High-capacity silicon-carbon material for lithium battery negative electrode and preparation method

A silicon-carbon material, high-capacity technology, applied in the field of electrochemistry, can solve problems such as increasing production costs, reducing efficiency and product yield, and weak binding force, achieving the effects of improving conductivity, improving stability, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

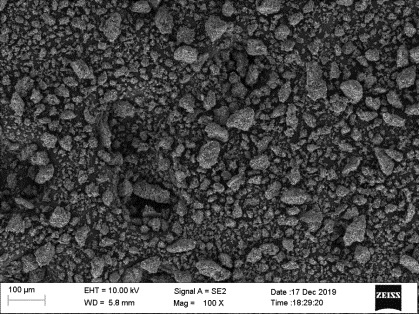

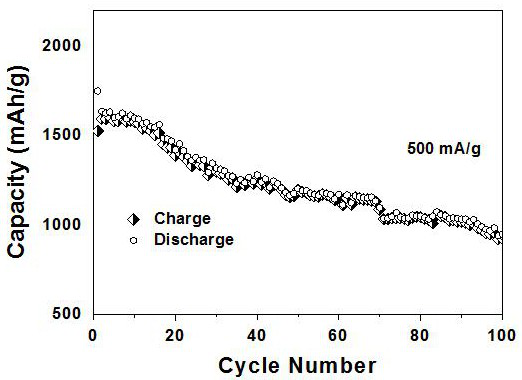

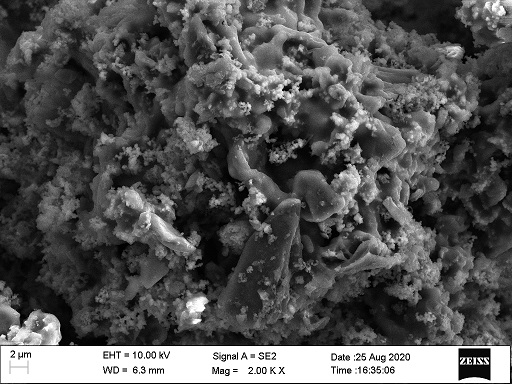

Image

Examples

Embodiment 1

[0045] In this embodiment, the preparation method of the highly stable silicon-carbon negative electrode material for lithium batteries is as follows:

[0046] (1) Disperse 2g of nano-silicon in 100mL of ethanol, ultrasonically disperse and stir evenly, and add 10g of chitosan aqueous solution with a concentration of 10% drop by drop to obtain dispersion A;

[0047] (2) Disperse 0.05g of carbon nanofibers in 100mL of ethanol to obtain dispersion B;

[0048] (3) Disperse 4g of graphite intermediate in 100mL of ethanol, ultrasonically and stir evenly, and dropwise add 0.5g of amino polyether silicone with a concentration of 50% to obtain dispersion D;

[0049] (4) Add dispersion A, 0.5g of WD-50 with a concentration of 100%, and dispersion B to dispersion D dropwise at the same time, control the rotation speed at 500rad / min, and stir at 80°C for 12 hours to obtain dispersion E ;

[0050] (5) Let the dispersion E stand still for 2 hours, collect the lower layer slurry, filter i...

Embodiment 2

[0053] In this embodiment, the preparation method of the highly stable silicon-carbon negative electrode material for lithium batteries is as follows:

[0054] (1) Disperse 5g of nano-silicon in 100mL of ethanol, ultrasonically disperse and stir evenly, and add 2g of 50% phytic acid aqueous solution drop by drop to obtain dispersion A;

[0055] (2) Disperse 0.1g of carbon nanotubes in 100mL of ethanol to obtain dispersion B;

[0056] (3) Disperse 5g of graphite intermediate in 100mL of ethanol, ultrasonically and stir evenly, and dropwise add 0.5g of WD-50 with a concentration of 100% to obtain dispersion D;

[0057] (4) Add dispersion A, 0.5g of WD-50 with a concentration of 100%, and dispersion B to dispersion D dropwise at the same time, control the speed at 1000rad / min, and stir at 60°C for 4 hours to obtain dispersion E ;

[0058] (5) Let the dispersion E stand still for 4 hours, pour off the supernatant to obtain the lower layer slurry, centrifuge it, dry it in vacuum ...

Embodiment 3

[0061] In this embodiment, the preparation method of the highly stable silicon-carbon negative electrode material for lithium batteries is as follows:

[0062] (1) Disperse 4g of nano-silicon in 100mL of isopropanol, ultrasonically disperse and stir evenly, and add 1.5g of 30% sucrose solution drop by drop to obtain dispersion A;

[0063] (2) Disperse 0.02g of carbon nanotubes in 100mL of isopropanol to obtain dispersion B;

[0064] (3) Disperse 2g of mesocarbon microsphere intermediate in 100mL of isopropanol, ultrasonically and stir evenly, and dropwise add 0.4g of KH550 with a concentration of 50% to obtain dispersion D;

[0065] (4) Add dispersion A, 0.4 g of KH550 with a concentration of 50%, and dispersion B to dispersion D dropwise at the same time, control the speed at 1500 rad / min, and stir at 40°C for 8 hours to obtain dispersion E;

[0066] (5) Let the dispersion E stand still for 3 hours, collect the slurry in the lower layer, dry it in a blast oven at 70°C for 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com