured refined lime milk and the sodium silicate fine liquid, conducting slag removal and washing on a product of the hydrothermal reaction, and obtaining the active calcium silicate. The production method of the active calcium silicate can effectively solve the problem that impurity content of the active calcium silicate serving as pack is high.

Owner:NORTHEASTERN UNIV +1

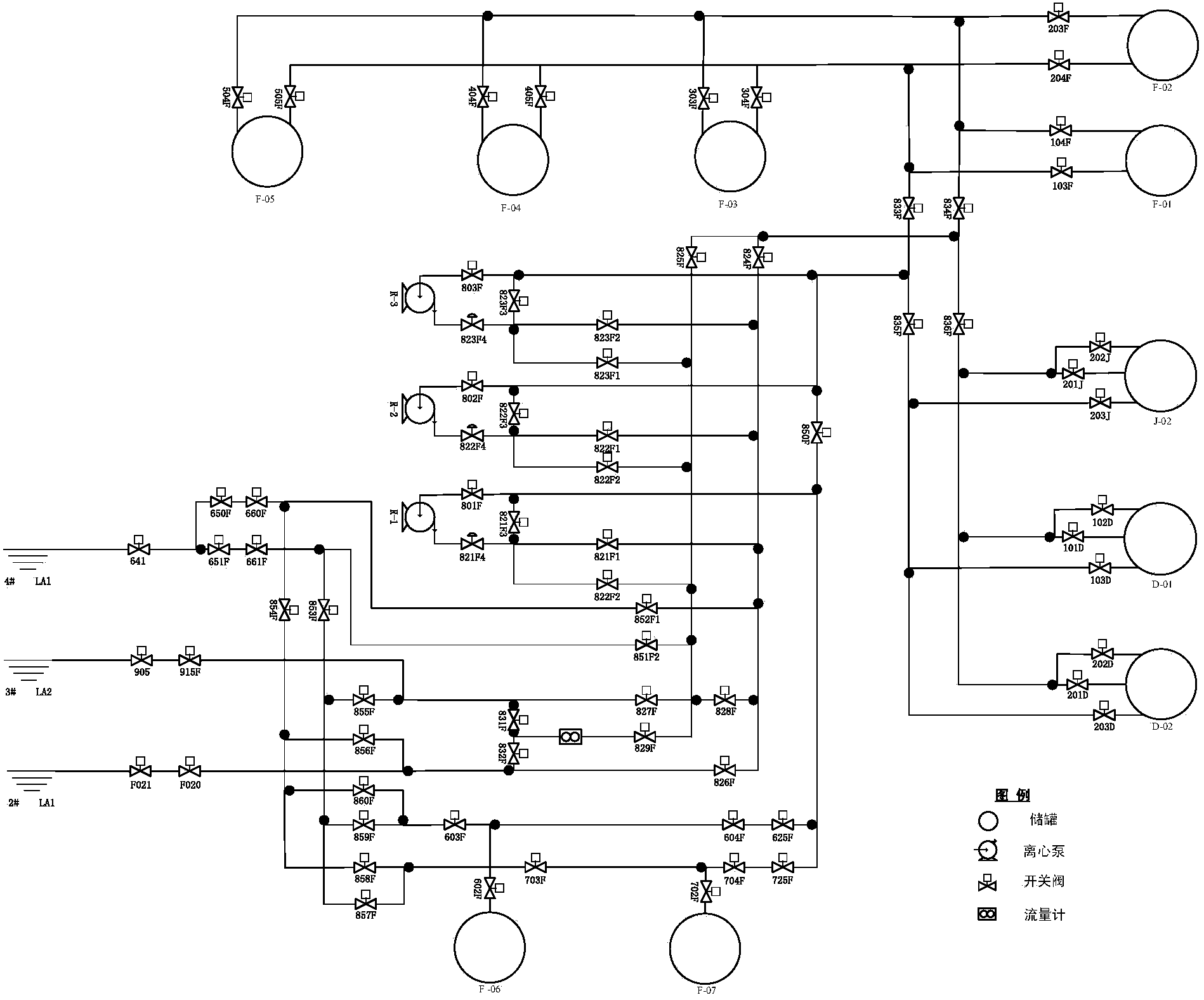

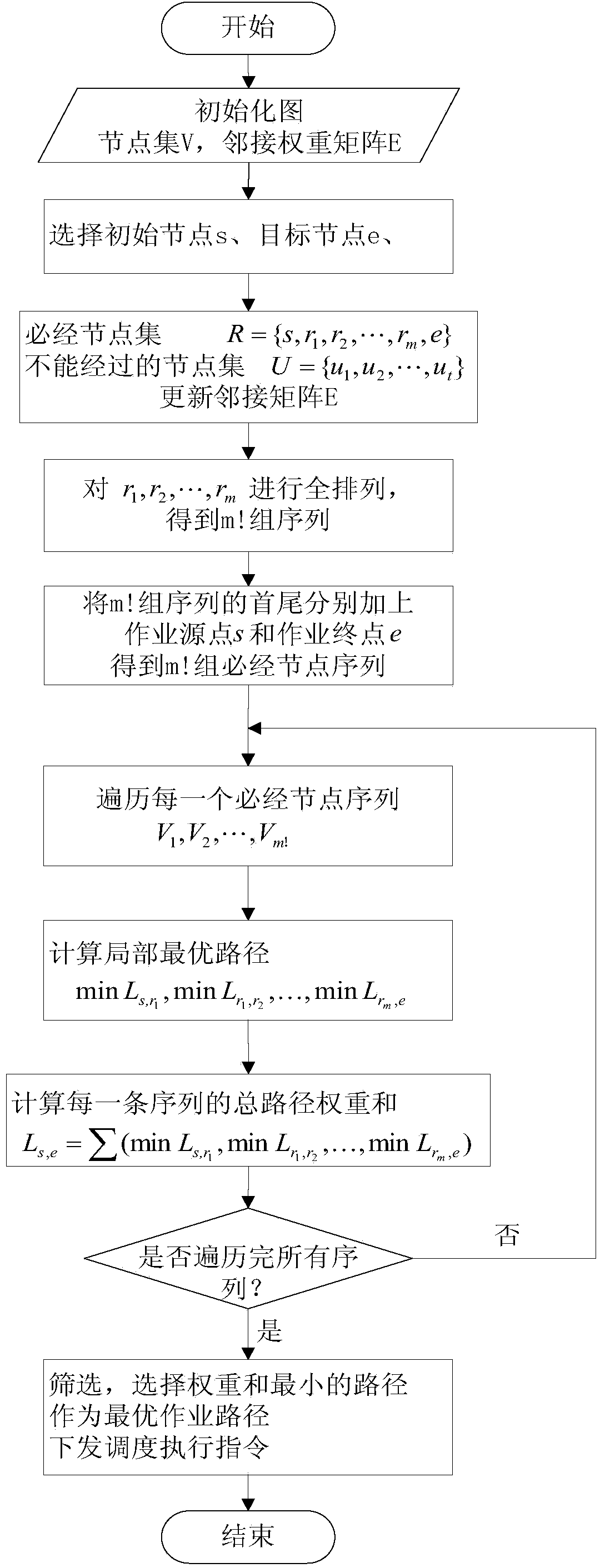

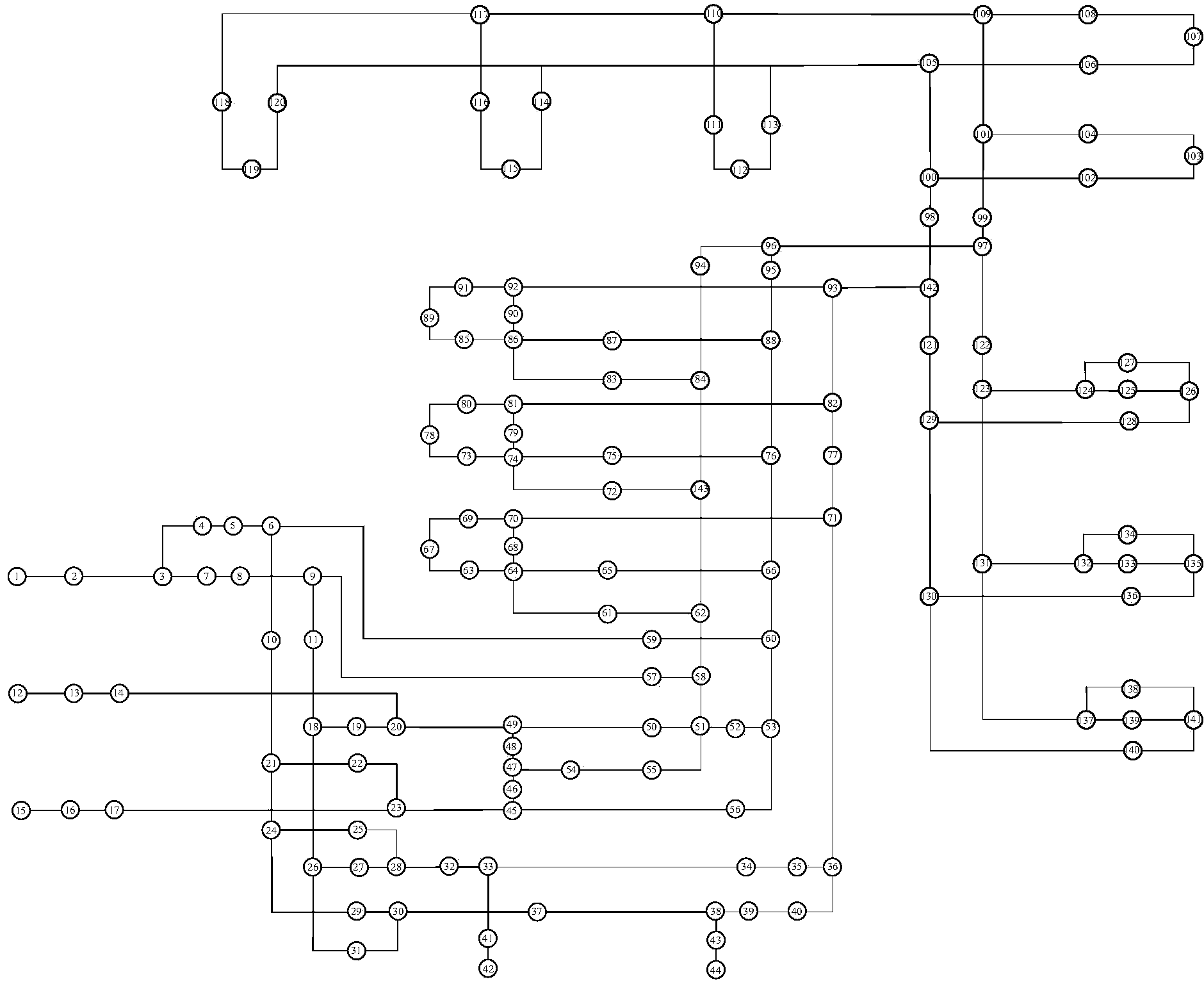

Crude oil tank farm scheduling method

ActiveCN104008431AReduce production accidentsLow running costForecastingLogisticsComputer scienceWork safety

The invention discloses a crude oil tank farm scheduling method which can accurately and rapidly provide a comprehensively-planned and comprehensively-optimized scheduling scheme for tank farm scheduling. According to the method, the aim of looking for the optimal working route by supporting a designated device which is sure to be passed by and a designated device which cannot be passed by under the constraint conditions such as tank farm devices and pipeline real-time states and by taking the shortest path as the optimization target is considered. By means of the method, enterprise operation cost is greatly lowered, production accidents caused by human subjective judgment are reduced, work safety of a crude oil tank farm is guaranteed, and the scheduling level and the economical efficiency in the tank farm are improved.

Owner:南京富岛信息工程有限公司

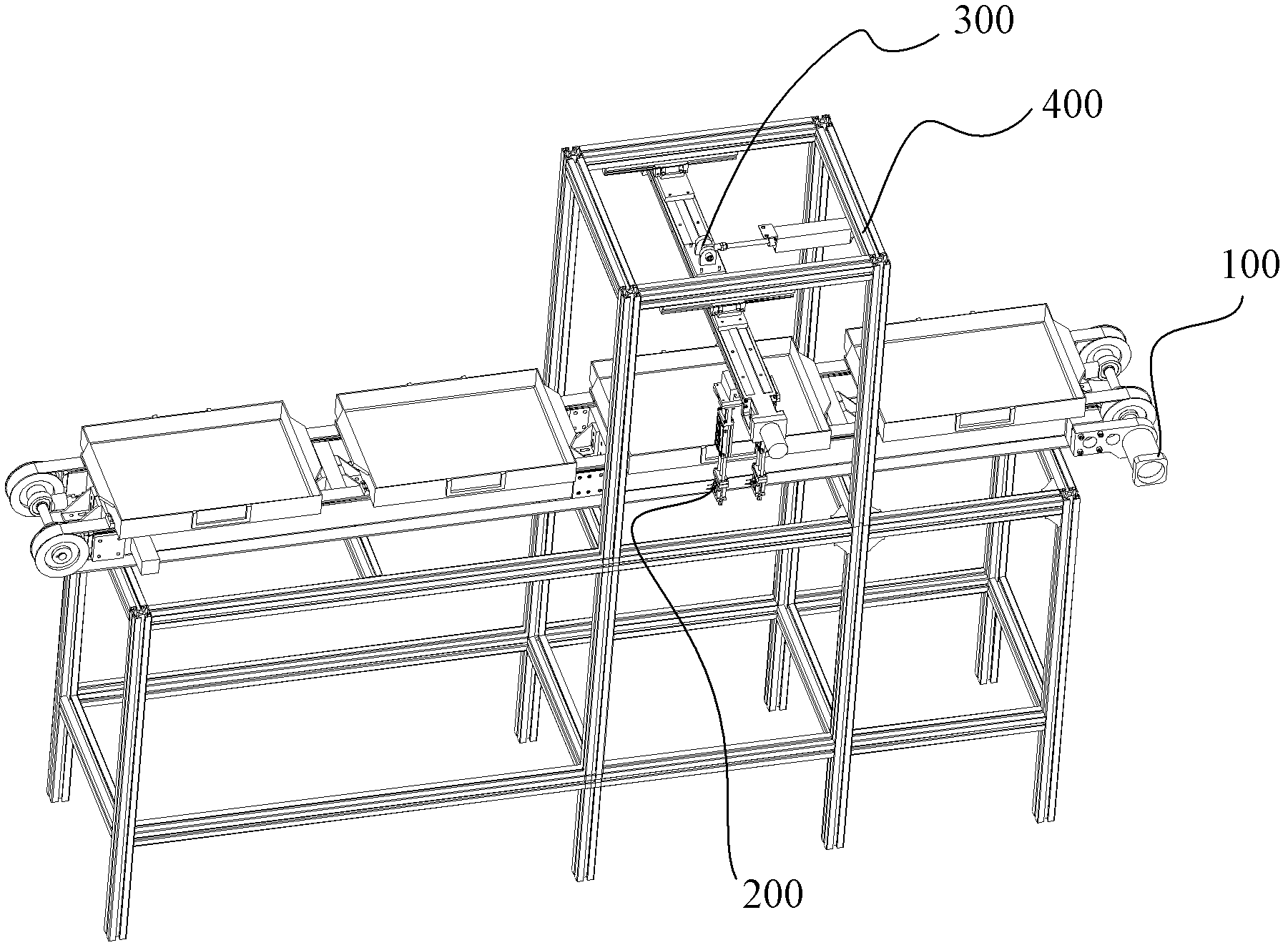

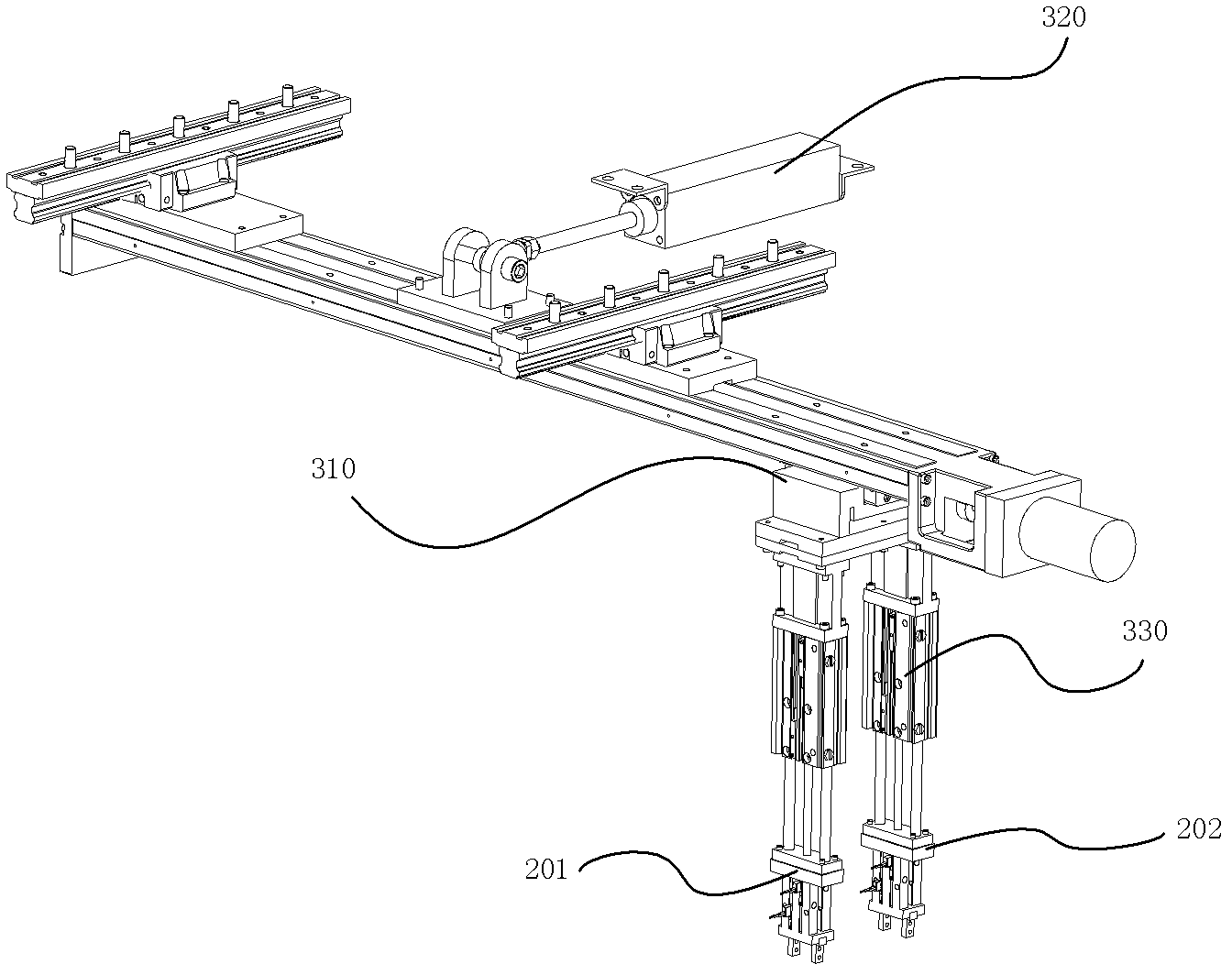

Mechanical arm capable of taking and placing materials

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

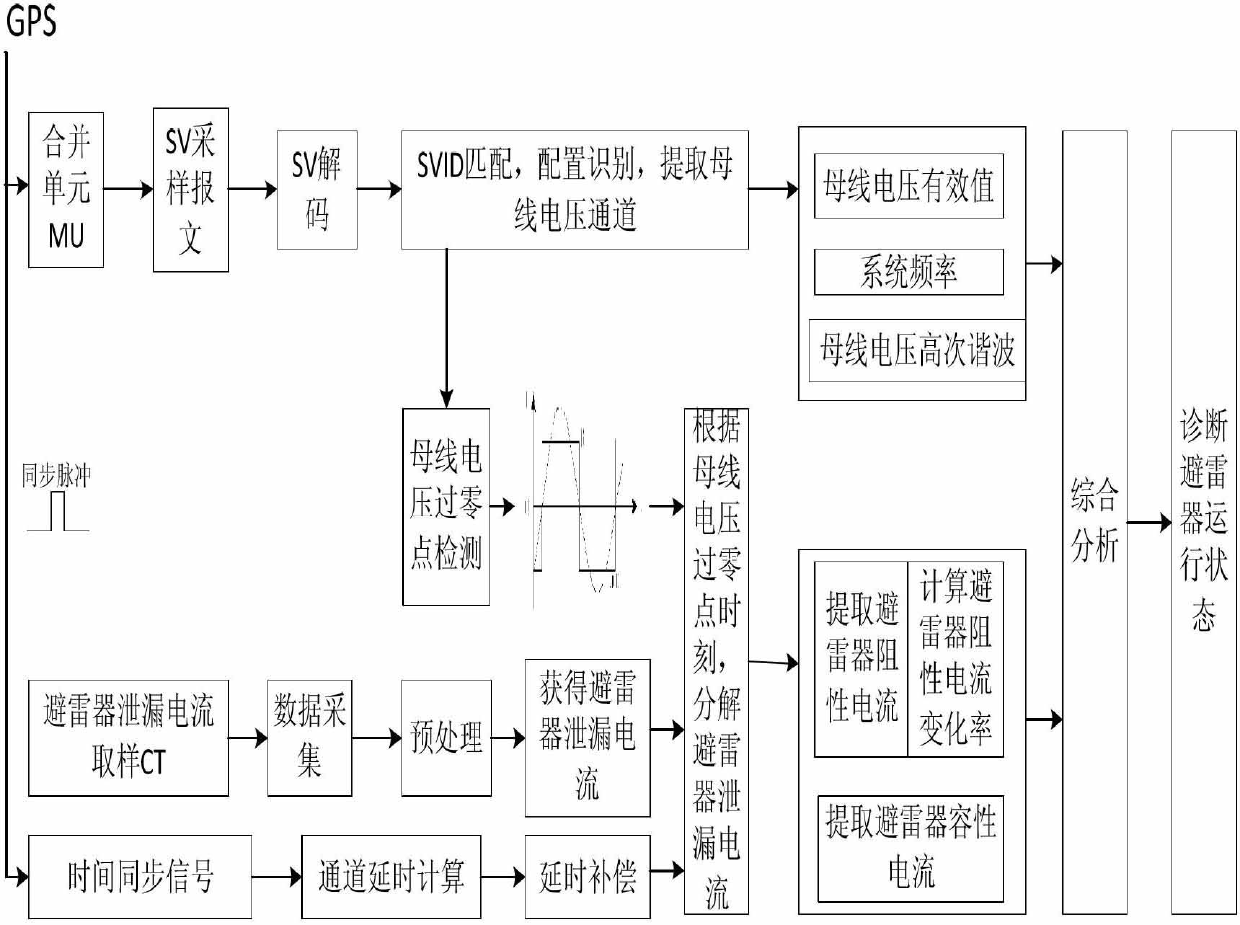

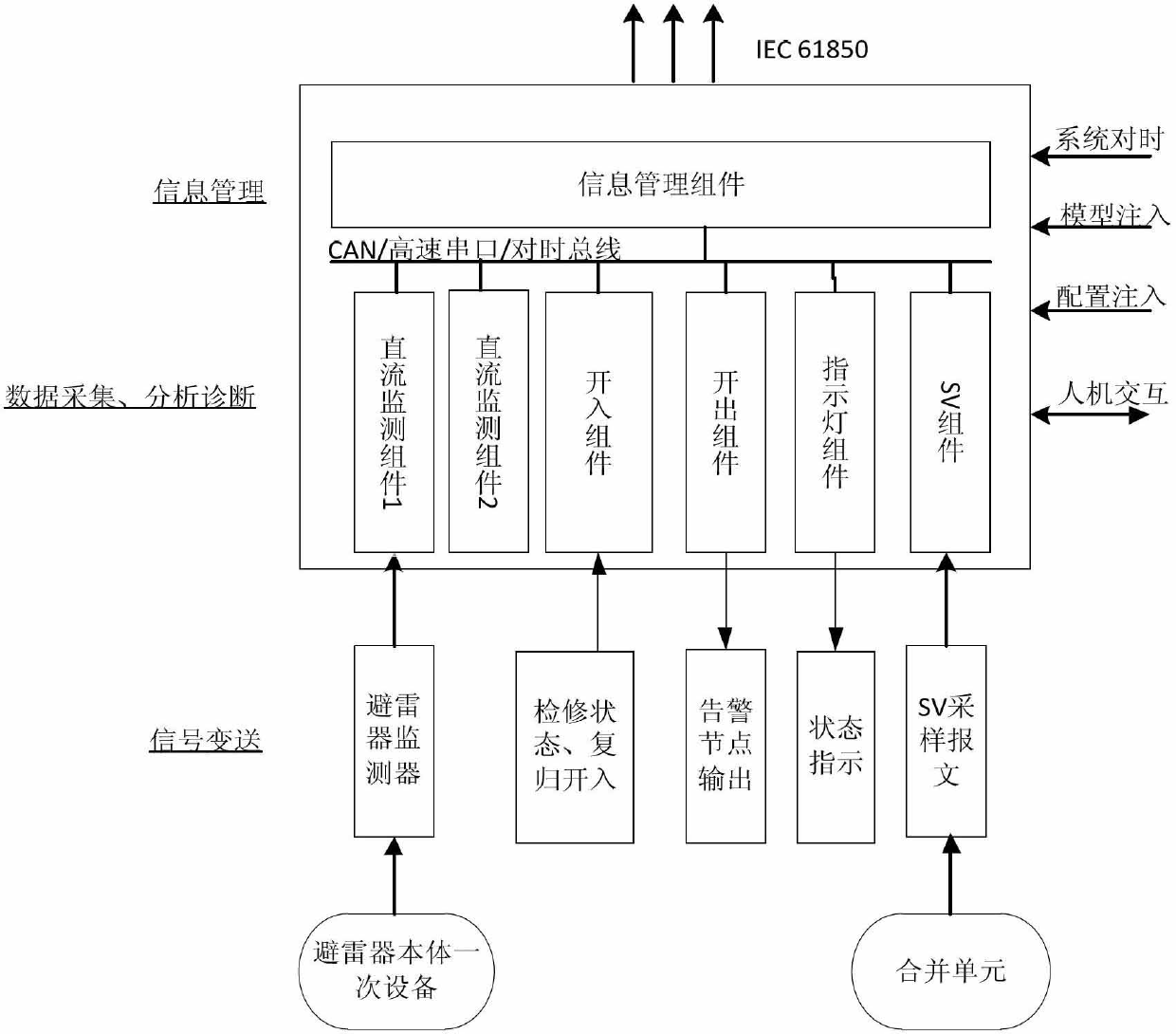

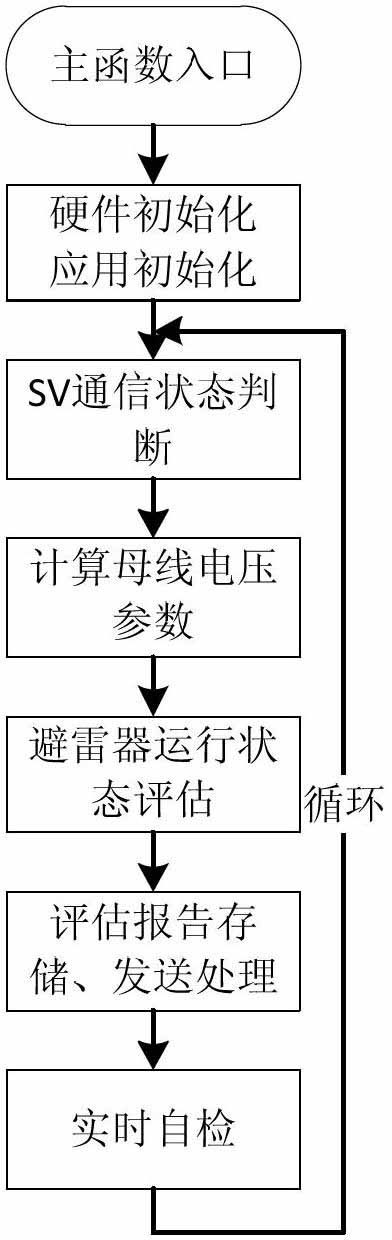

Device and method for monitoring arrester resistance current by introducing unconventional potential transformer (PT)

