Patents

Literature

47results about How to "Reduce the likelihood of forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

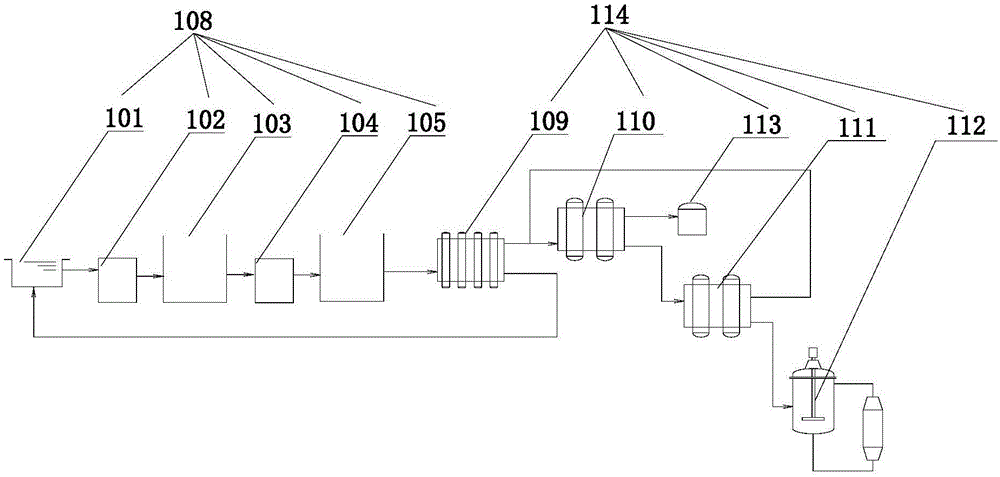

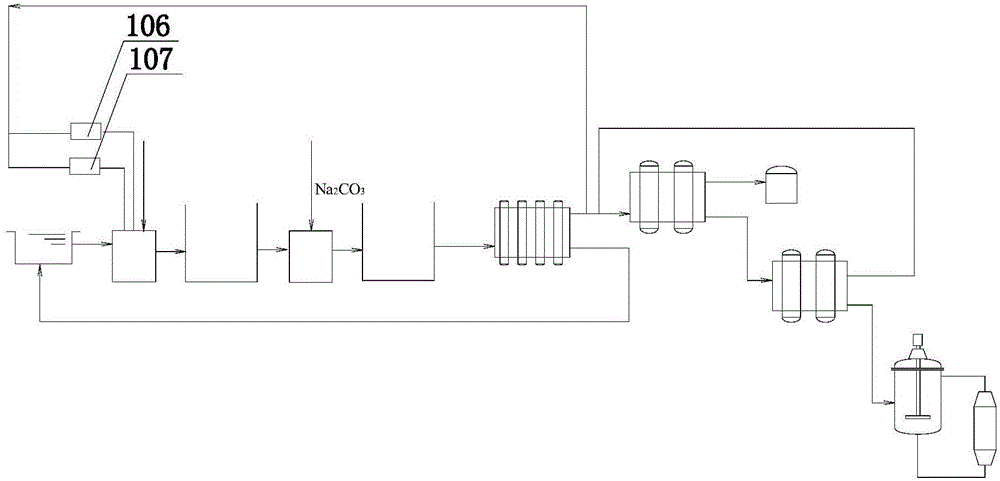

Treatment method and equipment of high-salt waste water

InactiveCN105084587AEfficient removalReduce the likelihood of formingMultistage water/sewage treatmentWater circulationChemistry

The invention provides a treatment method and equipment of high-salt waste water. The treatment method comprises the steps that A, agents are added to the high-salt waste water for pretreatment to reduce hardness, and then nanofiltration softening treatment is carried out to obtain a first separating medium and a first concentrated solution; B, the first separating medium is further purified to obtain pure water to be reused, and the first concentrated solution is returned to the step A to carry out agent adding pretreatment on the high-salt waste water as part of the agents to reduce the hardness. The treatment equipment comprises an agent adding pretreatment device, a nanofiltration softening device and a purifying device. The nanofiltration softening device comprises a first water inlet, a first concentrated solution outlet and a first separating medium outlet, the first concentrated solution outlet is connected with the agent adding pretreatment device, and the first separating medium outlet is connected with the purifying device. The treatment method has the advantages that the method is simple and convenient to operate, water produced through nanofiltration is recycled, the quantity of the added agents is reduced, pollution caused by discharging to environment is avoided, full environment friendliness is achieved, the waste water treatment capacity is high, and waste water zero discharging can be achieved.

Owner:BEIJING WOTEER WATER TECH

Preparation method and application of inoculant for thin-wall quenching part

The invention discloses a preparation method of an inoculant for a thin-wall quenching part. The preparation method comprises the following steps: uniformly mixing 70-80% of Si, 0.6-1% of Sr, 0-3% of Ba, 0.9-1.4% of Al, 0-0.7% of Ca, 0.5-1% of a carburant and the balance of Fe and inevitable trace elements to obtain a mixture; smelting, cooling, pouring, quenching and crushing the mixture; mixing the mixture with Fe3O4 powder; and pressing, clustering and crushing the mixture and the Fe3O4 powder. The invention further discloses an application of the inoculant for the thin-wall quenching part. The inoculant for the thin-wall quenching part provided by the invention can be adopted to improve comprehensive properties of the thin-wall quenching part, and improves inoculation efficiency.

Owner:成都宏源铸造材料有限公司

Nodular cast iron inoculant, and preparation method and application thereof

The invention discloses a nodular cast iron inoculant which comprises the following components in percentage by weight: 60-65% of Si, 3.5-6.0% of Zr, 1-2% of Ca, 0-1.4% of Al, 0.5-1.5% of Fe3O4, and the balance of Fe and inevitable minor elements. The nodular cast iron inoculant disclosed by the invention can improve the comprehensive properties of the nodular cast iron and enhance the inoculation efficiency.

Owner:成都宏源铸造材料有限公司

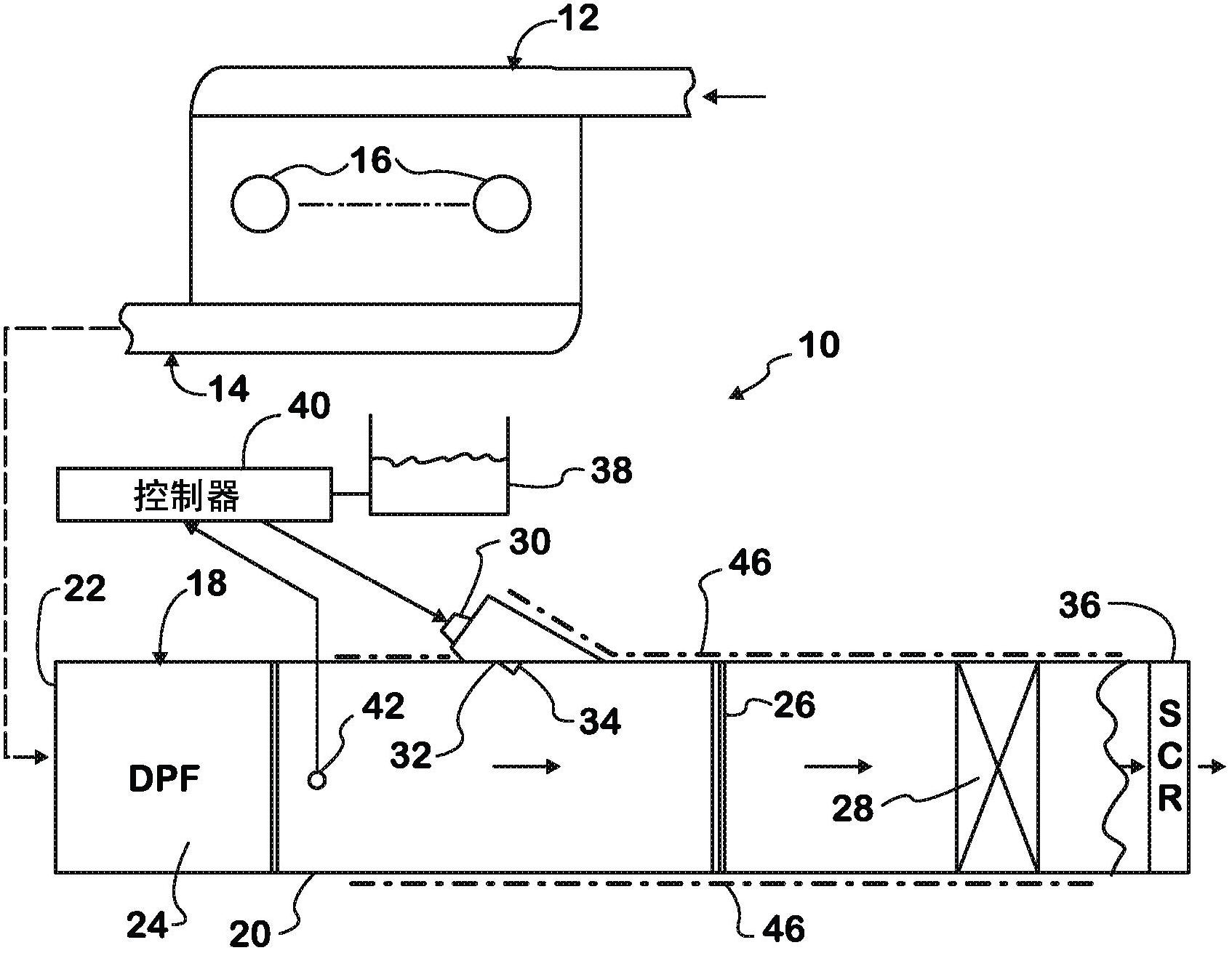

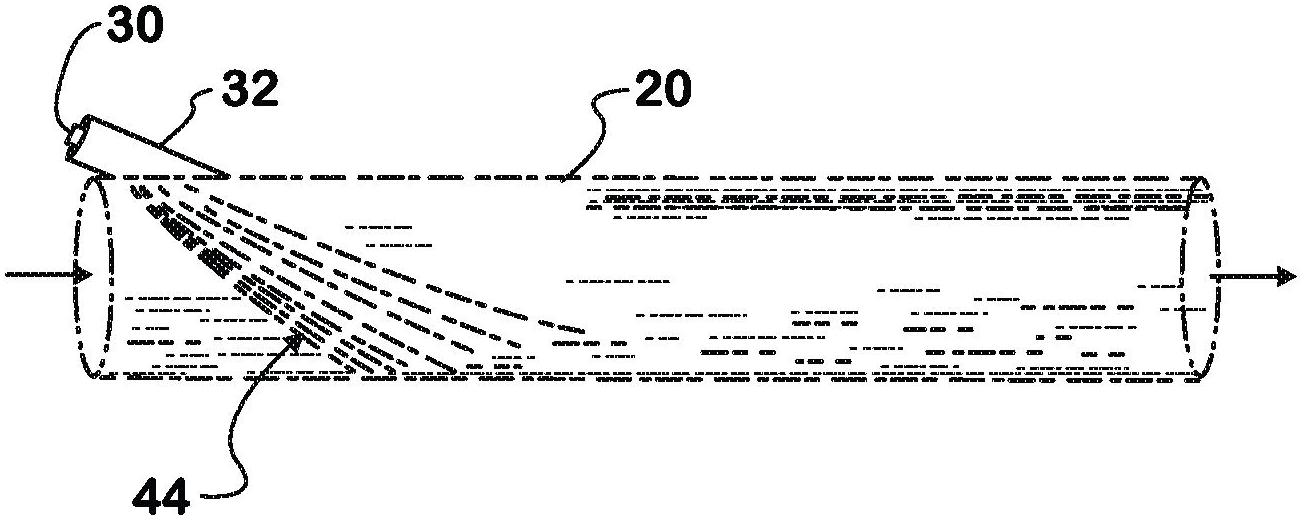

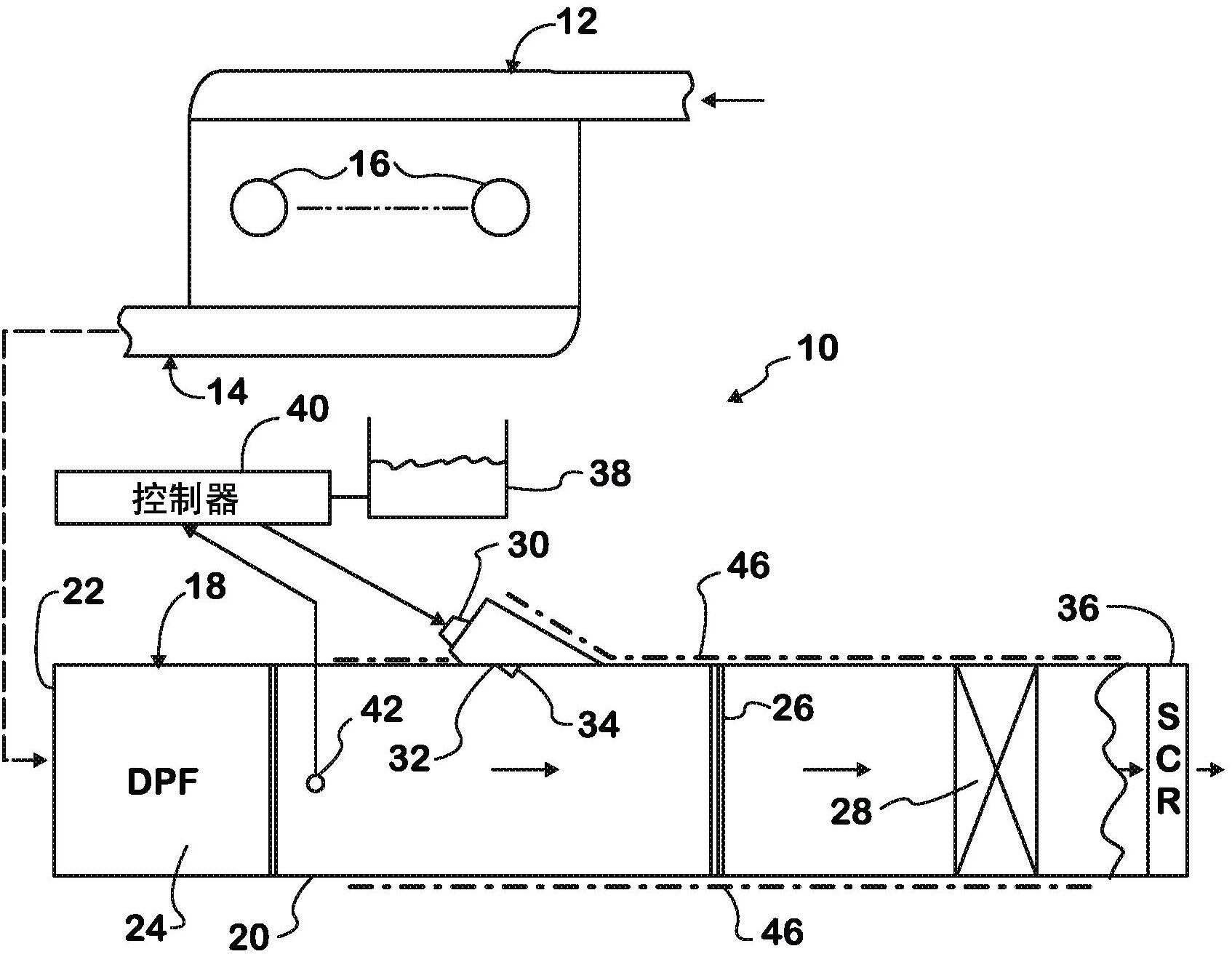

Mitigating potential for urea deposit formation in engine exhaust

InactiveCN102639828AReduce the likelihood of formingReduce the duration of sprayingInternal combustion piston enginesExhaust apparatusParticulatesEnvironmental engineering

Owner:INT ENGINE INTPROP CO LLC

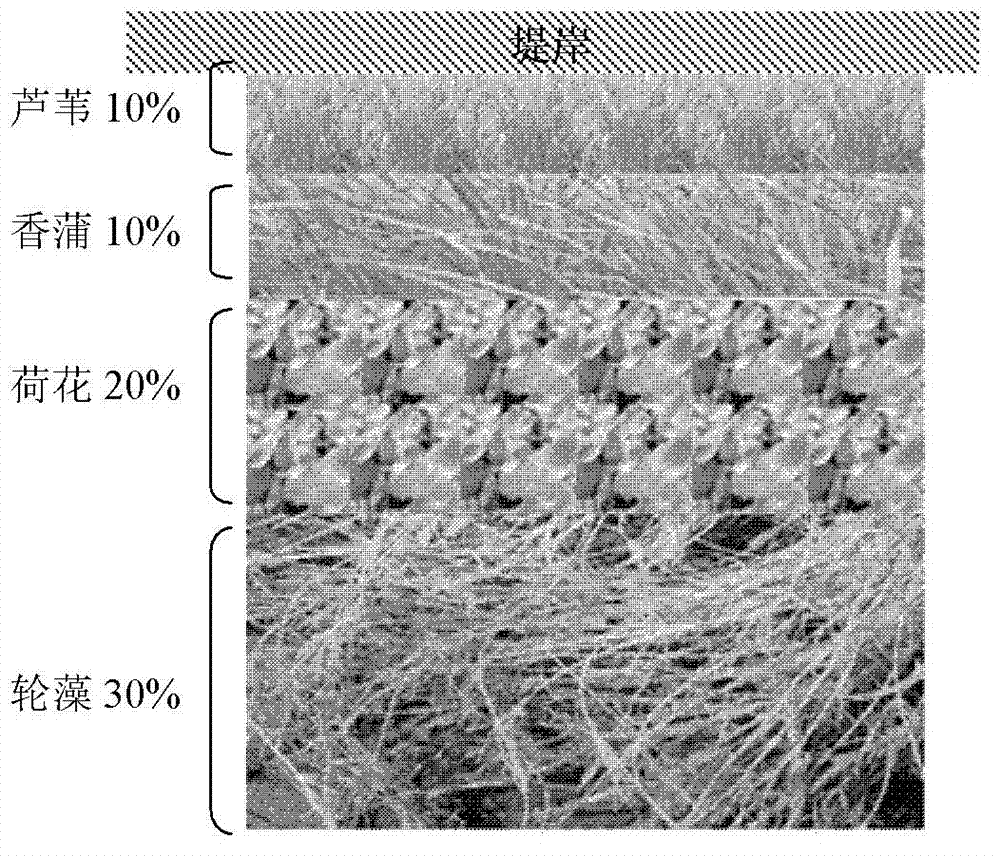

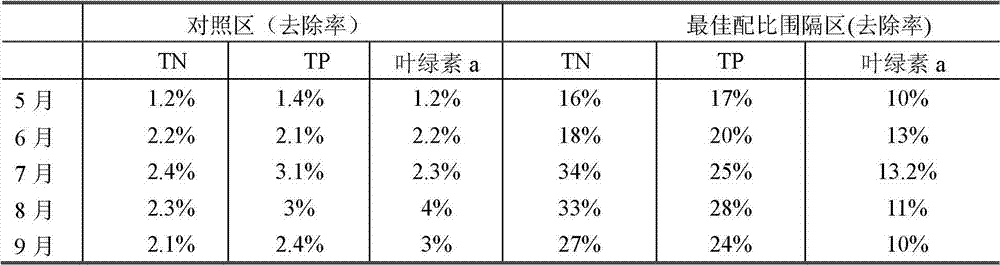

Method for controlling lake eutrophication and paludification by using aquatic plant configuration

