Method for measuring material level of storage tank in production of trichlorosilane

A technology of trichlorosilane and a measurement method, which is applied in the direction of displaying a liquid level indicator through weight measurement, etc., can solve the problems of high daily management and maintenance costs of radioactive sources, unfavorable operator health, and floating dust affecting measurement accuracy, etc., so as to reduce production. Accidents, increased service life, and the effect of improving conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

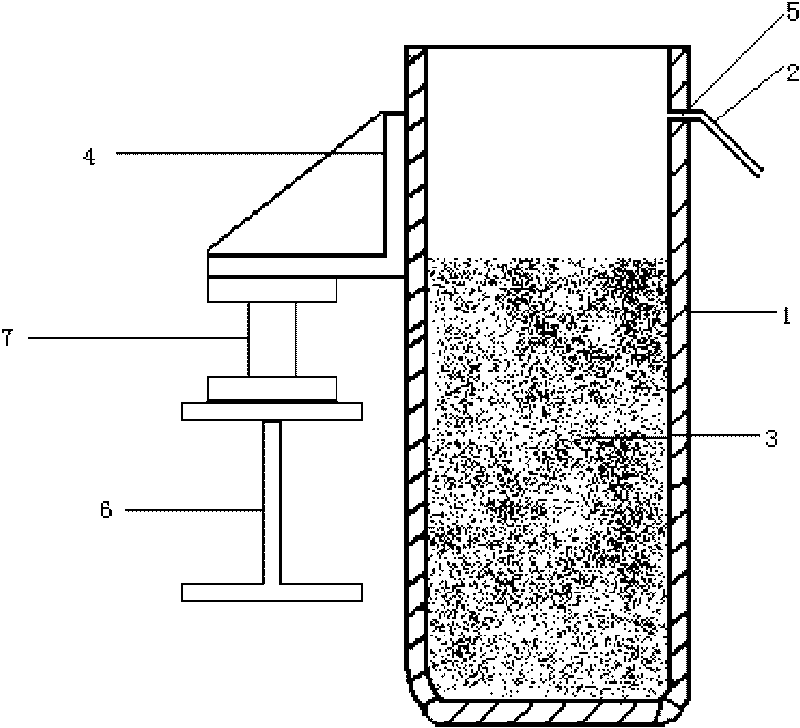

[0033] Attached figure 1 The shown storage tank produces trichlorosilane. The storage tank includes a tank body 1 and a support 4 fixedly connected to the tank body 1. One side of the tank body 1 is provided with a discharge port 5, and the discharge port 5 passes through a metal soft The pipe 2 is connected with the pipeline, and a load cell 7 is arranged under the support 4 , and the load cell 7 is placed on the support device 6 .

[0034] The silicon powder storage tank is a cylindrical container with a diameter of 1.4m. The self-weight of the silicon powder storage tank is 2754kg, and the bulk density of the silicon powder is 1.4g / cm 3 . The reading of the load cell of the silicon powder storage tank is 5000kg, and the level height of the silicon powder is:

[0035] L=m / (Sρ)

[0036] =(5000kg-2754kg) / [3.14*(0.7m) 2 *1.4]g / cm 3

[0037] =1.043m

[0038] That is, the material level of the silicon powder storage tank is 1043mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com