A heat-resistant recycled die-casting aluminum alloy and its preparation method

A casting aluminum alloy and heat-resistant technology, which is applied in the field of heat-resistant recycled die-casting aluminum alloy and its preparation, can solve the problems of high cost, low thermal expansion coefficient, and poor heat resistance of heat-resistant cast aluminum alloy, and reduce the cost of the alloy , high resource utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

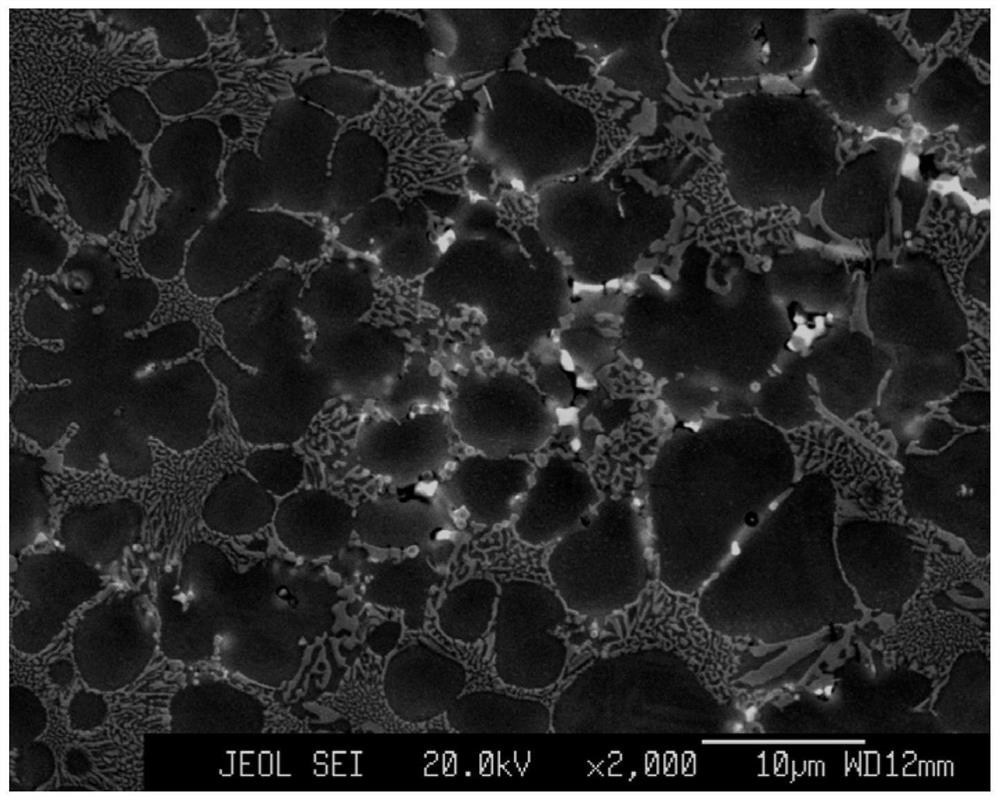

Image

Examples

Embodiment 1

[0027] Design ingredients: Al-12% Si-1.2% Fe-1.0% Mg-0.6% Ni-0.3% Mn-0.1% Cr-0.01% B; i.e. of Si, 1.2% of Fe 12%, and 1.0% Mg , 0.6% Ni, 0.3% of Mn, 0.1% of Cr, 0.01% of B and the balance consisting of Al;

[0028] (1) After the separation, cleaned, preheated scrap material added aluminum melting furnace, melting temperature of 750 ℃, remelted at a melt sampled intermediate position, the test chemical composition of the melt;

[0029] (2) difference from the control elements in the design of the main component and the component Found alloys including Si, Ni, Fe, Cr and other high melting point additives, heated to 760 deg.] C, to adjust the content and the melt temperature of the alloying elements through feed supplement;

[0030] (3) melt temperature adjusted to 720 ℃, the ingot was added Mg, Al-B intermediate alloy, low-melting alloy;

[0031] (4) by a melt-line refining, insulation, cast into the slag ingots, remelting after casting unit for preparation of high heat resistant a...

Embodiment 2

[0035] Design ingredients: Al-12% Si-1.4% Fe-0.95% Mg-0.5% Ni-0.2% Mn-0.12% Cr-0.03% B; i.e. from 12% of Si, 1.4% of Fe, 0.95% of Mg , 0.5% Ni, 0.2% of Mn, 0.12% of Cr, 0.03% of B and the balance consisting of Al;

[0036] (1) After the separation, cleaned, preheated scrap material added aluminum melting furnace, the melting temperature is 760 deg.] C, in the melt after intermediate position remelted sample, the test chemical composition of the melt;

[0037] (2) difference from the control elements in the design of the main component and the component Found alloys including Si, Ni, Fe, Cr and other high melting point additives, heated to 780 deg.] C, to adjust the content and the melt temperature of the alloying elements through feed supplement;

[0038] (3) melt temperature adjusted to 740 ℃, the ingot was added Mg, Al-B intermediate alloy, low-melting alloy;

[0039] (4) by a melt-line refining, insulation, cast into ingots after the slag / poured into the holding furnace, for ...

Embodiment 3

[0043] The design composition is as follows:

[0044] Al-10% Si-0.9% Fe-1.35% Mg-0.7% Ni-0.25% Mn-0.08% CR-0.02% B; that is, 10% Si, 0.9% Fe, 1.35% Mg, 0.7% Ni, 0.25% Mn, 0.08% Cr, 0.02% B and margin were made of Al.

[0045] (1) After selection, cleaning, preheated waste aluminum material is added to the smelting furnace, the melting temperature is 750 ° C, and the chemical component of the melt is taken after the molten temperature of 750 ° C.

[0046] (2) The difference in the content of the main alloy element in the design component and the measured component, including Si, Ni, Fe, Cr, etc., the temperature of the above-mentioned alloy element and the melt temperature of the above-mentioned alloy element are adjusted by supplementing the feedstock.

[0047] (3) Adjust the melt temperature to 720 ° C, add a low melting point alloy such as Mg ingot, AL-B intermediate alloy;

[0048] (4) The melt is refined, heats up, and the slag is poured into a ingot. After the remembering, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com