InactiveCN102730836AReduce the likelihood of formingReduce rot accumulationSustainable biological treatmentBiological water/sewage treatmentEutrophicationPaludification

The invention discloses a method for controlling lake eutrophication and paludification by using aquatic plant configuration. The method comprises the following steps of: investigating the contamination degree and the species and coverage of aquatic plants of a water body; selecting the proportion and planting positions of the aquatic plants by combining water quality index changes and plant species differences over the years; and harvesting the aquatic plants to reduce biogenic sediment so as to slow down the paludification process. By the method, the economic cost for lake control can be effectively reduced, and local materials are used, so that the method is easy, simple and feasible and has strong operability and wide applicability; and the implementation of the technology does not influence the original ecological functions of a lake ecological system, thus the method has great significance for maintaining the ecological health of lakes for a long time.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

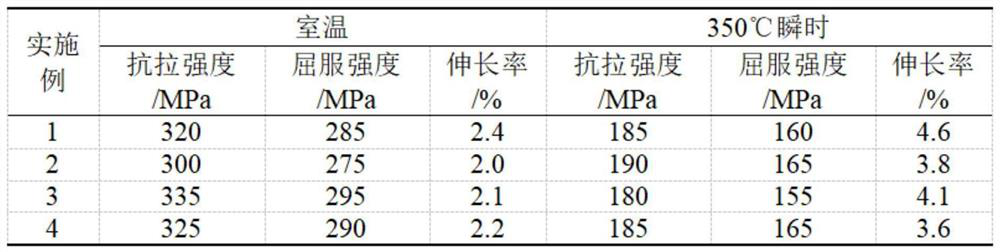

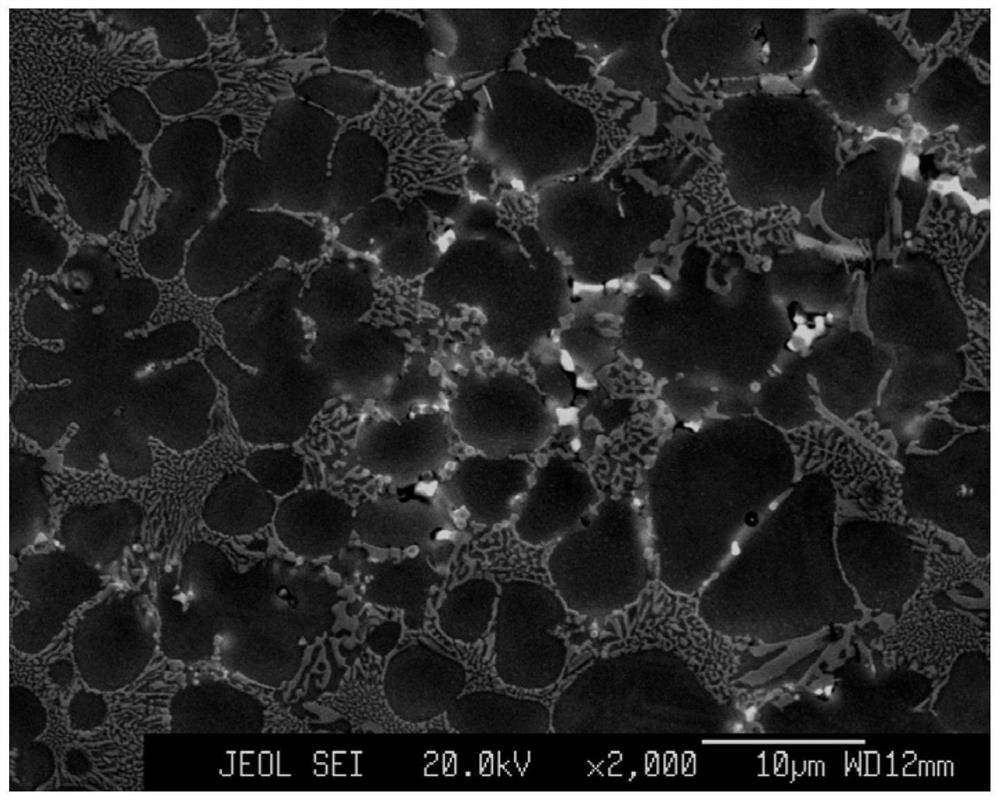

Heat-resistant regeneration die-cast aluminum alloy and preparation method thereof

The invention discloses a heat-resistant regeneration die-cast aluminum alloy and a preparation method thereof, and belongs to the field of regeneration die-cast aluminum alloy preparation. The invention provides the heat-resistant regeneration die-cast aluminum alloy capable of reducing the preparation cost and the preparation method of the heat-resistant regeneration die-cast aluminum alloy. Chemical components of the heat-resistant regeneration die-cast aluminum alloy include 10.0%-12.0% of Si, 0.50%-0.75% of Ni, 0.95%-1.35% of Mg, 0.9%-1.4% of Fe, 0.20%-0.30% of Mn, 0.08%-0.12% of Cr, 0.015%-0.03% of B, smaller than or equal to 0.15% of an impurity element and the balance Al. The preparation method includes the steps that smelting is conducted; sampling is conducted to adjust the alloycomponents; refining is conducted after low-melting-point alloy addition; slag removal is conducted; and casting is conducted. According to the heat-resistant regeneration die-cast aluminum alloy andthe preparation method, Ni and Cu are replaced with the low-cost impurity element Fe, and the alloy cost is effectively reduced; and by means of the compound modification technology of the Mn, the Cr, the B and the like, the size of the iron-rich phase is refined, and the high-temperature strength of the alloy is ensured.

Owner:肇庆南都再生铝业有限公司 +2

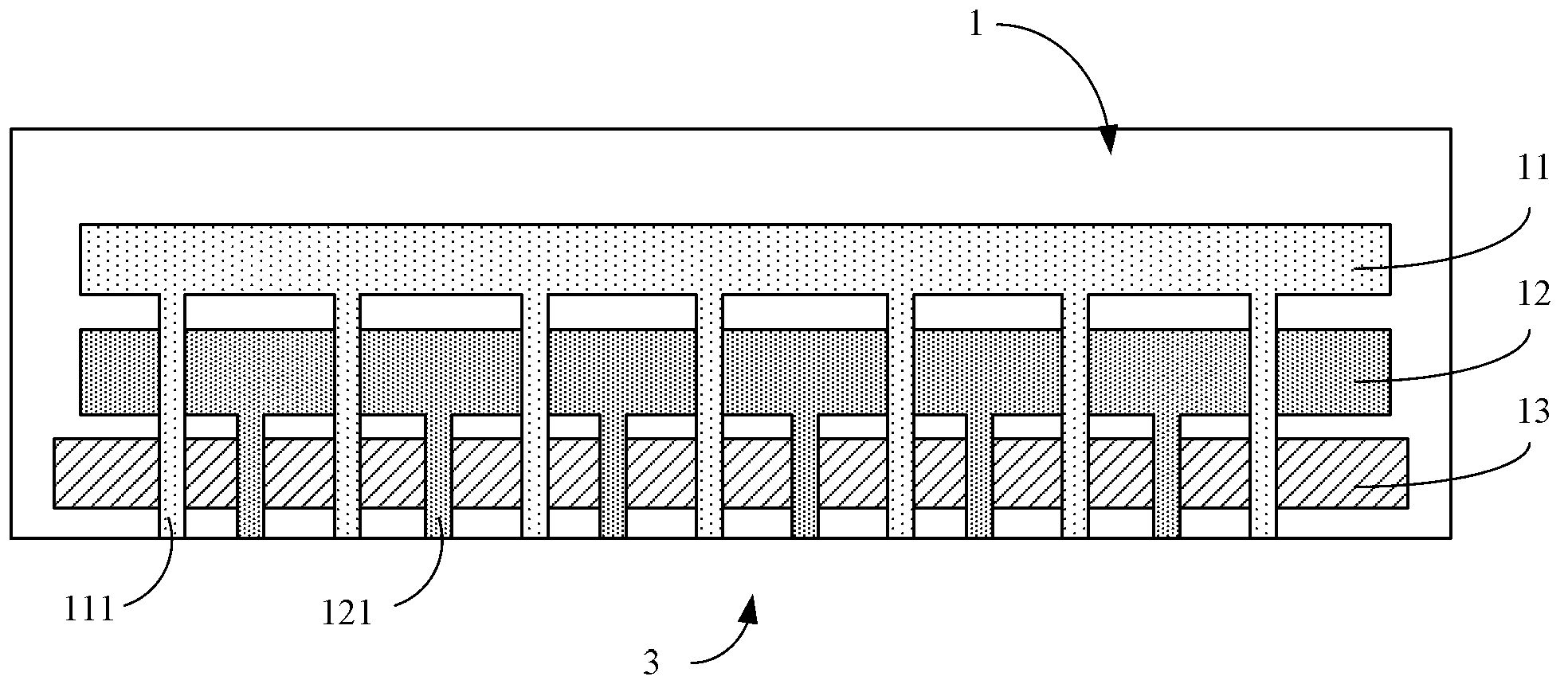

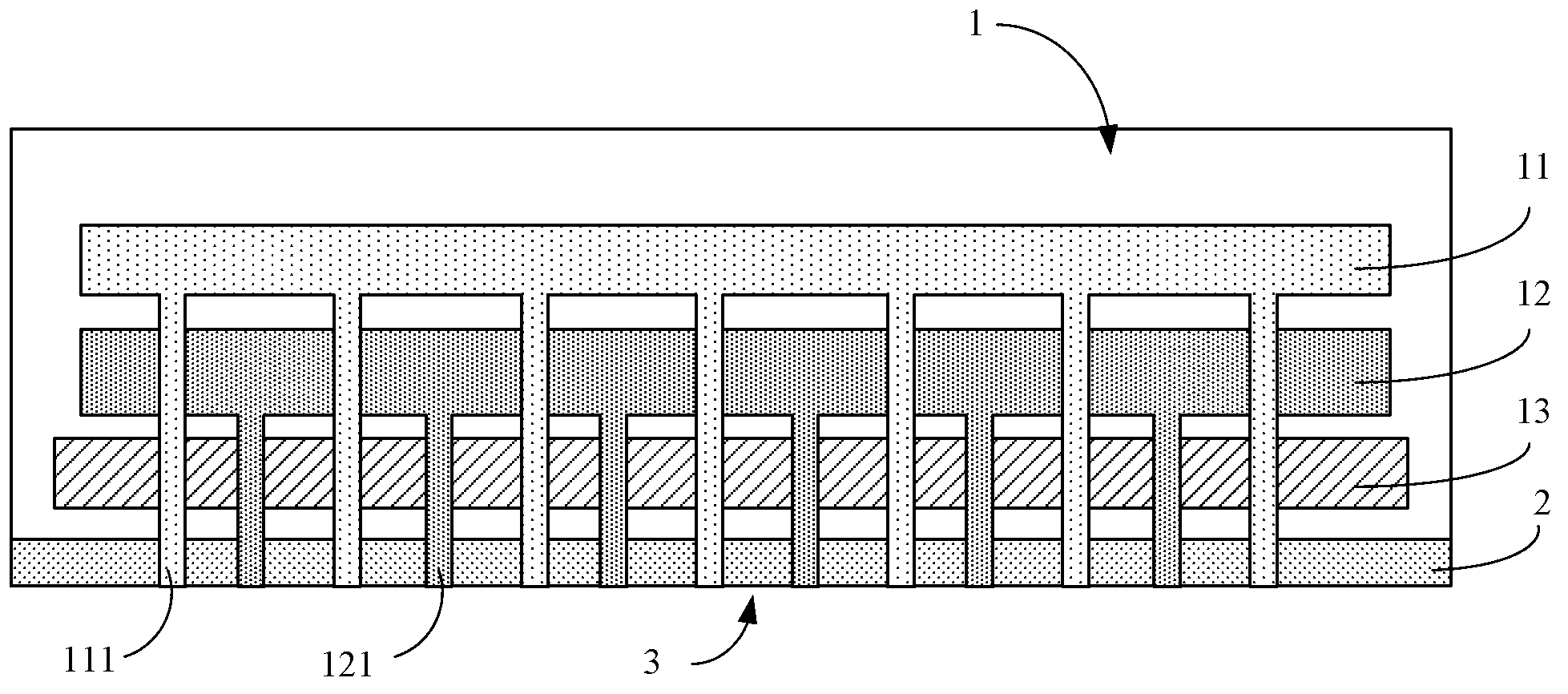

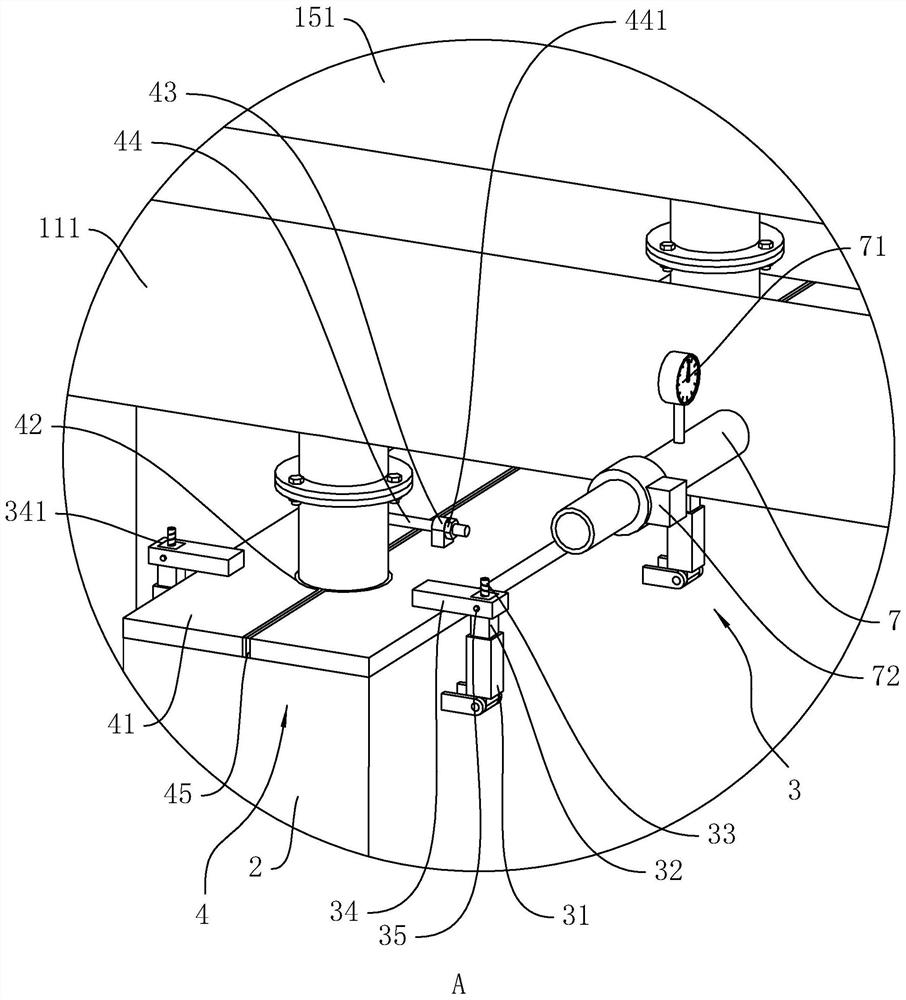

Shower head and vapor deposition equipment

InactiveCN103320865AReduce the likelihood of formingImprove flatnessPolycrystalline material growthFrom chemically reactive gasesParticulatesForming gas

The invention discloses a shower head and vapor deposition equipment. The vapor deposition equipment comprises the shower head. According to the shower head and the vapor deposition equipment, a vapor outlet face of the shower head is a smooth surface and has high flatness, so that the attachment attaching capability of the vapor outlet face of the shower head is lowered greatly, and small particulate attachments, which are just formed on the vapor outlet face of the shower head, are separated from the vapor outlet face of the shower head and fall off during reaction; and the sizes of the attachments are small at the moment, the attachments can be decomposed by heat from a heater during falling and form gas again, and a film growing layer of a substrate can not be affected, so that the probability of forming impurity particles is reduced greatly, and film forming quality and process yield are improved.

Owner:光垒光电科技(上海)有限公司

Preparing method and application of nucleating agent for cam shaft

The invention discloses a preparing method of a nucleating agent for a cam shaft. The preparing method comprises the following steps that 60-75% of Si, 0.01-1.0% of Al, 0.05-0.5% of Ca, 0.1-1.0% of Ba, 3-5% of Cr, 0.03-0.05% of V, 5-8% of Nd, 0-1% of Mn, 0.5-1% of carburant and the balance Fe which are evenly mixed are melted, stirred, poured, cooled rapidly and crushed and then are mixed with Fe3O4 powder to be pressed into pellets to be crushed. The invention further discloses specific application of the nucleating agent for the cam shaft. By means of the nucleating agent for the cam shaft, the comprehensive performance of the cam shaft can be improved, and the nucleating efficiency is improved.