ActiveCN102680775AAccurately Calculate LatencyRestore accuratelyCurrent/voltage measurementElectrical testingBusbarCurrent sensor

The invention discloses a method and a device for monitoring arrester resistance current by introducing unconventional PT. Firstly, the monitoring device accesses sampled value (SV) messages of merging units (MU), decodes the SV messages, detects the time of zero crossing point of busbar voltage, calculates the channel delay accurately by relying on an external synchronous clock, and restores sinusoidal waveform of the busbar voltage accurately. Secondly, the monitoring device collects leakage current sensor information mounted on a grounding wire of an arrester, and decomposes the leakage current of the arrester into resistance current and capacity current. Thirdly, the monitoring device determines the operation condition of the arrester based on the change rate of the resistance current and the ratio of the resistance current value in the arrester leakage current. According to the method and the device for monitoring arrester resistance current, the problem that some online monitoring devices cannot introduce busbar voltage signals for calculating the arrester resistance current when the busbar voltage is digital signals in intelligent substations or digital substations is solved effectively, defects of early aging, insulation hidden dangers and the like of arresters can be found earlier, and application prospect in the market is broad.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

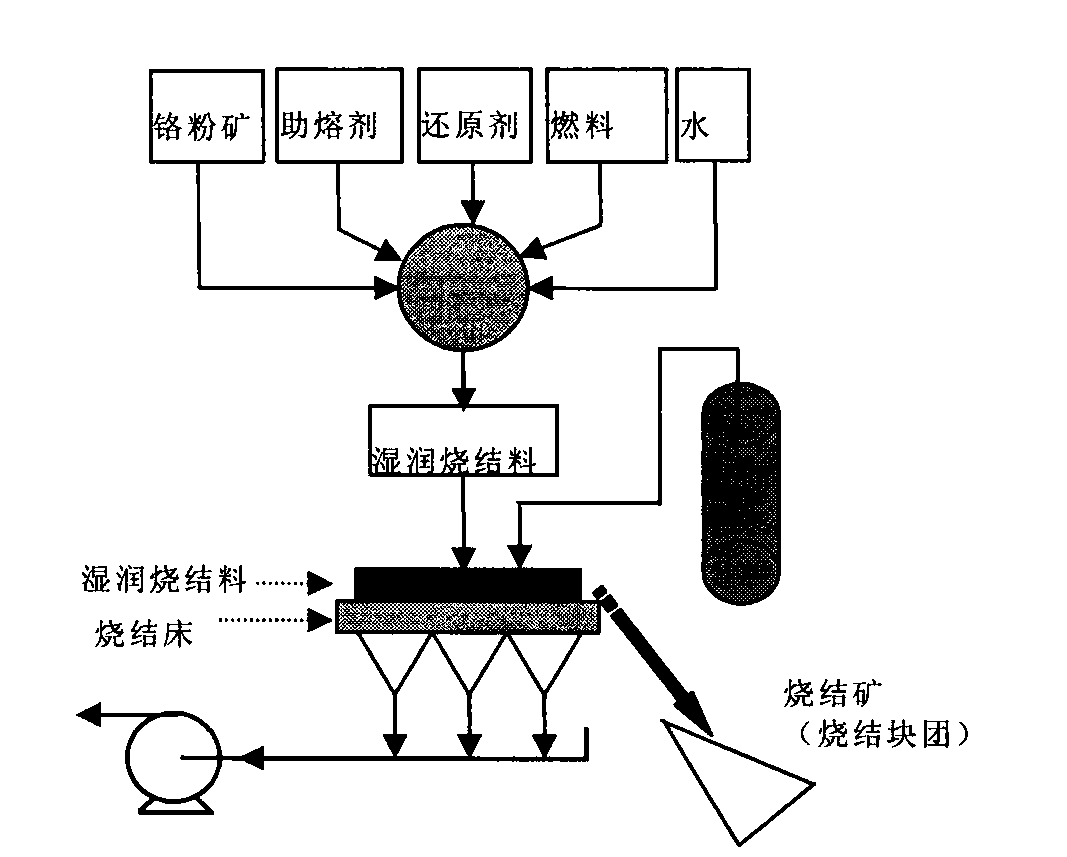

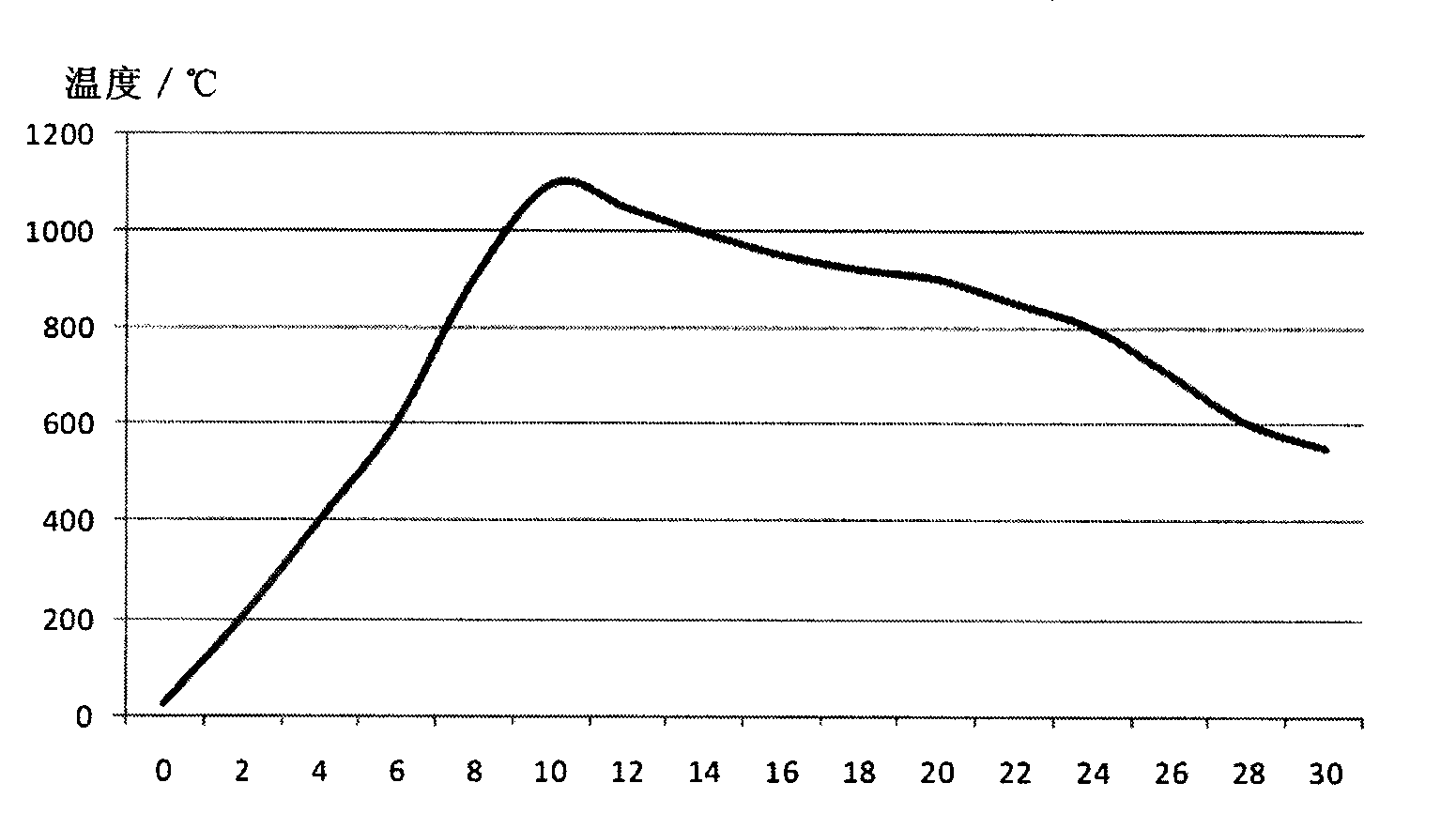

Pretreatment method for chromium powder ore used for smelting production of ferrochrome alloy

The invention provides a pretreatment method for a chromium powder ore used for smelting production of a ferrochrome alloy. The method comprises the steps of 1) mixing the chromium powder ore with a fluxing agent, a reducing agent and a fuel to obtain a mixture; and 2) sintering the mixture to obtain a sintered material. The method is short in process flow and low in sintering cost and is simple and practicable, and production of powder ore pollutions is not easy, so that relatively cheap powder chromium ore can be fully used, smelting consumption can be decreased greatly, and further smelting cost of the ferrochrome is reduced. The sintered material obtained by the sintering treatment method can be directly introduced into an ore smelting electric arc furnace for smelting after smashing. The method can enhance reducibility of furnace charging materials, reduce energy consumption and decrease usage proportion of other auxiliary materials such as coke, silica and the like in the smelting furnace charging materials. At the same time, possibility of reversing materials is greatly decreased, production security is increased and probability of production accidents is reduced greatly.

Owner:中国中化股份有限公司 +1

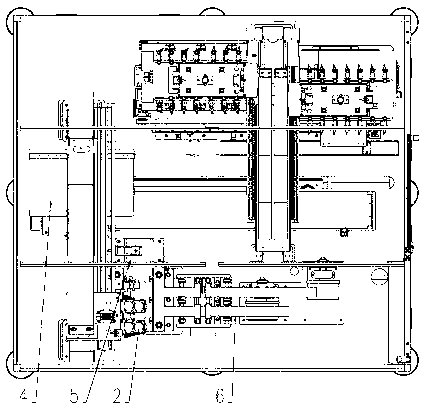

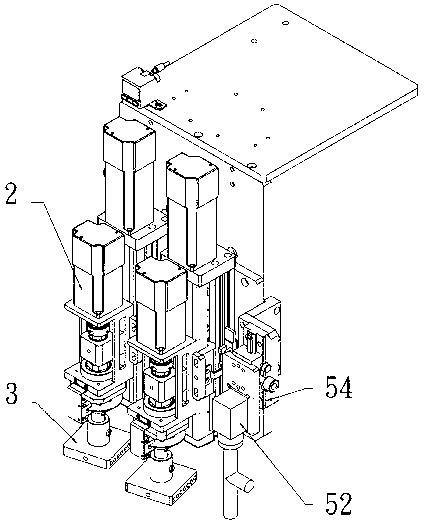

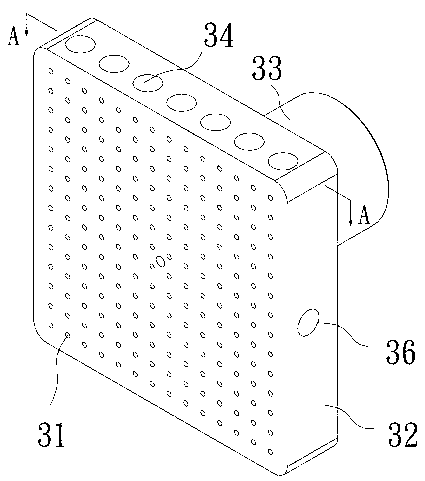

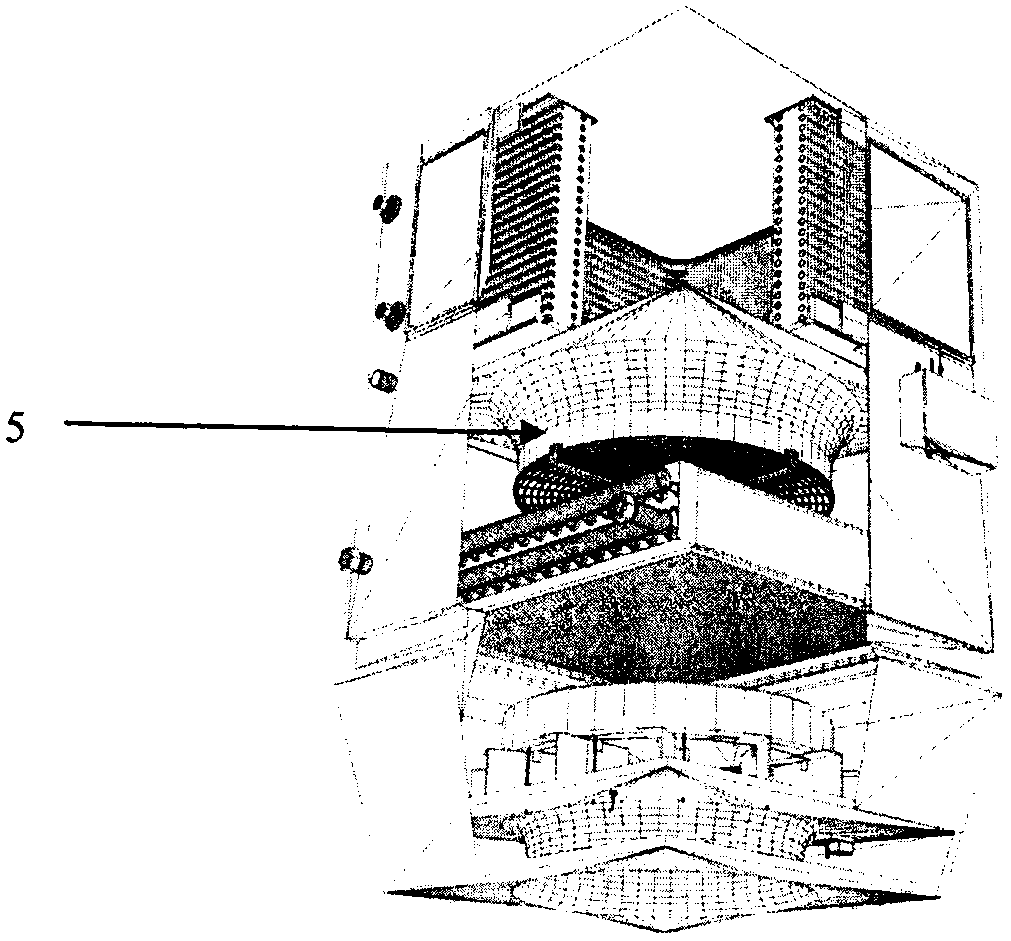

Reinforcement chip mounter

ActiveCN103220881AMeet the needs of useAvoid churnPrinted circuit manufactureSuction forcePulp and paper industry

The invention discloses a reinforcement chip mounter, comprising two rotary suction cup combinations, wherein each rotary suction cup combination is connected with a suction cup with a suction hole, each suction cup is provided with an adjusting air hole and an adjusting plug capable of being inserted into the adjusting air hole to block the suction hole, the suction force and the suction area can be adjusted through the adjusting plugs, the use requirements of reinforcement plates with different specifications are met, the cost is reduced, and the production efficiency is improved. Through the arrangement of the double rotary suction cup combinations, the reinforcement chip mounter has wider applicability and stronger flexibility and meets the production needs of various production modes, so that the working efficiency is greatly improved.

Owner:USUNFOSHANTECH

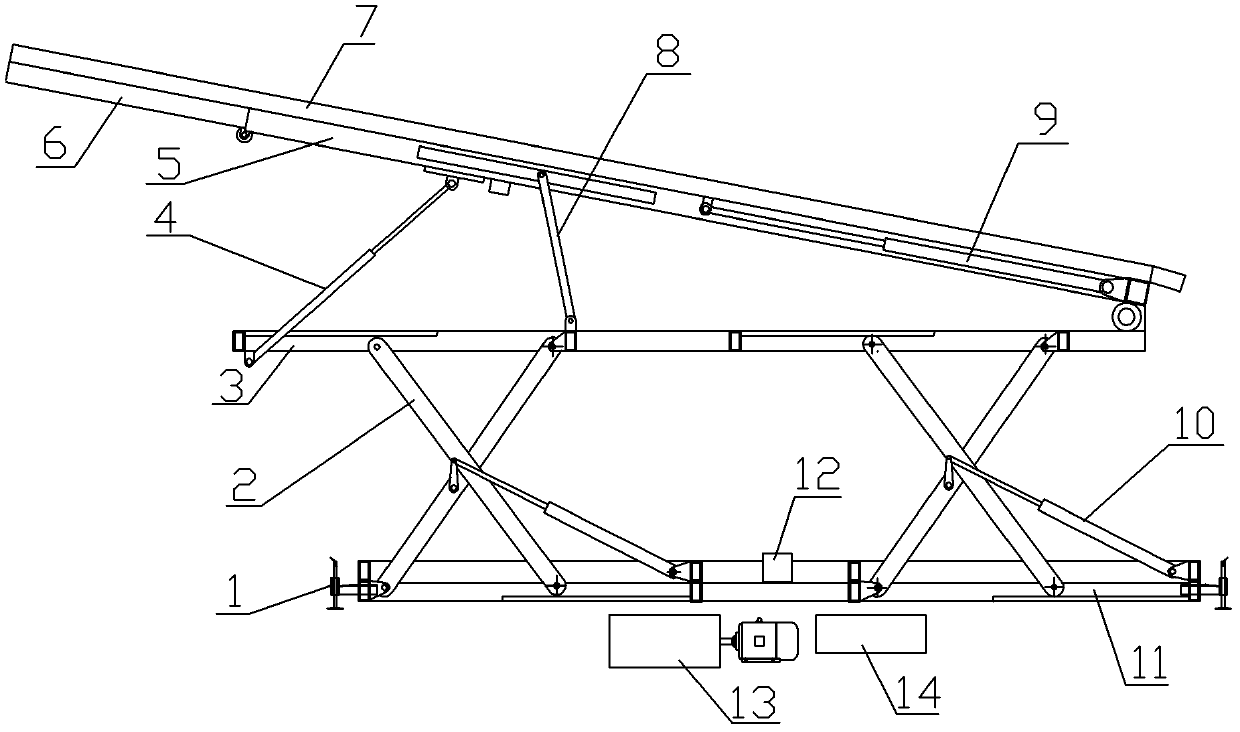

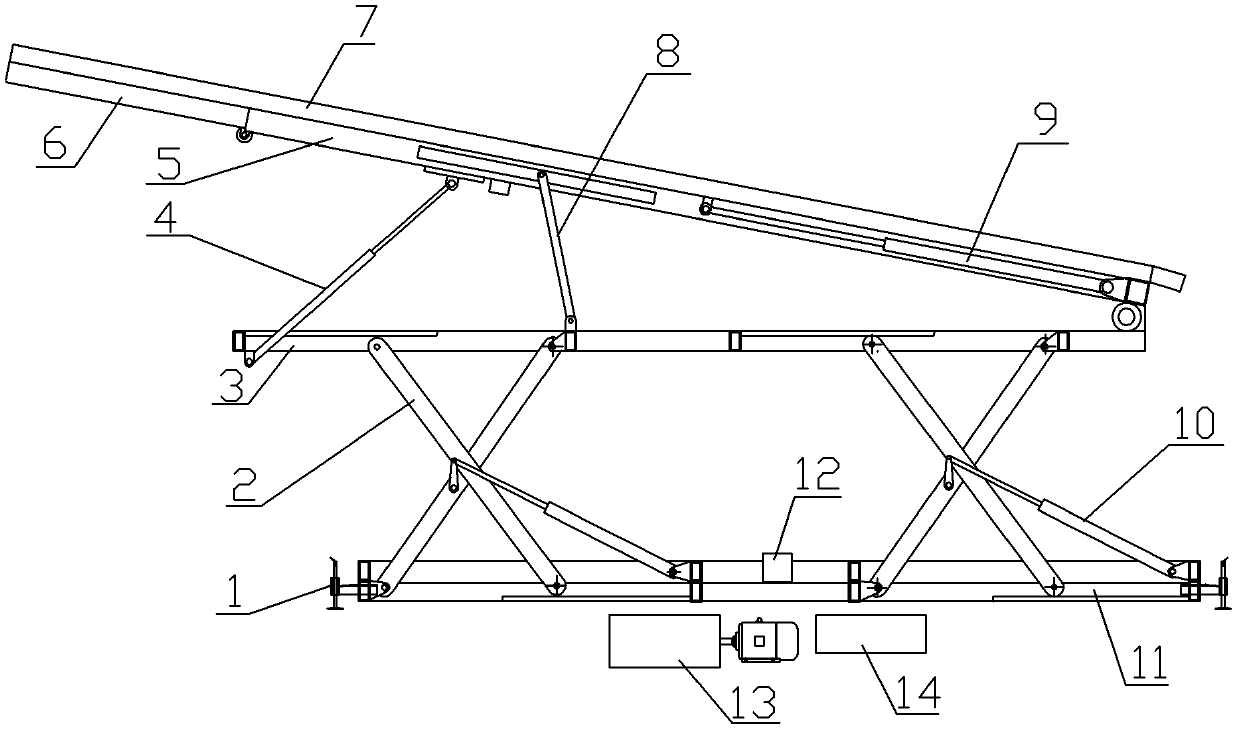

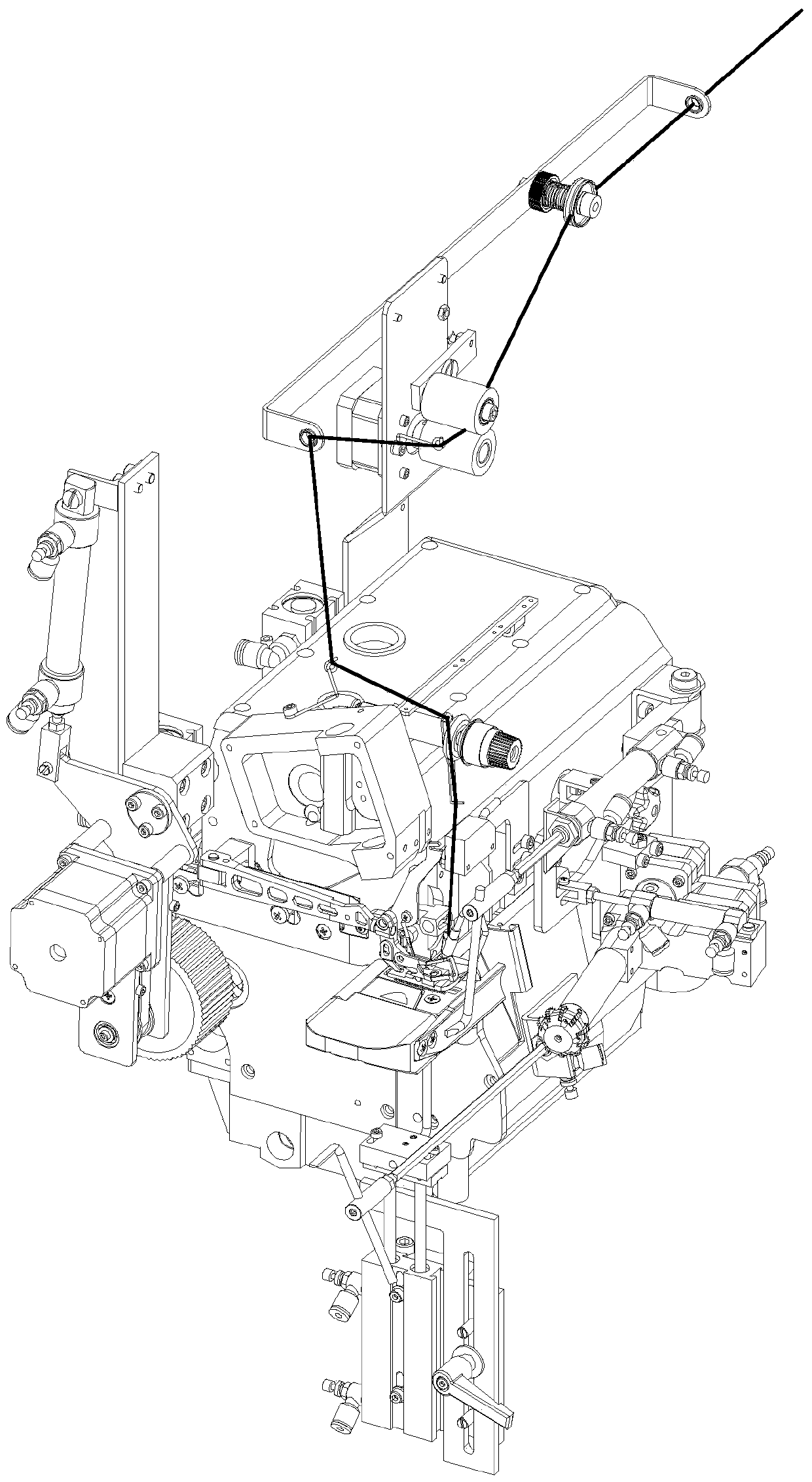

Hydraulic lifting pipe conveyer for oil drilling platform

InactiveCN102383745AEnsure safe production environmentImprove labor productivityDrilling rodsDrilling casingsOil drillingUltimate tensile strength

The invention discloses a hydraulic lifting pipe conveyer for an oil drilling platform and belongs to a pipe conveyer. The hydraulic lifting pipe conveyer structurally comprises a bottom frame, supporting rods, an upper frame, an inclined platform surface, an inclined slideway auxiliary support and a telescopic platform surface; lifting oil cylinders are arranged between the bottom frame and the supporting rods; the inclined platform surface is arranged at the upper part of the upper frame and is hinged with one end of the upper frame; an inclined lifting oil cylinder and the inclined slideway auxiliary support are arranged between the inclined platform surface and the upper frame; the telescopic platform surface comprises a V-shaped platform surface and an upper frame telescopic pipe, wherein the V-shaped platform surface is arranged at the upper part of the upper frame telescopic pipe; telescopic oil cylinders are arranged between the inclined platform surface and the V-shaped platform surface; platform supporting legs are arranged on the periphery of the bottom frame; a hydraulic valve component is arranged on the bottom frame; and the lifting oil cylinders, the inclined lifting oil cylinder and the telescopic oil cylinders are respectively connected with a pump station and a control cabinet through the hydraulic valve component. The invention has the characteristics that the height, the inclined surface and the telescopic platform surface can be adjusted according to the production site, so that the hydraulic lifting pipe conveyer achieves the best working position, thereby the labor intensity is reduced, the production safety is greatly improved, the safe production environment of workers is ensured, and the like.

