Patents

Literature

316results about "Level indicators by weight measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

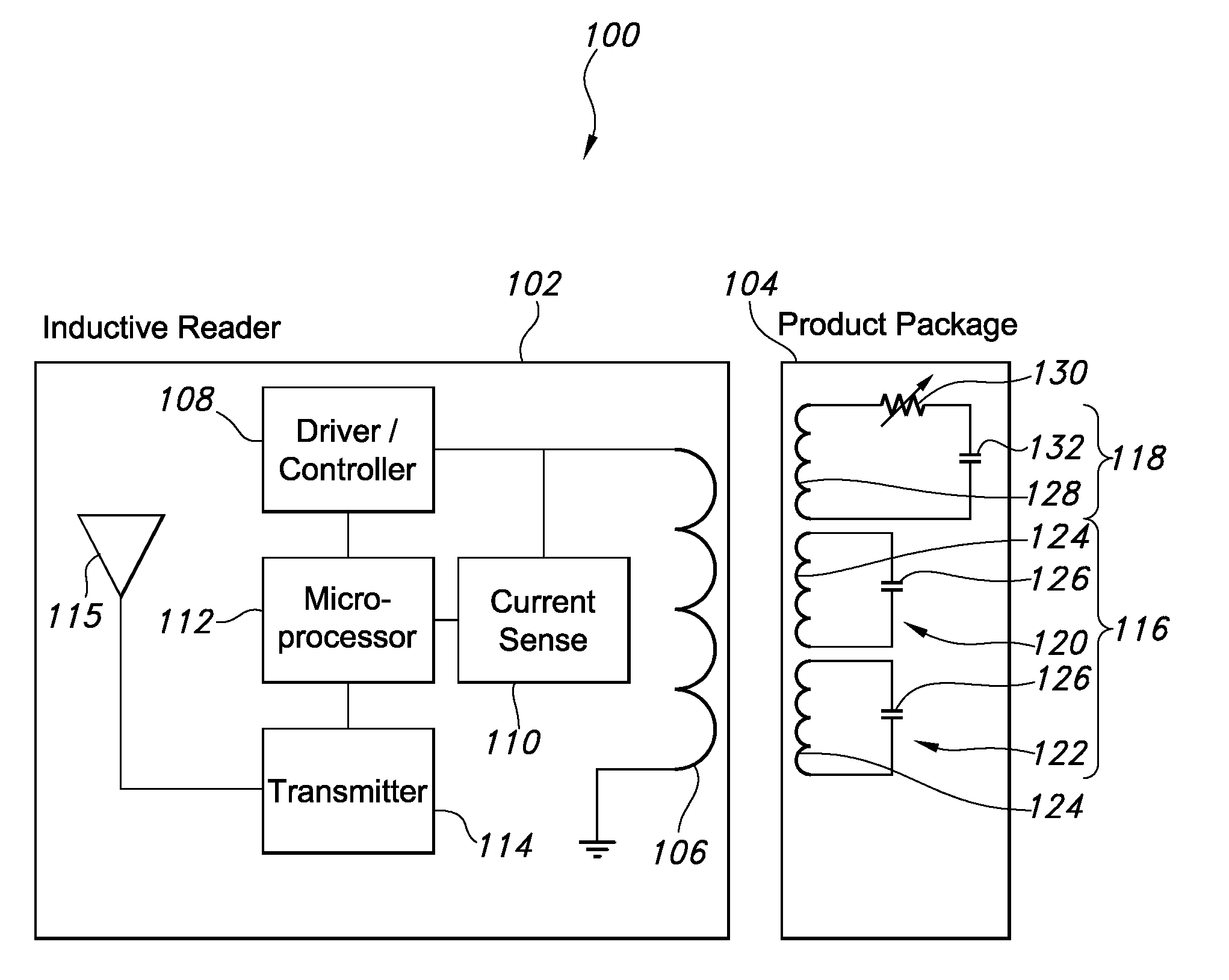