Owner:成都宏源铸造材料有限公司

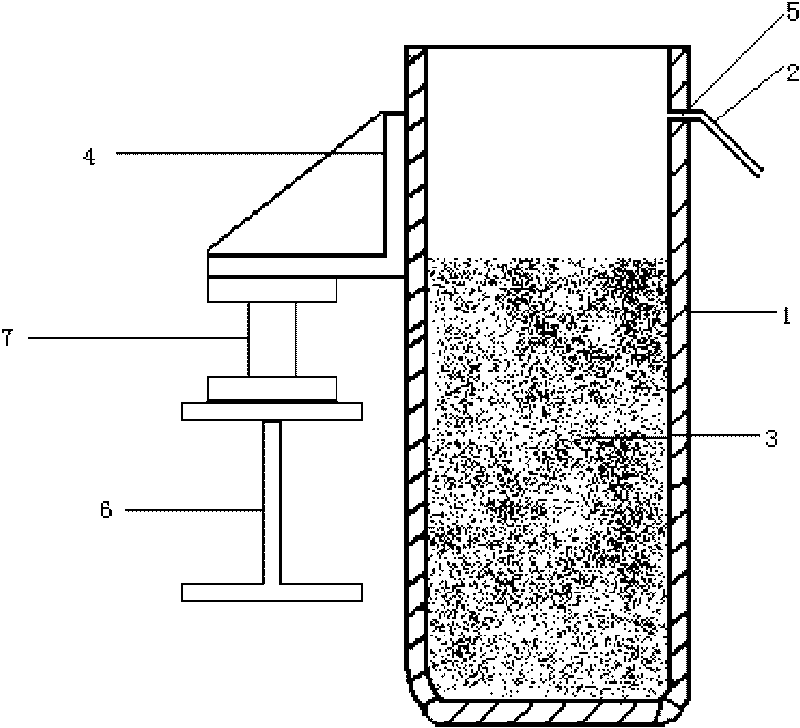

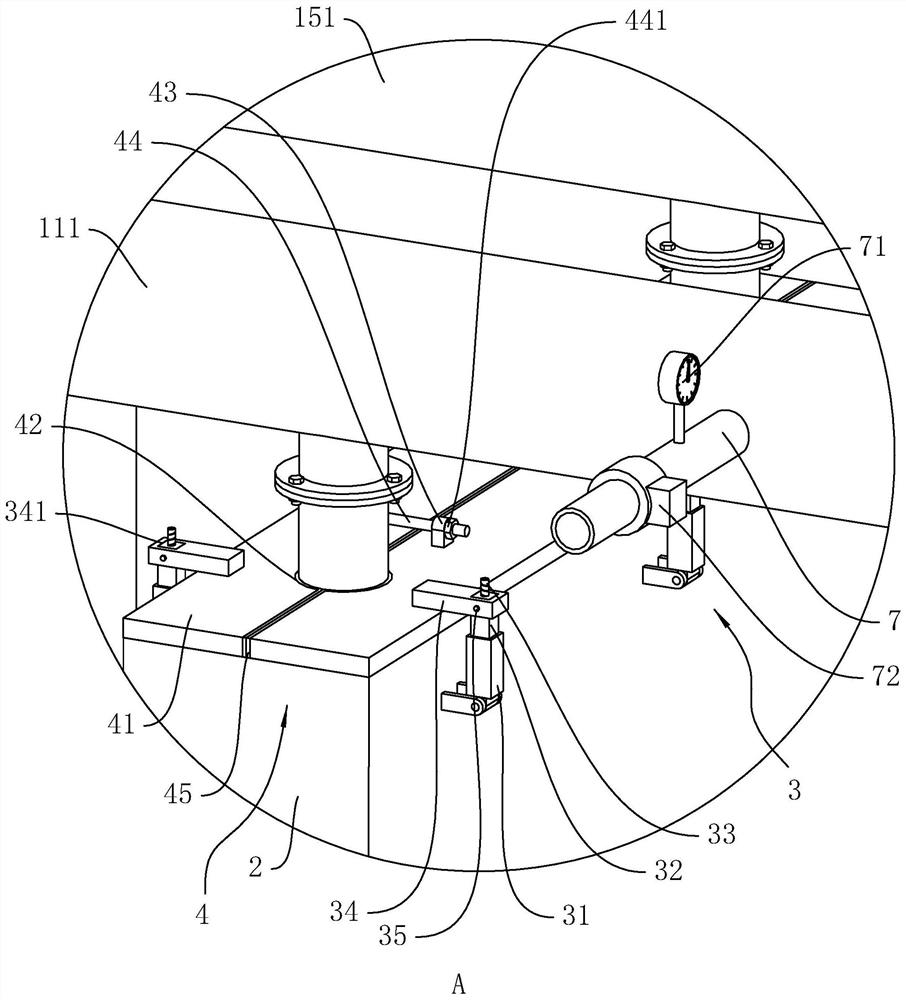

Method for measuring material level of storage tank in production of trichlorosilane

InactiveCN101706305AAccurate measurementTimely supplementLevel indicators by weight measurementProcess engineeringStorage tank

The invention relates to a method for measuring the material level of a storage tank in the production of trichlorosilane, which belongs to the production field of halogenated silicane. The invention solves the technical problem of providing the method for measuring the material level of the storage tank in the production of the trichlorosilane, and the method is free from the interference of floating dust. The method for measuring the material level of the storage tank in the production of the trichlorosilane measures the material level of the storage tank which is connected with a pipeline, and calculates the material level L of a material in the storage tank according to a formula L=m / (Sp) by measuring the total mass m of the storage tank and the material in the storage tank, wherein S is the cross-section area of the storage tank, and p is the stacking density of the material. The method can avoid the influence of the floating dust on a detection result, can measure the material level of the material in the storage tank more accurately, is beneficial to replenishing silicon powder or eliminating silicon dust in time, can effectively reduce the generation of production accidents and has extensive application prospect.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

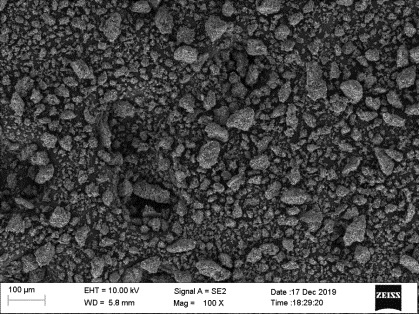

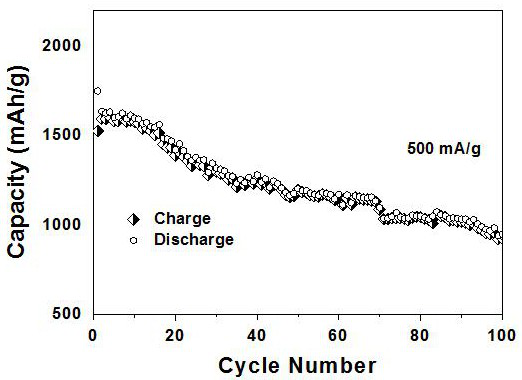

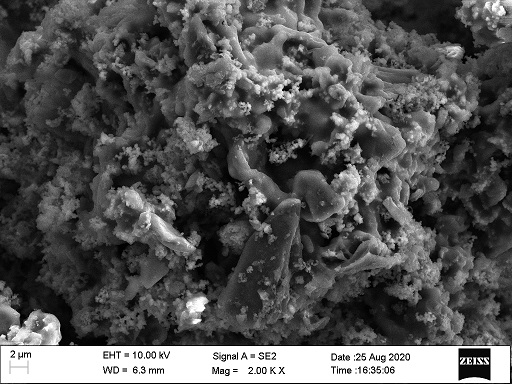

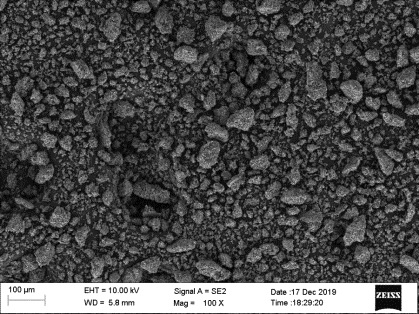

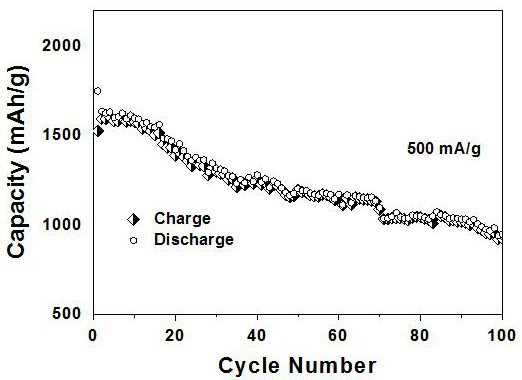

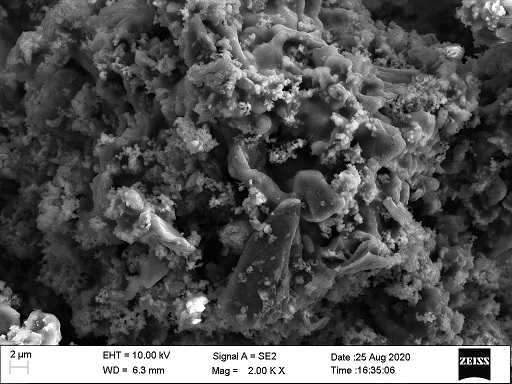

High-capacity silicon-carbon material for lithium battery negative electrode and preparation method

ActiveCN112234182AImprove stabilityPromote formationNegative electrodesLi-accumulatorsNano siliconElectrolytic agent

The invention provides a high-capacity silicon-carbon material for a lithium battery negative electrode and a preparation method. The material is mainly prepared in a liquid phase self-assembly mode,a porous structure with a conductive network is formed in the material after carbonization, and nano silicon is distributed in the material and is uniformly combined with a carbon intermediate material; meanwhile, a uniform conductive agent is distributed around to promote electron transmission, and the material is coated with a uniform modification layer, so that the compactness of the structureand the uniformity of the surface are realized, the expansion of the internal material is buffered, the contact between nano silicon and electrolyte is avoided, and the stability of the material is improved. The process is novel, and the prepared silicon-carbon negative electrode material has the advantages of high first effect, good stability and the like, and is suitable for industrial production.

Owner:郑州中科新兴产业技术研究院 +1

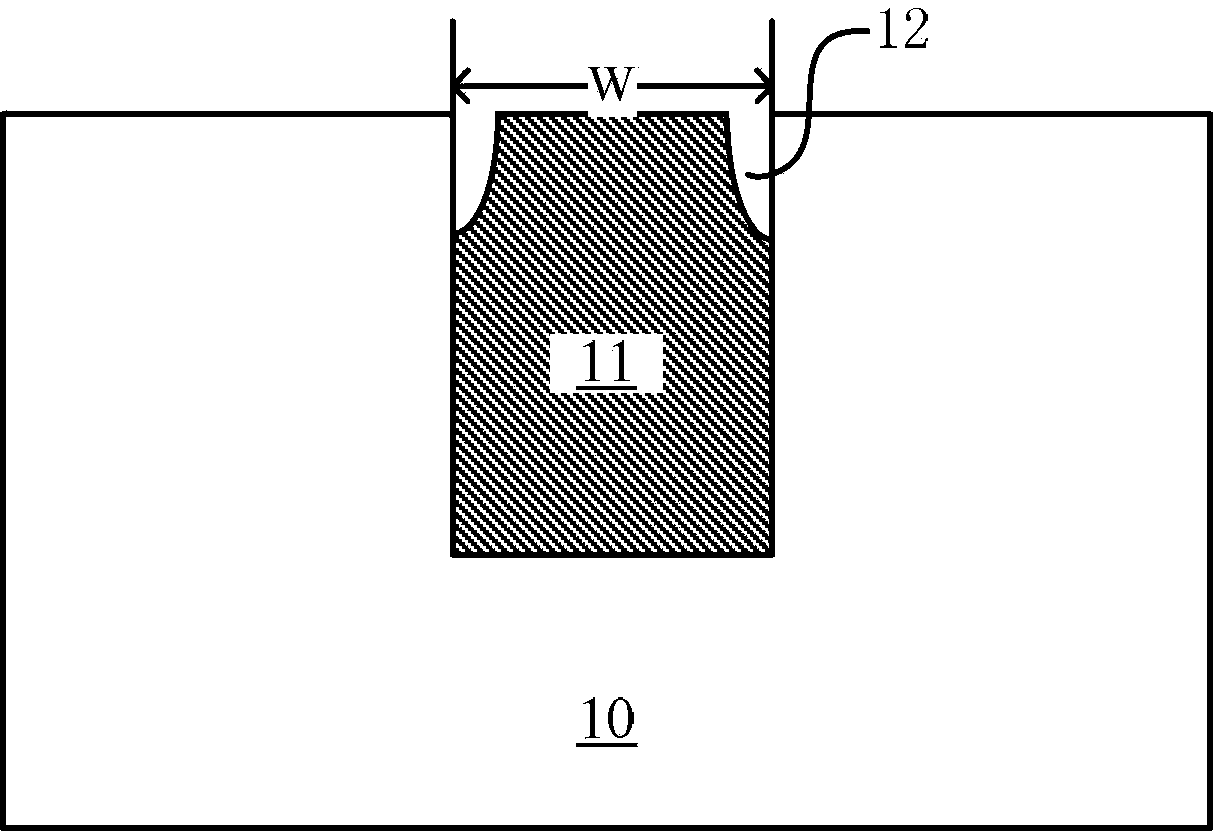

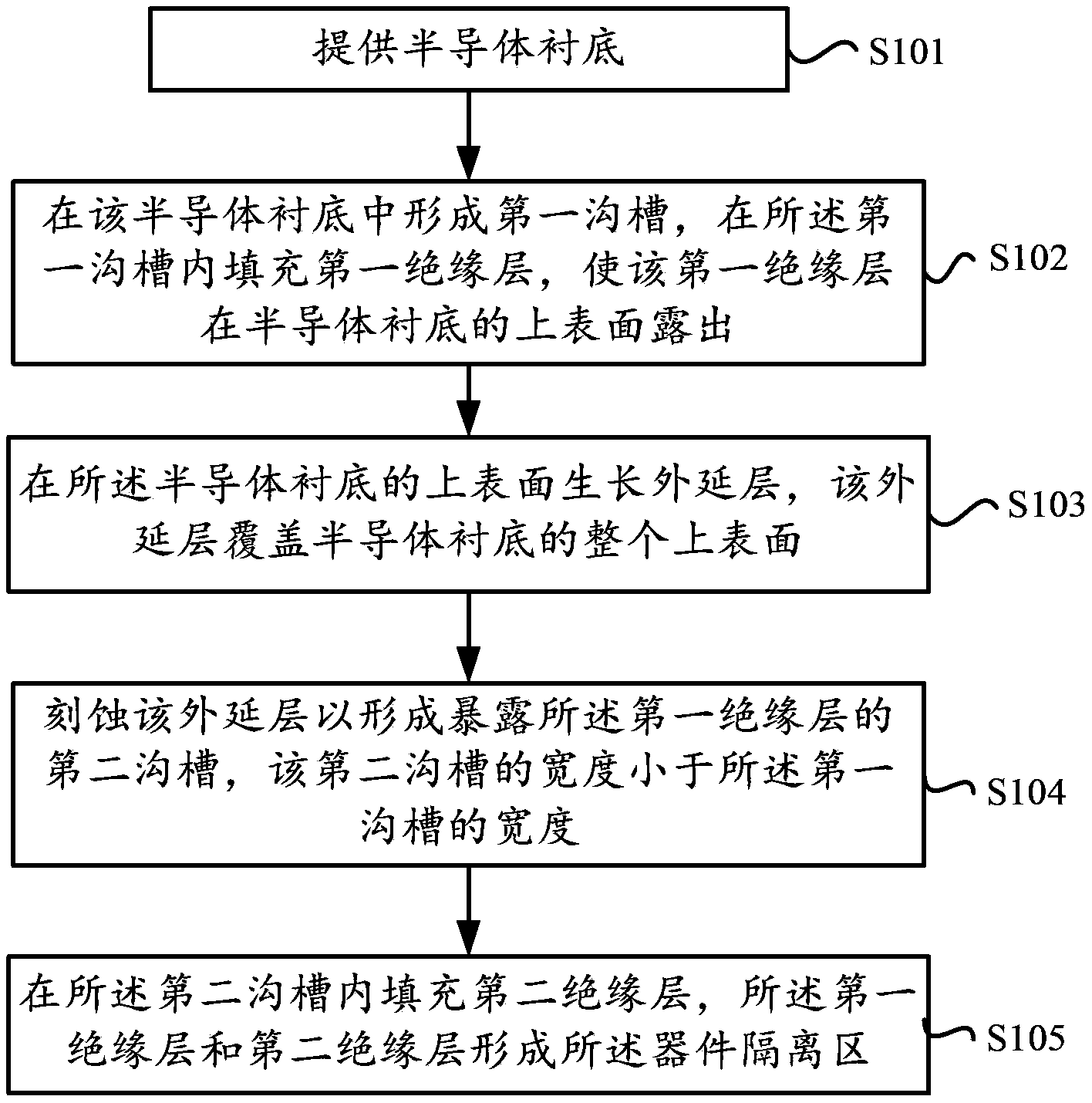

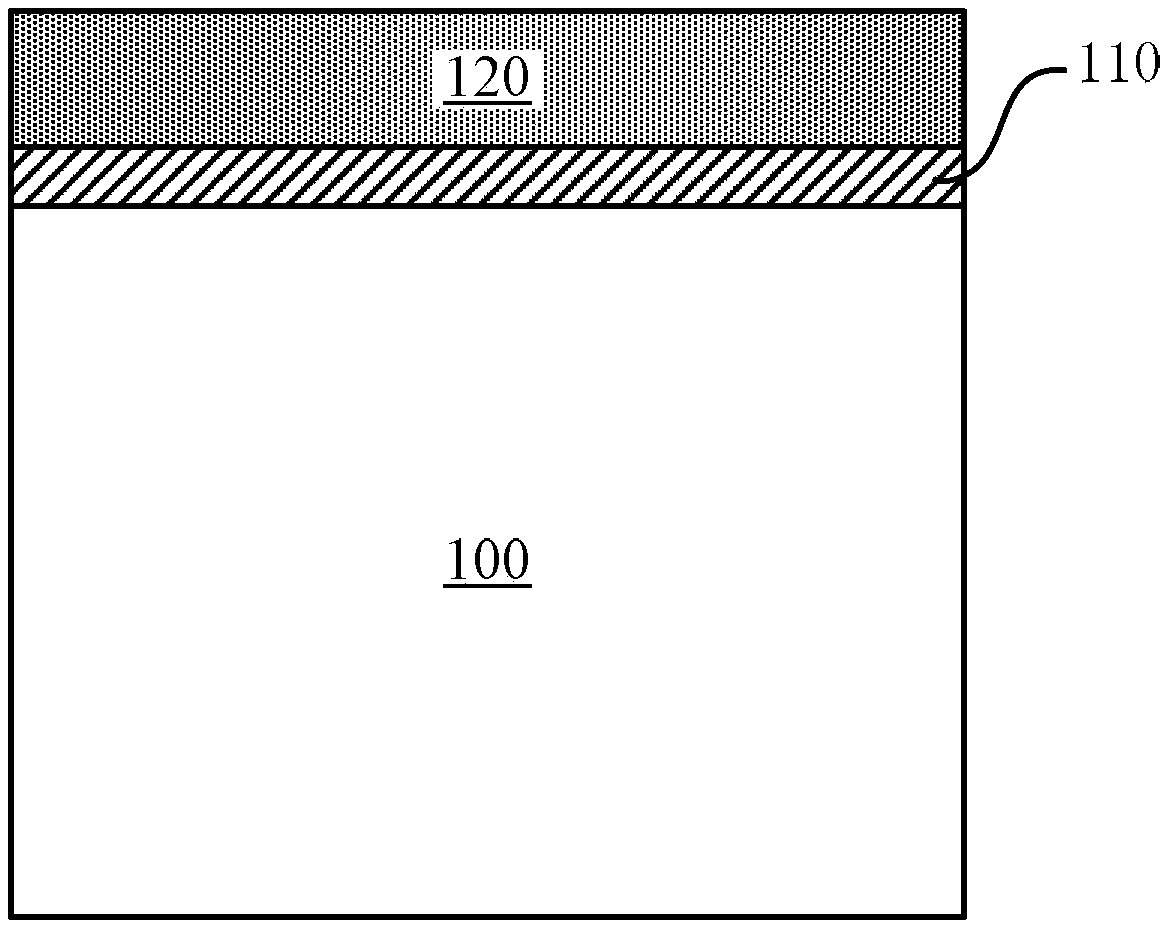

Semiconductor structure with device isolation areas and manufacturing method of semiconductor structure