Owner:山东济阳机械厂股份有限公司

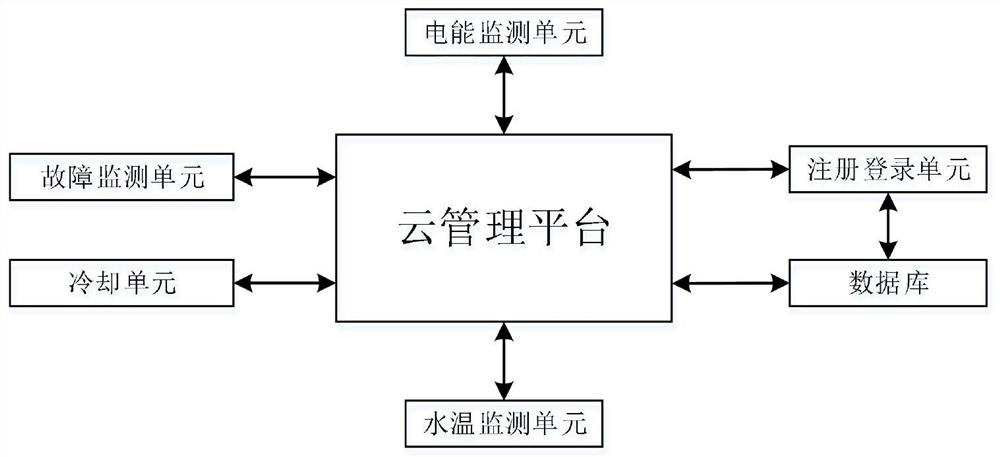

Induction heating power supply integrated management system

InactiveCN112512149AImprove securityReduce production accidentsThermometer detailsElectric devicesControl theoryHeat power

The invention discloses an induction heating power supply integrated management system, relates to the technical field of heating power supply integrated management, and solves the technical problem that in the prior art, three-phase electric wire and direct current bus data cannot be analyzed so as to cause reduced safety performance. According to the system, three-phase electric wire data and direct current bus data are analyzed through an electric energy monitoring unit, so that the electric energy in heating power supply equipment is monitored; the data of the three-phase wire and the direct-current bus is analyzed, and the equipment is monitored in real time, so that the safety performance of workers is improved, and production accidents are reduced; the temperature of each waterway is monitored through a water temperature monitoring unit, and the waterways are divided into a first-stage waterway, a second-stage waterway and a third-stage waterway; a first-stage temperature threshold value, a second-stage temperature threshold value and a third-stage temperature threshold value are correspondingly set for each waterway according to the grades of the waterways; and different temperature thresholds are set according to different waterways, so that the working efficiency of the equipment is improved, and unnecessary resource waste is reduced.

Owner:淮北市华明工业变频设备有限公司

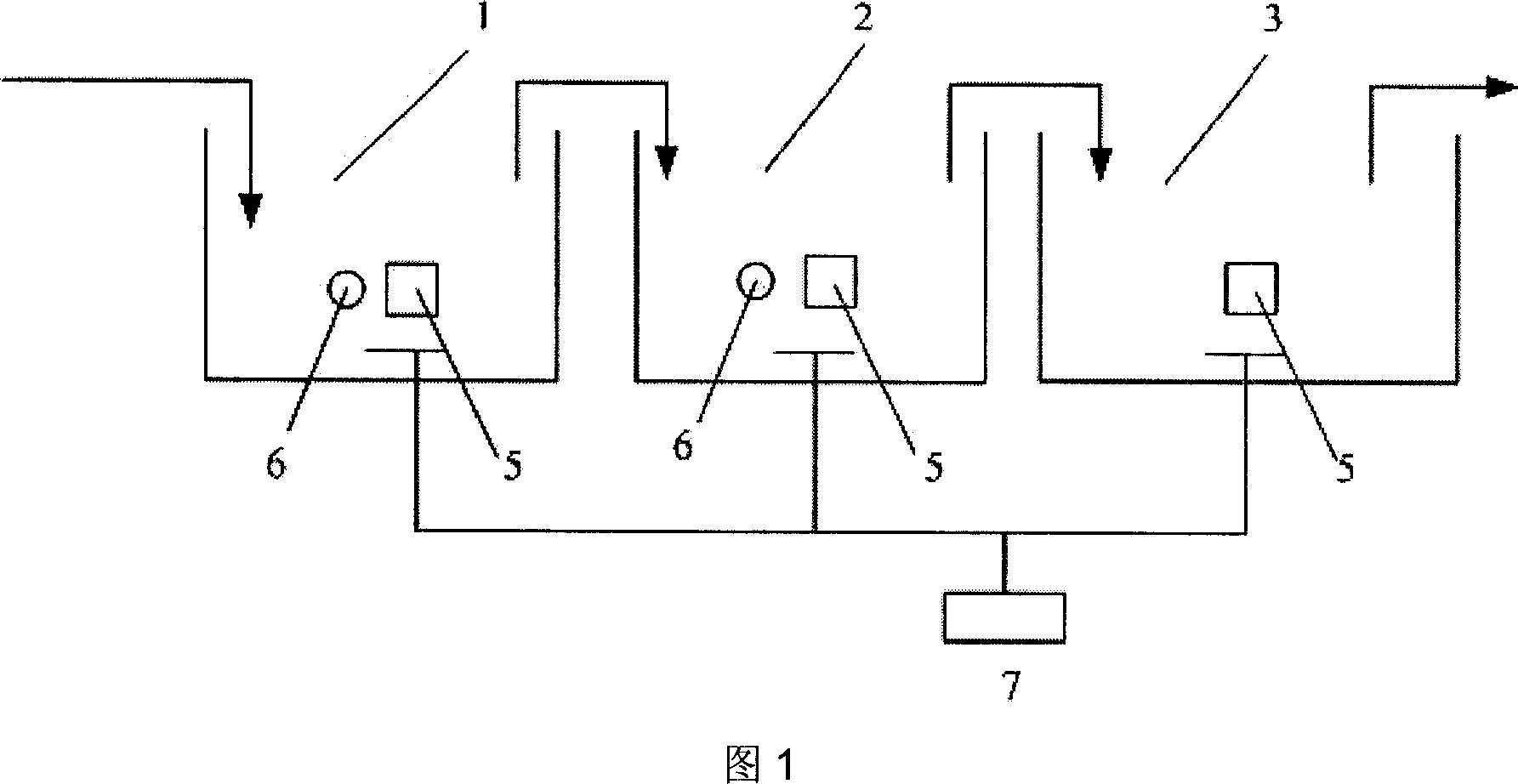

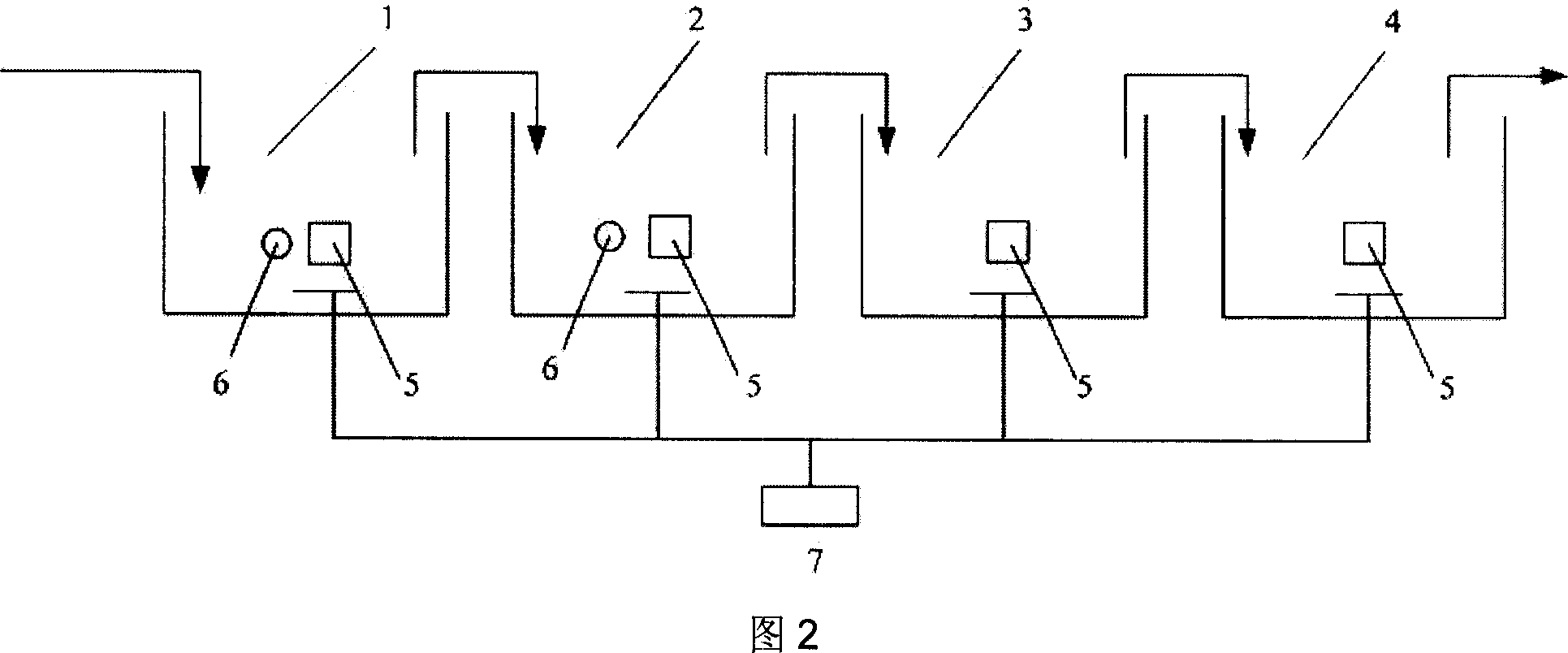

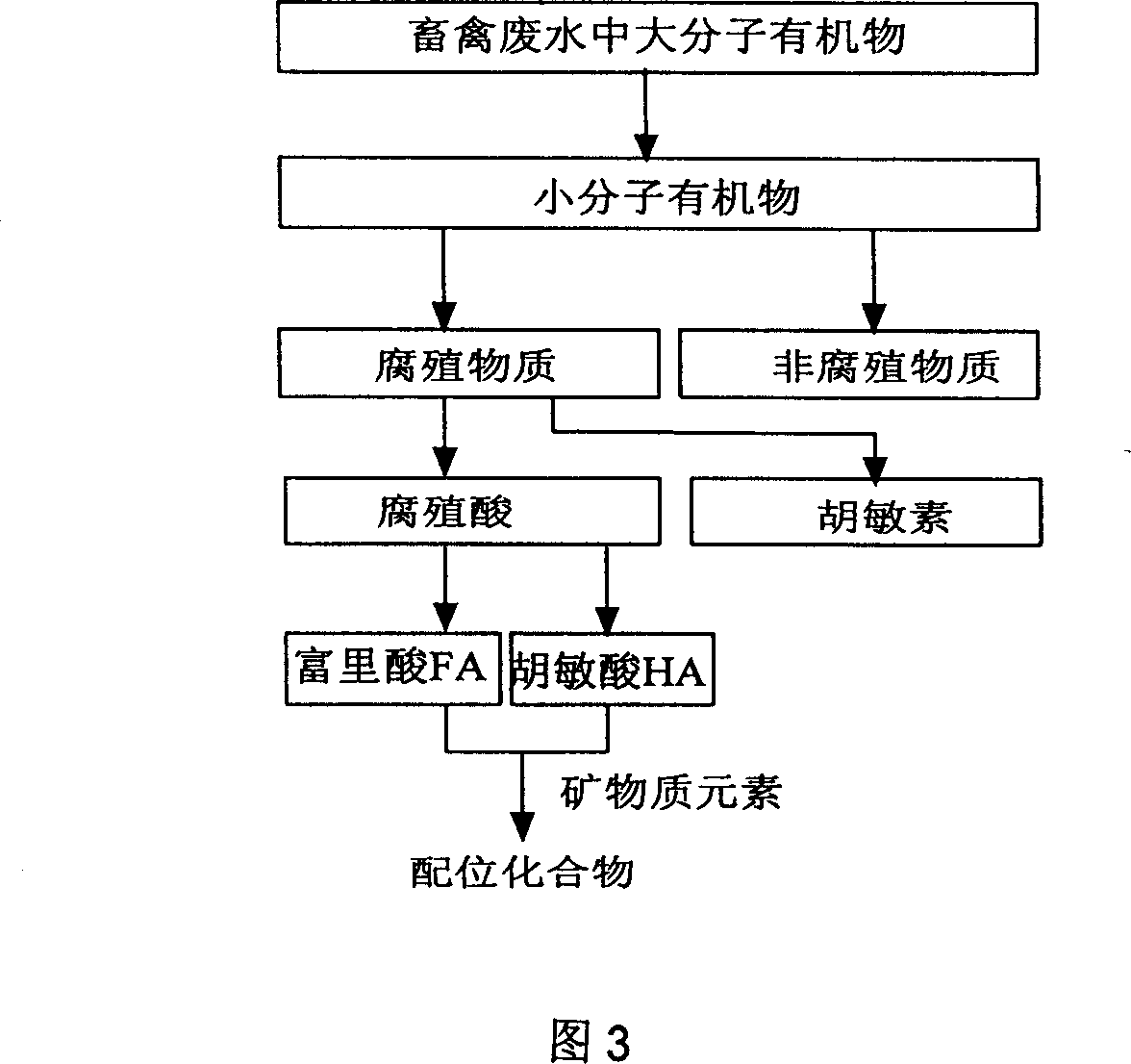

Method of preparing biological activity water by fecaluria of livestock and poultry and application thereof

InactiveCN101054251AImprove biological environmentFood value increasedMultistage water/sewage treatmentSustainable biological treatmentBiotechnologyDisease

The invention belongs to processing of organic junk and organic waste water and resource technology field, more particularly relates to a method of producing biological active water by livestock and poultry dung urine. The invention utilizes rocks containing various mineral matters and humus to culture soil microorganism crowd with humification function for clearing environmental pollution of livestock and poultry dung urine at the same time, processed effluent can improve sprouting rate and germinating biability of paddy seeds apparently, can be applied to organic farm production, improvement of livestock and poultry drinking water on farm, environmental improvement of hut microorganism; applied to paddy may strengthen resistance of rice blast, raise edible taste value of paddy, applied to vegetable and fruit may raise output and quality, strengthen the ability of resistance disease, reduce even avoid the use of pesticide and chemical fertilizer; applied to farm may avoid that livestock and poultry use antibiotic to reduce production accident. The invention not only reduce environmental burden, but also has ability of restoration destroyed environmental; may form cycle type agriculture in area, promote development of organic agriculture.

Owner:TONGJI UNIV

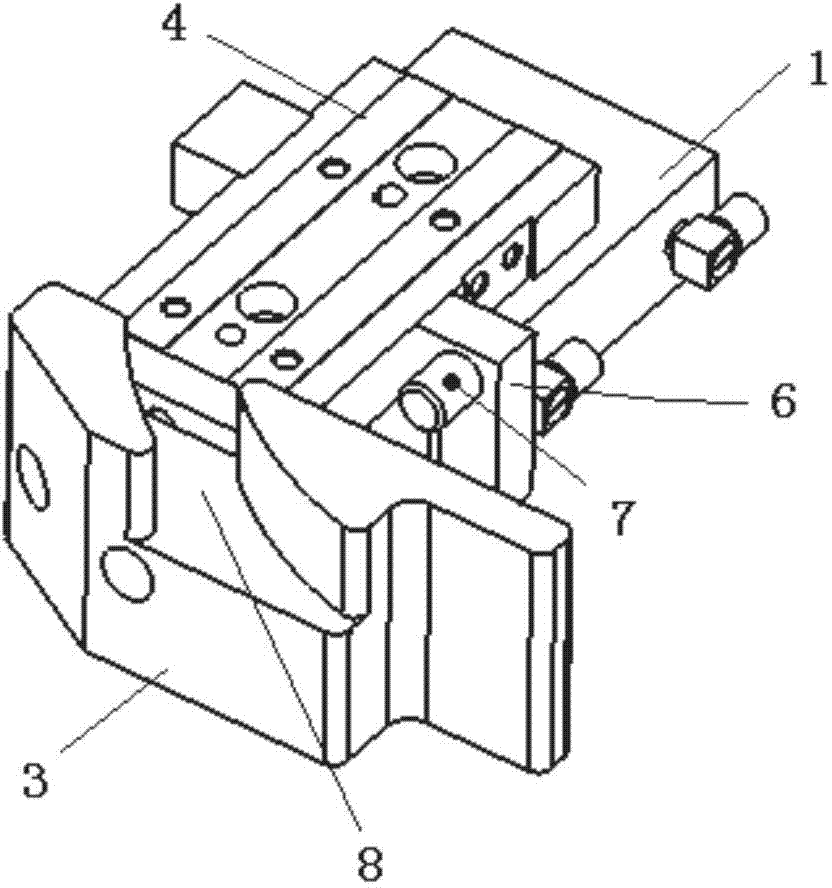

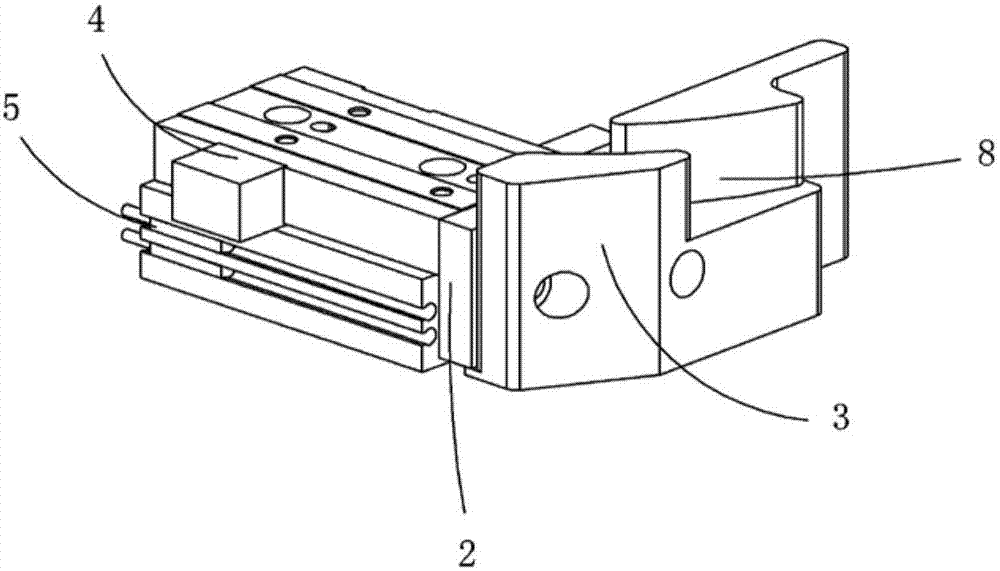

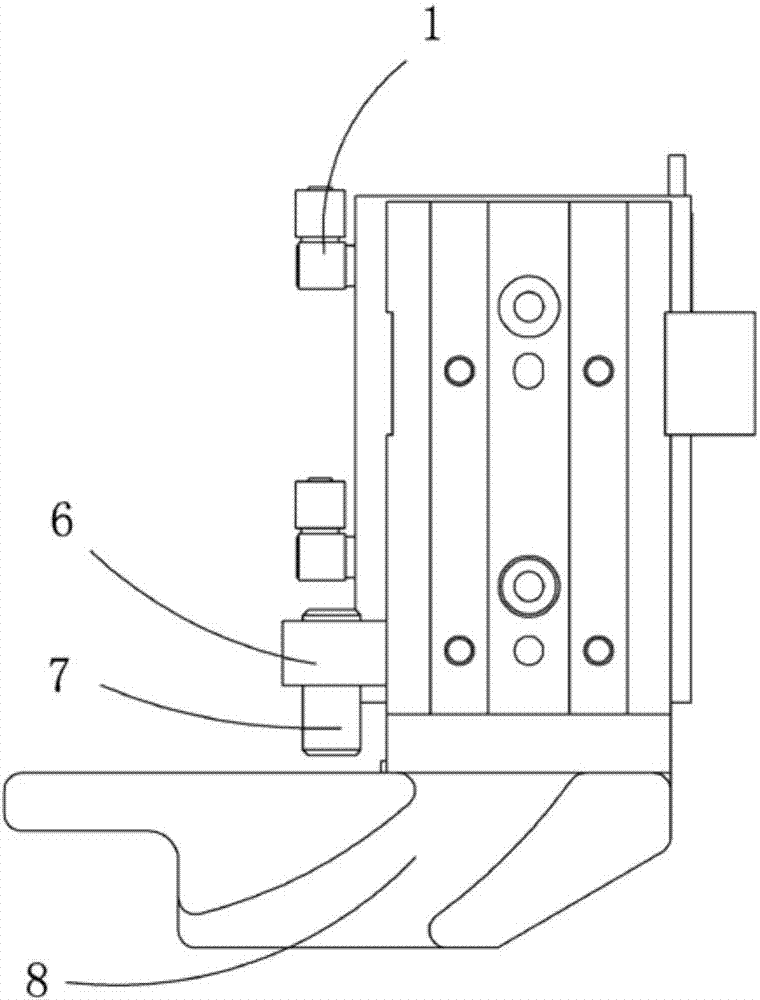

Wedge-shaped block type clamp pushing and pulling mechanism

The invention relates to a wedge-shaped block type clamp pushing and pulling mechanism. The wedge-shaped block type clamp pushing and pulling mechanism is characterized in that a pushing block is connected to the front end of a piston rod of a cylinder; a wedge-shaped block is connected to the front end of the pushing block; two magnetic switches are mounted at the left side of the cylinder, and while a limiting block is mounted at the right side of the cylinder; a limiting nut is mounted on the limiting block; a solenoid valve is connected to the rear end of the pushing block and located above the cylinder; a cam groove is formed in the wedge-shaped block; the limiting nut is of a cylinder structure and can be adjusted relative to the position of the limiting block; a circular hole in which the limiting nut is inserted is formed in the limiting block; the cam groove is in match with a connecting rod on a clamp; the wedge-shaped block pushes the connecting rod to drive the clamp to move to be opened and closed; the magnetic switches are used for feeding back the state of the cylinder on real time so as to control the solenoid valve to be on and off, and therefore, disordering of the movement due to known state off the cylinder can be avoided, the time can be saved, the probability of production accident is decreased, and as a result, the production cost is decreased, and the working efficiency is increased.

Owner:BOZHON PRECISION IND TECH CO LTD

Horizontal type C-type steel transverse moving and turnover device

ActiveCN104925528AFully automatedIncrease productivityStacking articlesConveyor partsDrive motorHooking

The invention relates to a horizontal type C-type steel transverse moving and turnover device. The device is characterized by comprising a transverse moving mechanism and a turnover clamping mechanism. The turnover clamping mechanism comprises a support, a rotating frame, a first ejecting air cylinder, a second ejecting air cylinder, a third ejecting air cylinder, a hooking and pressing air cylinder, an L-shaped hooking and pressing plate, a feeding frame, a feeding air cylinder and a turnover driving motor; the support and the rotating frame are in opening ring shapes; a first opening is formed in the support, and a second opening is formed in the rotating frame; the rotating frame is rotatably assembled on the support; the first ejecting air cylinder and the second ejecting air cylinder are arranged on the rotating frame, and a circumferential rack is arranged on the periphery of the rotating frame; a gear is mounted on an output shaft of the turnover driving motor, and the feeding air cylinder is provided with a feeding cylinder rod which can stretch out downwards; the feeding cylinder rod is connected with the feeding frame, and the third ejecting air cylinder and the hooking and pressing air cylinder are mounted on the feeding frame; and the L-shaped hooking and pressing plate is mounted on a hooking and pressing cylinder rod of the hooking and pressing air cylinder. The horizontal type C-type steel transverse moving and turnover device can achieve full automation, and the production efficiency can be improved.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE

Predication method for dynamic tail-escaping amount of strip steel

ActiveCN103691744AReduced tail throwHigh yieldMeasuring devicesMetal rolling arrangementsMeasurement pointWave shape

The invention relates to a predication method for a dynamic tail-escaping amount of strip steel. The method is characterized by comprising the following steps: (1) collecting strip shape flatness data of section measuring points of the strip steel in a width direction and data information of the distance away from a strip steel head corresponding each set of the data, and forming a data file with a text format; (2) carrying out effective data extraction on each independent strip steel strip shape data file and carrying out meshing distributed processing; (3) fitting a partial waveform of the strip steel and formulating a judgment standard; (4) carrying out wave shape judgment on certain length data of the tail part of the strip steel section by section and combining a wave shape severe degree to judge whether tail escaping is needed or not; and (5) carrying out process correction on a predicated length and correcting an undersize tail-escaping amount in tail-escaping amount predication according to a minimum cutting length requirement of the process. According to the method, the tail-escaping amount of the strip steel of an application set is reduced and the yield of the application set is improved; a production accident is prevented from occurring; the method is simple and easy to operate.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

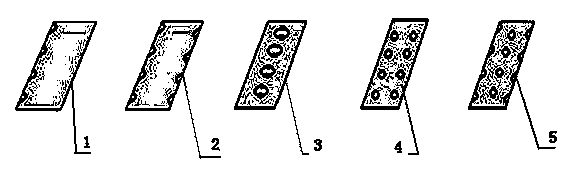

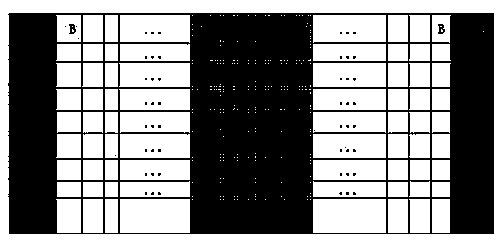

Precursor fiber bundle for production of a carbon fiber bundle, a process for producing the precursor fiber bundle, a carbon fiber bundle, and a process for producing the carbon fiber bundle

InactiveUS6294252B1Suitable for processingLow production costMonocomponent synthetic polymer artificial filamentNatural mineral layered productsFiber bundleMoisture

A separable tow of elongated polymeric filaments comprises a plurality of distinct sub-tows lightly and individually and separably joined, as by light crimping together along their edges or, if uncrimped, joined by presence of moisture, and capable of being packed into a container and later removed and separated. The filaments are preferably acrylic and have a total fineness of about 300,00-1,500,000 denier and the sub-tows each of which has a total fineness of about 50,000-250,000 denier, with a filament fineness of about 1-2 denier, and each sub-tow has a degree of entanglement of about 10-40 m.sup.-1 as measured by the hook drop test. The separable tow is made of a plurality of sub-tows, after separately drawing the sub-tows and subsequently removably joining the sub-tows into a single tow.