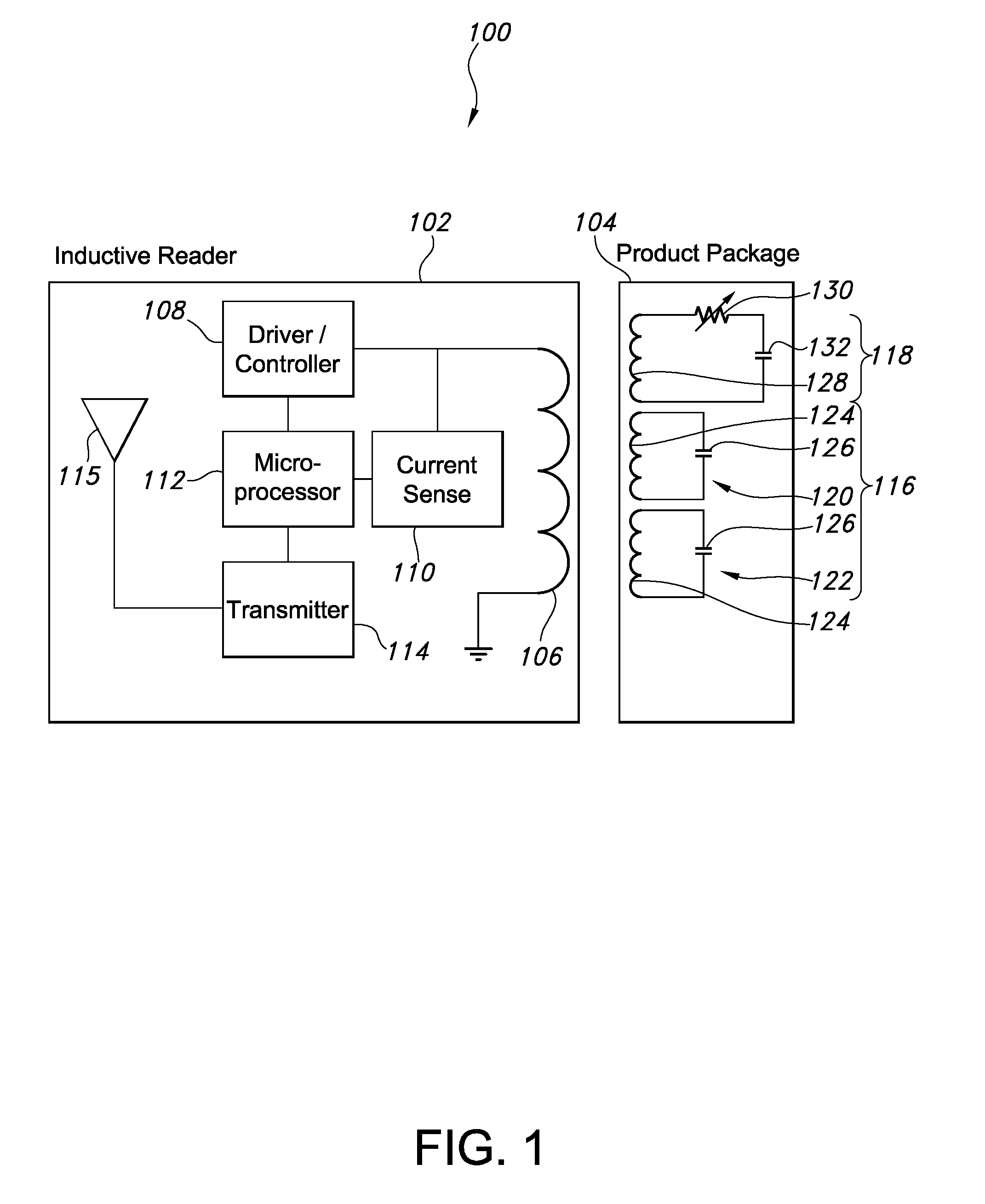

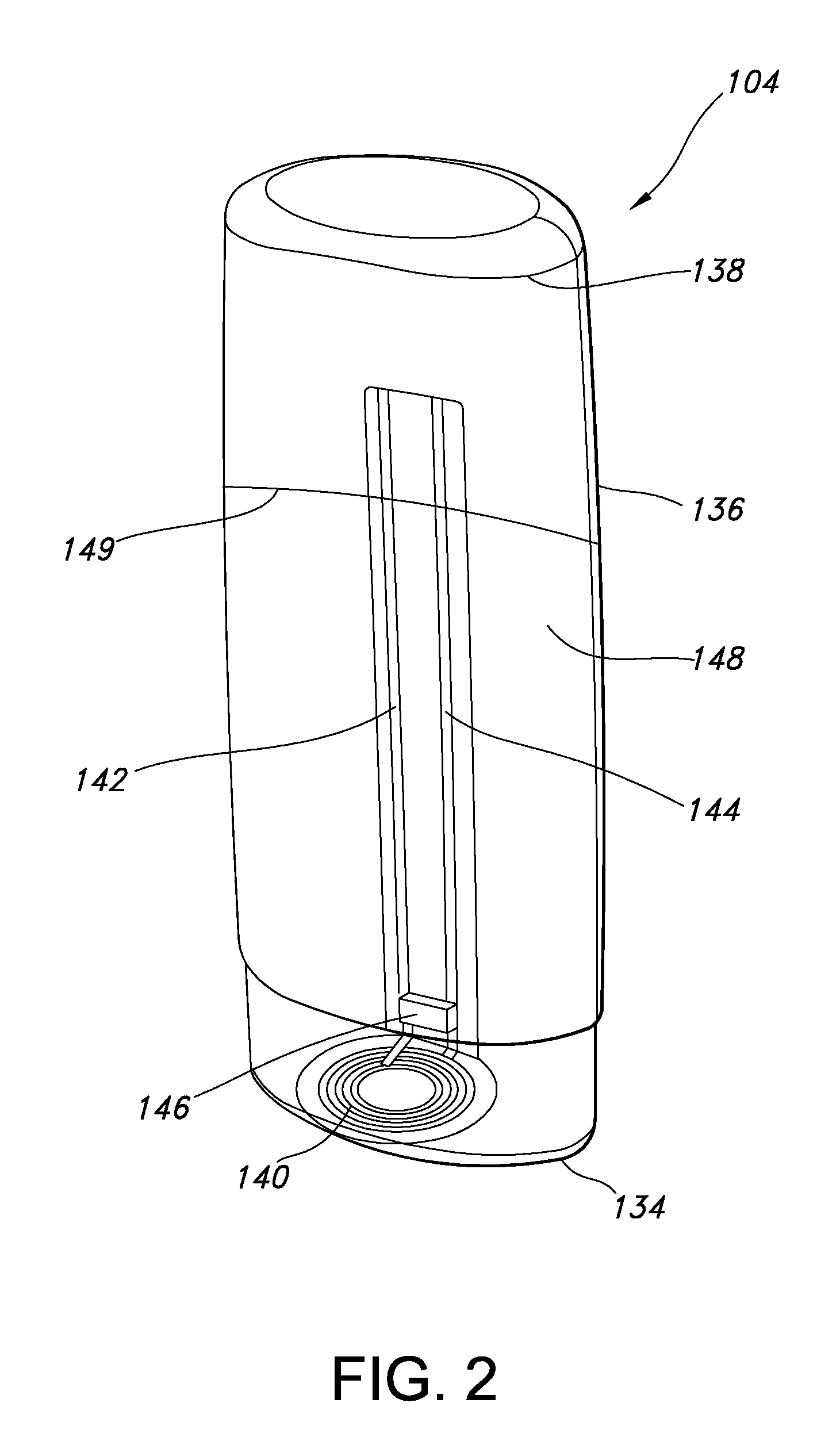

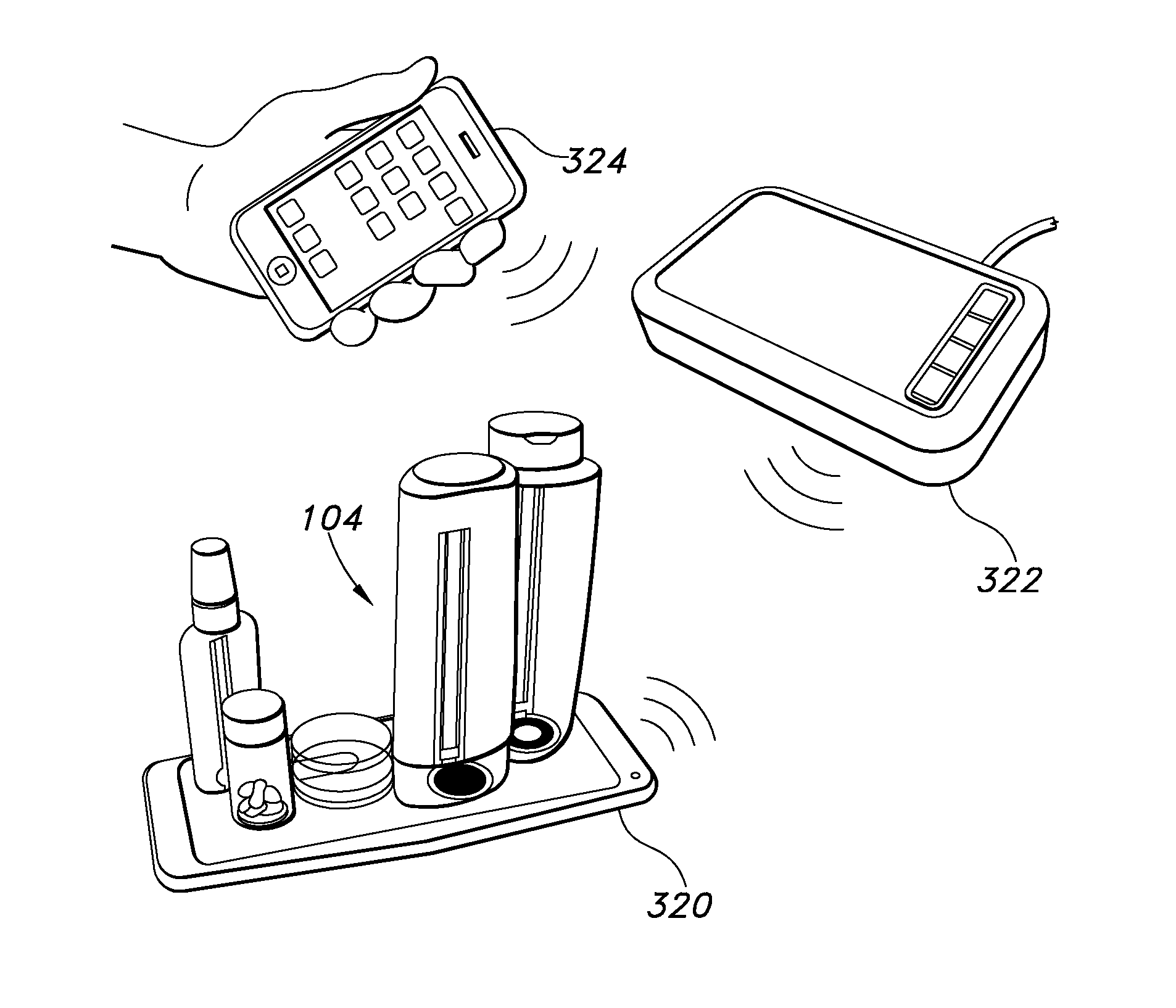

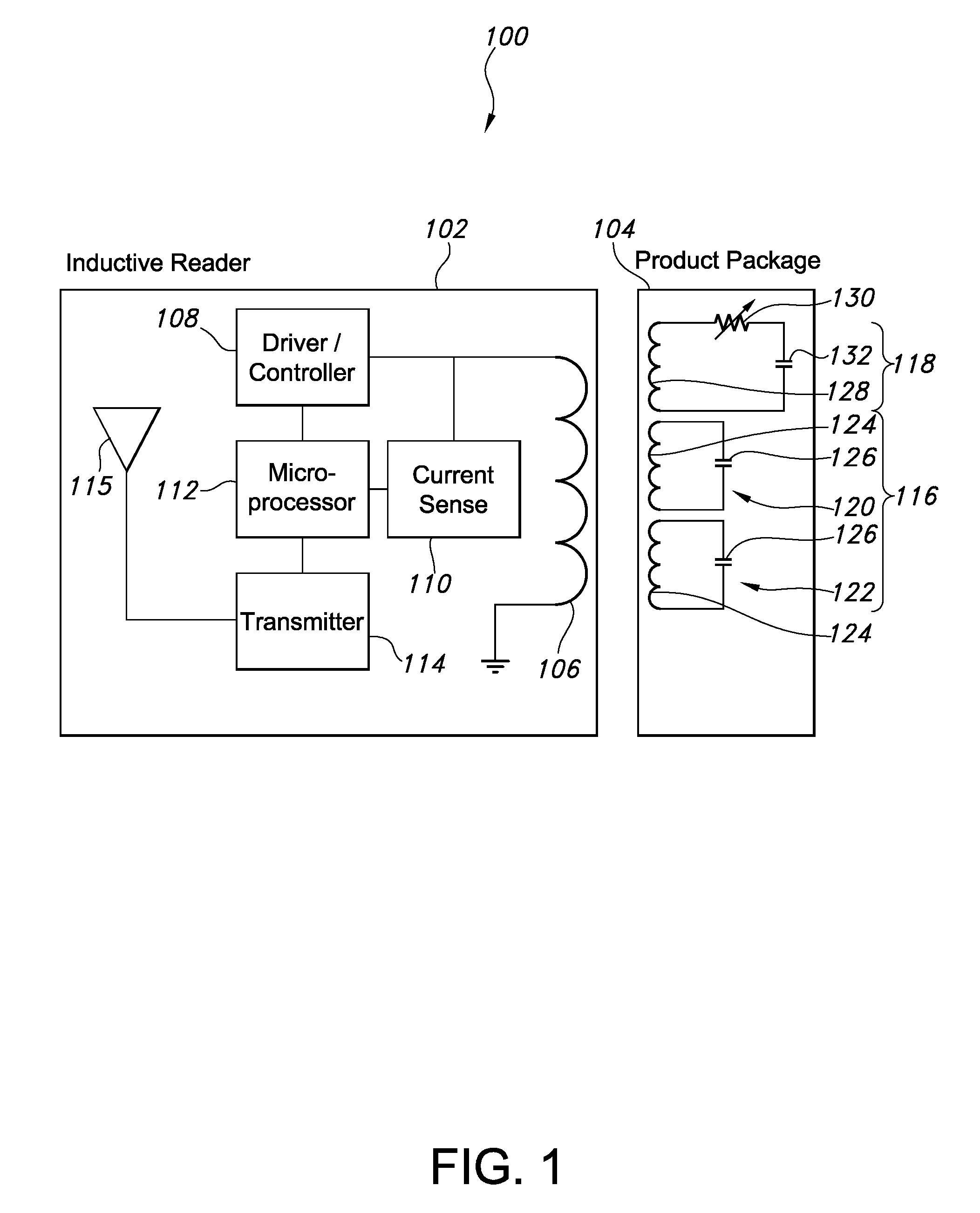