InactiveCN104282615ASmall sizeReduce the likelihood of formingSolid-state devicesSemiconductor/solid-state device manufacturingWork performanceSemiconductor structure

The invention provides a manufacturing method of a semiconductor structure with device isolation areas. The method includes the steps of providing a semiconductor substrate; forming first groves in the semiconductor substrate, filling the first grooves with first insulating layers, and making the first insulating layers exposed out of the upper surface of the semiconductor substrate; making an epitaxial layer grow on the upper surface of the semiconductor substrate, wherein the epitaxial layer covers the whole upper surface of the semiconductor substrate; etching the epitaxial layer to form second grooves which make the first insulating layers exposed, wherein the width of the second grooves is smaller than the width of the first grooves; filling the second grooves with second insulating layers, and forming the device isolation areas through the first insulating layers and the second insulating layers. The invention further provides the corresponding semiconductor structure. By means of the manufacturing method and the semiconductor structure, the stability of the work of semiconductor devices can be improved, and the work performance of the semiconductor devices can be improved as well.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Preparation method and application of gray pig iron inoculant

Owner:成都宏源铸造材料有限公司

Polymer composite PE water supply pipe

The invention belongs to the technical field of connecting pipes, and particularly relates to a polymer composite PE water feeding pipe. The polymer composite PE water supply pipe comprises an outer pipe, an inner pipe and an extruding mechanism, wherein a certain gap is formed between the inner pipe and the outer pipe, the inner pipe is fixedly connected in a segmented mode, and the extruding mechanism is arranged inside the inner pipe; the extruding mechanism comprises an extrusion ring, an elastic support rod and a mounting ring, the mounting ring is uniformly and fixedly arranged on the inner wall of the outer pipe, and the elastic support rod is uniformly and fixedly arranged on the inner surface of the mounting ring around the circumference; the extrusion ring is fixedly connected tothe inner end of the elastic support rod, the extrusion ring is made of flexible metal, and the extrusion ring is uniformly arranged in the wall of the inner pipe. The polymer composite PE water supply pipe is mainly used for solving the problems that in the prior art, a large amount of water scale is formed in the pipeline due to mineral substances in a mining area when the PE water supply pipeis used for delivering a water source to a resident in the mining area, so that the dewatering efficiency is greatly reduced due to the fact that the water supply pipe is blocked, and meanwhile, the body health of people is harmed after the water scale is formed are solved.

Owner:临沂经纬塑业有限公司

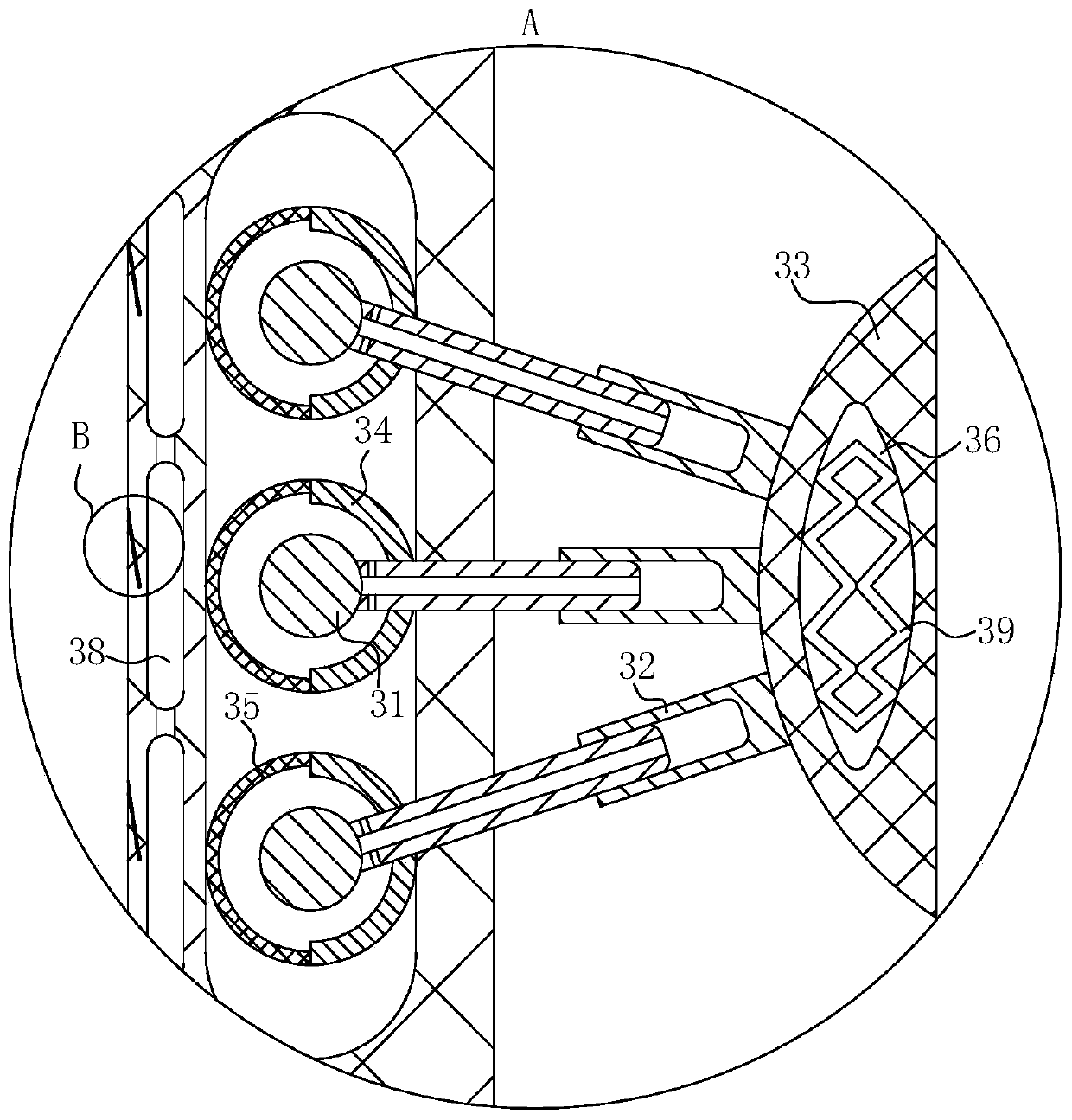

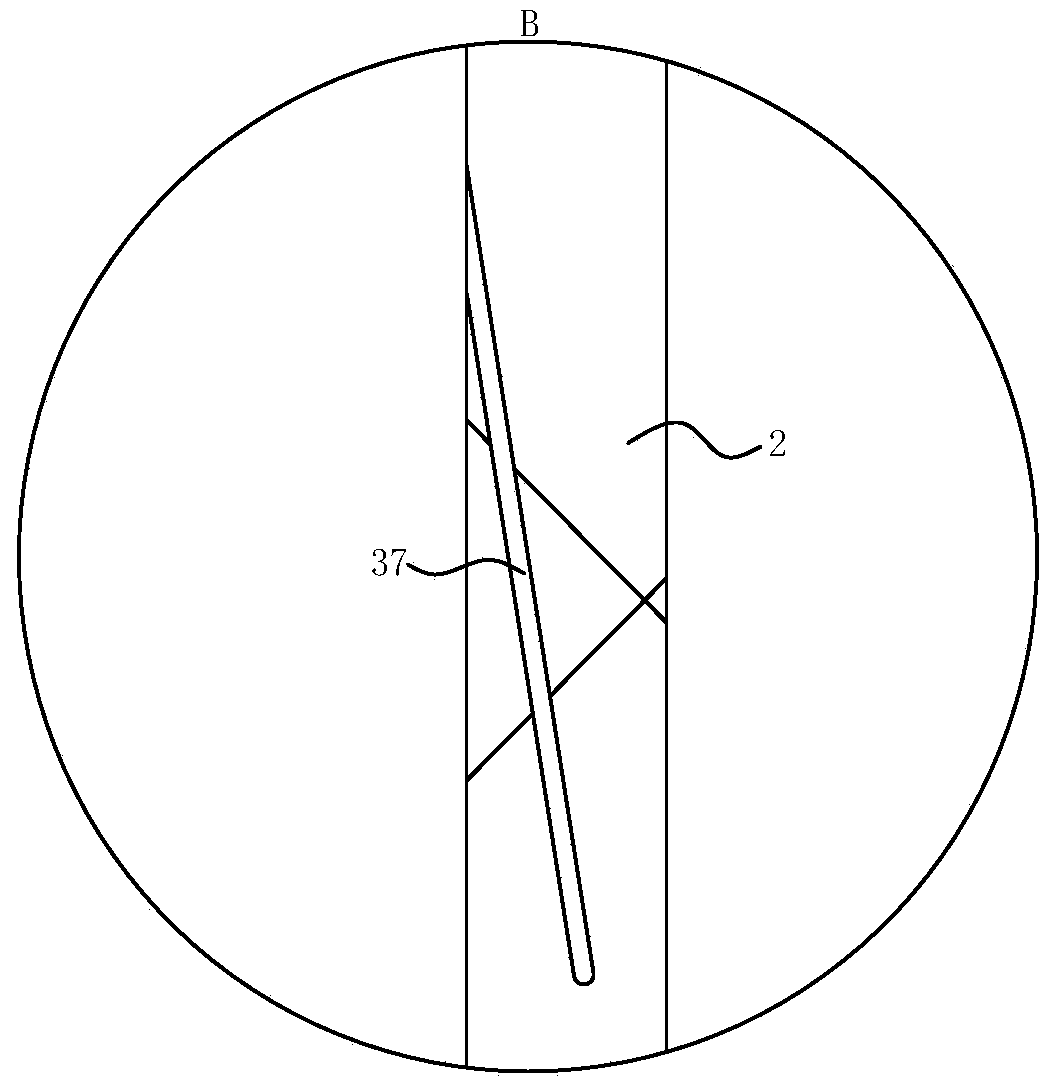

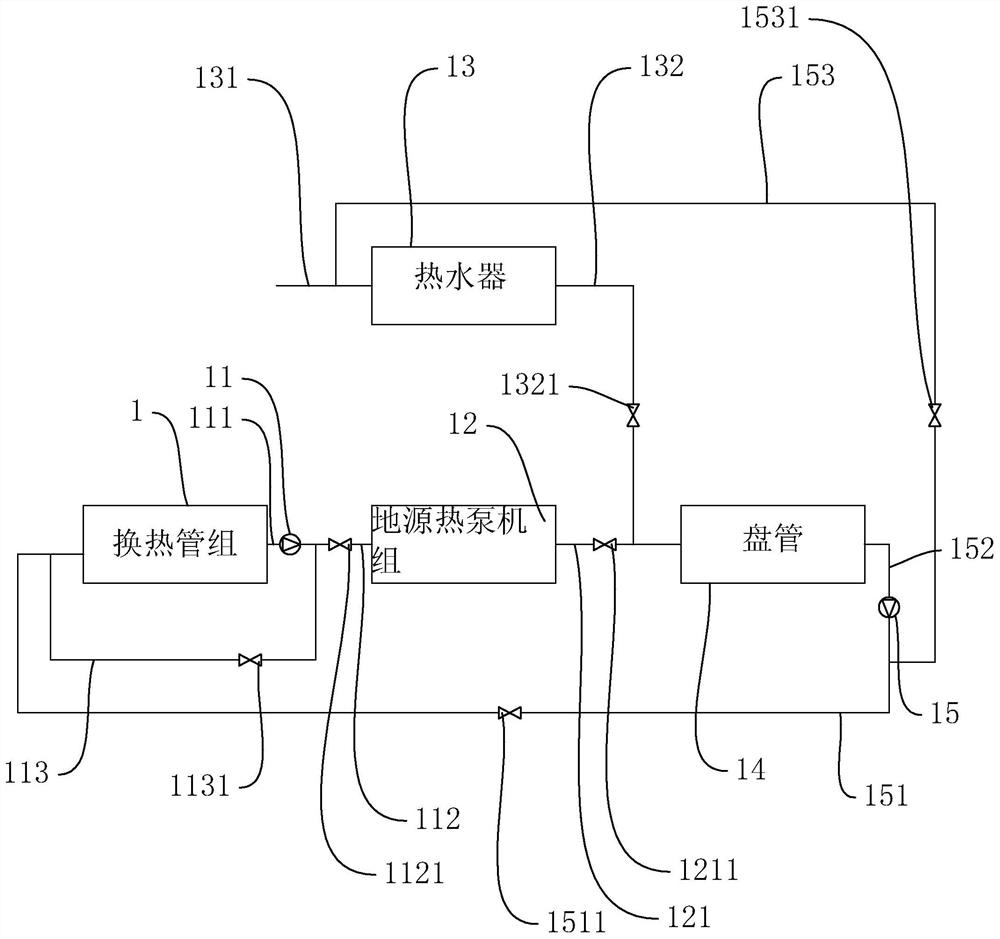

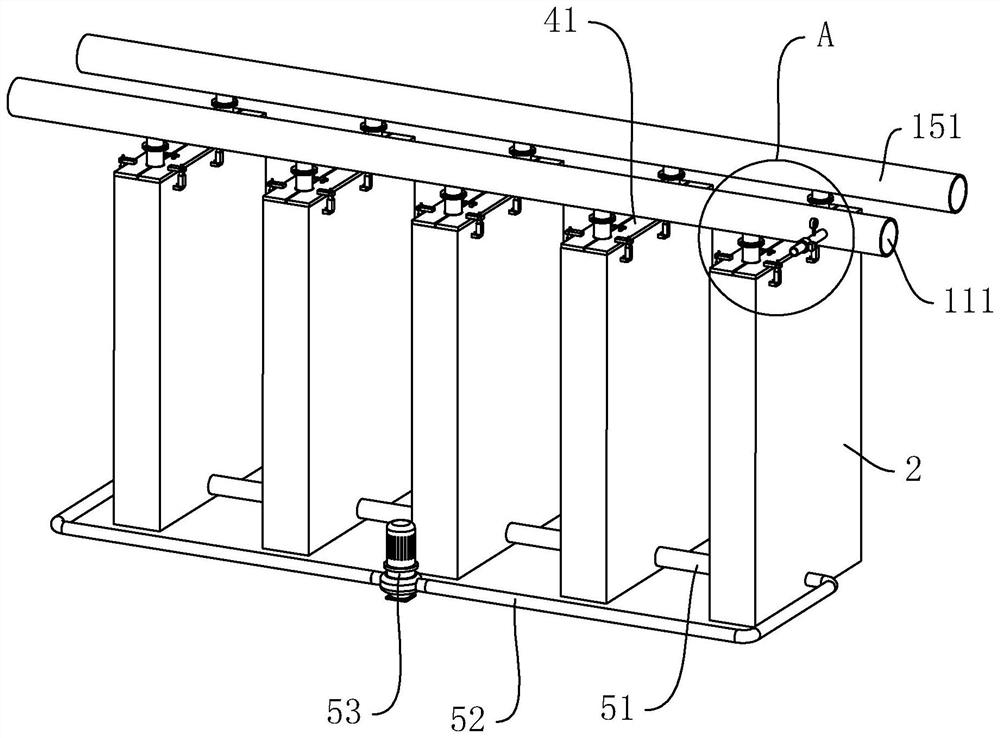

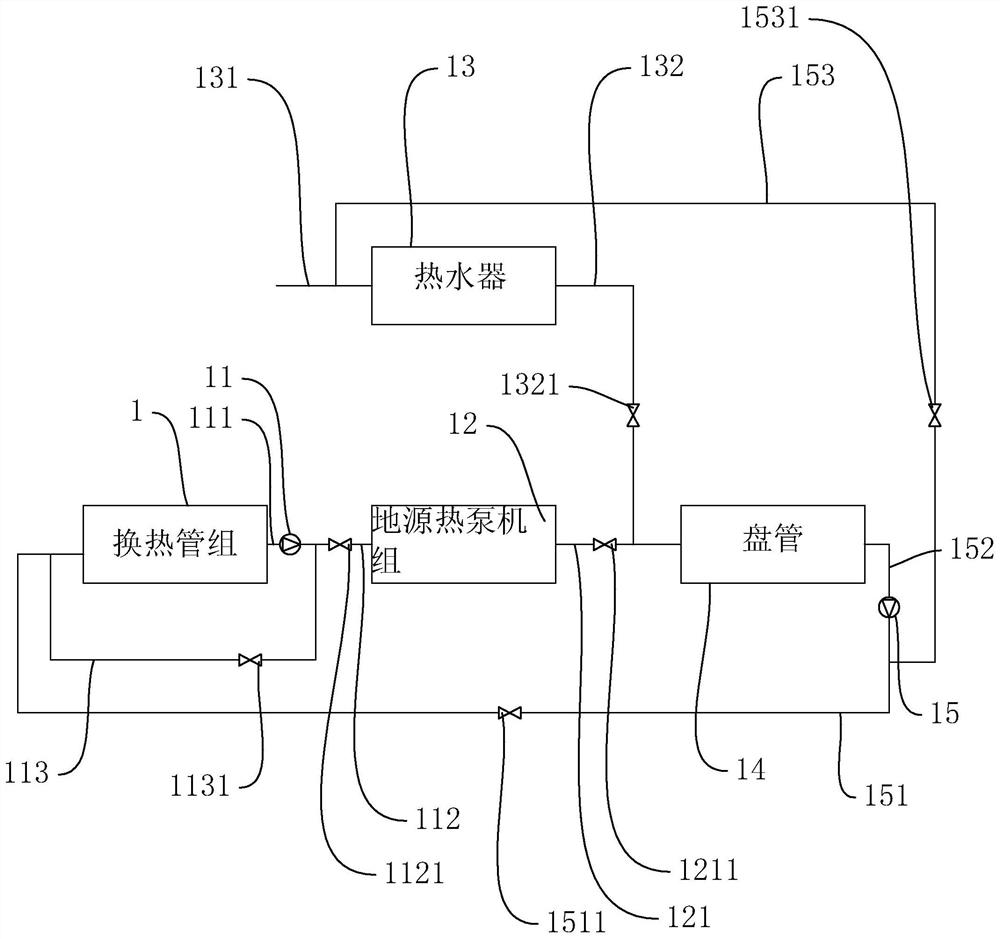

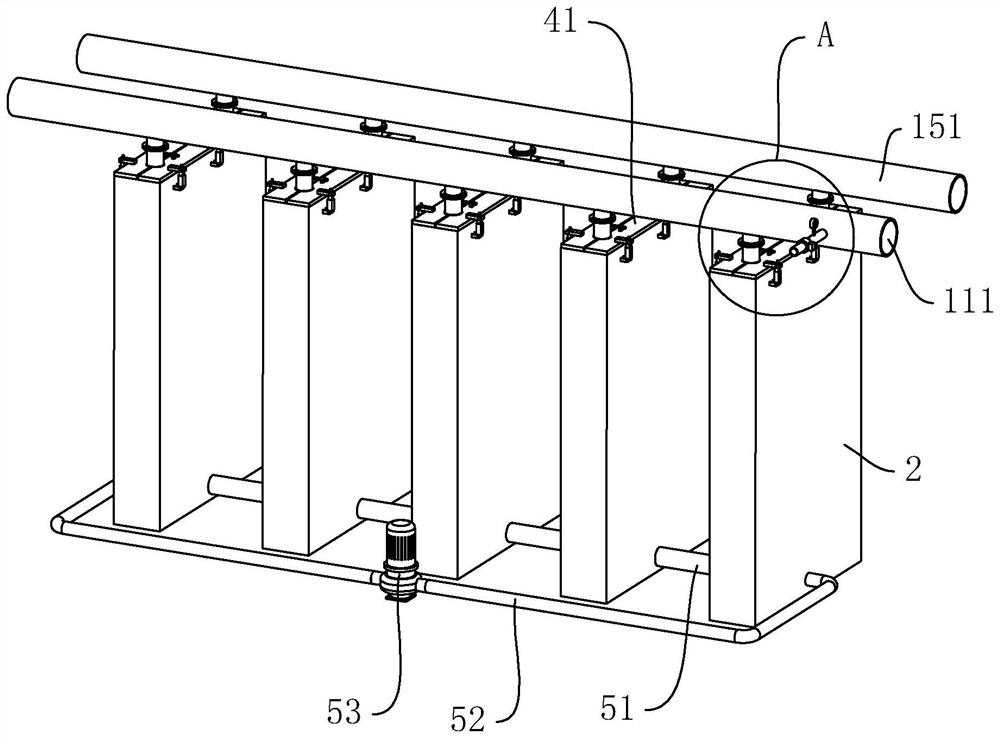

Ground source heat pump system

ActiveCN112361658AImprove time utilizationReduce the likelihood of formingFluid heatersSolar heating energyThermodynamicsCirculator pump