Owner:TORAY IND INC

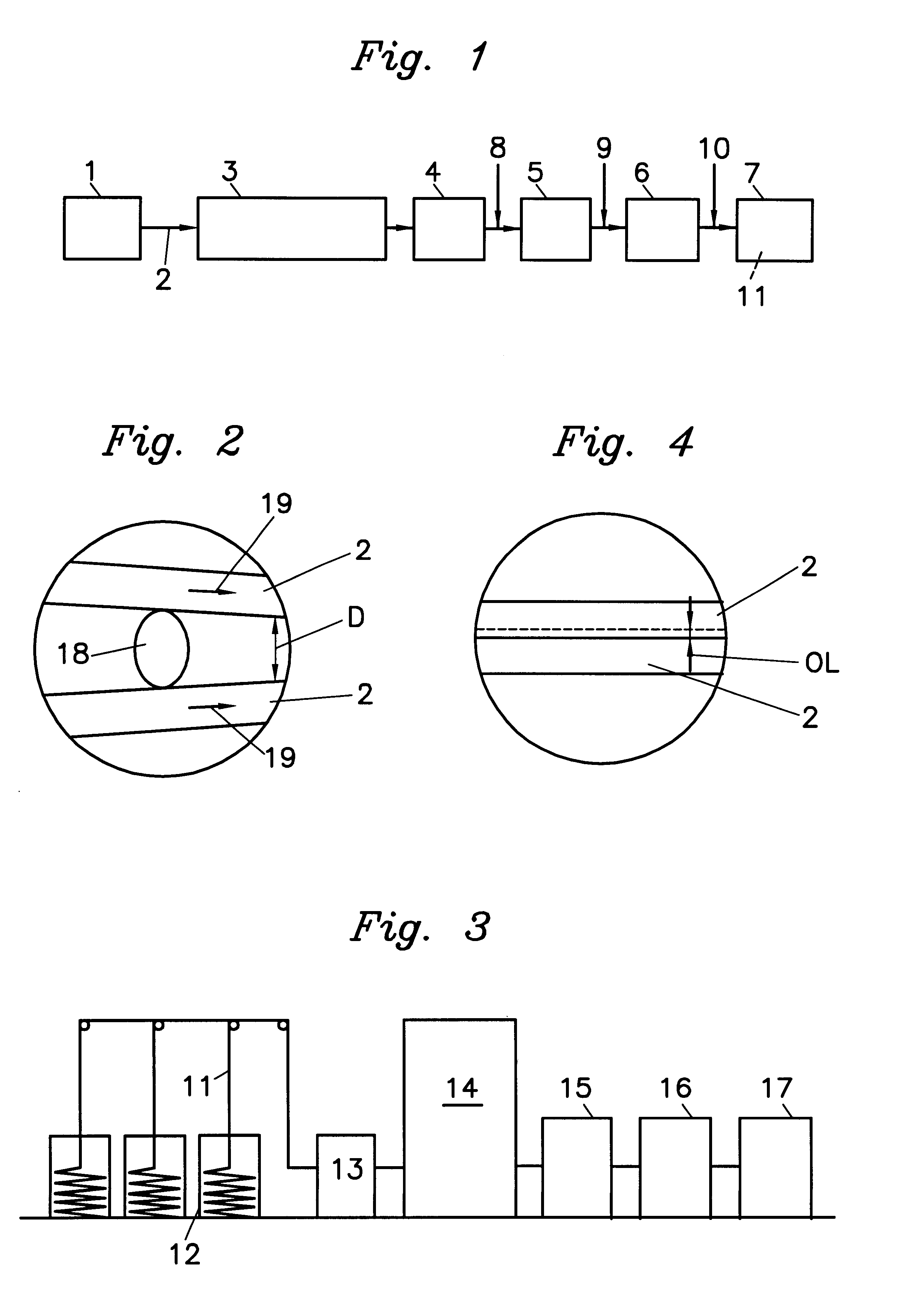

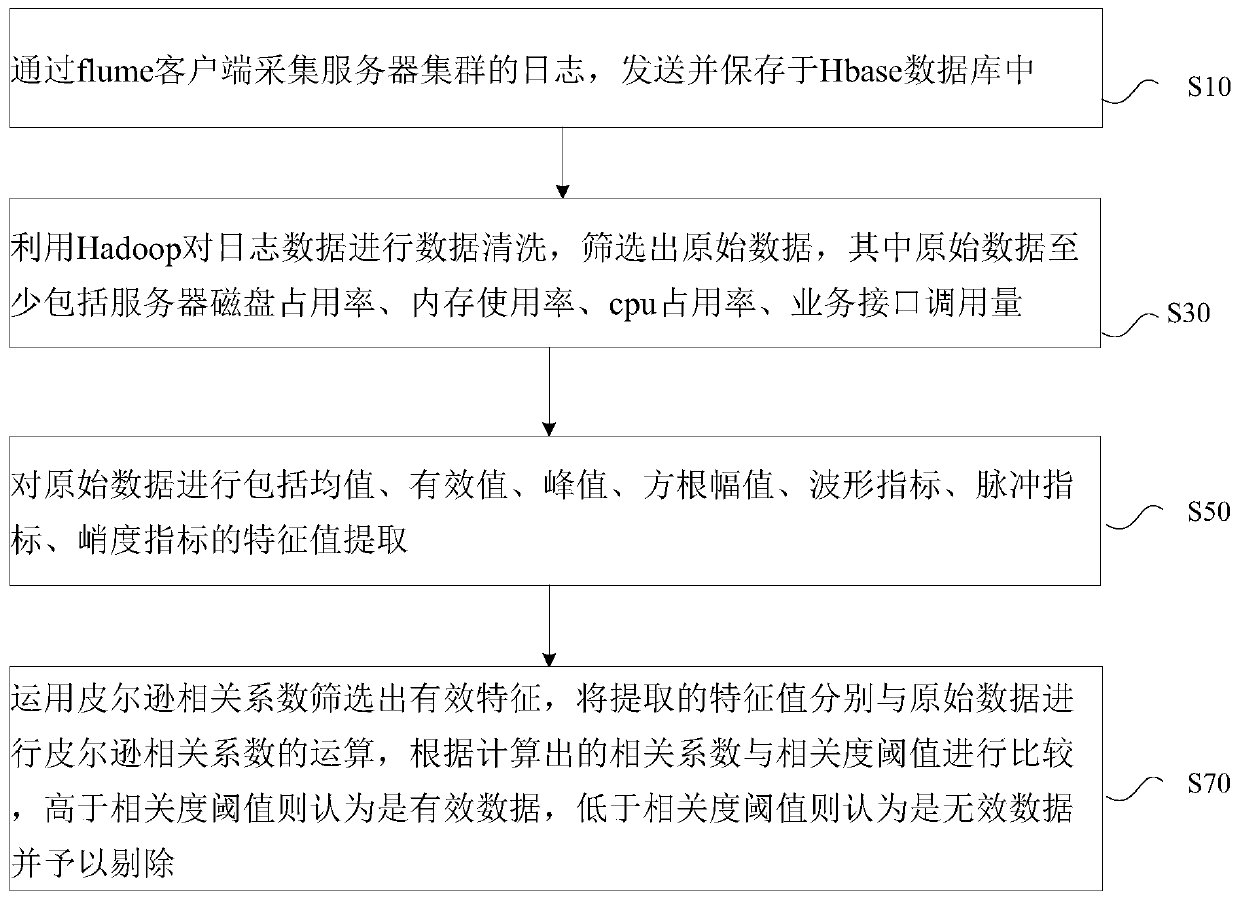

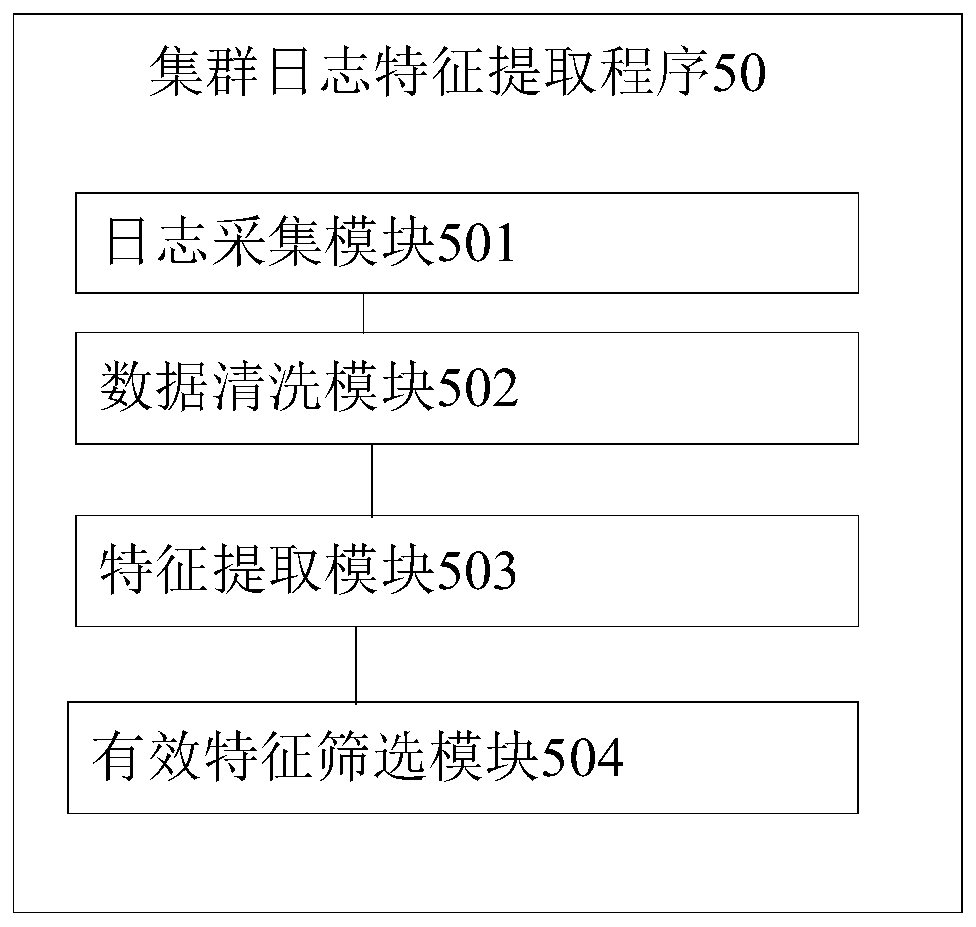

Cluster log feature extraction method and device and storage medium

PendingCN109992569AReduce production accidentsSpecial data processing applicationsFile system functionsCorrelation coefficientFeature extraction

The invention relates to base frame operation and maintenance, and provides a cluster log feature extraction method and device and a storage medium, and the method comprises the steps: collecting a log of a server cluster through a flume client, and sending the log to a database; performing data cleaning on the log data, and screening out original data; extracting characteristic values including amean value, an effective value, a peak value, a square root amplitude value, a waveform index, a pulse index and a kurtosis index from the original data; and respectively carrying out Pearson correlation coefficient operation on the extracted characteristic values and original data, comparing the calculated correlation coefficient with a correlation degree threshold value, regarding the data as valid data if the correlation degree is higher than the correlation degree threshold value, regarding the data as invalid data if the correlation degree is lower than the correlation degree threshold value, and eliminating the invalid data. According to the invention, the effective information of the production data of each host in the server cluster can be effectively screened out, and the characteristic values of the production data are extracted from the effective information, so that the fault prediction and fault classification of a production system are facilitated, and the occurrence ofproduction accidents is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

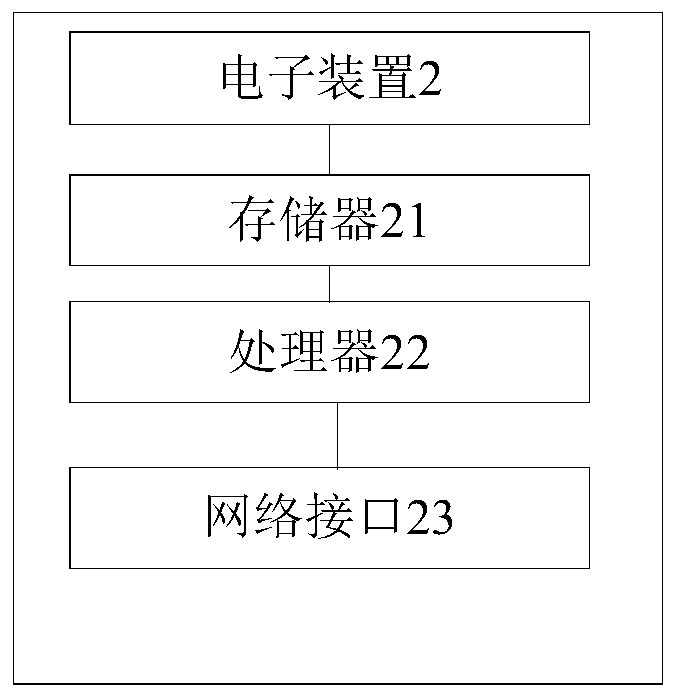

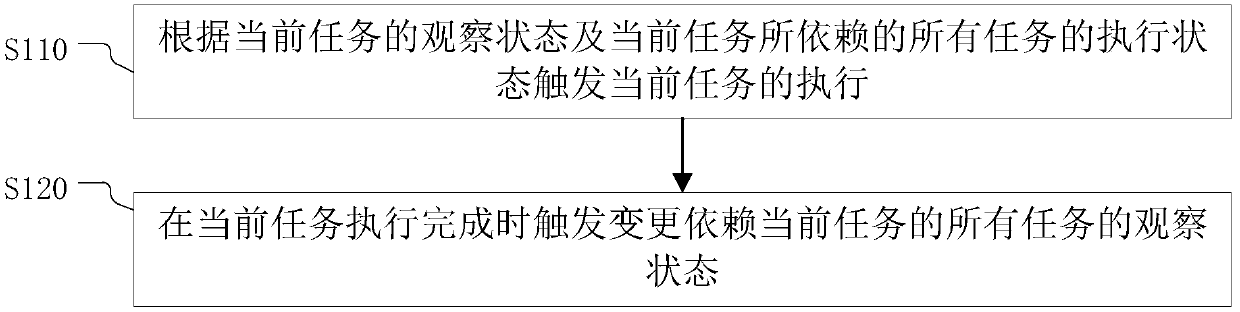

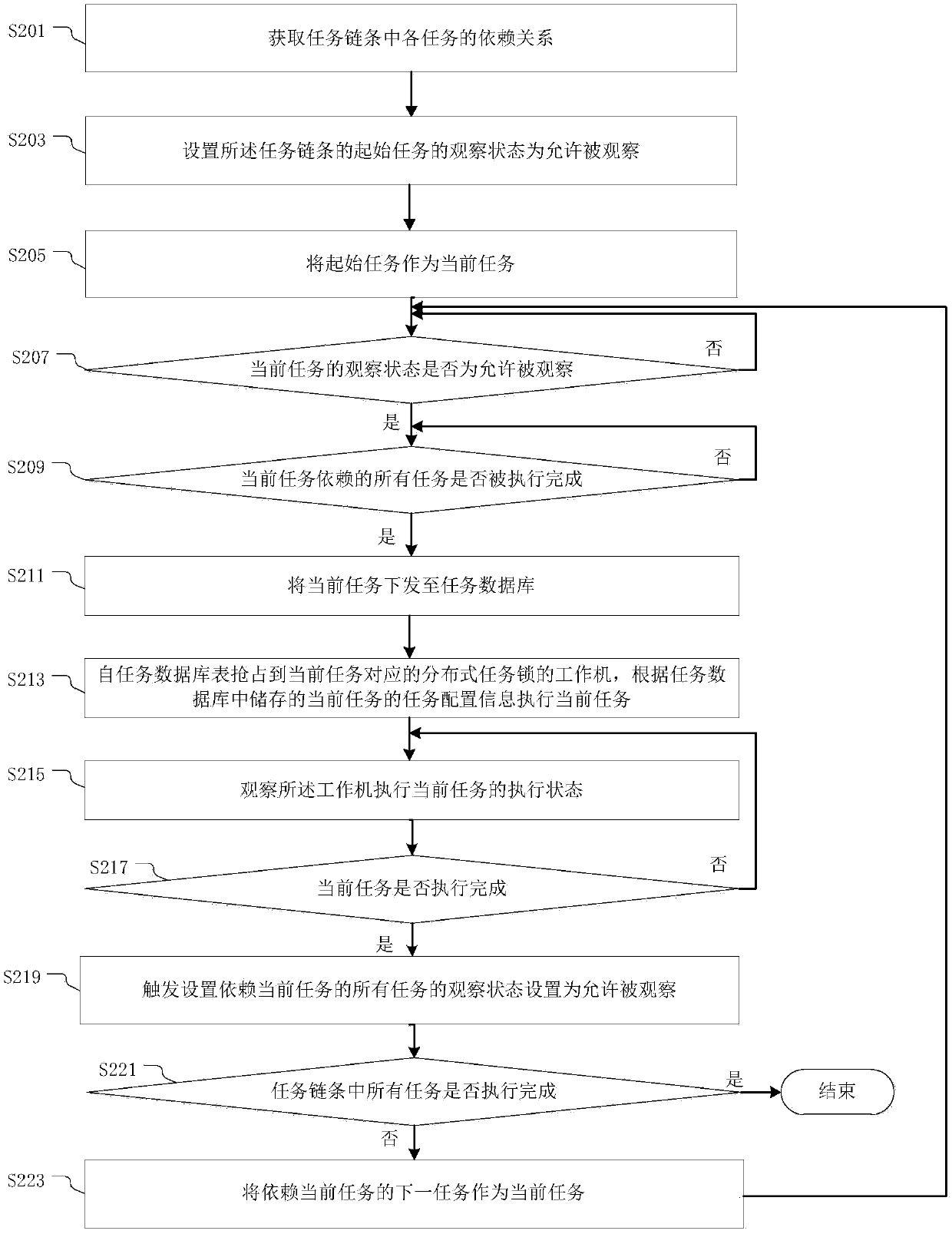

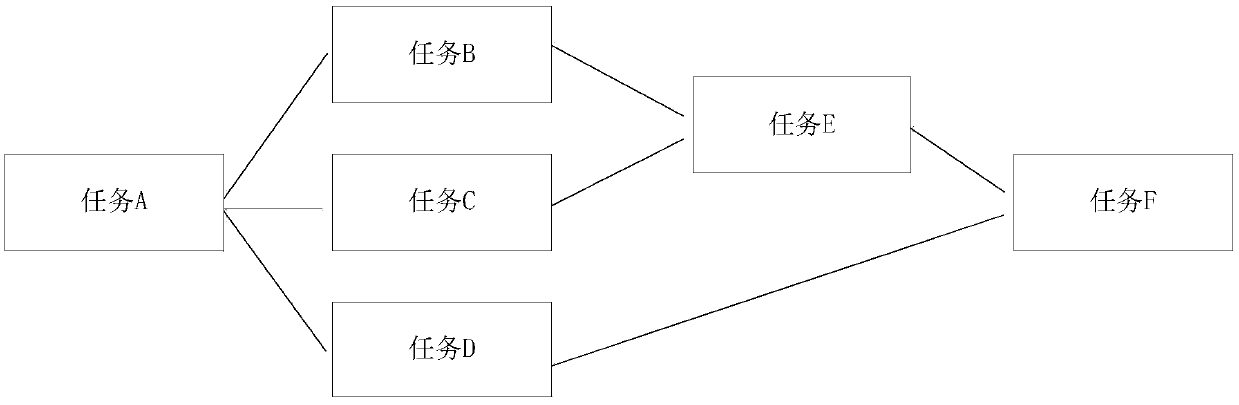

Distributed task scheduling method and device, electronic equipment and storage medium

PendingCN110858158AReduce waiting timeReduce production accidentsProgram initiation/switchingOperating systemDistributed computing

The invention provides a distributed task scheduling method and device, electronic equipment and a storage medium. The distributed task scheduling method comprises the steps of triggering execution ofa current task for each task of a task chain according to an observation state of the current task and execution states of all tasks on which the current task depends according to a sequence of dependency relationships of the tasks in the task chain; and triggering to change the observation states of all tasks depending on the current task when the execution of the current task is completed. Themethod and the device provided by the invention can improve the task execution efficiency.

Owner:JINGDONG TECH HLDG CO LTD

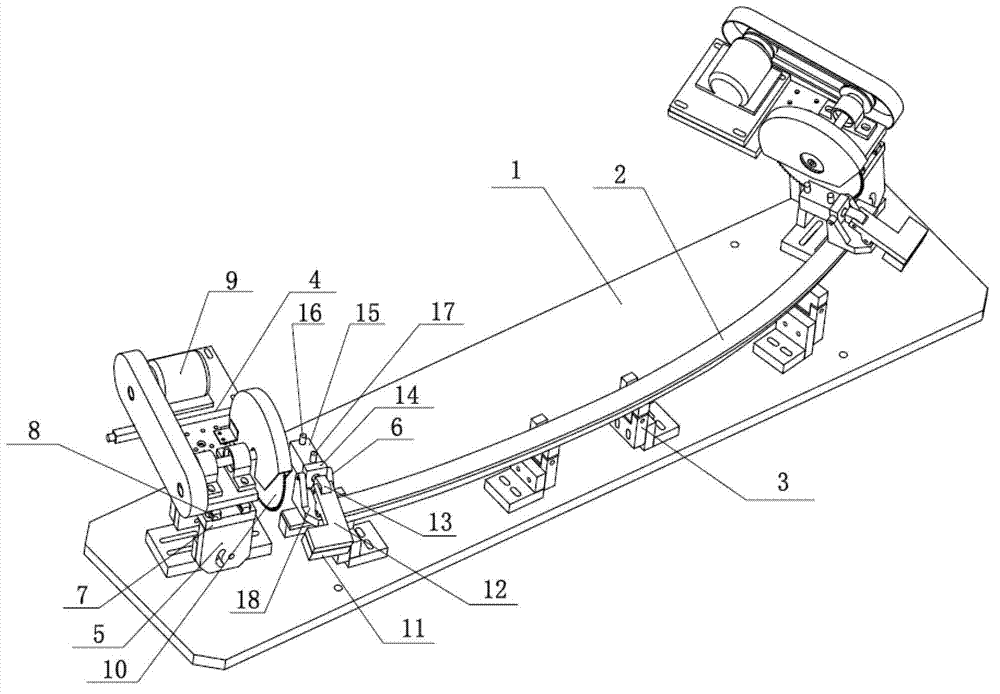

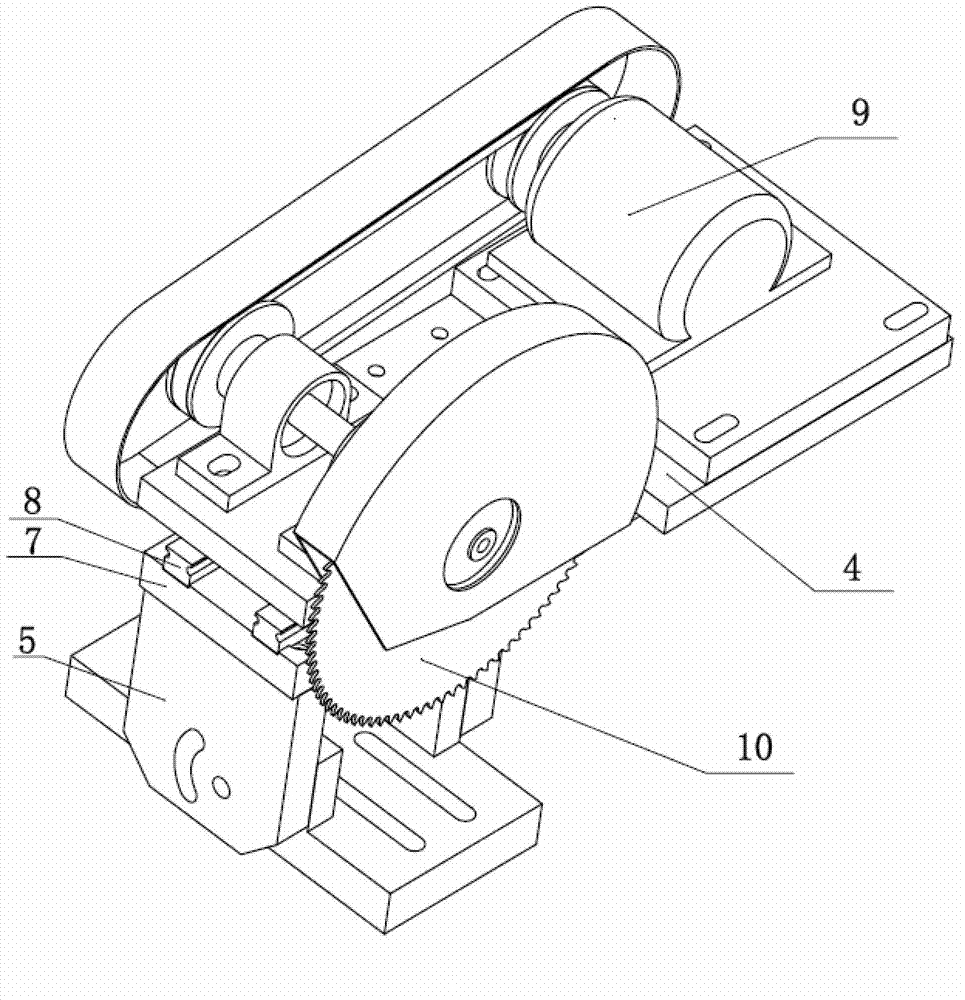

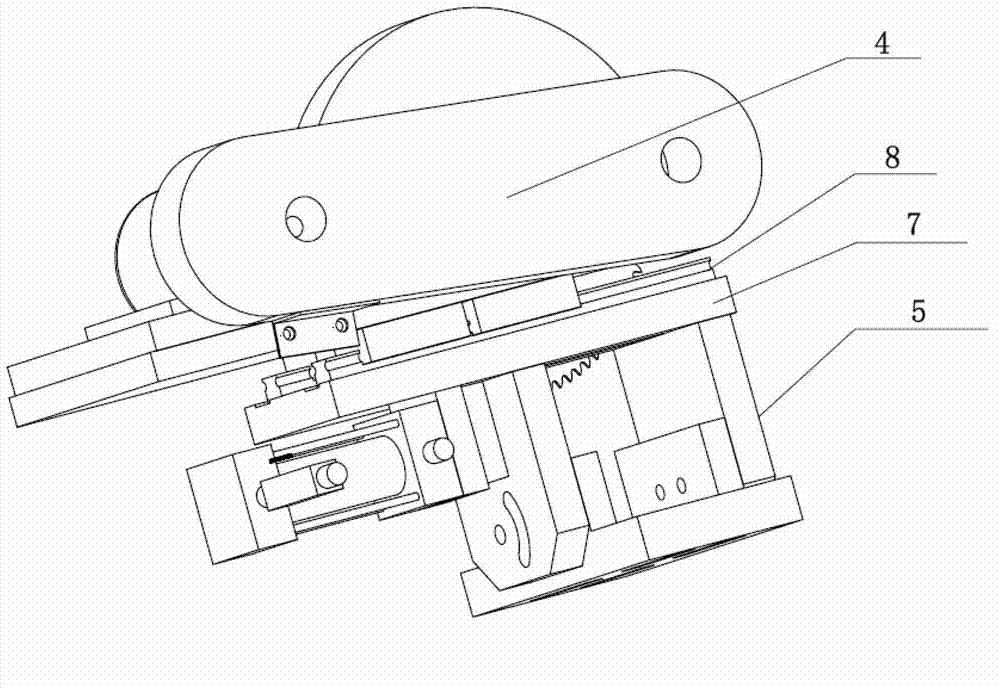

Automatic bending and saw cutting tool on bending machine

ActiveCN103111848AEasy to installSimple structureOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to an automatic bending and saw cutting tool on a bending machine. The automatic bending and saw cutting tool on the bending machine comprises material pressing devices, pushing devices and saw cutting devices. The material pressing devices are arranged at two ends of a bending die, the bending die is erected on a plurality of bending die supports, the bending die supports are arranged on a base plate, the two pushing devices are arranged on the base plate and mutually symmetrical, the saw cutting devices are arranged at the upper ends of the pushing devices, and the saw cutting devices are pushed by the pushing devices and move along linear guide rails fixed on upper end faces of guide rail fixing plates of the pushing devices. Saw bits of the saw cutting devices are driven by belts and belt wheels, the saw bits are directed at two end faces of the bending die, and the material pressing devices at the two ends of the bending die fix section bars closely attached to the arc face of the outer side of the bending die for saw cutting. The structure is simple, operation is convenient and safe, and movement is sensitive.

