A high-formability low-chromium ferritic stainless steel and its manufacturing method

A manufacturing method and formability technology, applied in the field of high-formability low-chromium ferritic stainless steel and manufacturing, can solve problems such as impacts that have not been clearly studied, and achieve the effect of low alloy cost and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiments and drawings.

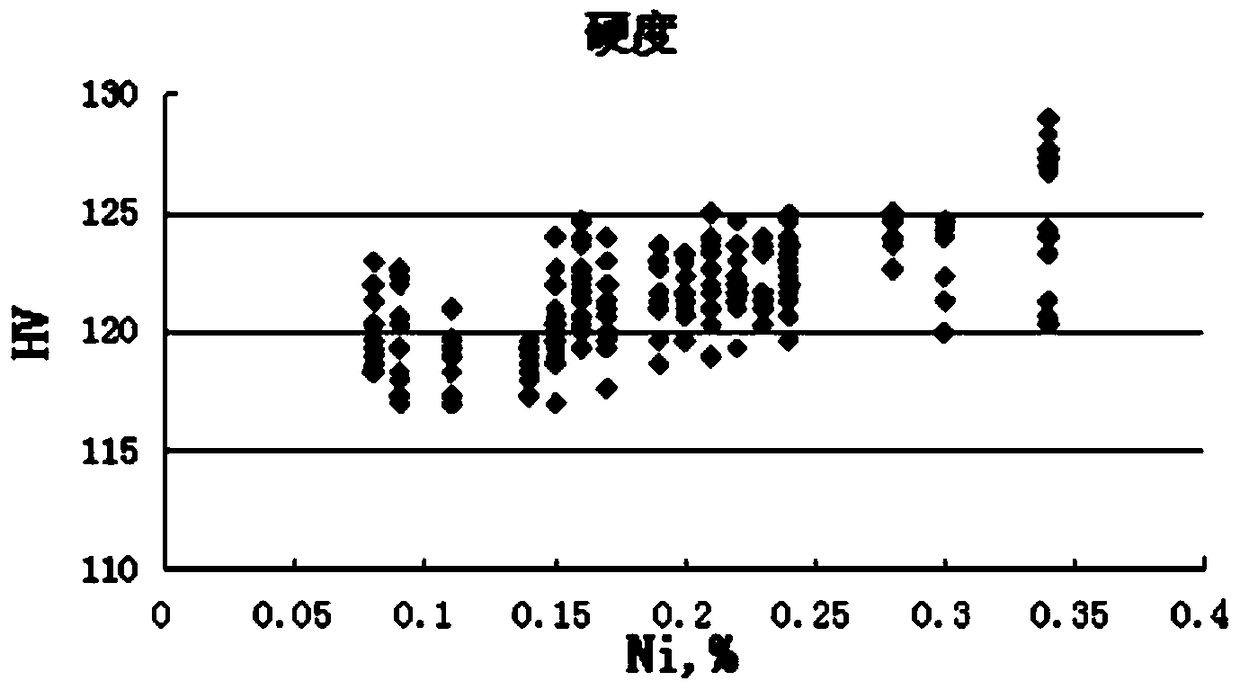

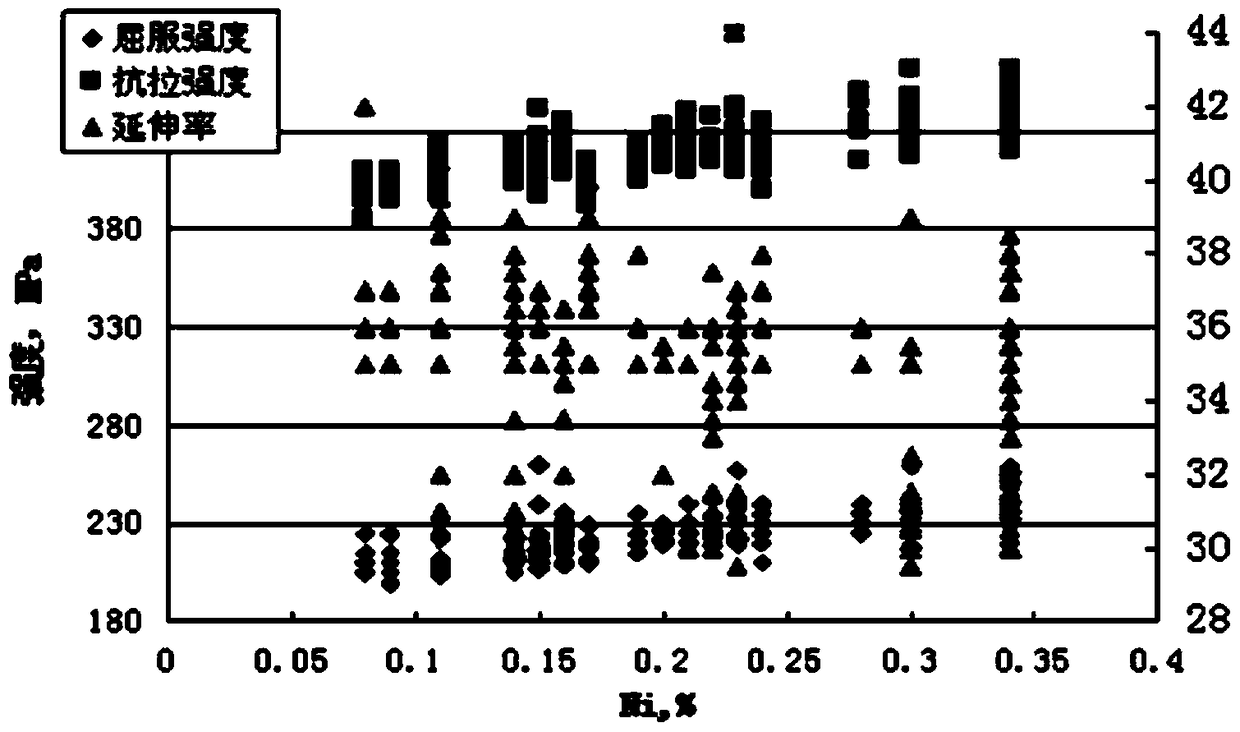

[0041] by figure 1 , figure 2 It can be seen that with the increase of the content of impurity element Ni, the hardness and strength have a tendency to increase, so the content of Ni must be strictly controlled, and the influence mechanism of Cu on strength and hardness is the same as that of Ni.