The invention relates to a ground source heat pump system. The system is applied to the technical field of geothermal energy utilization, and comprises a heat exchange pipe group, a first circulatingpump, a ground source heat pump unit, a water heater, a coil pipe and a second circulating pump. The heat exchange pipe group is buried in the soil and is connected with the first circulating pump through a first water pipe, the first circulating pump is connected with the ground source heat pump unit through a first branch pipe, the ground source heat pump unit is connected with the water inlet end of the coil pipe through a second water pipe, the coil pipe is pre-buried in a building room, the water outlet end of the coil pipe is connected with the second circulating pump through a second branch pipe, and the second circulating pump is connected with the heat exchange pipe set through a return pipe. The ground source heat pump system has the effect of accelerating temperature rise duringindoor heating.

Owner:南京金海设计工程有限公司

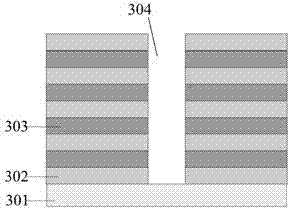

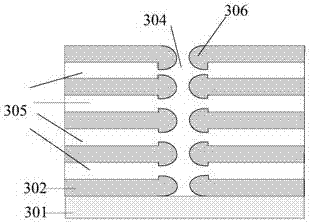

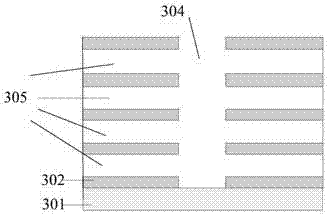

Metal grid electrode preparation method of 3D NAND memory

ActiveCN107507766AReduce the likelihood of formingImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideSilicon dioxide

The invention provides a metal grid electrode preparation method of a 3D NAND memory. The metal grid electrode preparation method of a 3D NAND memory comprises steps of providing a substrate, wherein a silicon oxide layer / silicon nitride layer alternative staking structure and a grid line gap going through the silicon oxide layer / silicon nitride layer alternative stacking structure are formed on the substrate, adopting an etching solution with a selection ratio of the silicon nitride to the silicon oxide greater than 1 to etch the silicon nitride layer in the silicon oxide layer / silicon nitride layer alternative staking structure, forming a hollowed area in a 303 position of the silicon nitride layer, removing silicon dioxide which is a side product during the silicon nitride layer etching process, and filling the hollow area with a metal medium to form the metal grid electrode. The metal grid electrode preparation method of the 3D NAND memory can remove the side product silicon dioxide which is generated during the process of etching the silicon nitride before filling with metal medium. As a result, the opening of the position filled with the metal medium is not blocked by the side product, and the opening of the area filled with the metal medium is not reduced. The metal grid electrode preparation method of the 3D NAND memory reduces the possibility of forming an gap inside the metal grid electrode and can improve the performance of the 3D NAND memory.

Owner:YANGTZE MEMORY TECH CO LTD

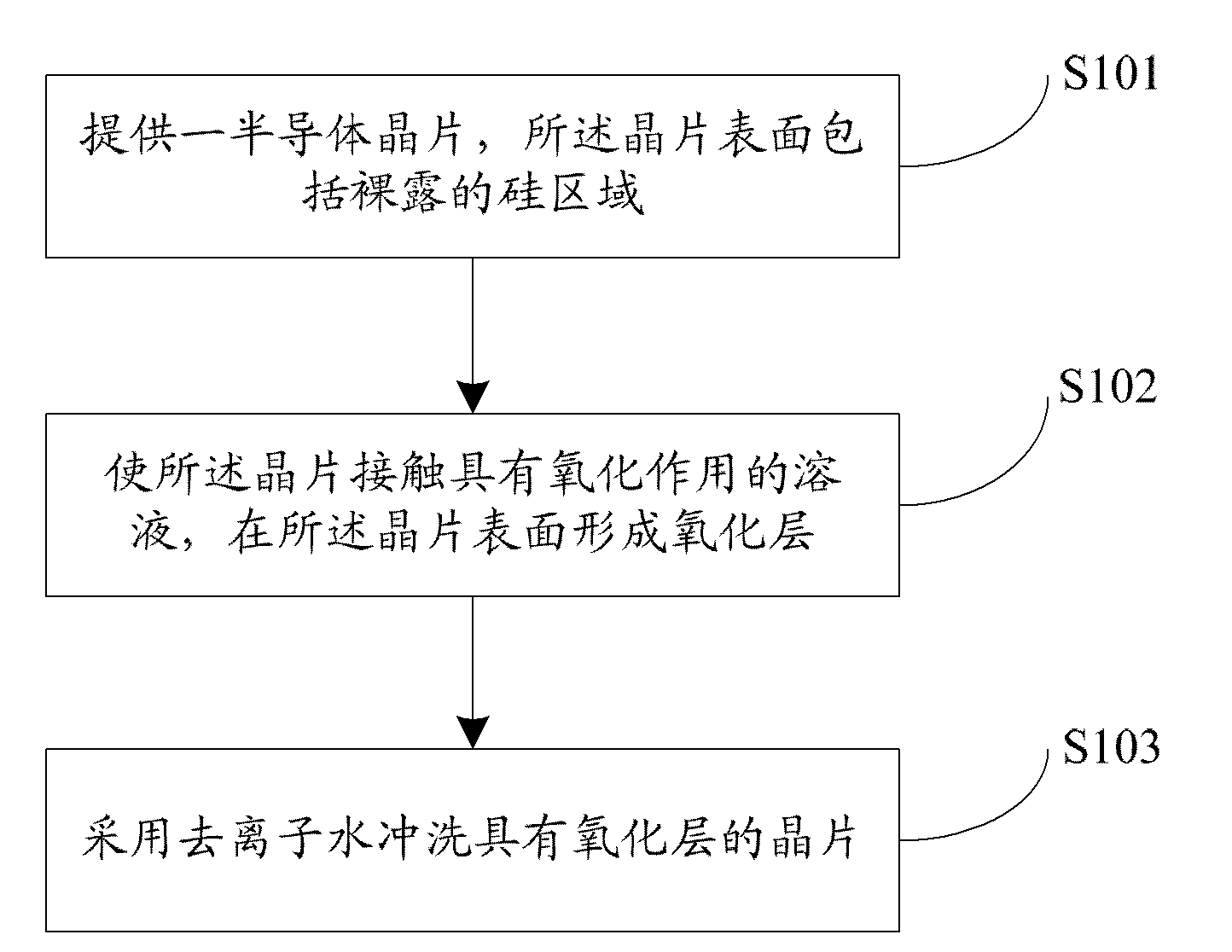

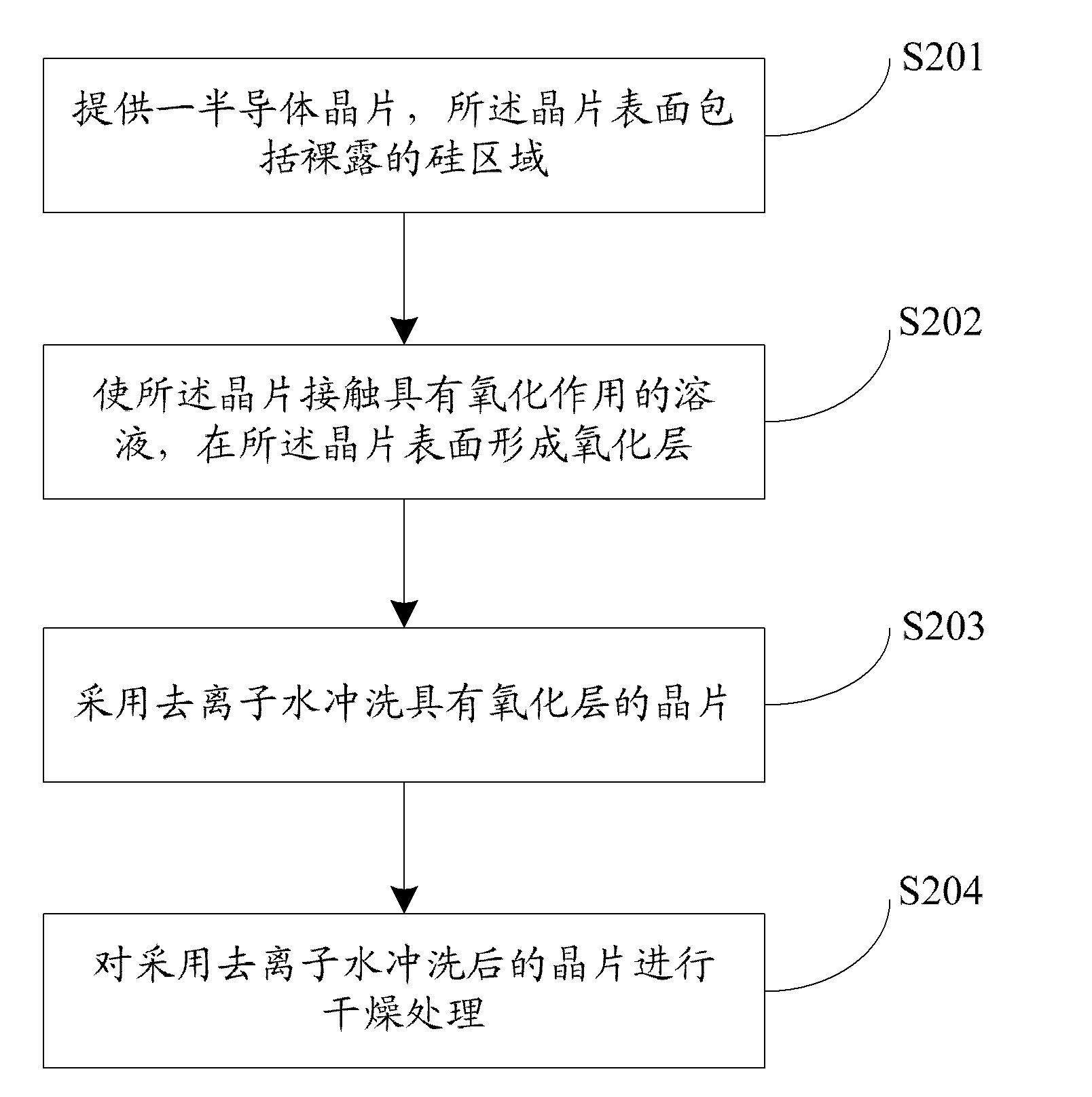

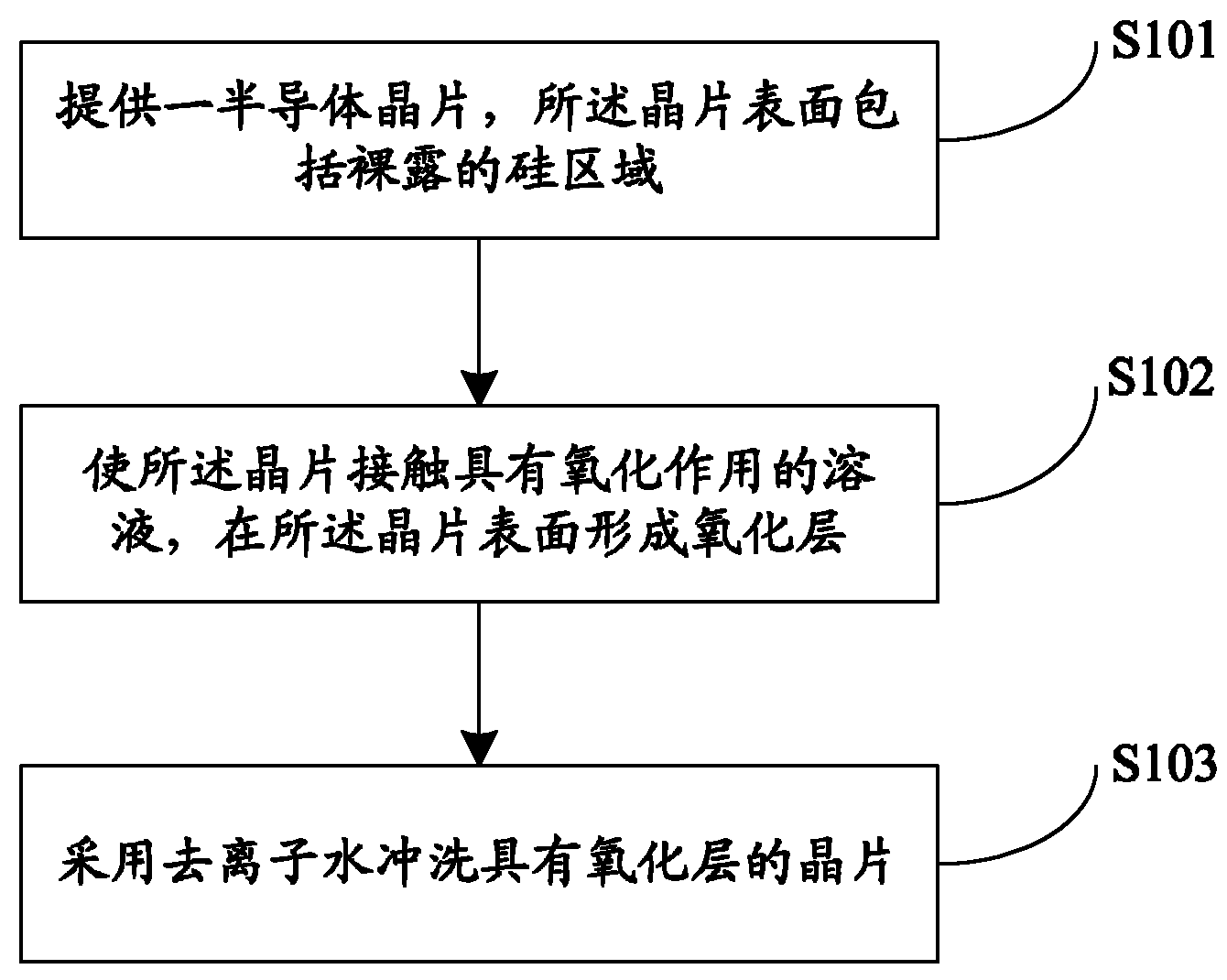

Wet chemical cleaning method

InactiveCN102468130AReduce the likelihood of formingNo increase in process costSemiconductor/solid-state device manufacturingIonSurface oxidation

The embodiment of the invention discloses a wet chemical cleaning method. The wet chemical cleaning method comprises the following steps of: providing a semiconductor wafer, wherein the surface of the wafer comprises an exposed silicon region; contacting the wafer with a solution with an oxidation effect and forming an oxidation layer on the surface of the wafer; and washing the wafer with the oxidation layer by using deionzied water. By the method, one thin oxidation layer is formed on the surface of the semiconductor wafer and silicon exposed on the surface of the wafer is prevented from being directly contacted with the deionized water, so that when the wafer is washed by using the deionized water, no exposed silicon is dissolved into water, the silicon is not separated out in the subsequent drying process and the possibility of forming water track on the surface of the semiconductor wafer is reduced. According to the method, the solution with the oxidation effect in the conventional production process can be adopted, so the process cost is reduced.

Owner:CSMC TECH FAB1 +1

Preparation method and application of grey cast iron inoculant

The invention discloses a grey cast iron inoculant. The formula of the grey cast iron inoculant comprises the following components in percentage by weight: 66-70% of Si, 1-3% of Zr, 1-2% of Ca, 0-2.5% of Mn, 0.5-1.5% of Fe3O4 and the balance of Fe and inevitable trace elements. By adopting the grey cast iron inoculant disclosed by the invention, the comprehensive performance of the grey cast iron can be improved, and the inoculating efficiency is improved.