Owner:NINGBO HONGXIECHENG AUTO PARTS CO LTD

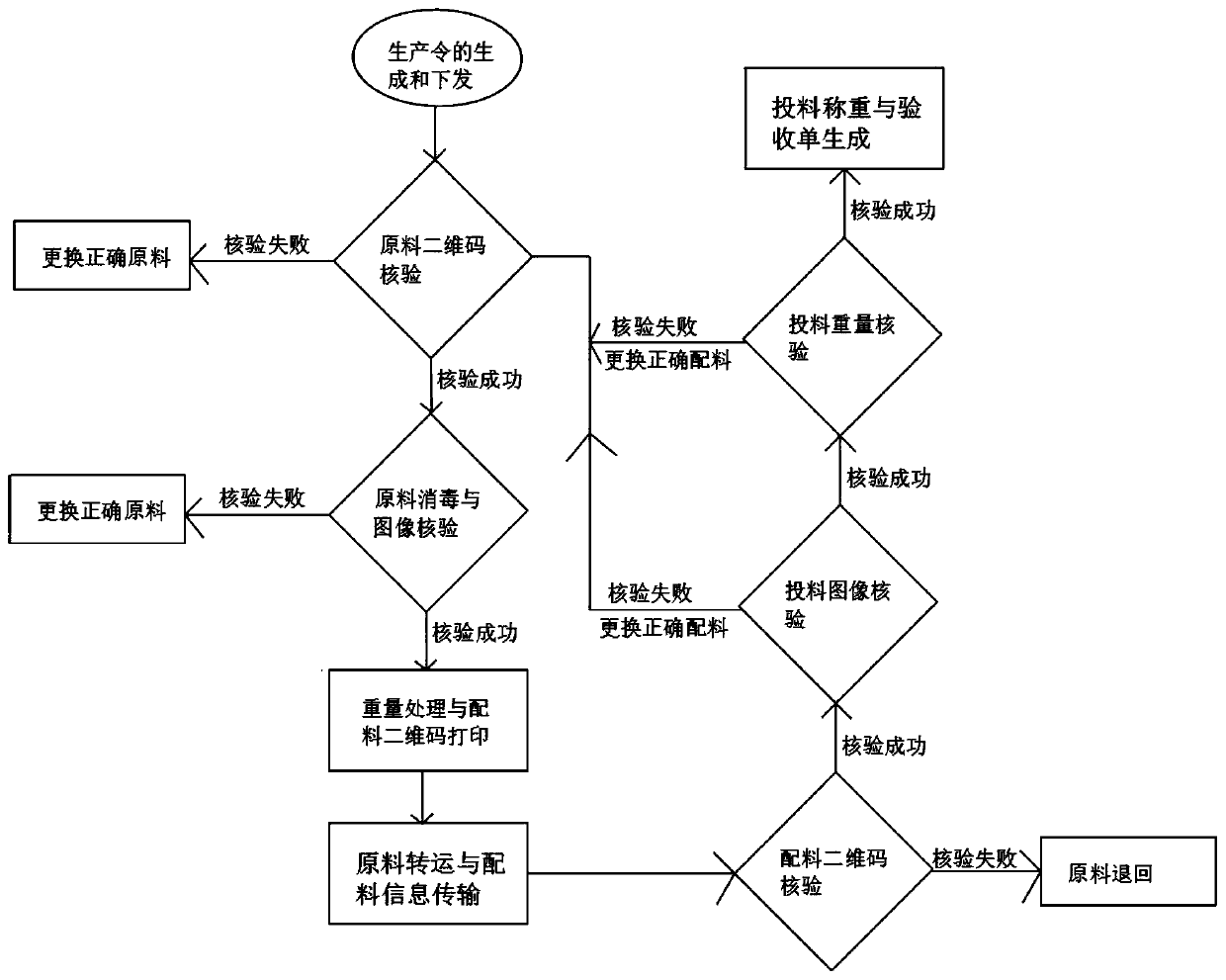

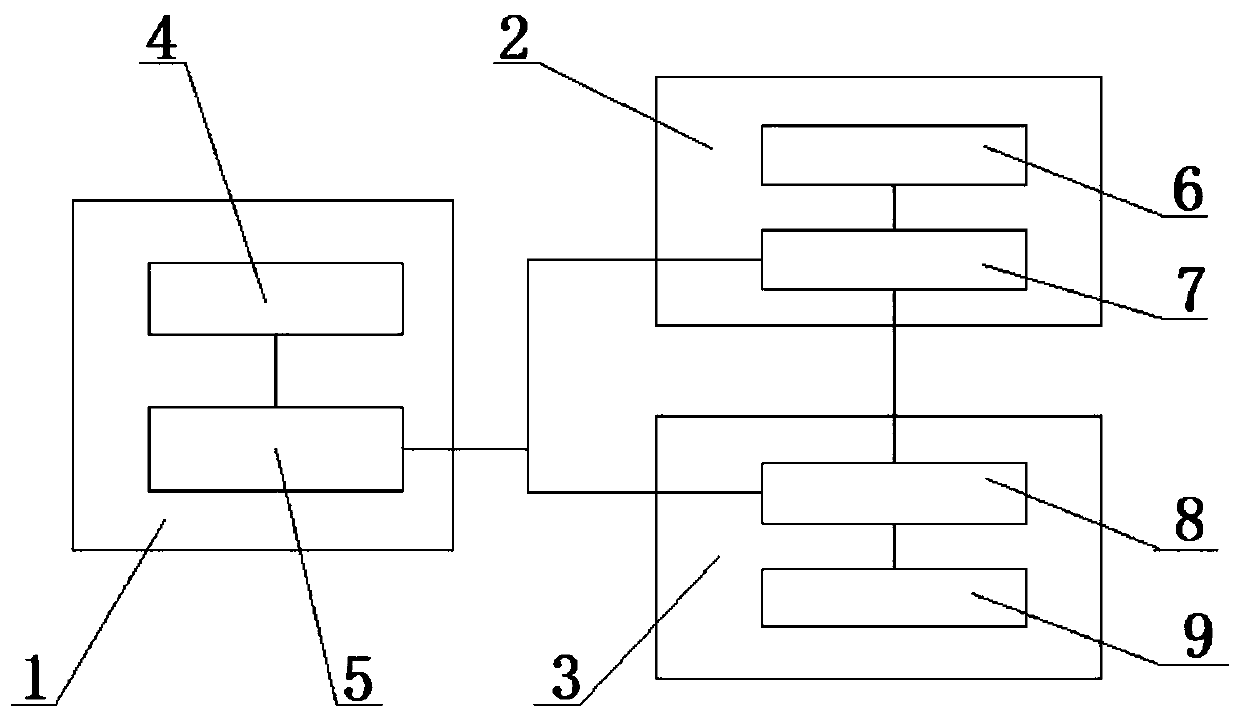

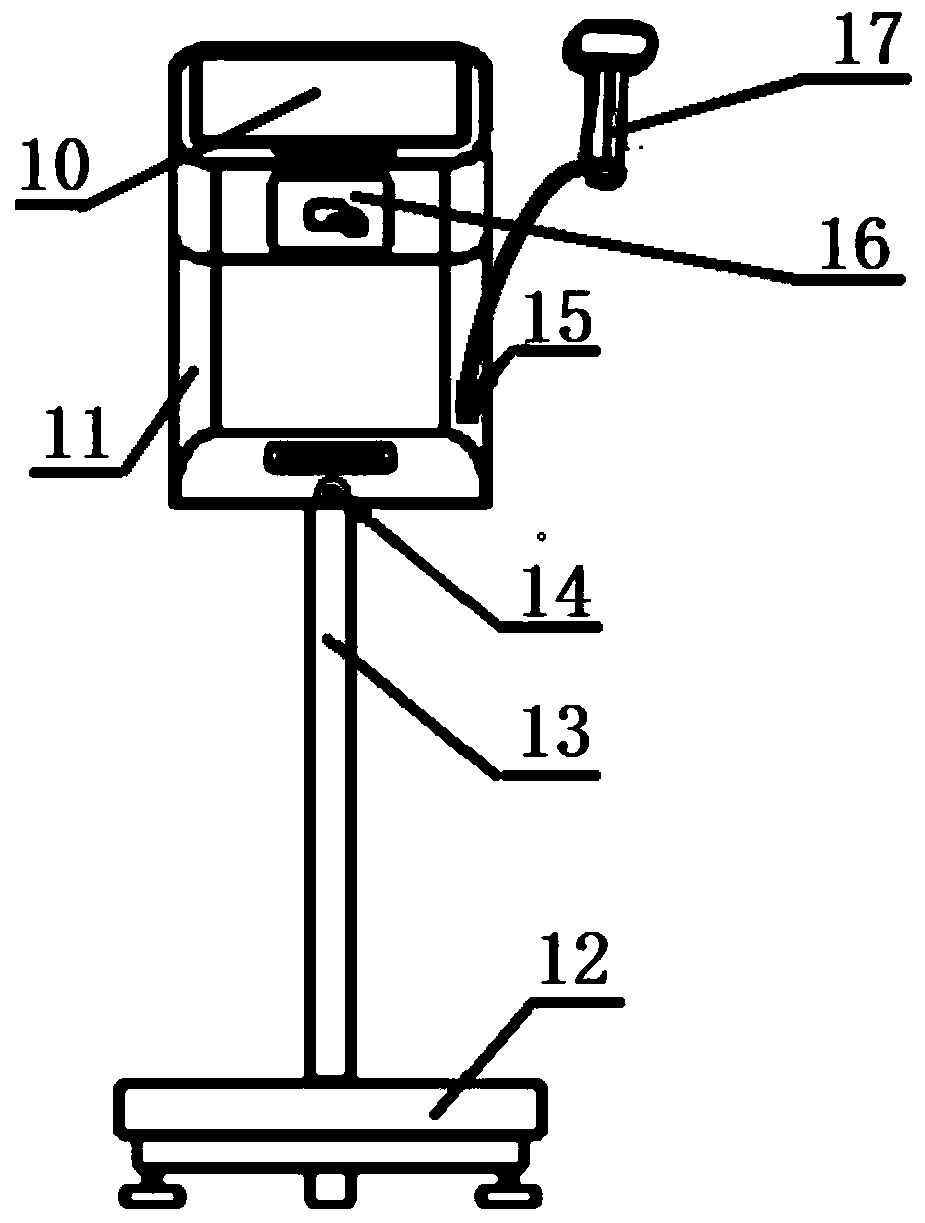

Double-verification type batching and feeding production method

ActiveCN110503171AReasonable and complete processReliable principleCo-operative working arrangementsLogisticsInformation transmissionMethods of production

The invention belongs to the technical field of batching and feeding production, and relates to a dual-verification batching and feeding production method. The method comprises the steps of productionorder generation and issuing, raw material two-dimensional code verification, raw material disinfection and image verification, weight processing and batching two-dimensional code printing, raw material transfer and batching information transmission, batching two-dimensional code verification, feeding image verification, feeding weight verification and feeding weighing and acceptance list generation. The double-verification type batching and feeding production method can be used in cooperation with a batching and feeding weighing system, double-verification type weighing mistake-proofing devices are arranged at a batching position and a feeding position, and batching needed by production is fed after being subjected to two-dimensional code verification at the batching position and the feeding position, image verification, weight weighing, weight verification and other processes. The production method is reasonable and complete in process and accurate in batching, raw materials can berecognized and verified, verification and feeding information tracing can be conducted in the feeding area, it is guaranteed that raw material feeding is accurate, and labor cost is saved.

Owner:山东动脉智能科技股份有限公司

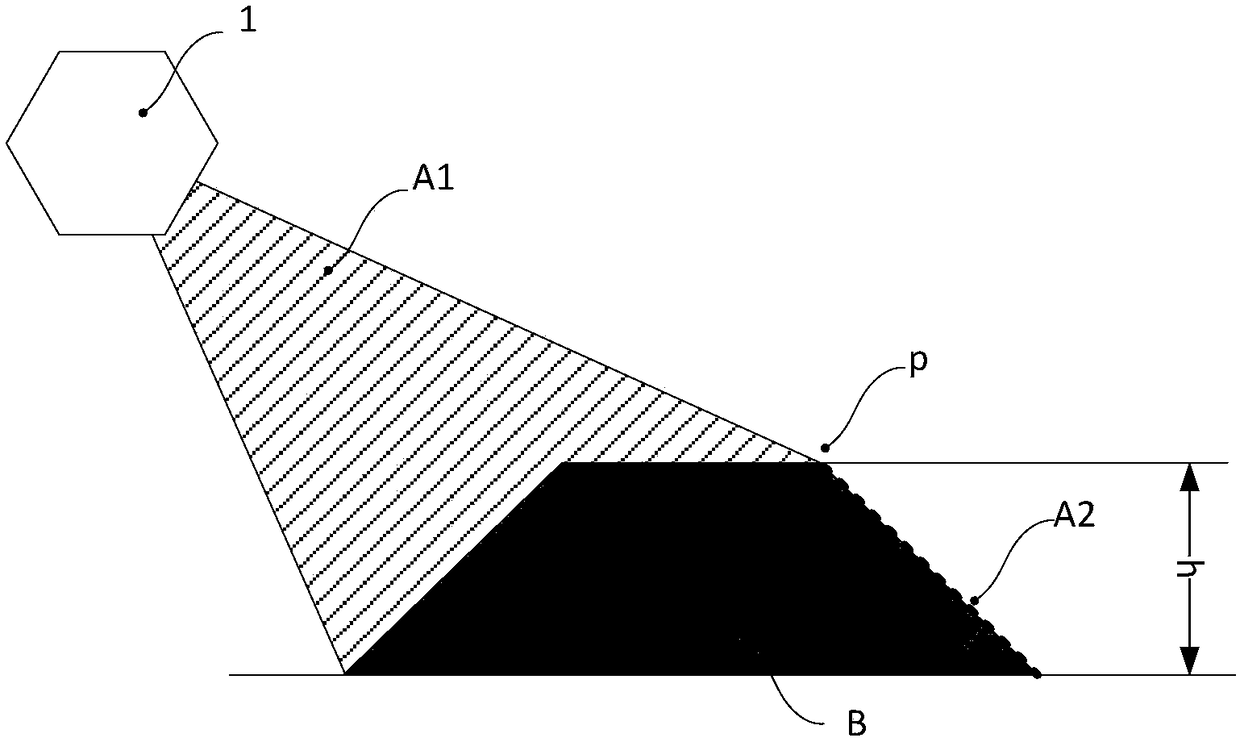

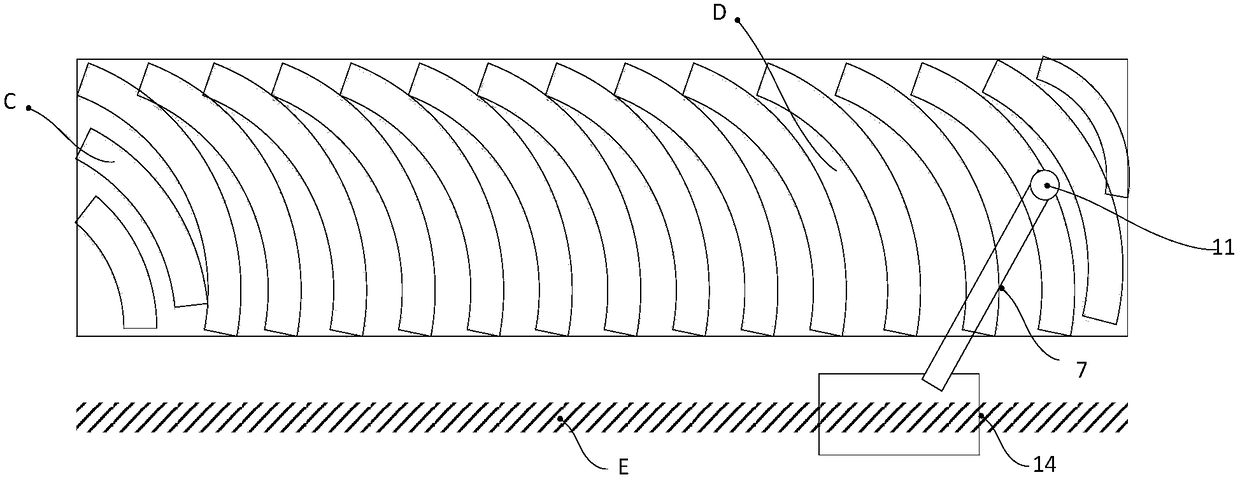

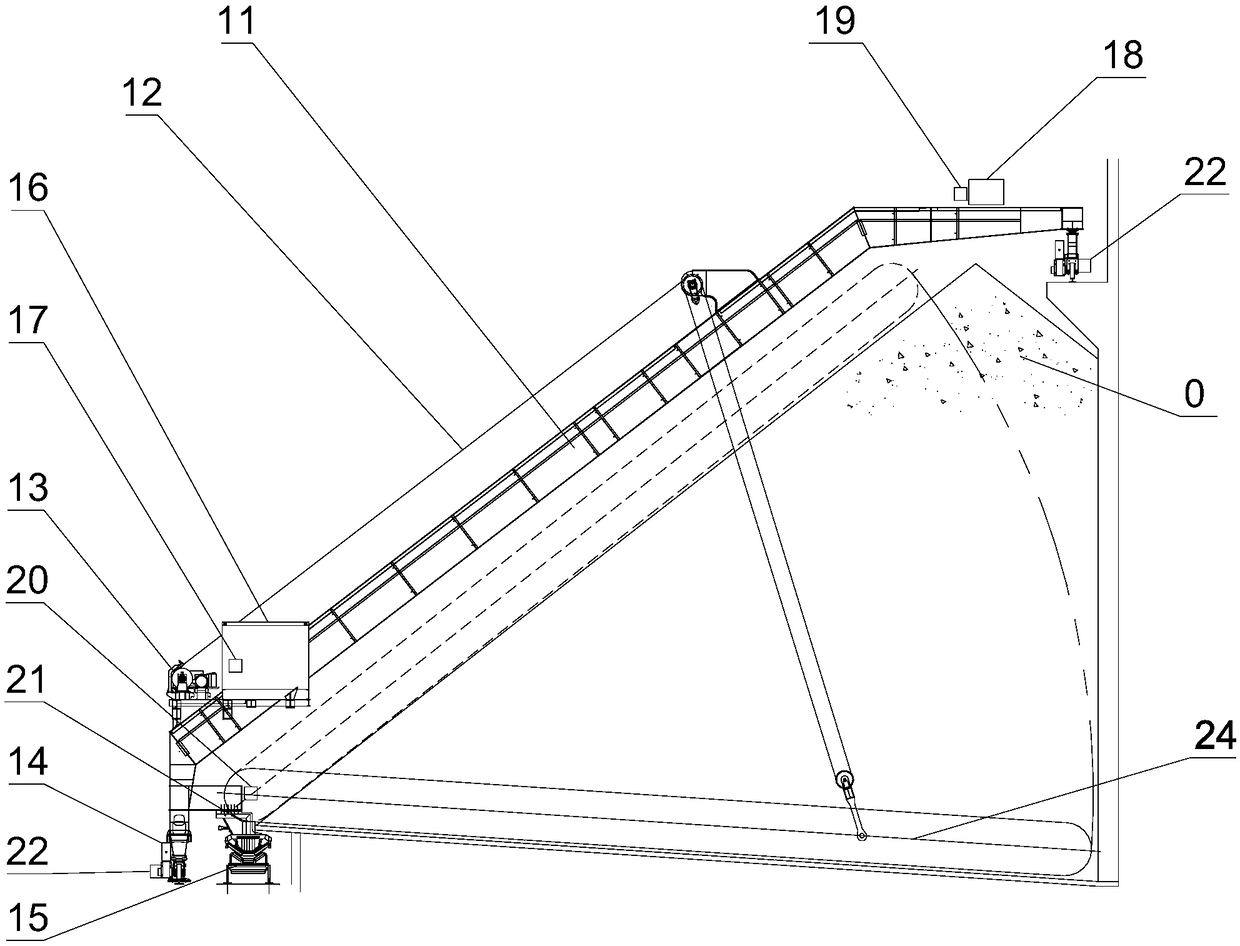

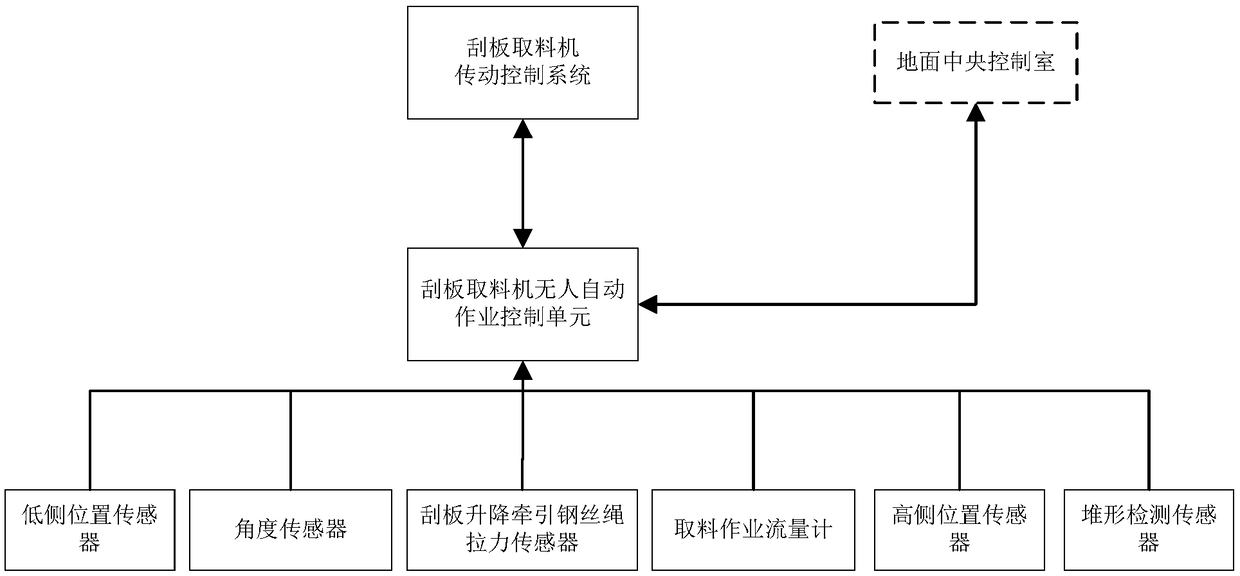

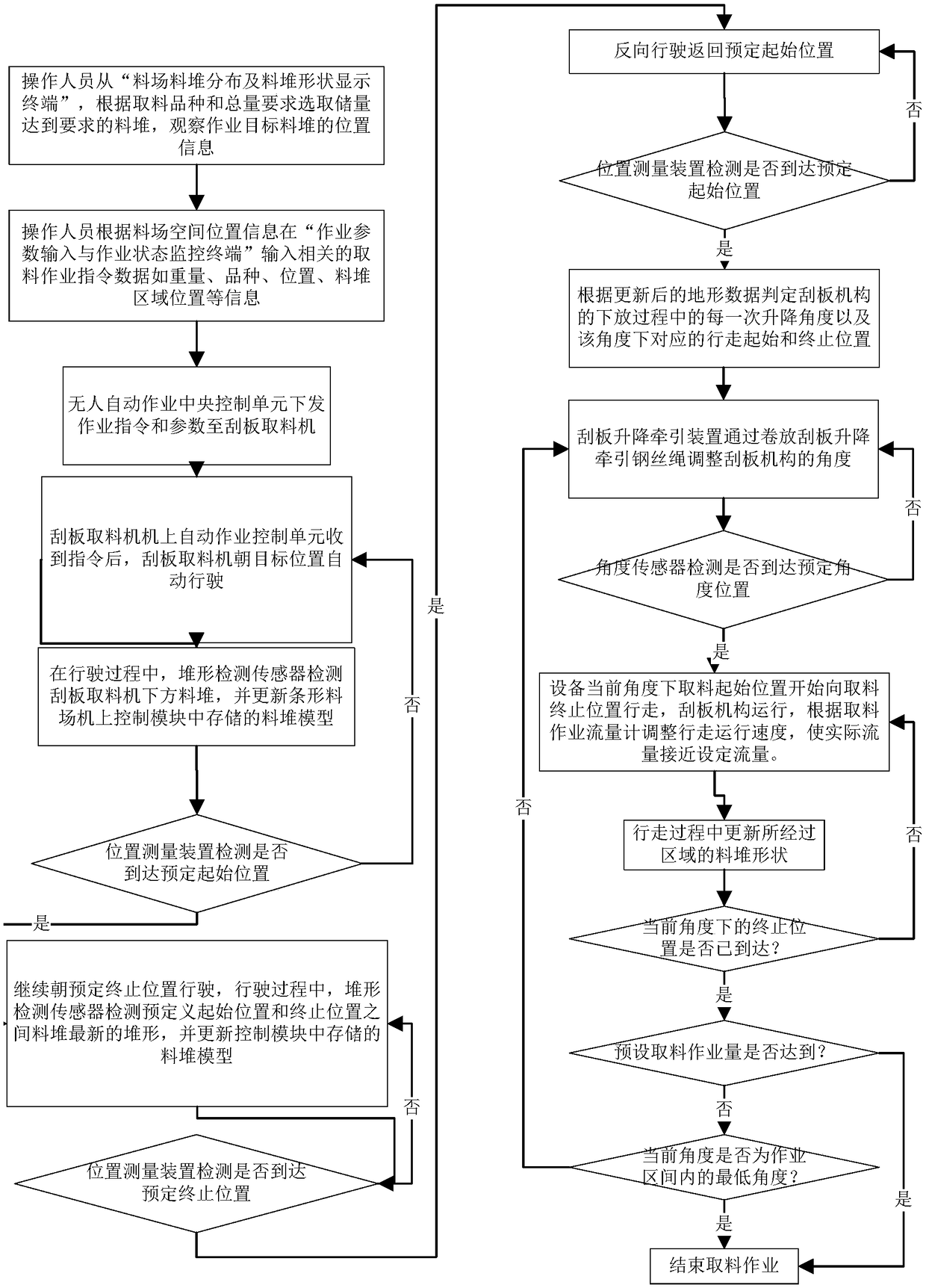

Stacking and reclaiming system with statistics of material information of stocking yard

PendingCN108182715AGuaranteed stockyard utilizationOvercoming the low degree of automationDrawing from basic elementsSurveying instrumentsAngle of reposeData information

The invention relates to a stacking and reclaiming system with statistics of material information of a stocking yard. The system comprises a stacking and reclaiming device, a control module and a detection module, the detection module at least comprises a geographical morphology detection apparatus, the detection module transmits detected data information to the control module, the control modulecomprises a data server and a calculating module, the control module stores the received data information in the data server and updates the data information in real time, geographical morphology dataof the whole stocking yard is stored in the data server in the format of DEM topographic data, the control module can convert the geographical morphology data of the whole stocking yard to 2D or 3D stacked display through the calculating module, and the 2D or 3D stacked display at least comprises the material name, the stacked volume, the stacked angle of repose and stacked profile map information of each material pile in the whole stocking yard. According to the system, the material statistical information of the whole stocking yard can be recorded in real time, the material statistical information of the whole stocking yard can be inquired through the control module, and the stocktaking function of the whole stocking yard is realized.

