Smooth and steady molding method of spheroidal graphite cast iron

A technology of smooth filling, ductile iron, applied in foundry equipment, control of pouring molten metal from ladle, metal processing equipment, etc. Small effect, reducing the possibility of sand inclusion defects, and improving the performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

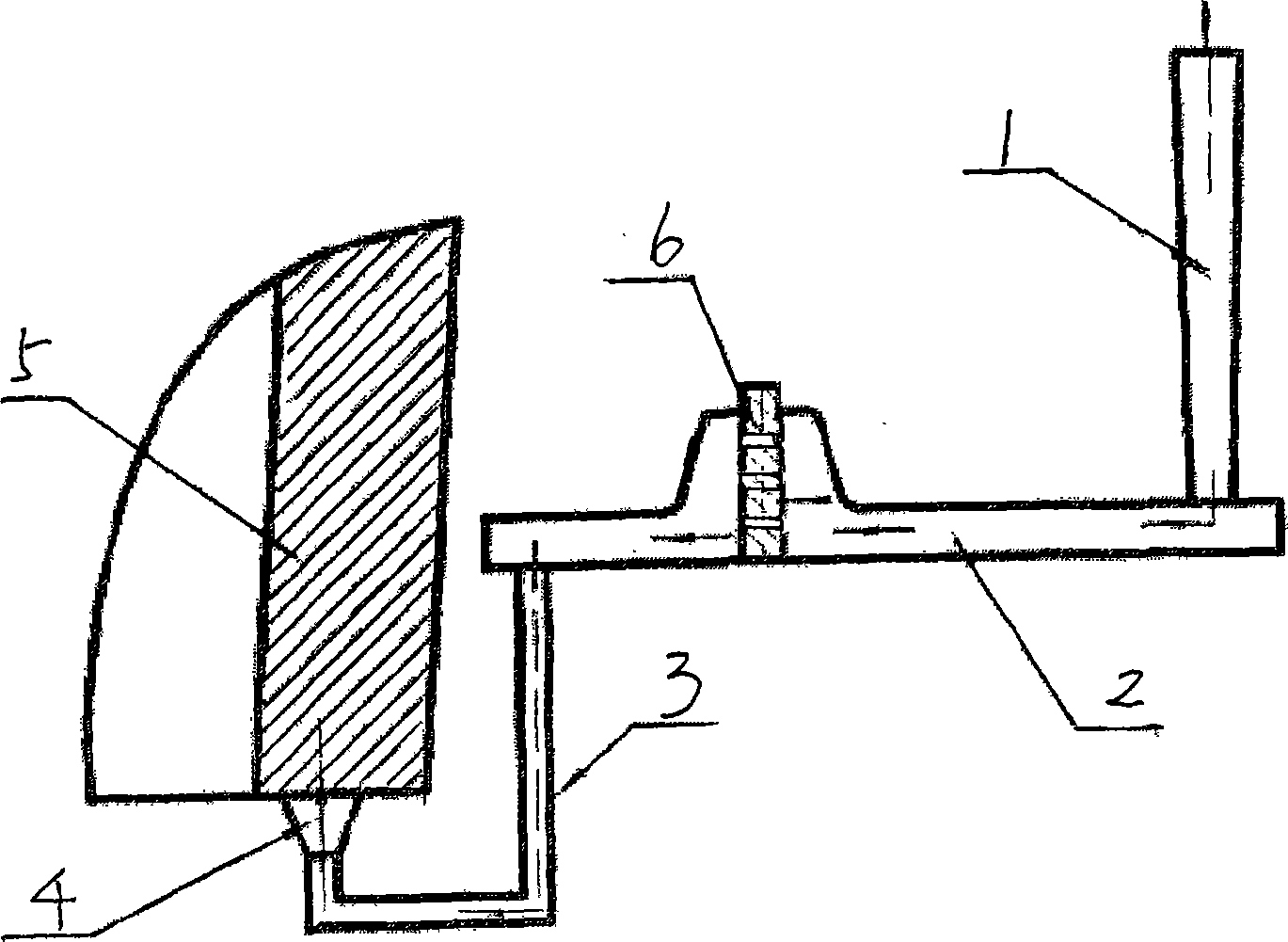

Image

Examples

Embodiment 1

[0018] A smooth filling method for nodular cast iron parts, including sand molding and casting through a runner. When casting, a slow casting speed is used. For castings less than 100 kg, the casting time is 15-30 seconds (Examples 16, 23, 29 second). The runner adopts the form of ceramic tube, and a filtering device for filtering impurities is set in the runner. The filter device is a ceramic block with filter holes to filter out impurities. When placing sand for modeling, vibrate the sand mold to make the shape compact.

Embodiment 2

[0020] When casting, use a slow casting speed. For castings between 100 and 1000 kg, the casting time is 30 to 60 seconds (for example, 30, 45, and 60 seconds); for castings between 1000 and 4000 kg, the casting time is 60 ~ 180 seconds; (examples 60, 120, 180 seconds); for castings larger than 4000 kg, the casting time is 180-480 seconds (examples: 180, 320, 480 seconds).

[0021] Specifically:

[0022] For castings weighing 2 tons, the casting time is 90 seconds. For castings weighing 10 tons, the casting time is 300 to 480 seconds.

[0023] 100% of the castings produced by the invention pass visual inspection, magnetic particle inspection, and ultrasonic inspection, without sand inclusion and secondary oxidation slag defects.

[0024] Due to the use of the present invention, the material properties of ductile iron castings are significantly improved. Taking the low temperature impact performance of wind turbine castings as an example, the -40±2℃ low temperature impact performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com