Owner:成都宏源铸造材料有限公司

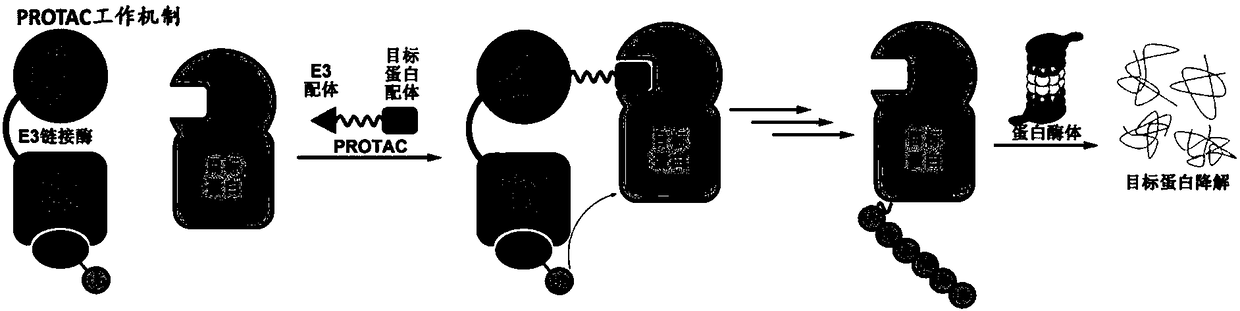

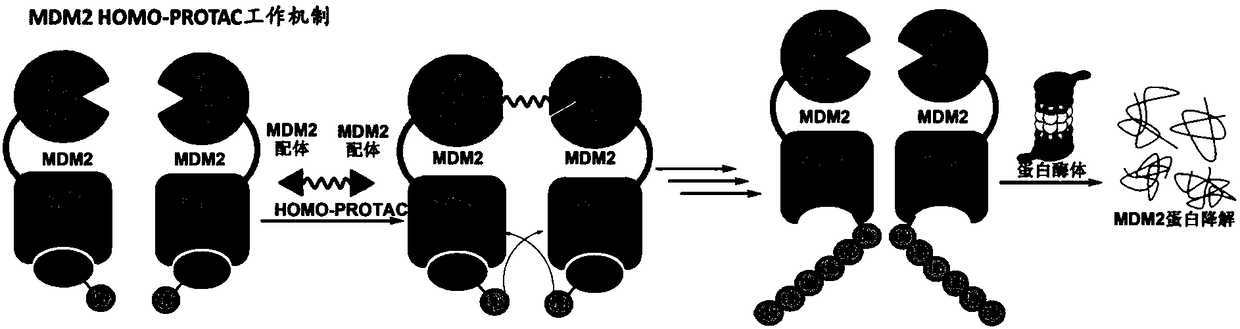

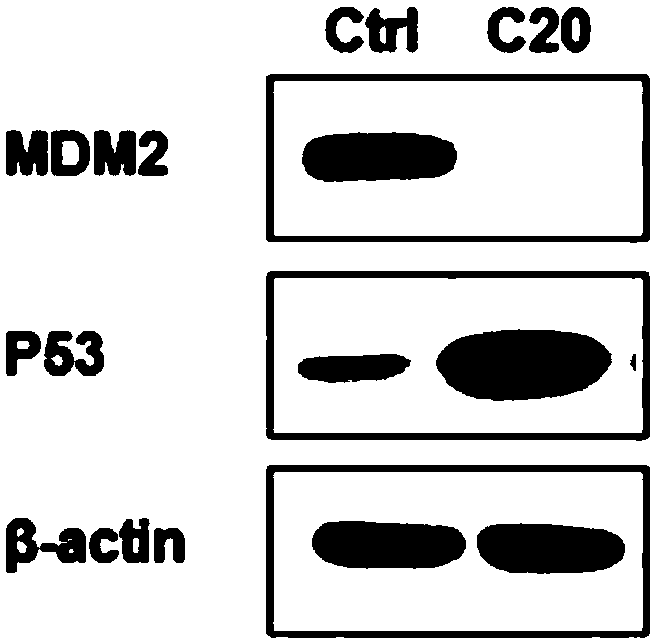

Dimer ester micromolecule PROTACs for inducing MDM2 to self-degrade E3 ubiquitin ligase

ActiveCN108610332AMake up for deficienciesGood anti-tumor effectOrganic active ingredientsOrganic chemistryArylHalogen

The invention provides dimer ester micromolecule PROTACs for inducing MDM2 to self-degrade E3 ubiquitin ligase. The structure of the PROTACs is shown in the specification, wherein in a compound (I), L1 is C1-C30 linear or branched alkyl with or without a substituent group, and any carbon atom in L1 is optionally replaced by heteroatom; R1, R2, R3 and R4 are C1-C30 linear or branched alkyl with orwithout a substituent group, C1-C30 aryl with or a without substituent group, C1-C30 linear or branched alkylaryl with or without a substituent group or C1-C30 linear or branched aryl alkyl with or without a substituent group respectively and independently; X1, X2, X3 and X4 are halogen respectively and independently.

Owner:SHAOXING UNIVERSITY

Continuous polymerization process using intensely stirred vessels

InactiveCN103025791AExtended stayReduce the likelihood of formingMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterReactor system

A continuous polymerization process where one or more stirred vessels(intermittent reactor vessels) are employed in oligomer transfer line for mixing additives. An additive is added in the stirred vessel either as a solution or as slurry. The additive may or may not be reactive with the other monomer of the polyester molecule. The additive reacts with the monomer and incorporates in the polymer backbone in one of the embodiment. One or more further additives are mixed with the pre-reactor monomer mix and are charged in the first reactor or charged through the stirred vessel in the form of single slurry or solution or multiple slurries or solutions. Any further vessels employed provide higher residence time proportionate to output and use of such vessels in reactor system is independent of the any further additives.

Owner:RELIANCE INDUSTRIES LIMITED

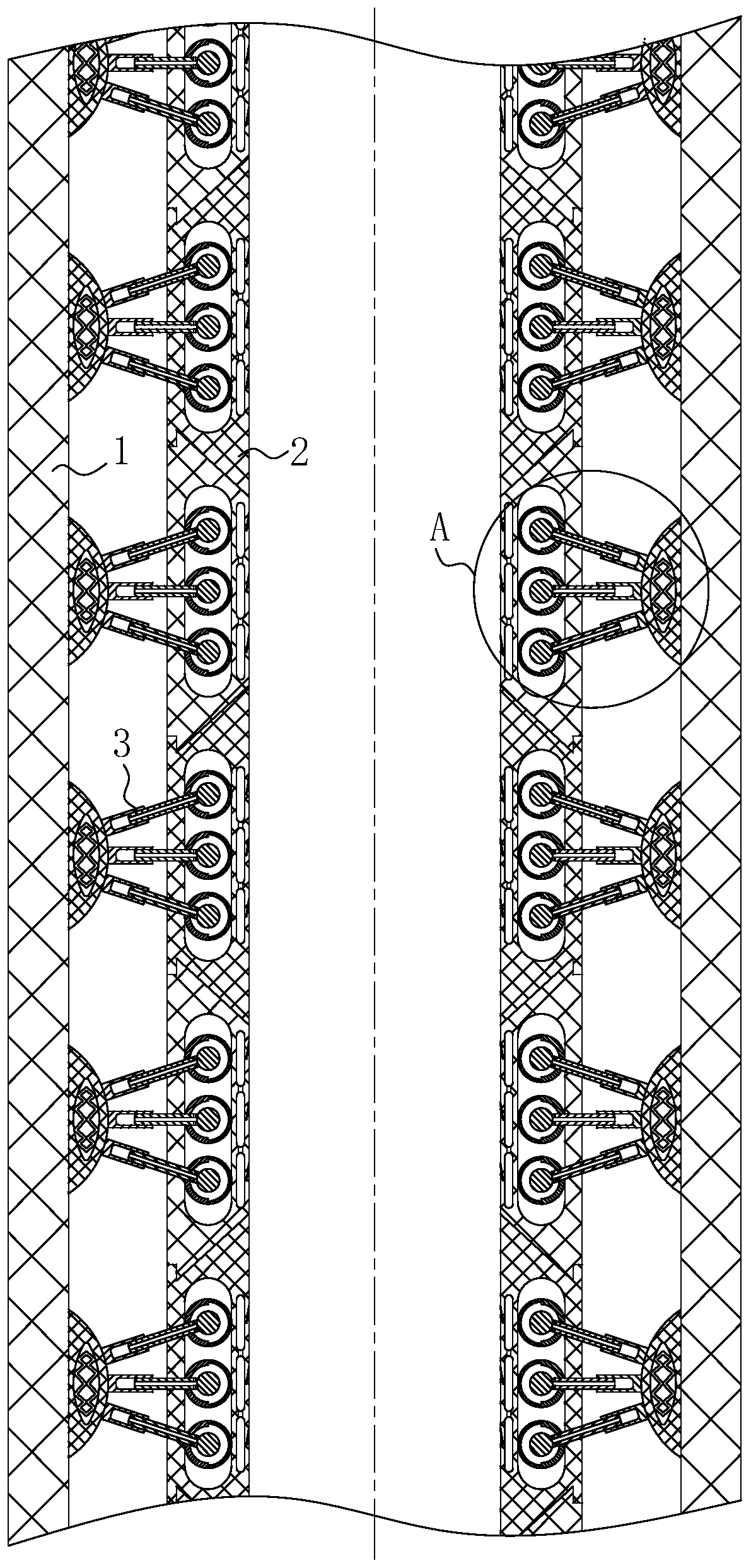

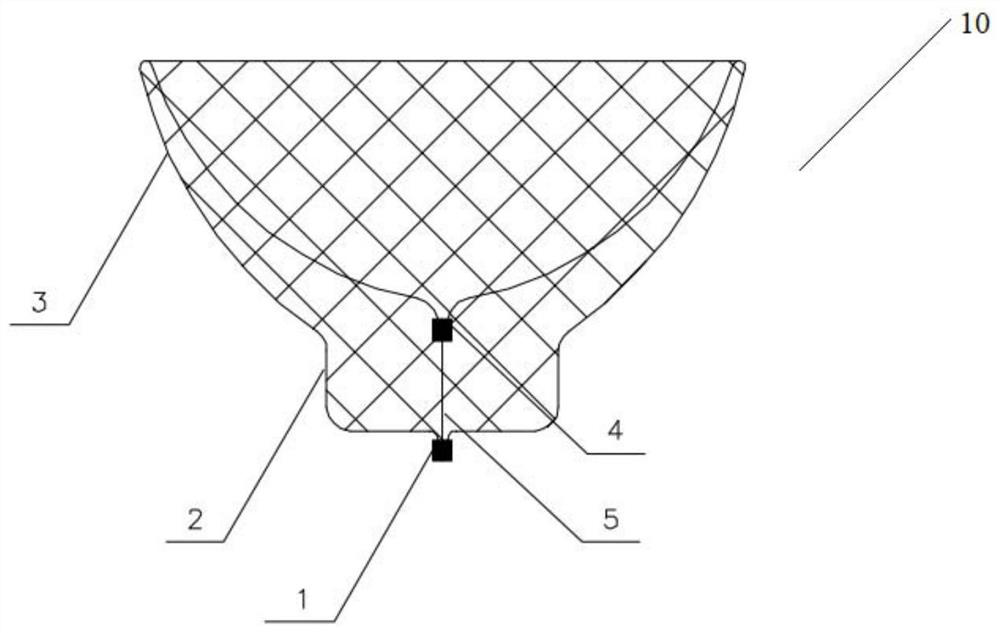

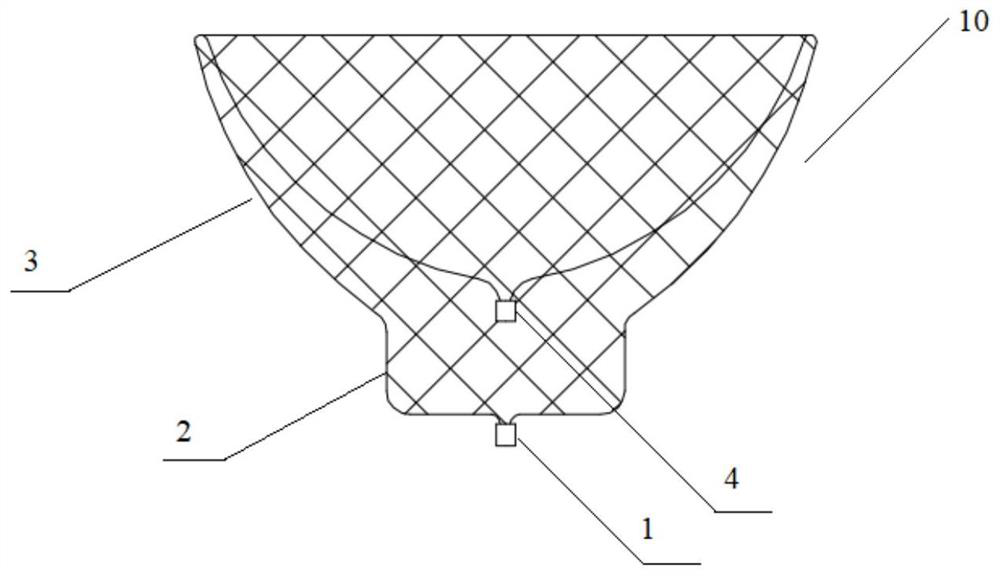

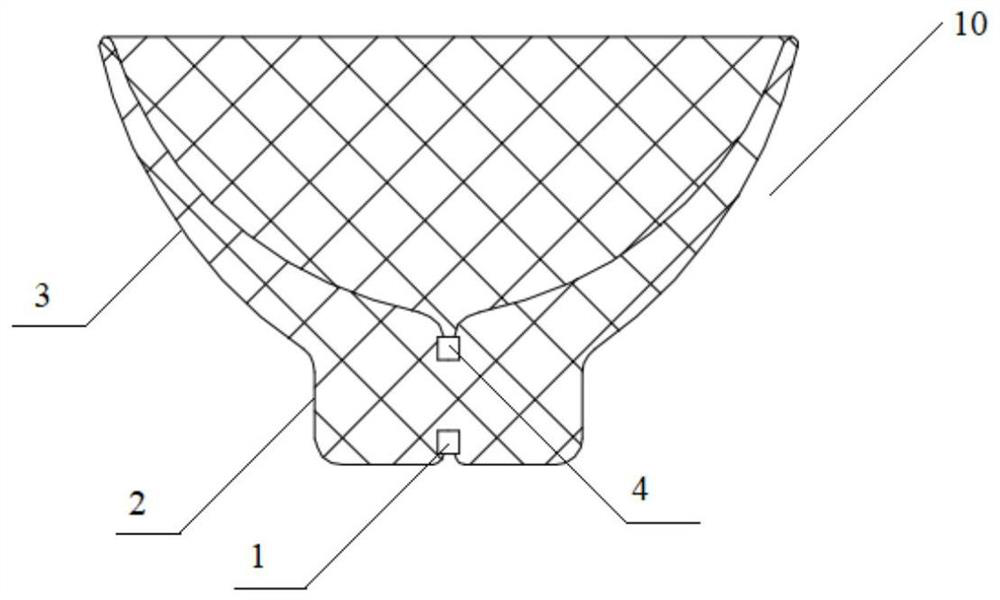

Aneurysm blocking device

The invention provides an aneurysm blocking device which is formed by an elastic net-shaped body, the near end of the elastic net-shaped body is folded inwards in the radial direction to be connected with a near-end marking part, the far end of the elastic net-shaped body is folded inwards in the radial direction to be connected with a far-end marking part and folded reversely, the far end of the elastic net-shaped body where the far-end marking part is located extends into the elastic net-shaped body, a double-layer net structure formed through reverse folding forms an expansion part elastic net-shaped body, a single-layer net structure which is not reversely folded forms a neck elastic net-shaped body, and in the self-expansion state, the radial size of the expansion part elastic net-shaped body is gradually increased from the near end to the far end or is increased firstly and then reduced. According to the blocking device capable of effectively treating the aneurysm, the problems that in the prior art, the blocking effect is poor, the operation cost is high, and the operation difficulty is large are solved, the possibility of arterial thrombosis can be reduced, and the risk that the aneurysm top is weak and prone to being broken is reduced.

Owner:SHANGHAI NOWYON MEDICAL CO LTD

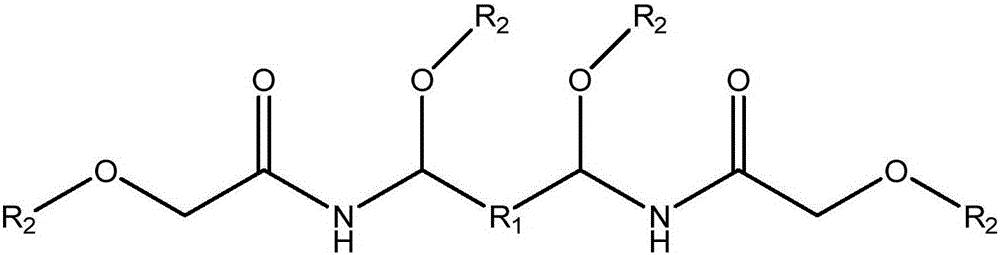

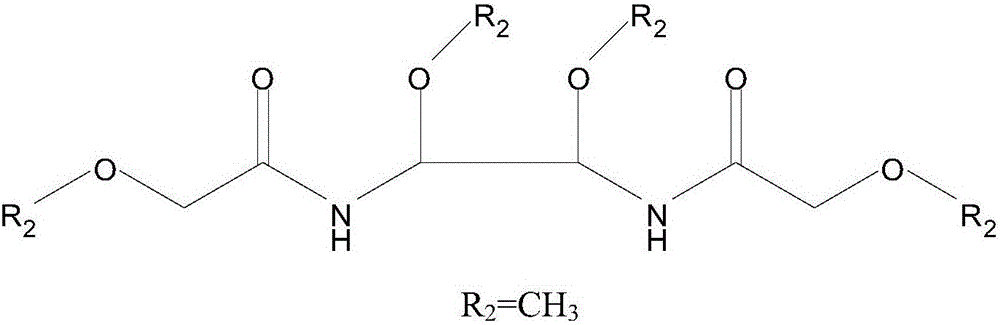

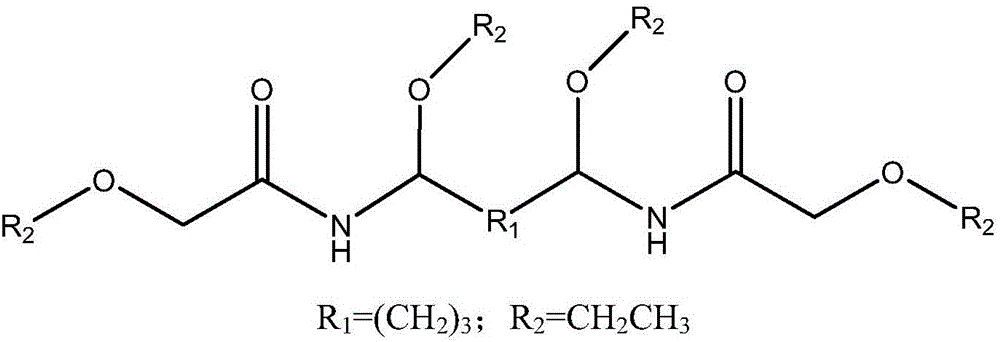

Textile finishing resin and preparation method thereof

ActiveCN106637957ARaw materials are easy to obtainLow priceOrganic compound preparationLight resistant fibresEnvironmental resistancePolymer chemistry

The invention provides textile finishing resin and a preparation method thereof. The structural formula of the textile finishing resin is as shown in the specification, wherein R1 is (CH2)n (n is equal to 0 or 3), and R2 is H, (CH2)n (n is equal to 1-3), or (CH2)mO(CH2)nH (m is equal to 1 or 2, and n is equal to 1 or 2). The preparation method comprises the following steps: glycolamide, dialdehyde and water are mixed, react for 3-5 hours under the conditions that the temperature is 50-70 DEG C and the pH value is 7.5-8, and then react for 3-5 hours under the conditions that the temperature is 30-60 DEG C and the pH value is 5-6.5, an alcohol compound is added after reduced pressure distillation, a reaction lasts for 3 hours under the conditions that the temperature is 40-50 DEG C and the pH value is 2.5-3, the pH value is adjusted to be 5.5-6.5 after the reaction is ended, and water is used for adjusting the solid content to obtain the textile finishing resin. According to the method, formaldehyde is not used as a raw material, which meets relevant standards and environmental protection requirements; used raw materials are simple, easy to obtain and cheap; in addition, after being applied to non-iron finishing of cotton fabrics, the resin prepared with the method reaches high non-iron level and low yellowing degree.