Owner:泰富智能科技有限公司

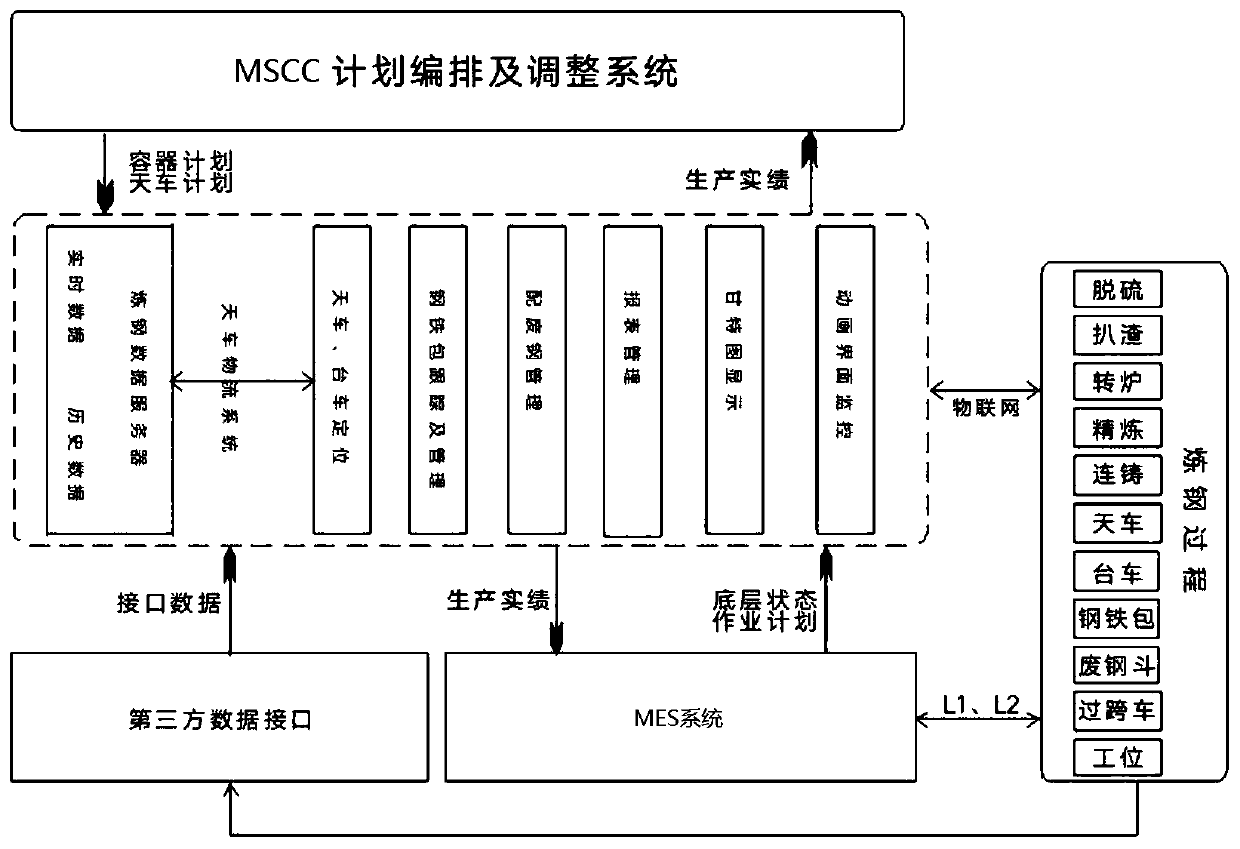

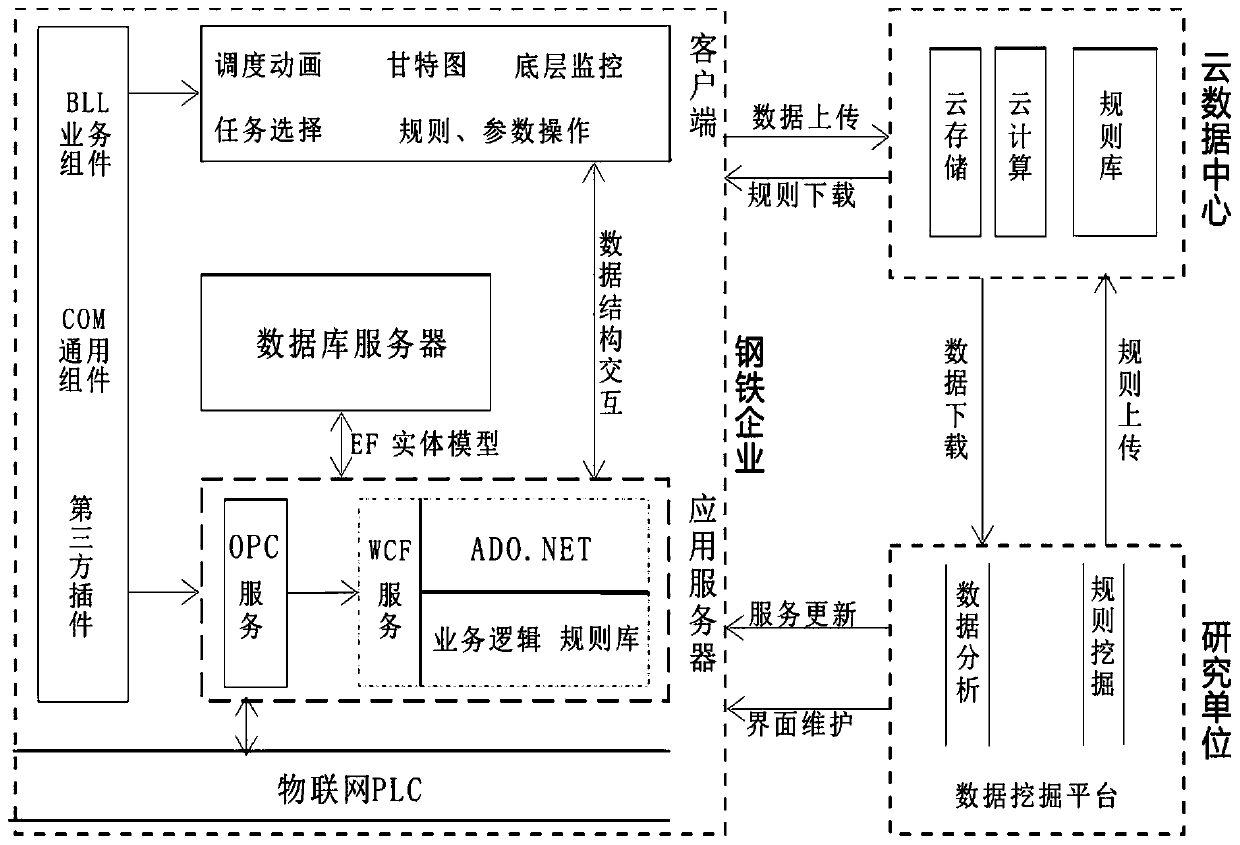

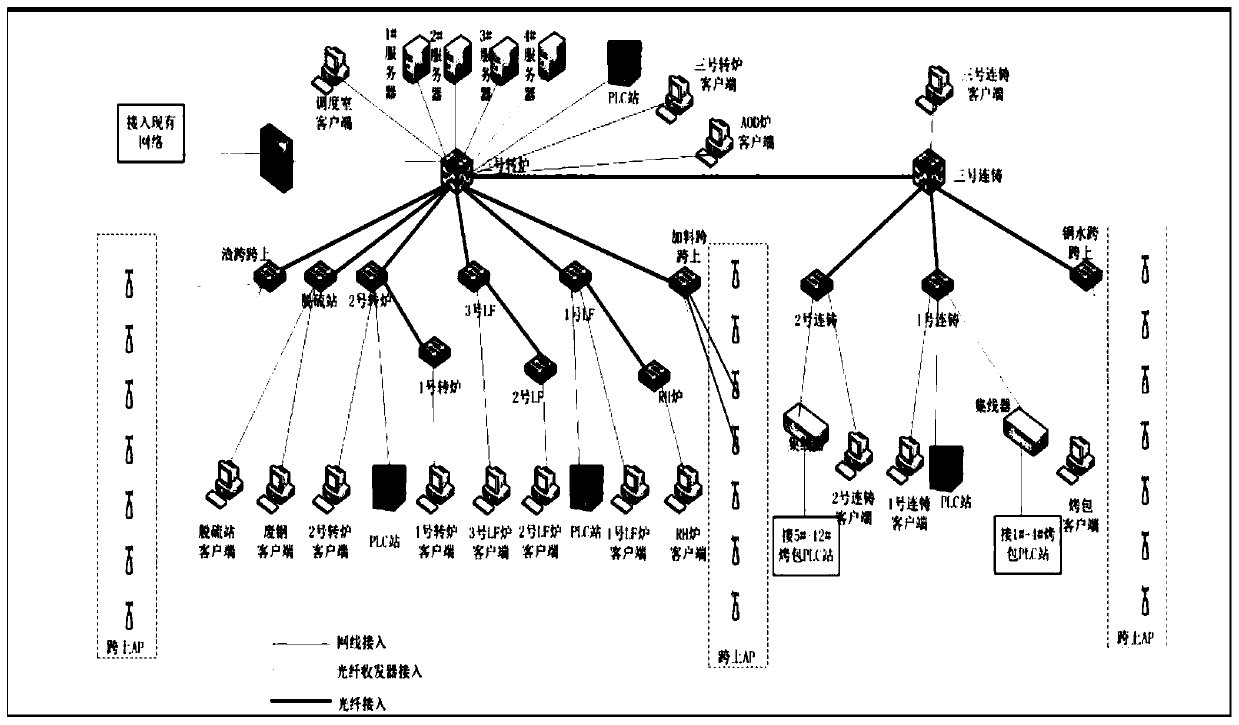

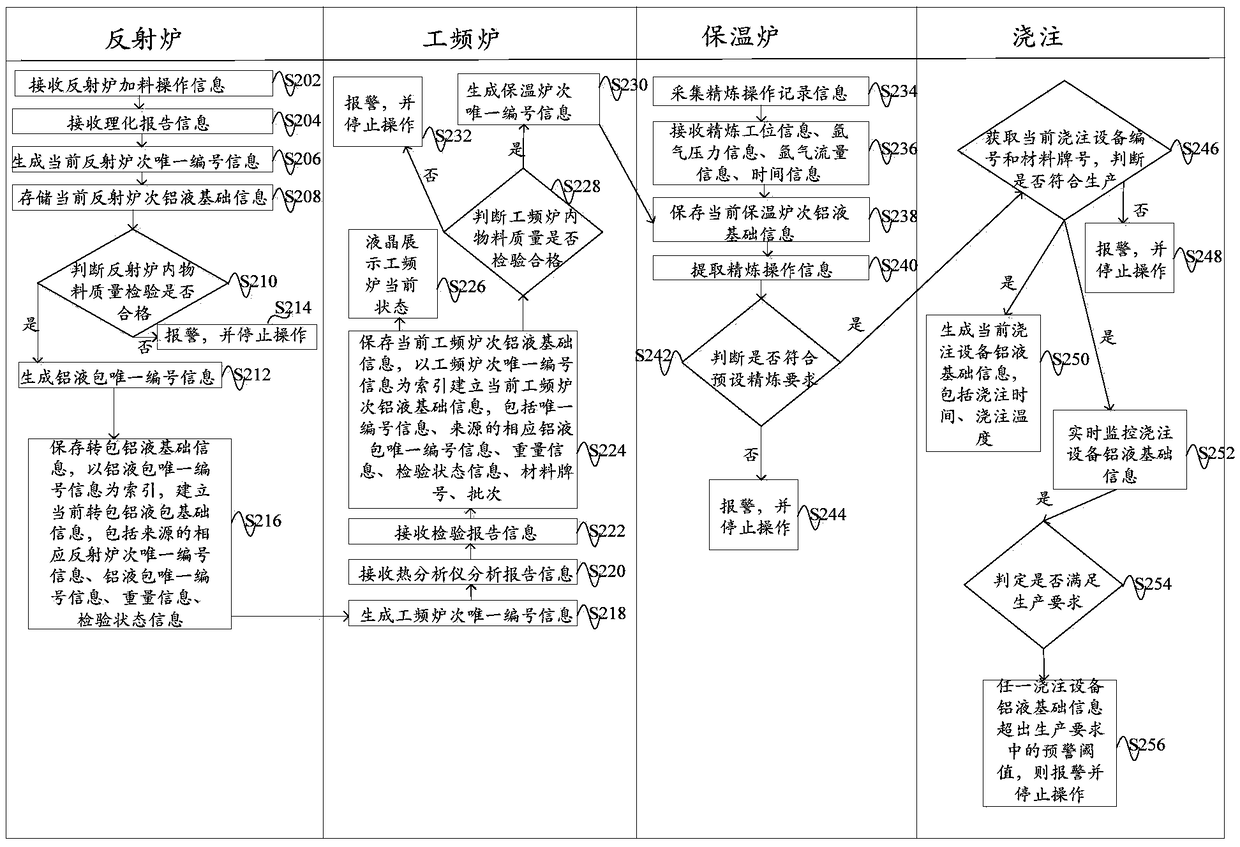

Steelmaking whole process logistics informatization method based on Internet of things

InactiveCN110442090AProcessing speedAvoid production chaosEnergy industryTotal factory controlSteelmakingInformatization

The invention discloses a steelmaking whole process logistics informatization method based on Internet of things. The method includes the following steps: 1) establishing underlying Internet of thingsbased on a PLC, collecting sensor or MES and secondary system data, and providing an underlying real-time signal; 2) providing positions of a crown block and a trolley prepared in real time based onpositioning of the crown block and the trolley of a coding cable. 3) identifying package numbers of containers, and identifying iron package and steel package numbers by scanning high temperature resistant bar codes; 4) tracking the container to realize real-time spatial positions of the steel packages, iron packages and scrap steel hoppers in a whole steelmaking workshop during steelmaking, and displaying the real-time spatial positions in an animated manner; 5) managing scrap steel, according to a scrap steel addition formula and the scrap steel added in the scrap hoppers, a plan of scrap steel addition amount and a specific executing crown block are given; 6) displaying the operation plan, and switching the display of Gantt charts of produced, in-production and unproduced tasks; and 7)displaying a steelmaking whole process in an animated manner, and marking all stop points of the steel / iron packages in the steelmaking whole process in detail. The steelmaking whole process logisticsinformatization method based on Internet of things saves energy, reduces consumption, optimizes the operation time of the crown block, improves the utilization rate and production efficiency of the containers and realizes the maximization of the enterprise benefit.

Owner:HUNAN NORMAL UNIVERSITY

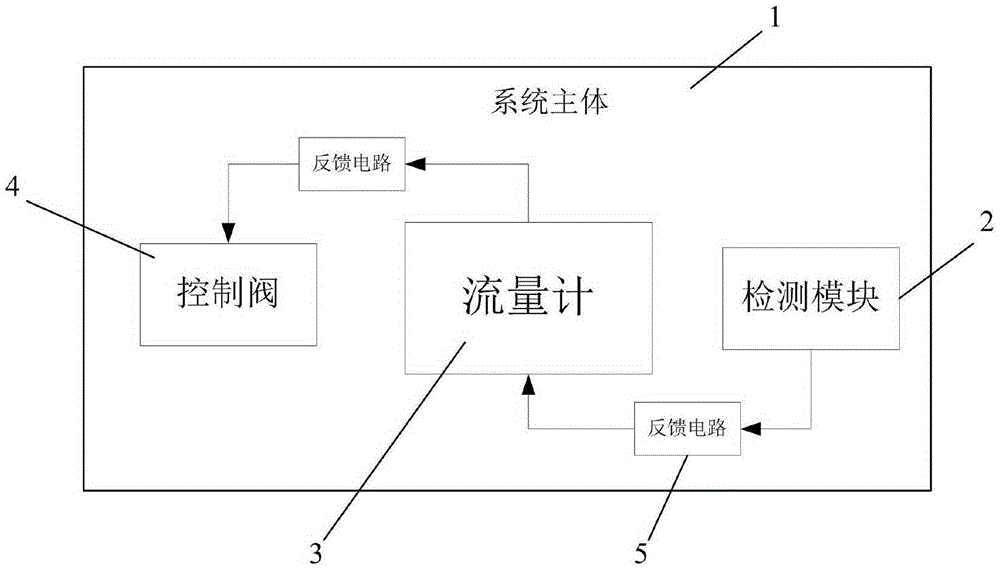

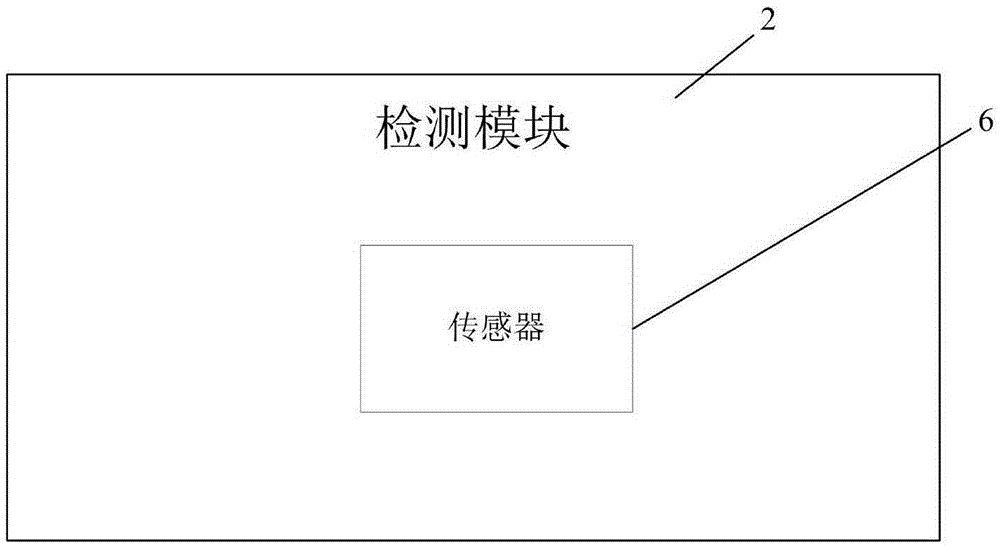

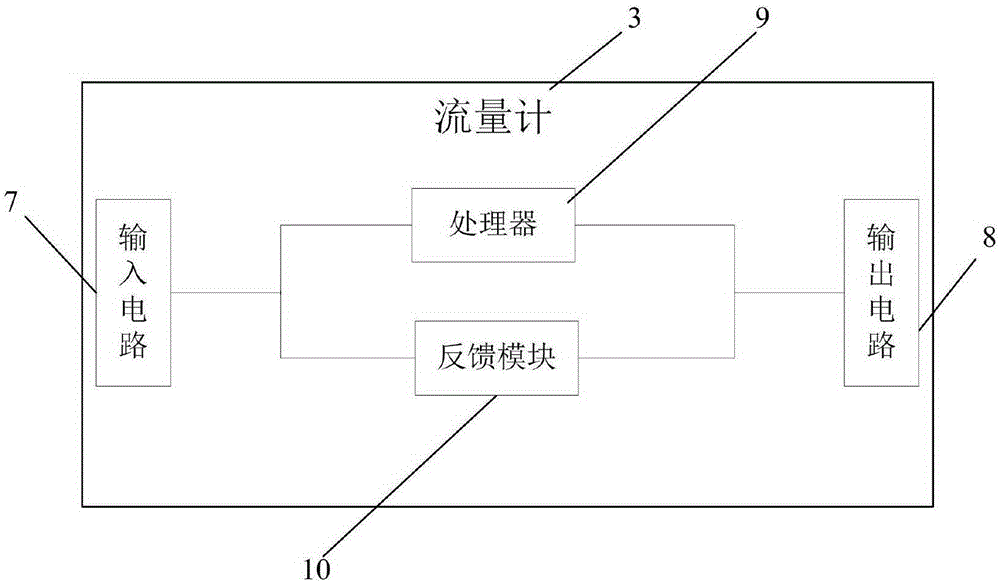

Intelligent high precision flow control system

InactiveCN106610671AHigh control precisionReduce usageFlow control using electric meansElectricityMicrocomputer

The invention provides an intelligent high precision flow control system which comprises a system body. The system body comprises a detection module, a flow meter, a control valve and a feedback circuit. The control valve and the detection module are electrically connected with the flow meter through the feedback circuit. The detection module detects a flow signal and transmits the flow signal to the flow meter through the feedback circuit. The flow meter transmits a correction feedback value to the control valve through the feedback circuit operation and processing. The control valve controls the flow value according to the correction feedback value. According to the invention, the detection module feeds back the signal to the flow meter through the feedback circuit to improve the control accuracy and avoid control malfunction, and then send a feedback signal to the control valve to precisely adjust the control valve; through two feedback signals, the control accuracy of the control valve is high; the use of intelligent microcomputers such as a controller is reduced; the cost of industrial production investment is greatly reduced; the flow is accurately controlled; production accidents are reduced; the production efficiency is improved; and the production cost is reduced.

Owner:JIANGSU RUNYI INSTR

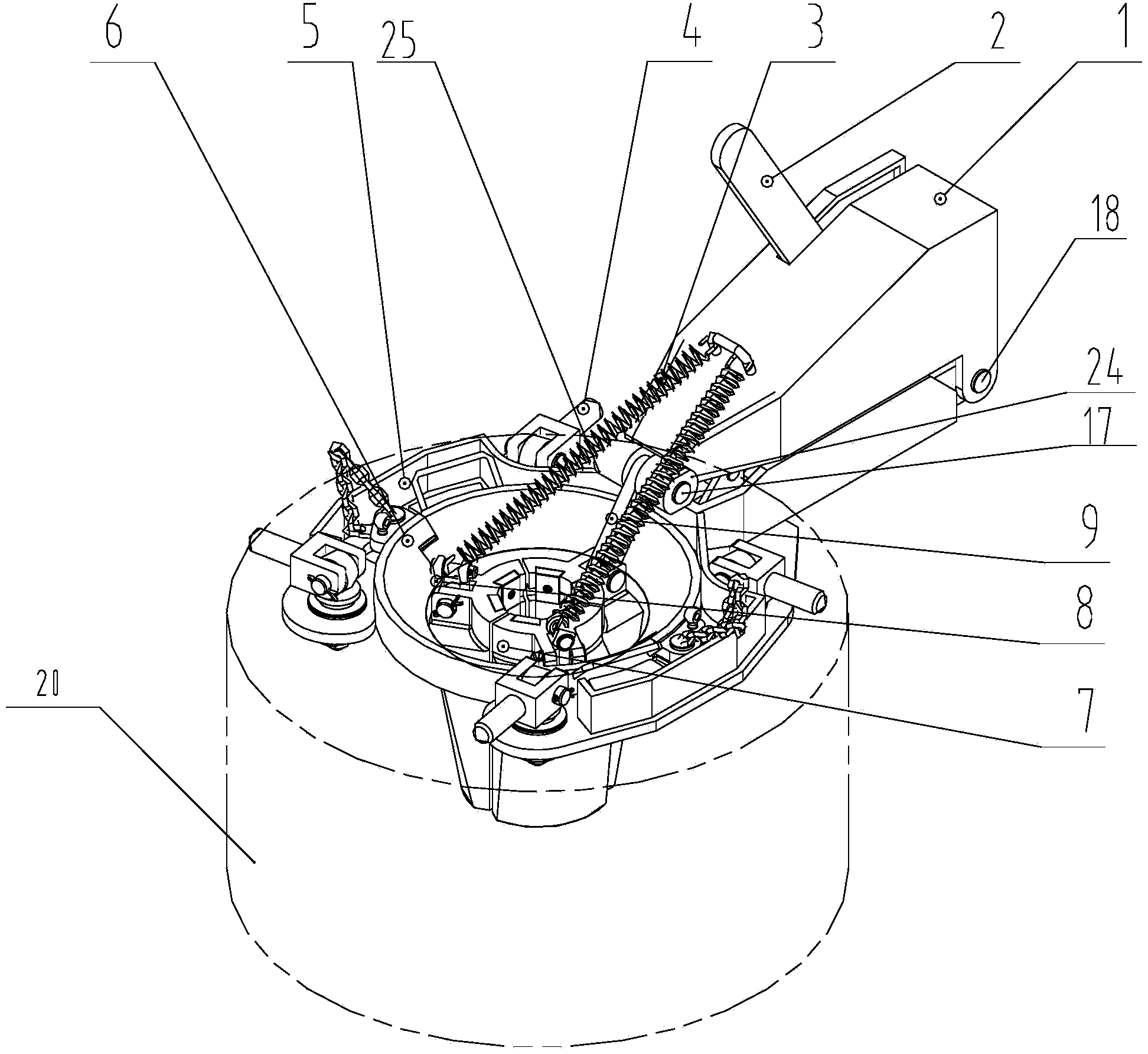

Fully-computerized glove overlock machine

ActiveCN105506868APrevent movementImprove seam qualityProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention relates to a fully-computerized glove overlock machine which comprises a glove overlock machine body and a control system. An automatic positioning device, a driving device, an expanding device and a rubber string conveying device are mounted on the glove overlock machine body and all controlled by the control system. The fully-computerized glove overlock machine has the advantages that full computer control of positioning, driving, expanding, rubber string conveying and the like is realized, high labor precision is achieved while labor efficiency is greatly improved, and glove overlock quality is guaranteed.