[0042] In steelmaking, by controlling the ratio of molten iron to scrap, the content of impurity elements Ni and Cu can be controlled. When the mass fraction of molten iron is greater than 20%, Ni+0.5Cu≤0.35%.

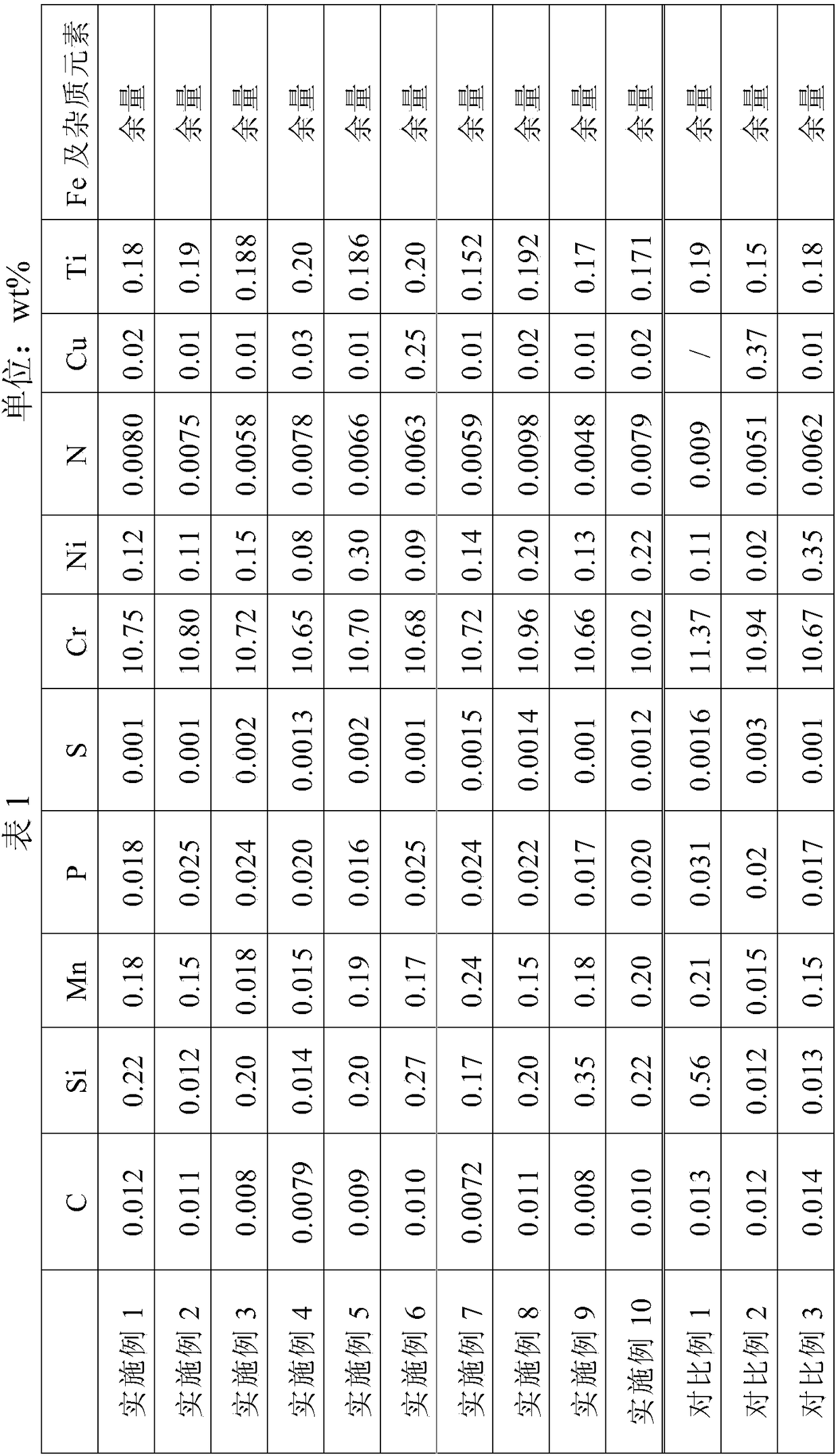

[0043] The present invention reduces the content of Si, Mn, and Cr, and strictly controls the content of Ni and Cu. The composition of the example is shown in Table 1. Table 2 is the process control of the example of the invention, and Table 3 shows the performance of the example of the invention. . It can be seen from the performance comparison between the embodiment and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com