Owner:ZIBO LURUI FINE CHEM CO LTD

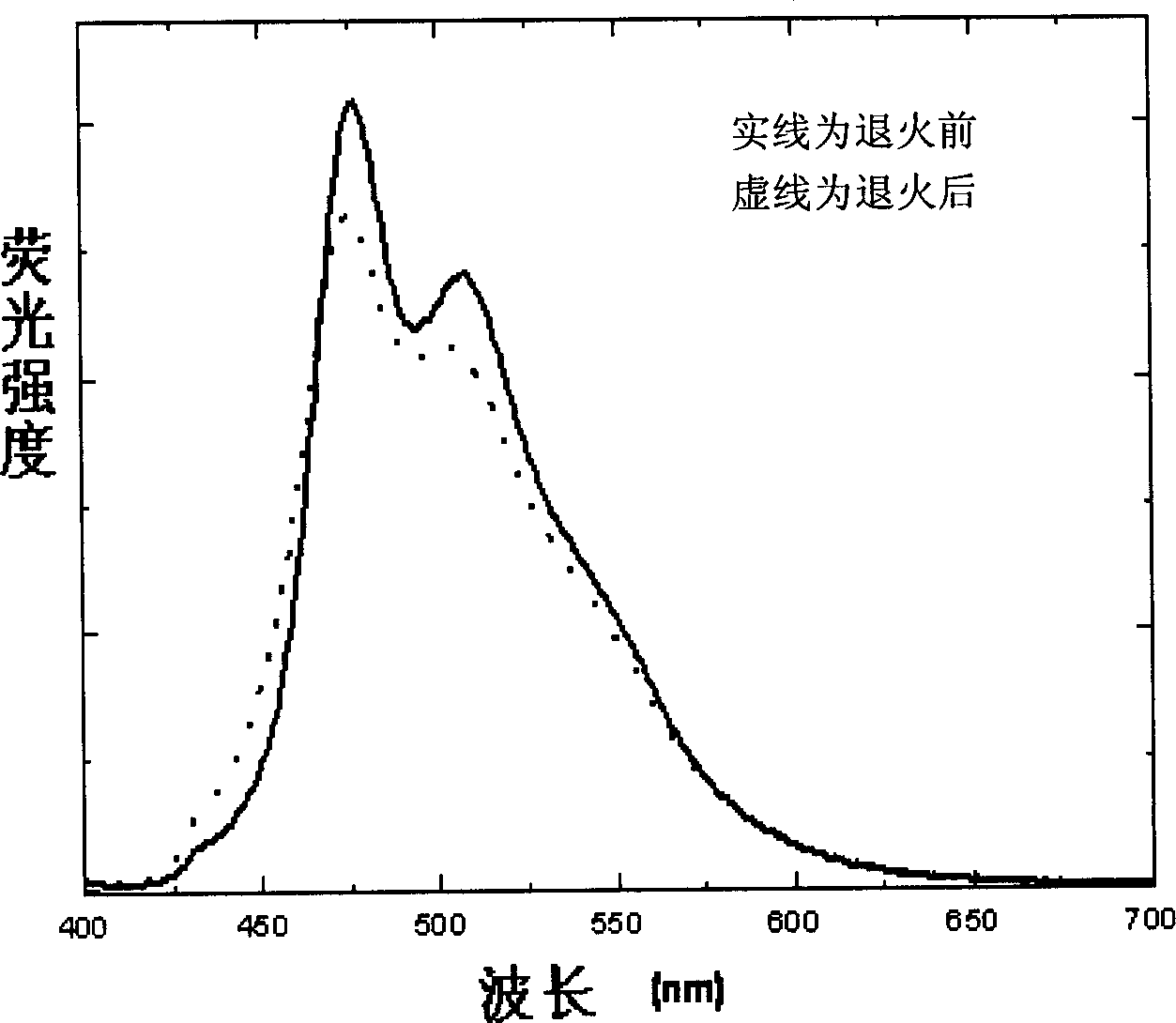

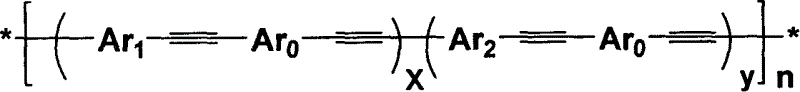

Luminous polyester material containing polyhedral sesquisilicane and its preparation method

InactiveCN1789370AImprove thermal stabilityImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPolyesterOrganic reaction

The invention, belonging to photoelectric material technology field, relates the new-type polyarylradicalacetylene luminescent material containing polyploidy sesquialter silicon hydride and preparing method. The invention uses fluorenes, thiophene, benzene, dehydrobenzene, carbazole and many kinds of polyploidy sesquialter silicon hydride as raw materials, and uses organic reaction to synthesize the polyarylradicalacetylene luminescent material containing polyploidy sesquialter silicon hydride which is organic / inorganic hybridization nano material. Due to the existence of polyploidy sesquialter silicon hydride, it is effective to stop the formation of aggregation, so the organic polymer material possesses the good organic polymer and spectroscopic stability. The organic / inorganic hybridization luminescent material possesses the high quantum efficiency and luminescent heat endurance. The material can be used to prepare organic light-emitting diode and other electron devices.

Owner:FUDAN UNIV

Graphene ceramic tile burning method

The invention discloses a graphene ceramic tile burning method. The burning method comprises the following steps: compounding 35 parts of potassium feldspar, wollastonite, spodumene, alundum powder, attapulgite, diatomite, yellow phosphorite slag and the like to obtain a raw material of graphene ceramic tiles; controlling the moisture of silica sol to obtain a wet blank and a dry blank in sequence; finally, sintering. During sintering, condensation occurs among silanol groups on the surfaces of colloidal particles in order to drive the components of the graphene ceramic tiles to get close andgather, gaps among the components are filled with the colloidal particles, and the colloidal particles are bonded through chemical bonds (Si-O-Si) to form a stable space network structure, so that thecomponents are firmly combined together, the pore forming probability is lowered greatly, the porosity is lowered remarkably, and graphene ceramic tiles with low water absorption can be obtained.

Owner:SICHUAN ANDGEM GRAPHENE TECH CO LTD

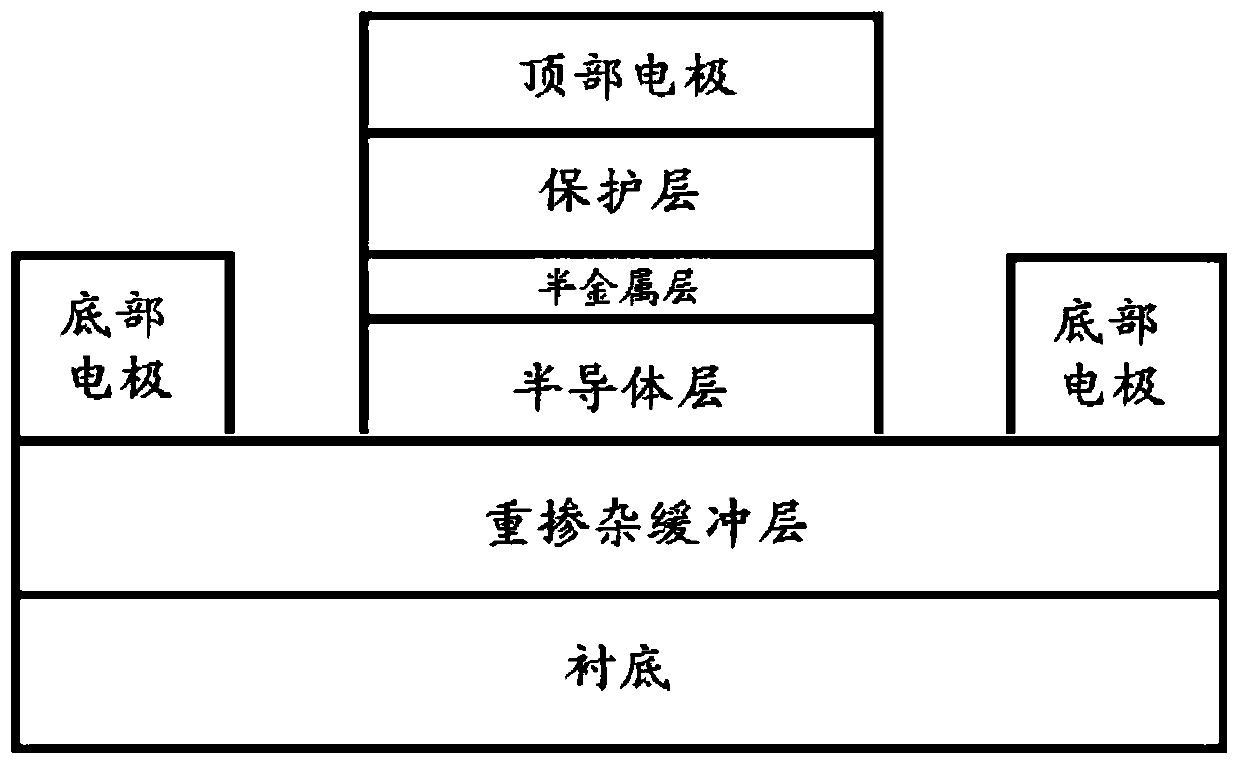

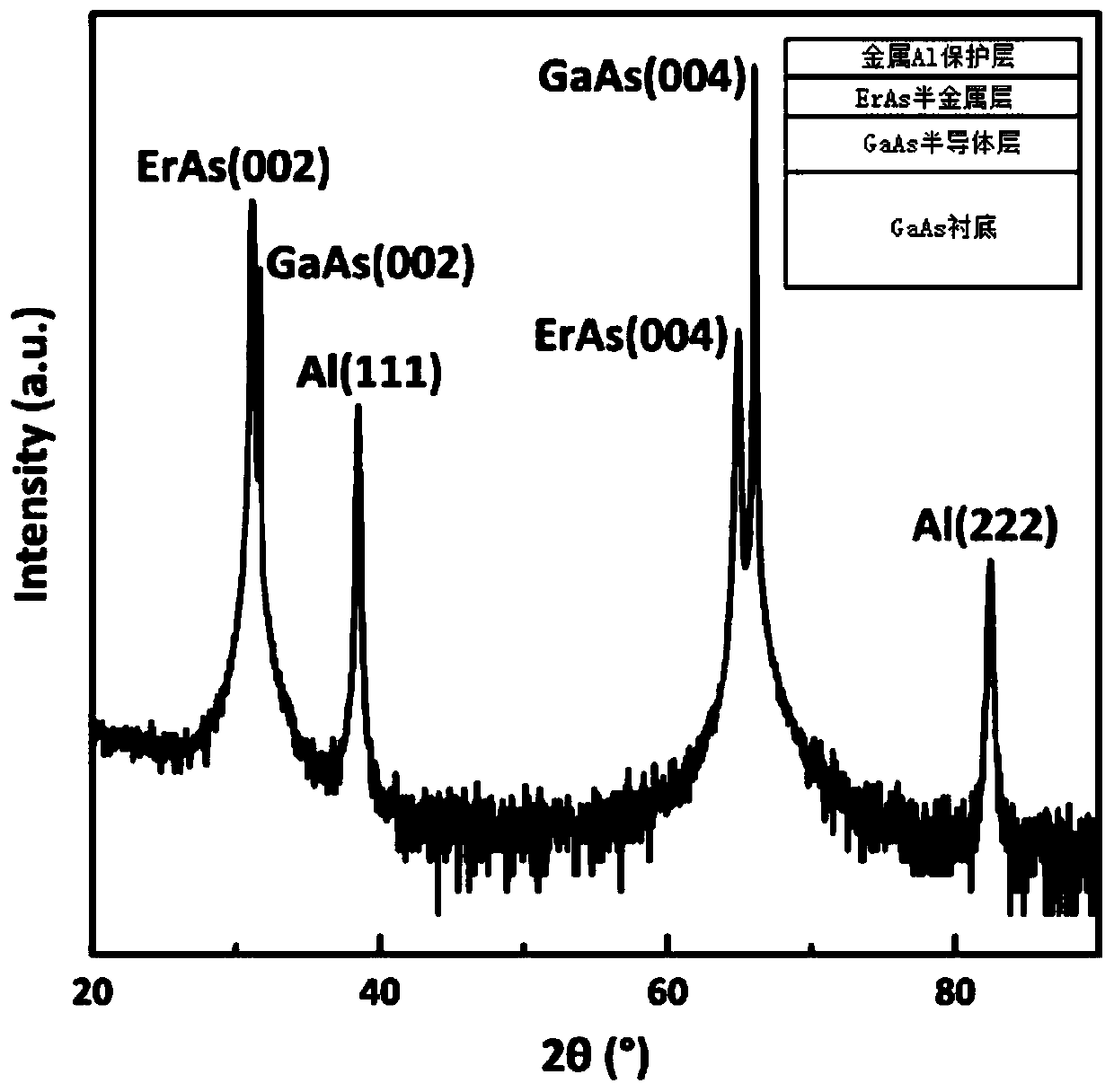

Semimetal/semiconductor Schottky junction, method for fabricating same, and Schottky diode

ActiveCN109979996AQuality improvementReduce the likelihood of formingSemiconductor/solid-state device manufacturingDiodeRare-earth elementThermal stability

The invention relates to the field of electronic materials, and in particular to a semimetal / semiconductor Schottky junction, a method for fabricating the same, and a Schottky diode. The semimetal / semiconductor Schottky junction comprises a semiconductor layer and a semimetal layer, wherein a Schottky contact is formed between the semiconductor layer and the semimetal layer; and a compound formingthe semimetal layer is a compound composed of a rare earth element and a group VA element. The semimetal / semiconductor Schottky junction has good thermal stability at an interface between the semiconductor layer and the semimetal layer. The Schottky diode based on the semimetal / semiconductor Schottky junction has an ideal factor of about 1.05, noise equivalent power that can be reduced to the order of pW / Hz1 / 2 or even sub-pW / Hz1 / 2, and sensitive detection performance.