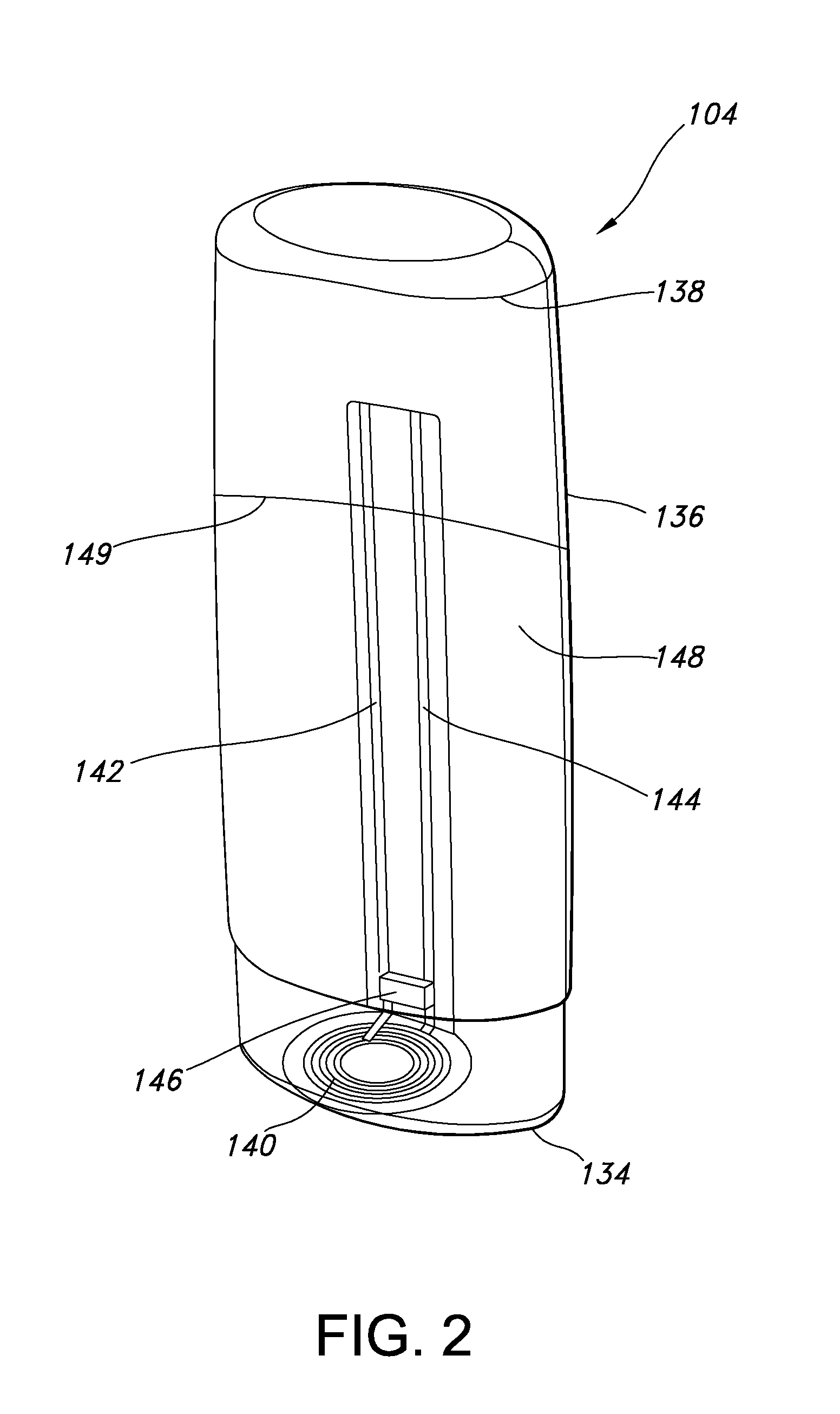

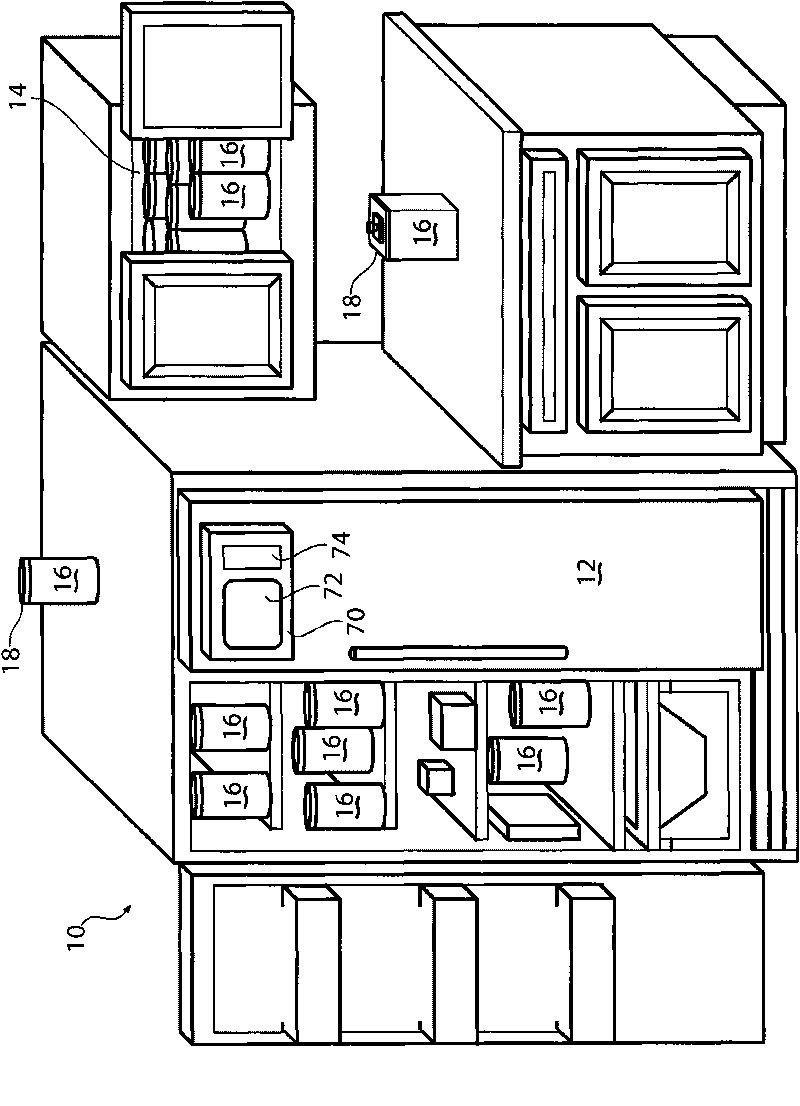

Point of sale inductive systems and methods