Owner:ZHEJIANG HAISEN KNITTING MACHINE TECHN

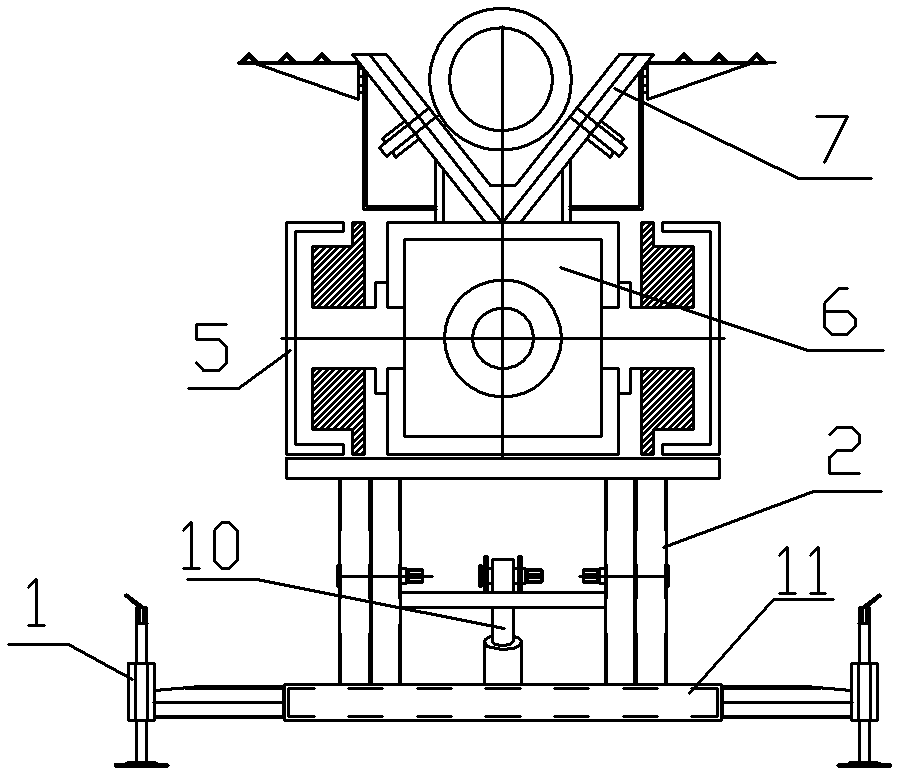

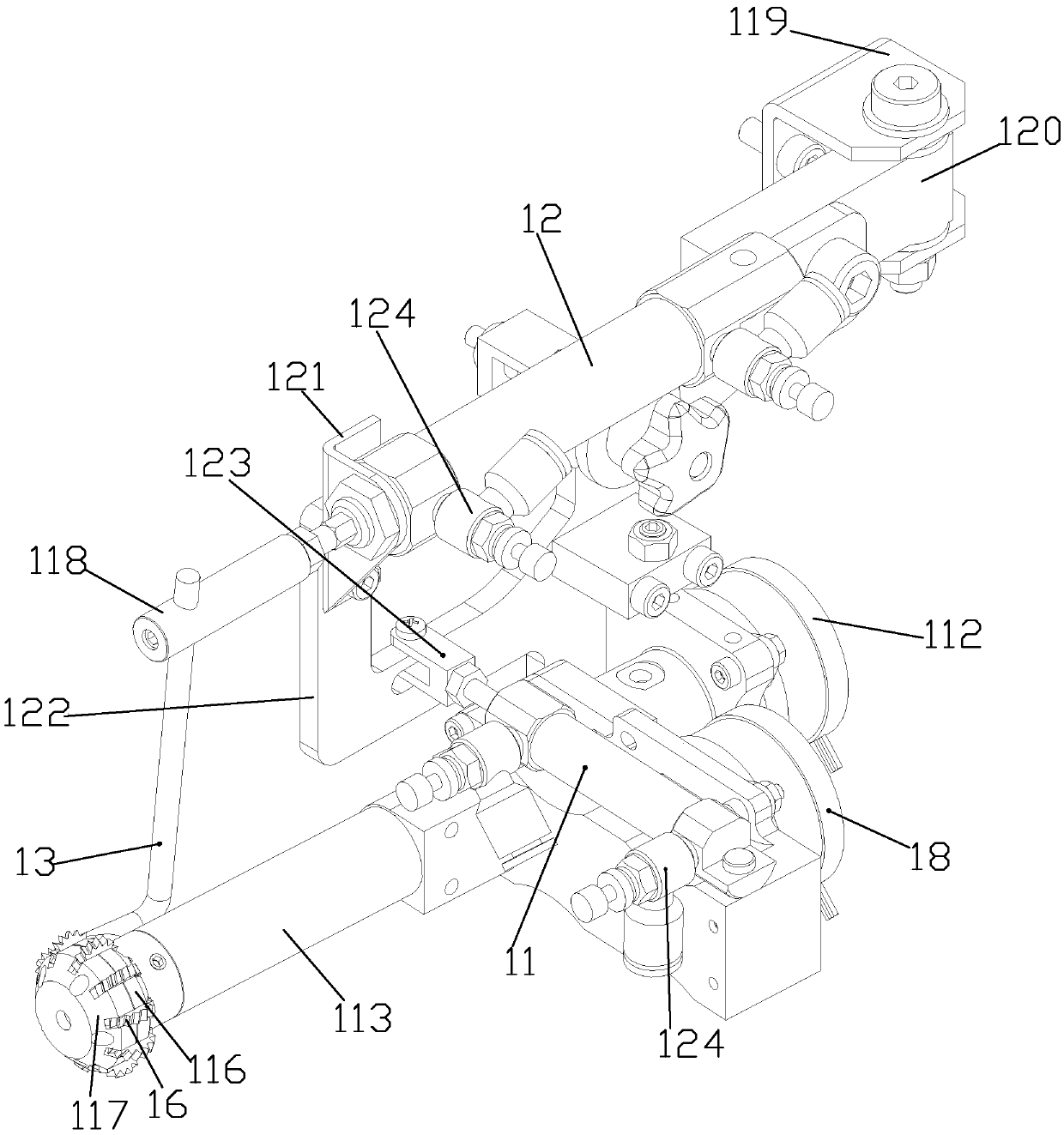

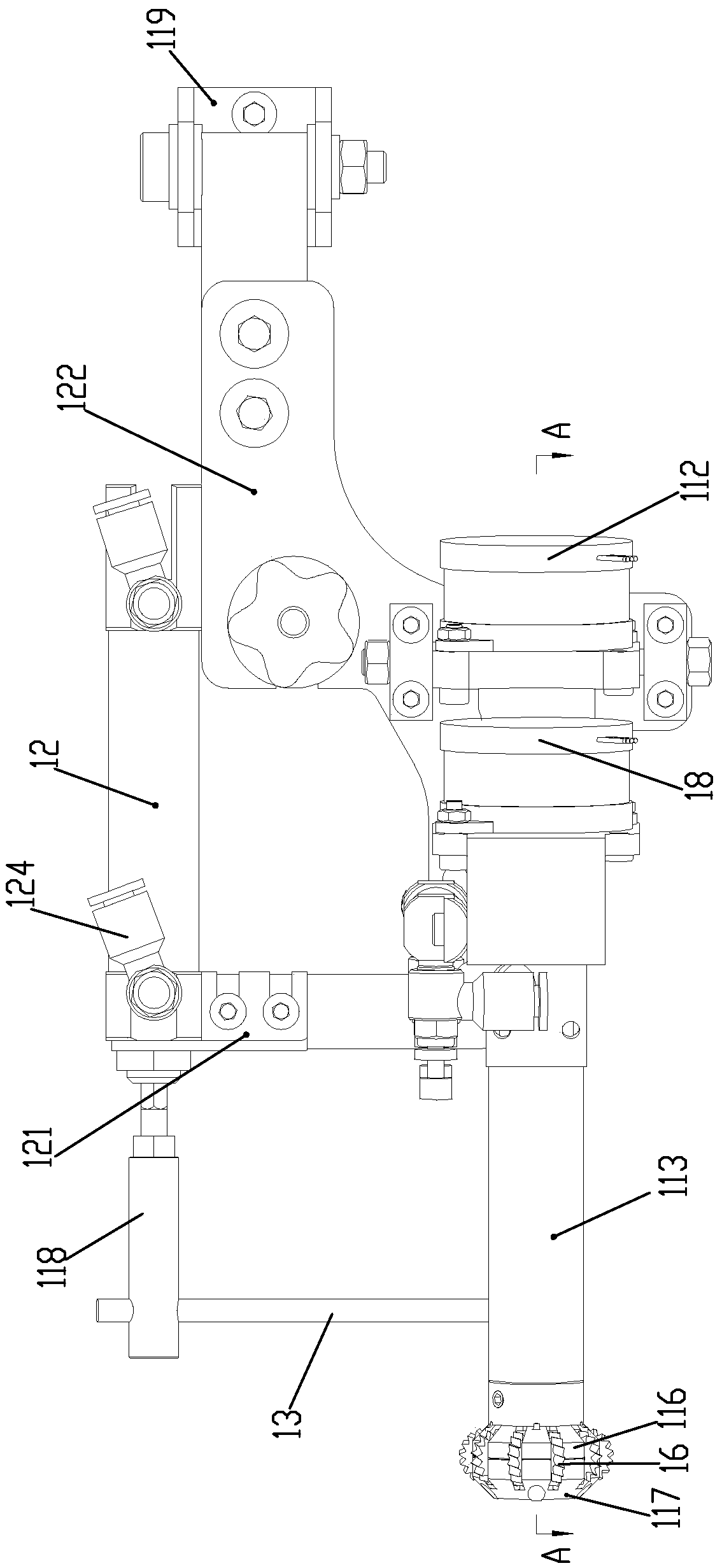

Power slip

ActiveCN103924936AReduced installation effortImprove drilling efficiencyDrilling rodsDrilling casingsWell drillingEngineering

The invention discloses a power slip, and belongs to the technical field of petroleum drilling corollary equipment. The power slip comprises a base, a slip body guide device is arranged on the base, and a locating sliding block is arranged on the outer side face of the slip body guide device. A sliding groove matched with the locating sliding block is arranged on the base, and the locating sliding block slides in or slides off the sliding groove in the circumferential direction. After the locating sliding block enters the sliding groove and is located, the axial movement of the slip body guide device is limited. After the locating sliding block leaves the sliding groove, the slip body guide device can be demounted from the base. Through the power slip with the structure, the slip body guide device is detachably mounted on the base, only the slip body guide device, a turntable bushing and the slip which are matched with tubular columns are replaced when the tubular columns with the different pipe diameters are replaced, the workload for mounting the slip is small, and the working efficiency of well drilling is high.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

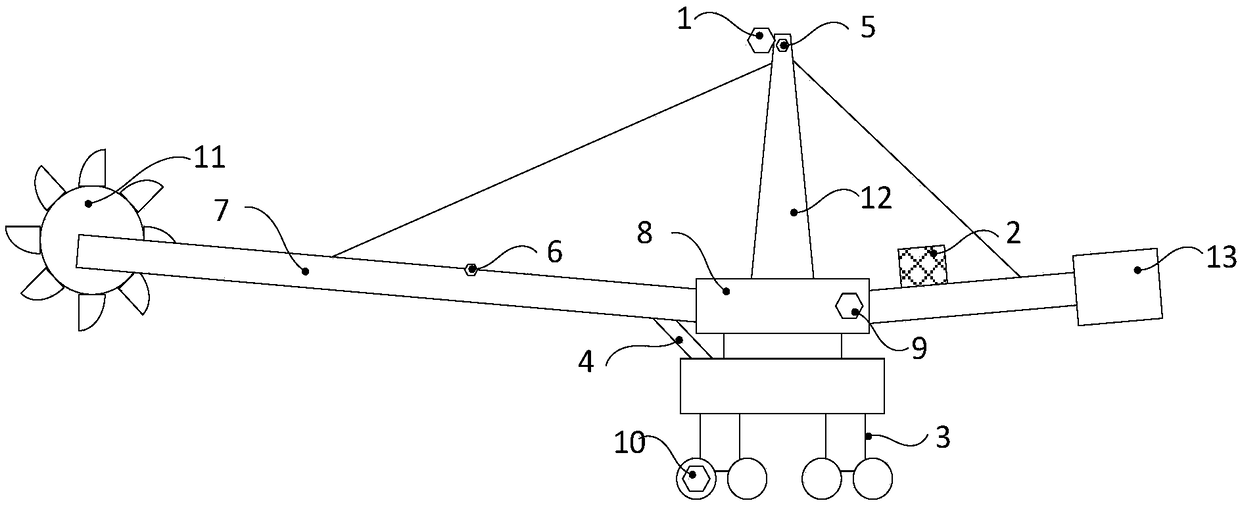

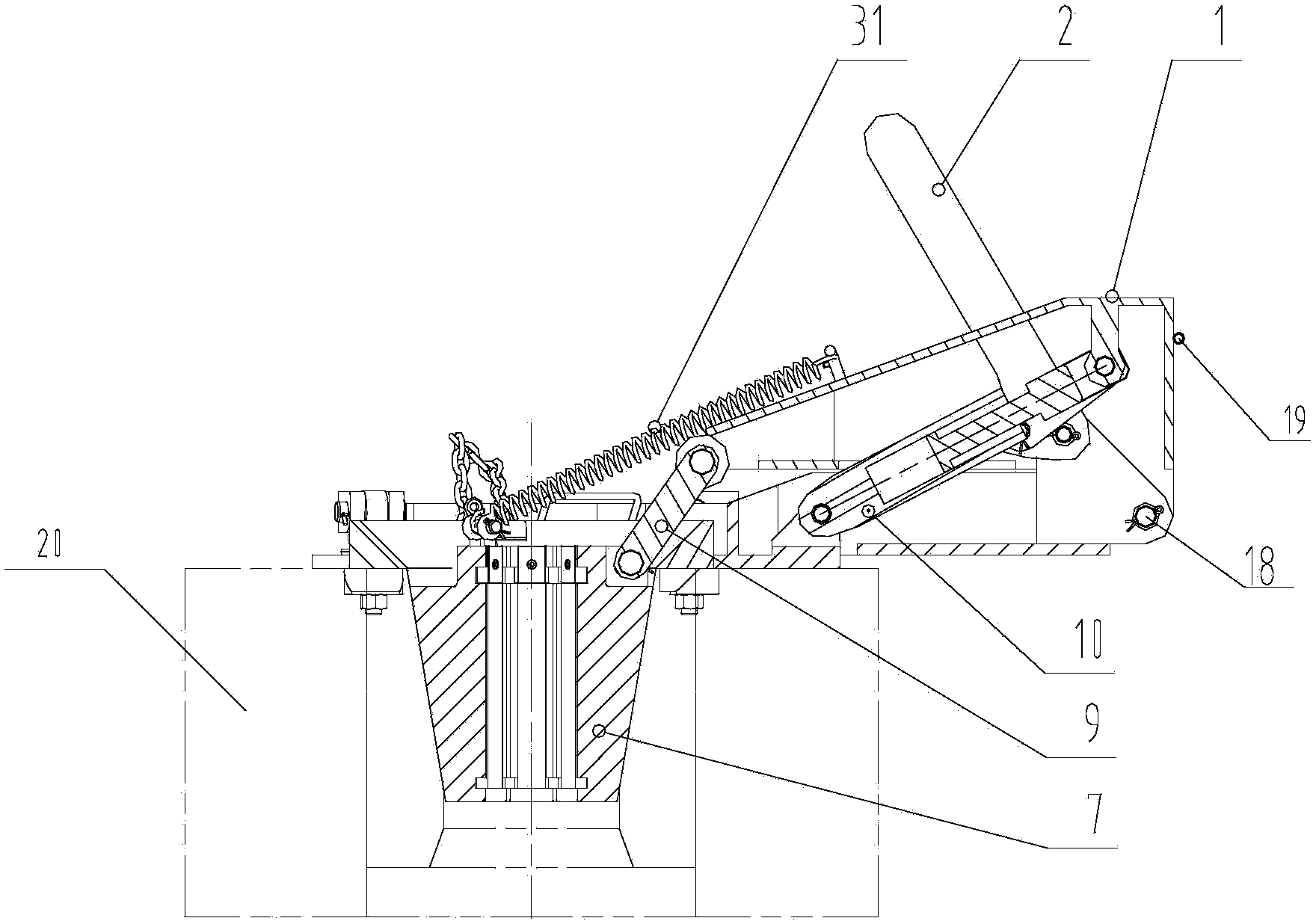

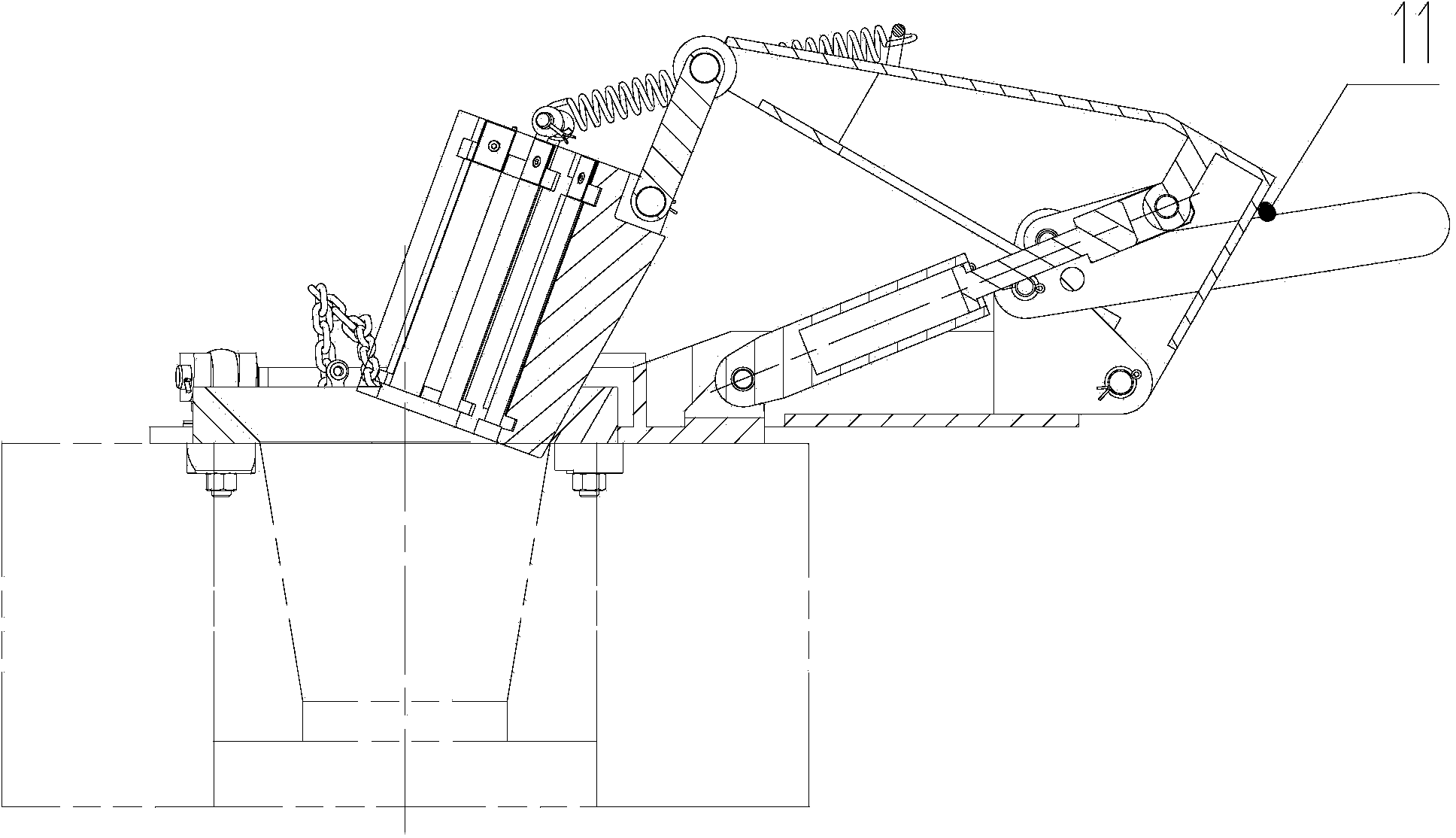

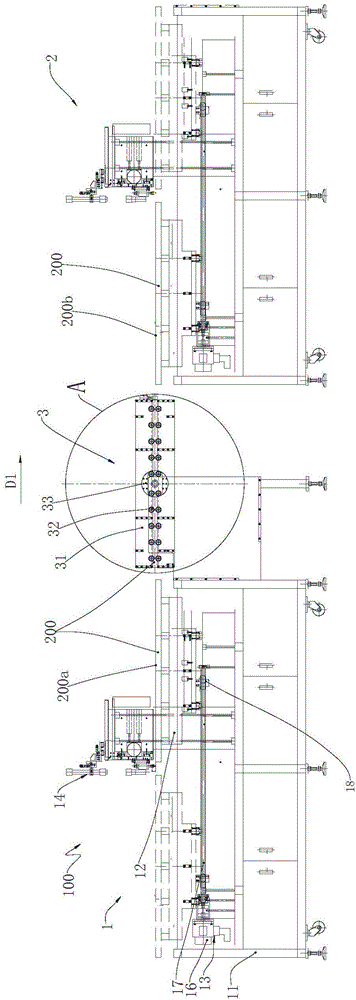

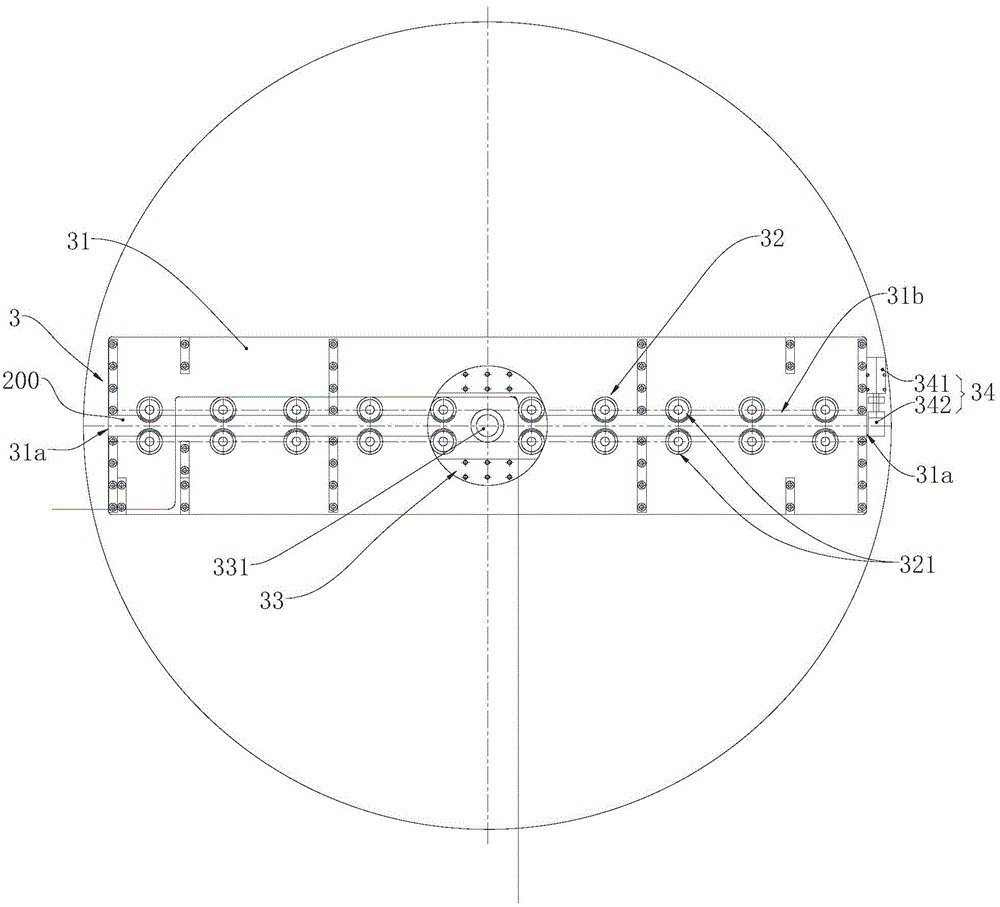

Automatic reclaiming system for strip-shaped stockyard

ActiveCN108639777AAchieve correctionIncrease productivityLoading/unloadingBulk cargoData information

The invention relates to an automatic reclaiming system for a strip-shaped stockyard. The automatic reclaiming system comprises a reclaiming machine, a control module and a detecting module, wherein the reclaiming machine comprises a rack, a reclaiming mechanism and a walking mechanism arranged on the rack; the reclaiming mechanism is connected with the rack, and the pitch angle of the reclaimingmechanism is adjusted through a pitching mechanism; the walking mechanism can move along rails in the strip-shaped stockyard; detected data information is transmitted to the control module by the detesting module; the control module carries out control operation on the acquired data information based on a reclaiming operation target command so as to obtain a control result; and the control modulecontrols the reclaiming machine to finish the operation target according to the control result. The current defects of low bulk cargo stockyard automation degree, high operator labor intensity, low operation efficiency and low site utilizing rate are overcome under the condition of fully ensuring the stockyard utilizing rate and exerting the reclaiming capability and other functions of the reclaiming equipment.