Owner:NANJING UNIV

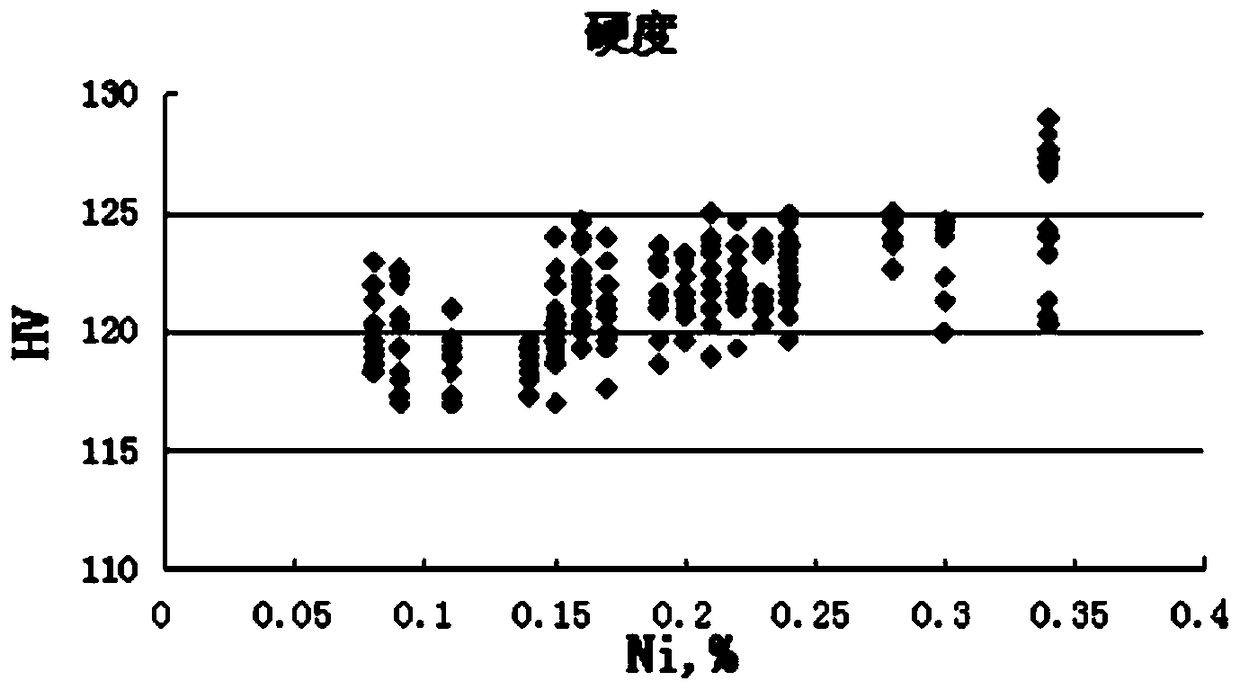

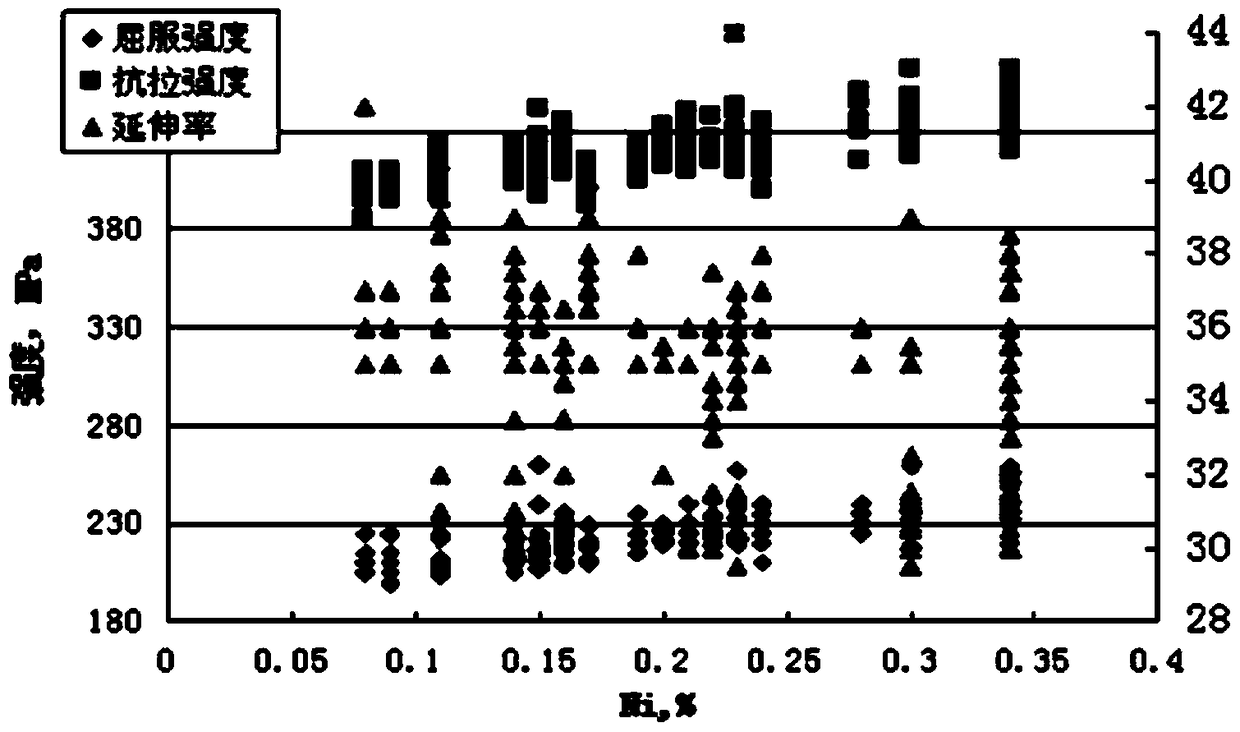

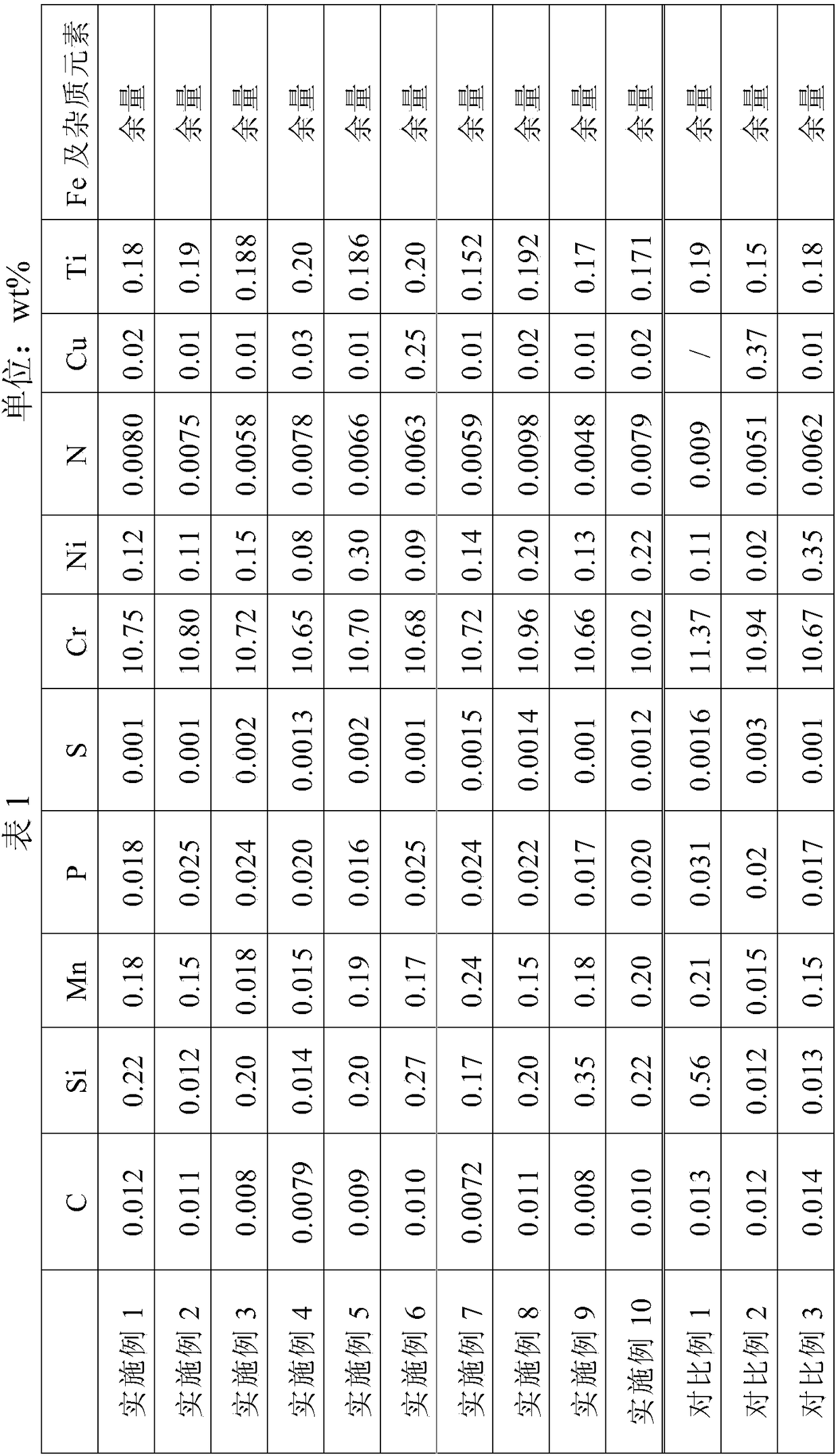

A high-formability low-chromium ferritic stainless steel and its manufacturing method

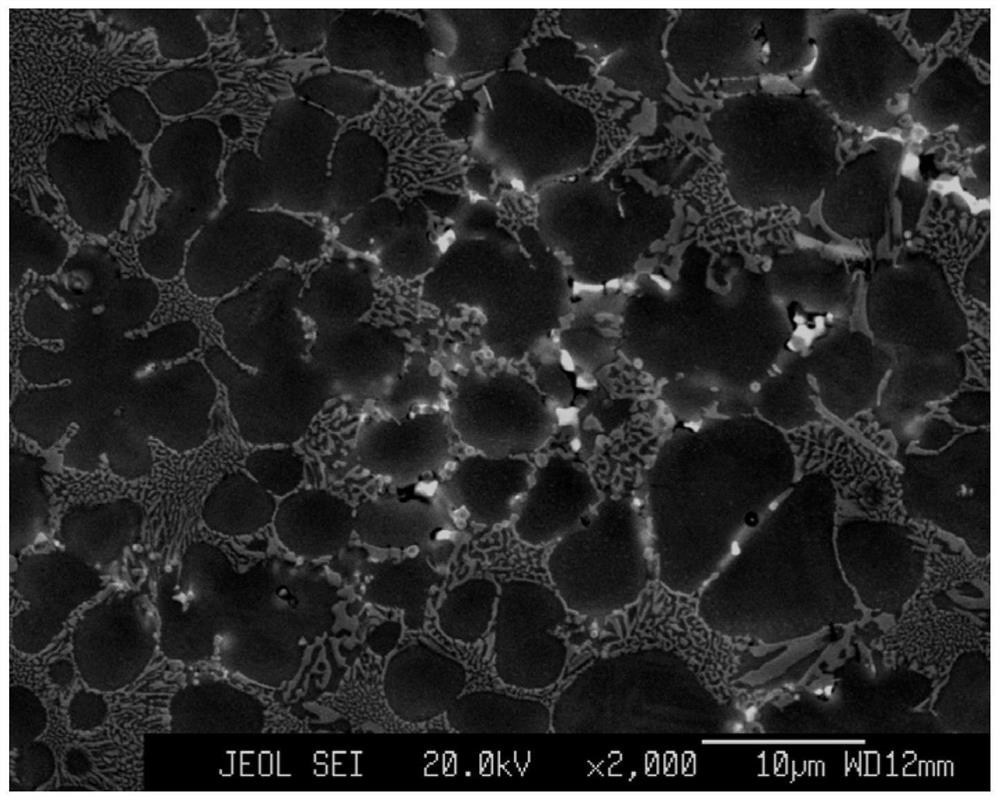

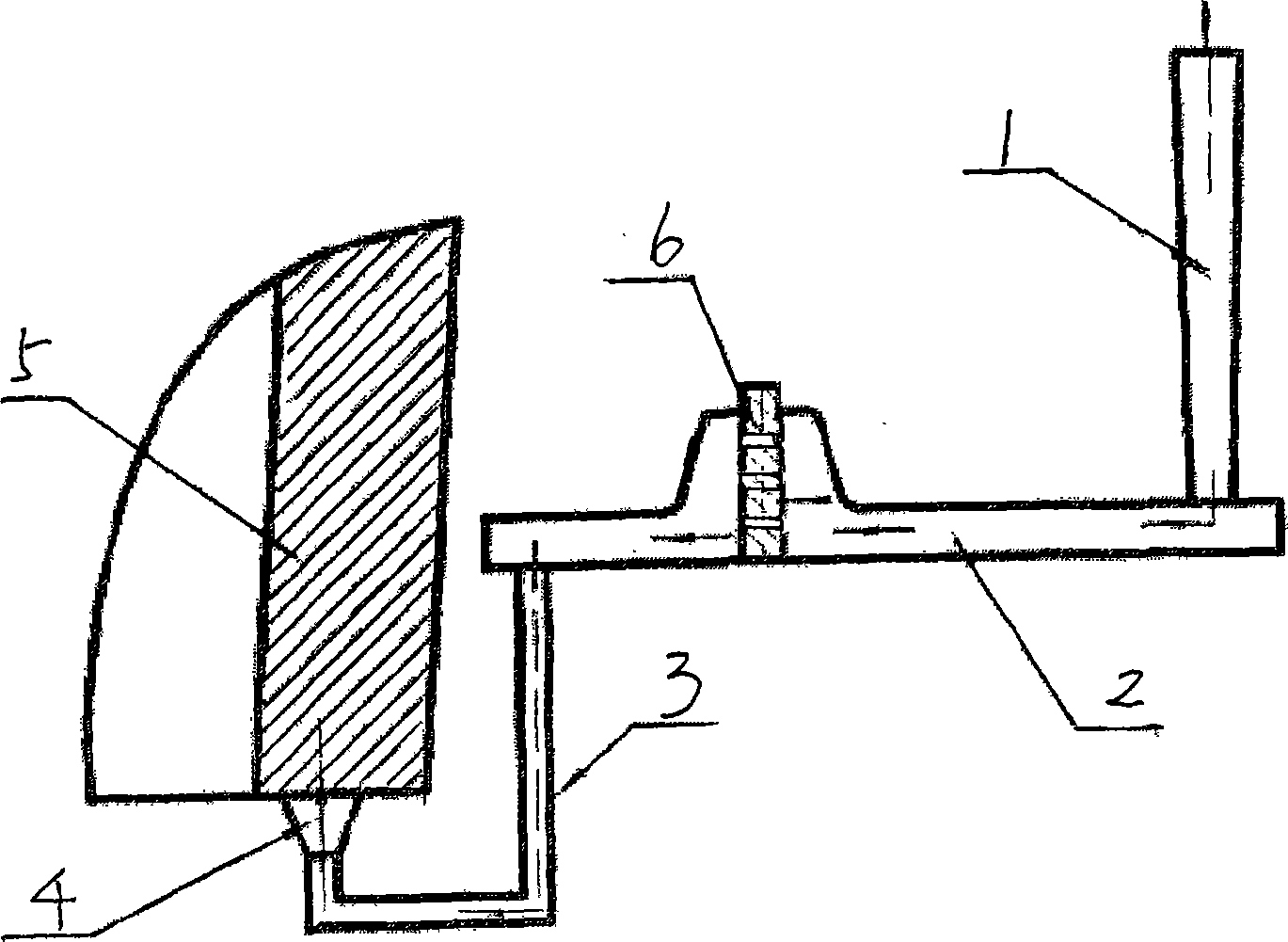

The invention discloses a high formability and low-chromium ferrite stainless steel and a making method thereof, the high formability and low-chromium ferrite stainless steel comprises the following chemical components by weight: less than or equal to 0.015% of C, 0.010-0.35% of Si, 0.015-0.25% of Mn, 9.5-11% of Cr, 0.15-0.20% of Ti, less than or equal to 0.025% of P, less than or equal to 0.002% of S, less than or equal to 0.010% of N, less than or equal to 0.025% of (C + N), 0.0010-0.0050% of Ca, less than or equal to 0.05% of Al, greater than or equal to 6 (C + N) of Ti, and balance of Fe and inevitable impurities, wherein the impurity element Ni content is less than or equal to 0.3%, Cu content is less than or equal to 0.3%, O content is less than or equal to 0.0050%, and the content of Ni+0.5Cu is less than or equal to 0.35%, and the total amount of other impurity elements is less than 0.05% of. The formability is improved by reduction of hardness and strength by reduction of the Cr, Si and Mn content and control of solid solution amount of the Cr, Si and Mn in the steel to reduce the solid solution strengthening effect; by strict control of the content of Ni and Cu, the possibility of the martensite phase formation is reduced to reduce the hardness and strength of the stainless steel to improve the formability. By control of mixed use ratio of molten iron and scrap steel, the content of the impurity elements Ni and Cu in the steel, the influence of the impurity elements Ni and Cu on the hardness and strength and other properties can be ultimately controlled.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

A heat-resistant recycled die-casting aluminum alloy and its preparation method

The invention discloses a heat-resistant recycled die-casting aluminum alloy and a preparation method thereof, belonging to the field of preparation of recycled die-casted aluminum alloys. The invention includes a method for providing a heat-resistant recycled die-casting aluminum alloy and a preparation method for reducing the preparation cost; the chemical composition of the heat-resistant recycled die-casted aluminum alloy is as follows: the content of Si is 10.0-12.0%, and the content of Ni is 0.50-0.75%. , the content of Mg is 0.95-1.35%, the content of Fe is 0.9-1.4%, the content of Mn is 0.20-0.30%, the content of Cr is 0.08-0.12%, the content of B is 0.015-0.03%, and the content of impurity elements is ≤ 0.15%, and the rest is Al; the preparation method is as follows: smelting, sampling to adjust the alloy composition, refining after adding low-melting point alloy, slag removal, and casting; the present invention effectively reduces the alloy content by replacing Ni and Cu with cheap impurity element Fe. Cost, and through the compound modification technology of Mn, Cr, B, etc., the size of the iron-rich phase is refined to ensure the high temperature strength of the alloy.

Owner:肇庆南都再生铝业有限公司 +2

Smooth and steady molding method of spheroidal graphite cast iron

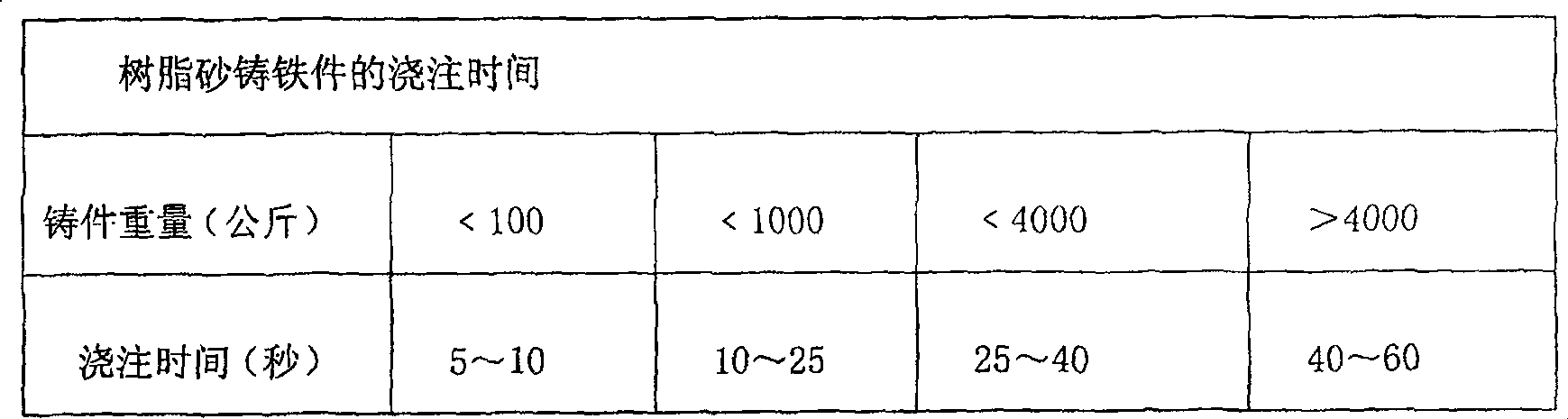

The invention relates to a ductile cast iron piece steady flow method, which comprises a sand blowing mounding and precede casting by a pouring path. While casting, the invention adopts slow casting speed, to the casting piece which is smaller than 100 kilogram, the casting time is 15 to 30 seconds, to the casting between 100 to 1000 kilogram, the casting time is 30 to 60 seconds, to the casting between 1000 to 4000 kilogram, the casting time is 60 to 180 seconds, to the casting piece larger than 4000 kilogram, the casting time is 180 to 480 seconds. The invention can realize stable flow, which makes the ductile cast iron have good quality.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

A smooth and steady molding method of spherical graphite iron castings

The invention discloses a smooth filling method of a nodular graphite casting, which comprises sand discharging and molding, and casting through a pouring channel. At casting, the invention adopts a slow speed casting, for a casting lower than 100 kilogram, the casting time is 15 to 30 seconds; for a casting of 100-1,000 kilogram, the casting time is 30 to 60 seconds; for a casting of 1,000 to 4,000 kilogram, the casting time is 60 to 180 seconds; for a casting more than 4,000 kilogram, the casting time is 180 to 480 seconds. The invention can realize smooth filling and guarantee good quality in nodular graphite castings.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

Ground source heat pump system

ActiveCN112361658BImprove time utilizationReduce the likelihood of formingFluid heatersSolar heating energyThermodynamicsEngineering

The invention relates to a ground source heat pump system, which is applied in the technical field of geothermal energy utilization, which includes a heat exchange tube group, a first circulation pump, a ground source heat pump unit, a water heater, a coil pipe and a second circulation pump, and a heat exchange tube group Buried in the soil and connected to the first circulating pump through the first water pipe, the first circulating pump is connected to the ground source heat pump unit through the first branch pipe, and the ground source heat pump unit is connected to the water inlet end of the coil through the second water pipe. Buried in the building room, the outlet end of the coil pipe is connected to the second circulation pump through the second branch pipe, and the second circulation pump is connected to the heat exchange tube group through the return pipe. The present invention has the effect of accelerating temperature rise when heating indoors.

Owner:南京金海设计工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com