Owner:泰富智能科技有限公司

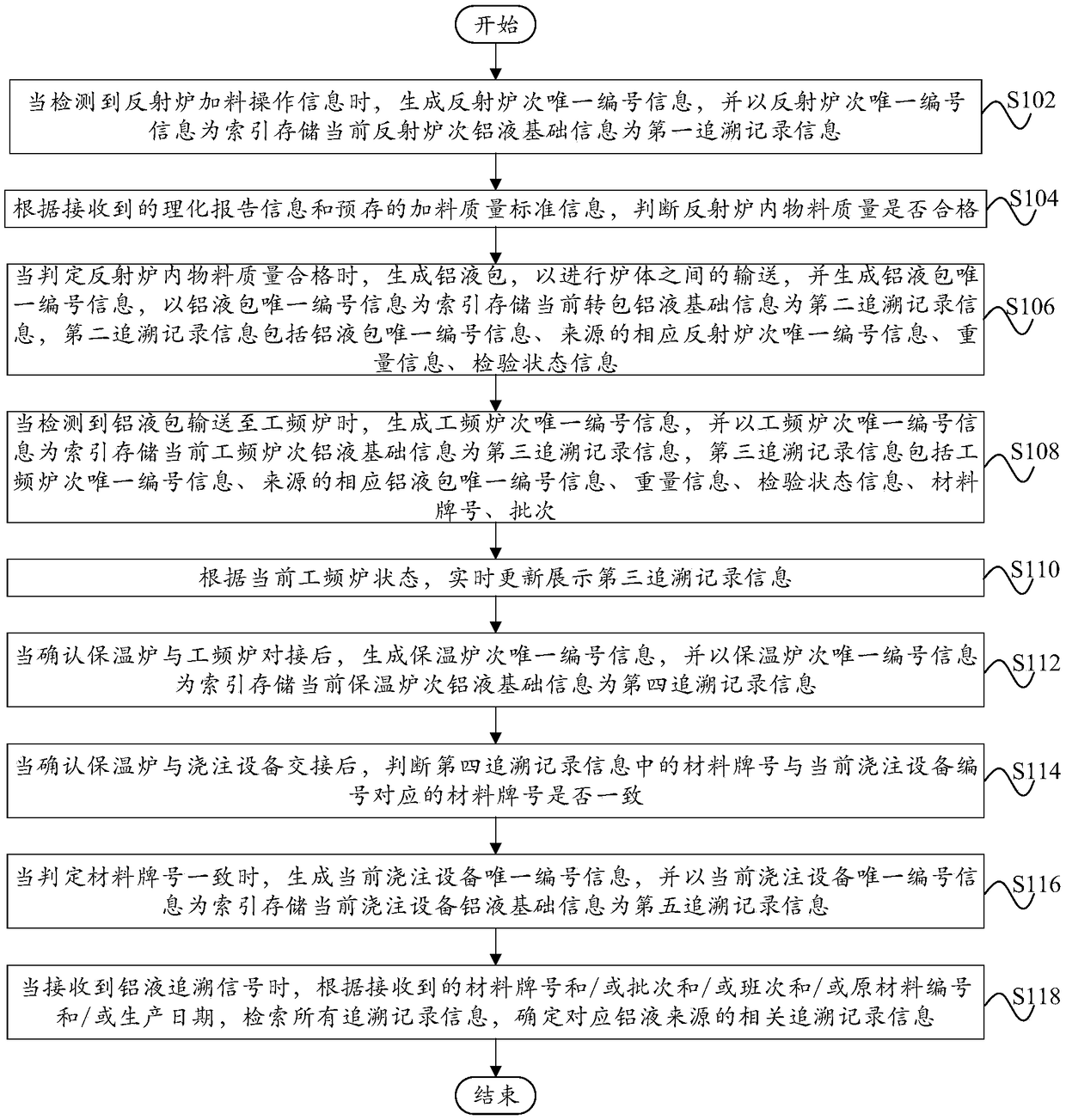

Method for tracing aluminum liquid smelting

InactiveCN109272256AGuaranteed achievabilityReduce production accidentsCasting safety devicesResourcesReverberatory furnaceControllability

A method for tracing aluminum liquid smelting is provided, which includes storing basic information of aluminum liquid of a current reverberatory furnace as first tracing record information with unique numbering information of reverberatory furnace as index, storing the basic information of the current subpackaged aluminum liquid as second traceability record information with the unique numberinginformation of the molten aluminum pack as the index; When the aluminum liquid ladle is detected to be transported to the power frequency furnace, storing the aluminum liquid basic information of thecurrent power frequency furnace as third tracing record information with the power frequency furnace unique number information as the index; When the heat preservation furnace is confirmed to be butted with the power frequency furnace, the unique number information of the heat preservation furnace is generated, and the basic information of the aluminum liquid of the current heat preservation furnace is stored as the fourth traceability record information based on the unique number information of the heat preservation furnace. All traceability record information is retrieved to determine the relevant traceability record information corresponding to the source of the molten aluminum. The technical scheme of the invention realizes the intelligent smelting production of aluminum liquid, the collection automation, the problem transparency, the abnormal early warning, the tracing precision and the process controllability.

Owner:BINZHOU BOHAI PISTON CO LTD

Mode of removing dust by vibrating filter screen in beating manner with aid of reverse blowing

The invention relates to a mode of removing dust by vibrating a filter screen in a beating manner with the aid of reverse blowing. A stainless steel filter screen, a supporting rack, a metal beating net, a cam, a motor, an electrical control unit and a fan are used. In the beating and vibrating mode, the motor, the supporting rack, the cam and the beating net are mainly used, the motor drives thecam to act on the supporting rack, and the supporting rack drives the beating net to vibrate and beat the filter screen. Reverse blowing only has an assisting effect, and a filter screen vibrating dust removal mode with a reverse blowing function is not added in requirements of the patent. The reverse blowing function is fulfilled in an assisted manner, and is characterized in that the electricalcontrol unit is additionally provided with a frequency converter to realize reverse rotation of the fan, and thus, air is blown outwards from the inside of the equipment. In the vibrating and beatingprocess, dust on a filtering net plate loosens and then drops in the equipment.

Owner:BEIJING JINGCHUANG XINYE TECH

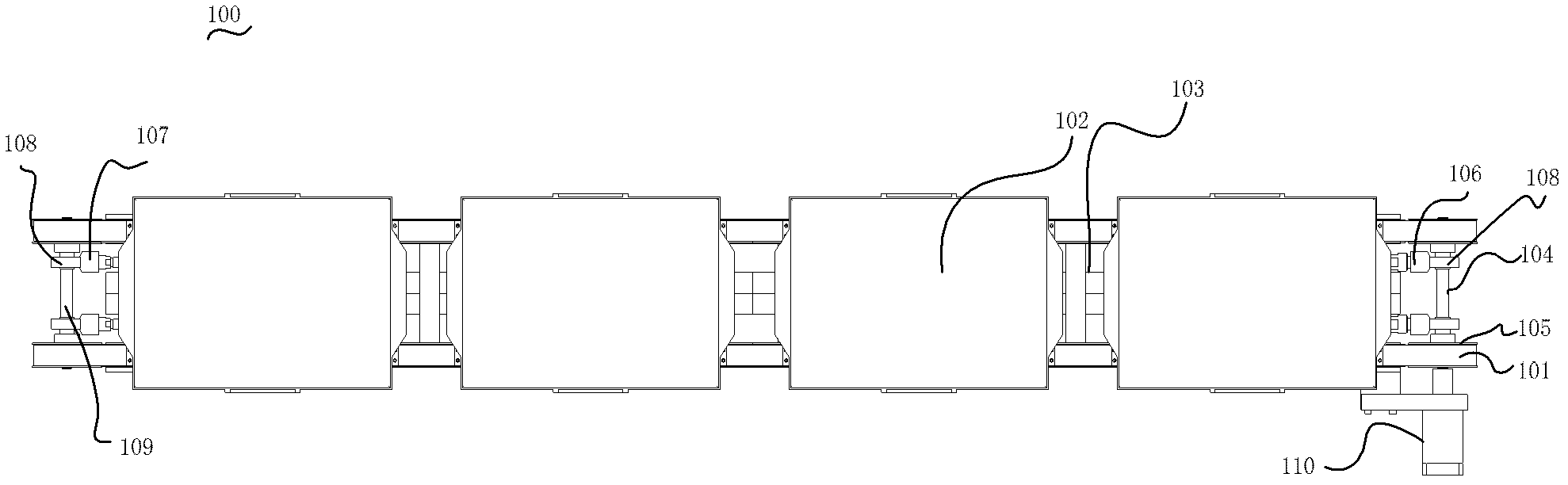

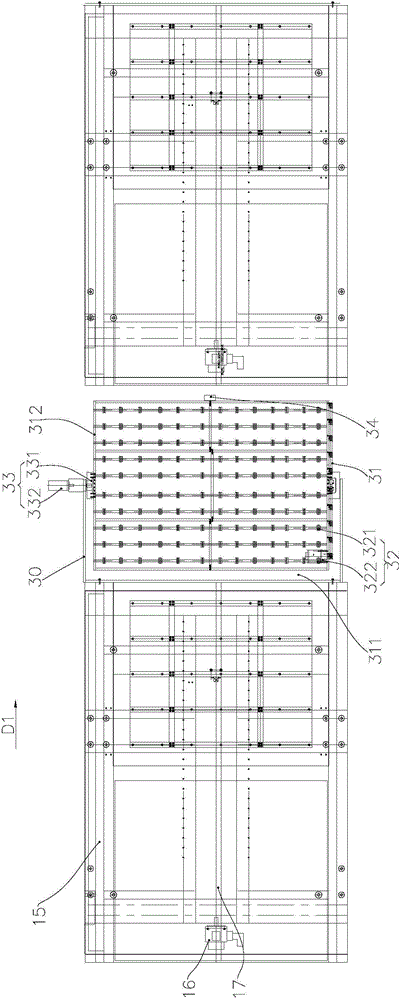

Panel display glass cutting system and method

InactiveCN106145640AImprove securityIncrease productivityGlass severing apparatusGlass productionEngineeringMechanical engineering

The invention relates to the technical field of glass cutting, and provides a cutting system and a cutting method for flat panel display glass. The cutting system provided by the present invention includes a first glass cutting machine, a second glass cutting machine and a horizontal turning machine, the second glass cutting machine and the first glass cutting machine are arranged side by side and alternately, and the horizontal turning machine will cut through the first glass cutting machine The final glass to be processed is turned over and sent into the second glass cutting machine, and the horizontal turning machine is arranged between the first glass cutting machine and the second glass cutting machine. Compared with the prior art, the cutting system of flat panel display glass provided by the present invention, when the horizontal turning machine turns over the glass to be processed, both the first glass cutting machine and the second glass cutting machine can simultaneously load materials, which greatly improves the production efficiency . The cutting method of the cutting system provided by the present invention introduces a combined processing method to maximize the use efficiency of the machine, smooth the production process and improve the production efficiency.

Owner:深圳市晶向科技有限公司

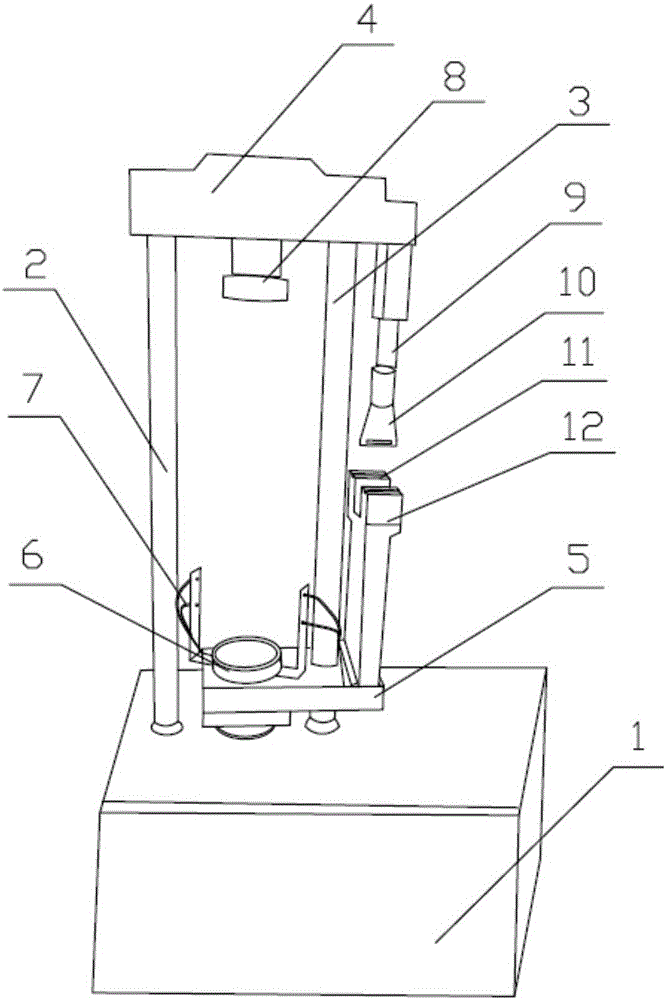

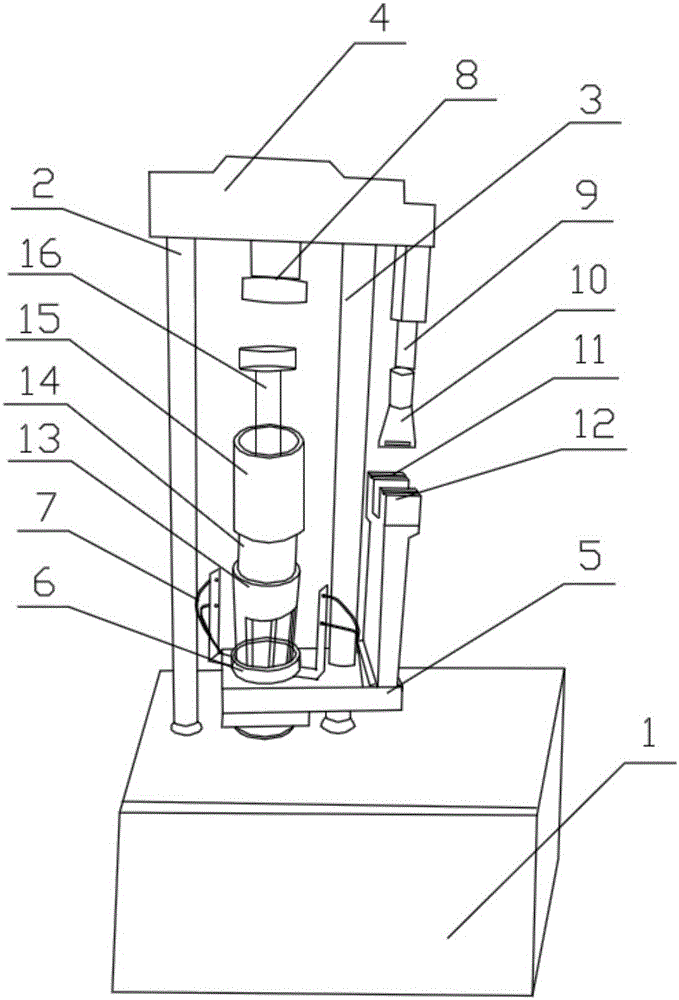

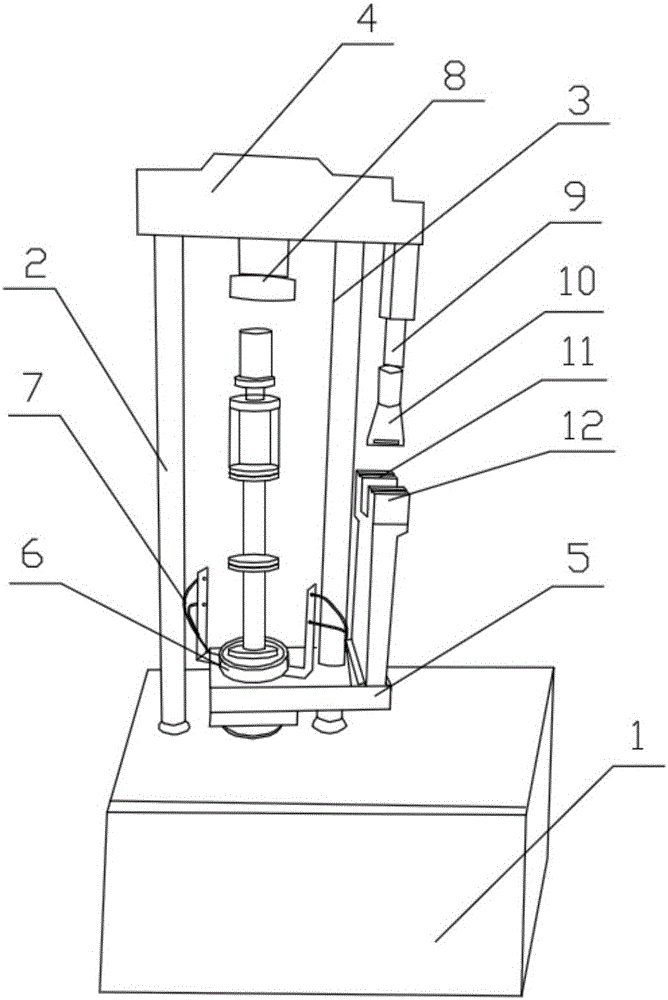

Multifunctional pressure tester for blast furnace tap-hole clay

ActiveCN106018092ASimple structureReduce production accidentsMaterial strength using tensile/compressive forcesEngineeringLight-emitting diode

The invention discloses a multifunctional pressure tester for blast furnace tap-hole clay. The tester comprises a box, a first upright column and a second upright column are arranged on the box and are fixedly connected through a cross beam, the second upright column is sleeved with a movable base, a support tray is installed on the portion, between the two upright columns, on the base, the bottom end of the support tray is connected with an infrared light emitting diode through an iron sheet, a first pressure sensor is fixedly installed on the cross beam and hung over the support tray, a second pressure sensor is hung and fixedly installed on the outer side of the second upright column, the lower side of the second pressure sensor is connected with a first blade, and the base is provided with a second blade and a third blade. The pressure tester is simple in structure, whether clay ramming is convenient or not on site can be judged according to pressure test values obtained after production and ageing, bending resistance and pressure resistance tests can be conducted on blast furnace tap-hole clay, and the test values play an important practical role in guiding and determining the quality of blast furnace tap-hole clay and reducing production accidents.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

Oil injecting type manipulator with function of rust removal for positioning pin production

InactiveCN109333568AAvoid corrosionAutomatic aggregationGripping headsCleaning using toolsPulp and paper industryManipulator

The invention relates to an oil injecting type manipulator with a function of rust removal for positioning pin production. The oil injecting type manipulator with the function of rust removal for positioning pin machining comprises a main frame, a conveying belt, a pressurizing rod and a clamping arm, an air pump is arranged in the interior of the main frame, and the air pump is connected with themain frame in a screw mode, an oil pump is installed on the right side of the main frame, and the oil pump is connected with the main frame in a screw mode; and the conveying belt is arranged at thetop of the main frame and is internally provided with a servo motor, the conveying belt is connected with the main frame in a screw mode, and the conveying belt is connected with the servo motor in ascrew mode, a sliding frame is arranged on the left side of the servo motor, and a power chamber is installed on the lower part of the sliding frame, and the sliding frame is connected with the conveying belt in a screw mode. The oil injecting type manipulator with the function of rust removal for positioning pin machining has the beneficial effects that a positioning pin producing device is provided with the oil injecting type manipulator with the function of rust removal and cleaning brushes, cleaning of surfaces of workpieces can be carried out, and the possibility that the surfaces of theworkpieces are influenced by external world and are rusted and corroded is prevented, so that production of unqualified products of positioning pins is reduced.

Owner:DONGGUAN UNIV OF TECH

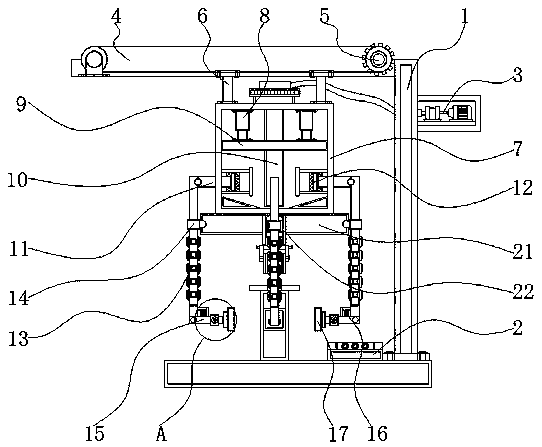

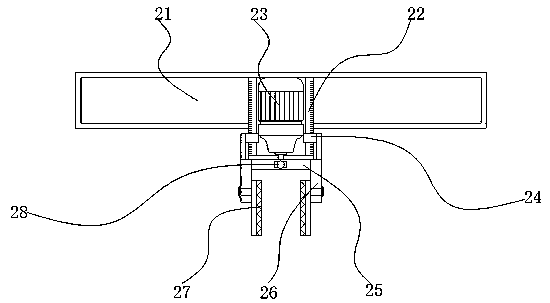

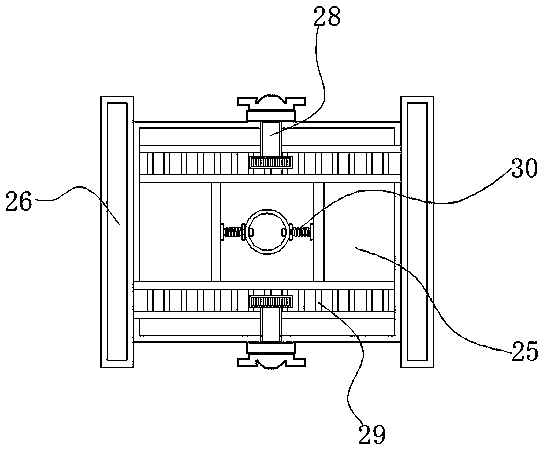

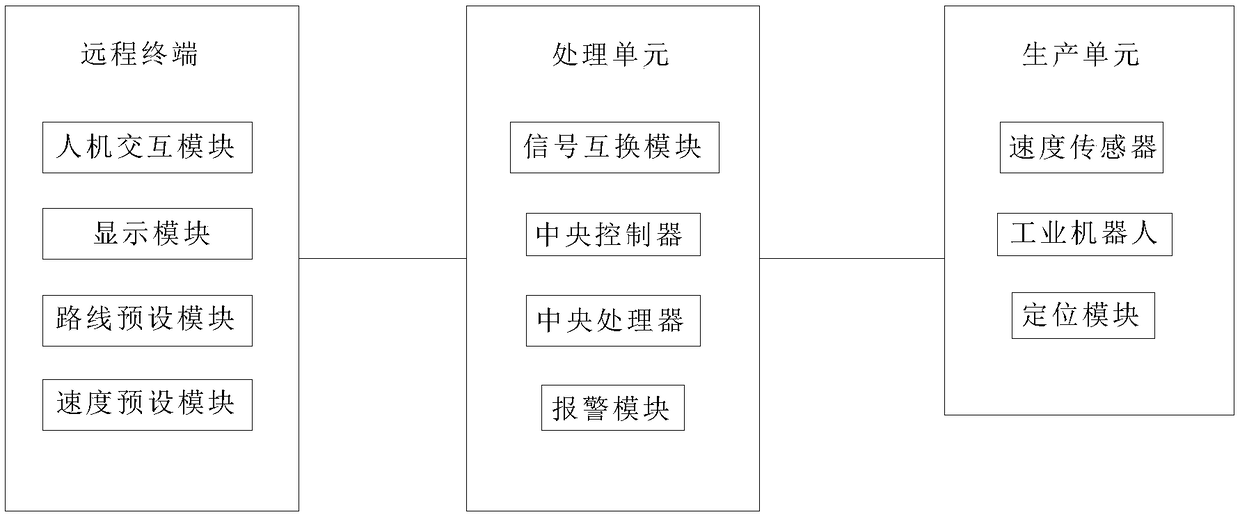

System for remotely controlling industrial robot and working method of system

InactiveCN108501001AHigh degree of intelligenceReduce production accidentsProgramme-controlled manipulatorLocal area networkManufacturing engineering

The invention discloses a system for remotely controlling an industrial robot. The system comprises a remote terminal, a processing unit and a production unit, wherein the remote terminal is in data connection with the processing unit through a wireless local area network, and the processing unit is connected with the production unit through a cable. The invention further provides a working methodof the system for remotely controlling the industrial robot. The industrial robot is remotely controlled and controlled to operate and work according to a preset route, speed, working frequency and the like, and the intelligent degree is high. When the industrial robot operates, various data are collected in real time and converted, and real-time monitoring is conducted; and when the data exceeda preset value range, the industrial robot is immediately controlled to stop working, and an alarm is given off, so that production accidents are greatly reduced, production smoothness is guaranteed,the production efficiency is improved, and good usage and safety value is achieved.

Owner:MAANSHAN YUANRONG ROBOT INTELLIGENT EQUIP CO LTD

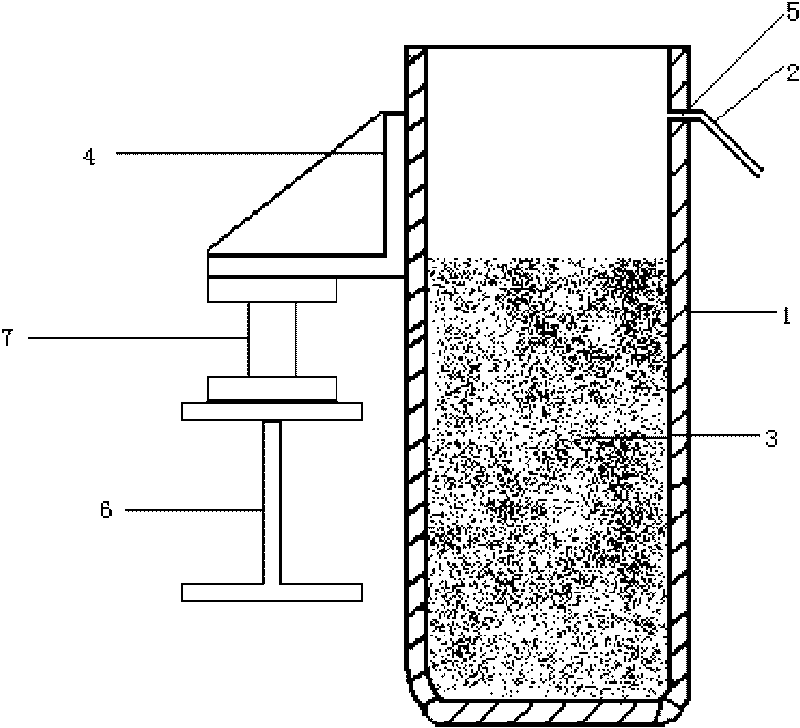

Method for measuring material level of storage tank in production of trichlorosilane

InactiveCN101706305AAccurate measurementTimely supplementLevel indicators by weight measurementProcess engineeringStorage tank

The invention relates to a method for measuring the material level of a storage tank in the production of trichlorosilane, which belongs to the production field of halogenated silicane. The invention solves the technical problem of providing the method for measuring the material level of the storage tank in the production of the trichlorosilane, and the method is free from the interference of floating dust. The method for measuring the material level of the storage tank in the production of the trichlorosilane measures the material level of the storage tank which is connected with a pipeline, and calculates the material level L of a material in the storage tank according to a formula L=m / (Sp) by measuring the total mass m of the storage tank and the material in the storage tank, wherein S is the cross-section area of the storage tank, and p is the stacking density of the material. The method can avoid the influence of the floating dust on a detection result, can measure the material level of the material in the storage tank more accurately, is beneficial to replenishing silicon powder or eliminating silicon dust in time, can effectively reduce the generation of production accidents and has extensive application prospect.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com