Systems and methods for the identification, powering and control of products and product packaging. The systems can include a point of sale display having a contactless power supply. The contactless power supply can provide a source of wireless power for products and product packaging. The products and product packaging can include light emitting diodes, e-ink displays and printed speaker circuits that activate as the operating frequency of the contactless power supply varies. Other embodiments include product level sensors, inductive reader networks, printed temperature sensors, product alignment systems, passive identification circuits and methods for controlling operation of the same.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

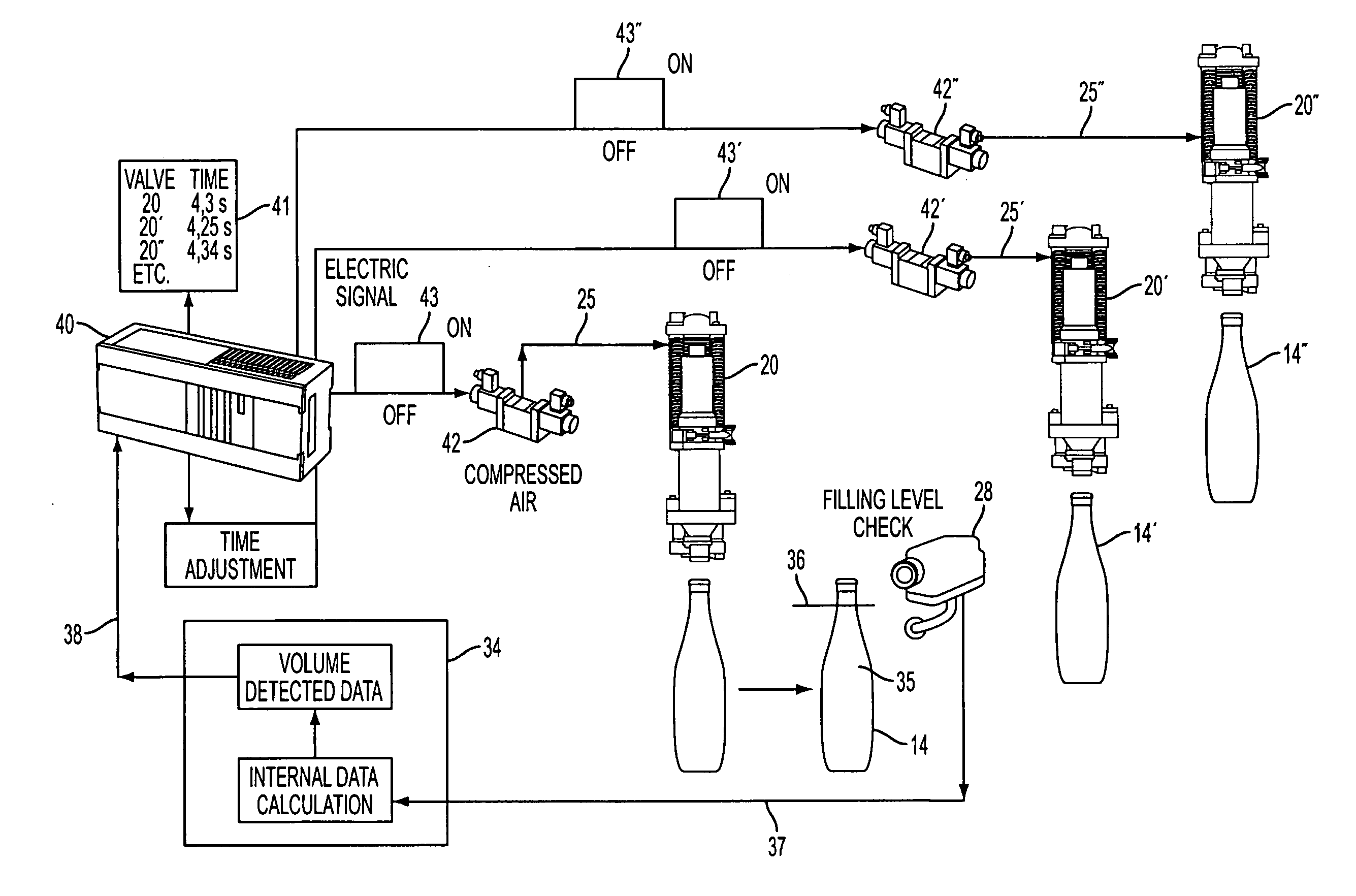

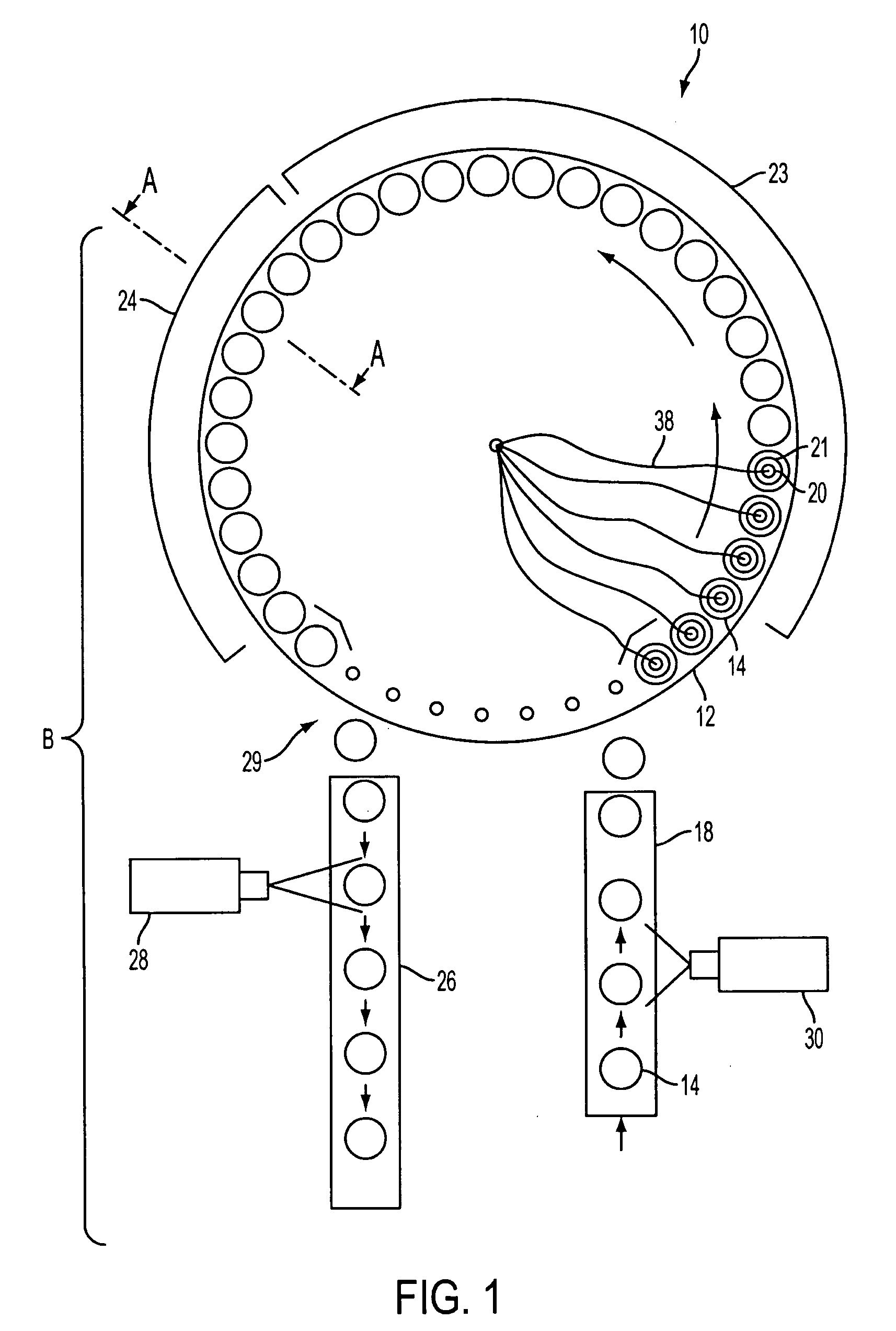

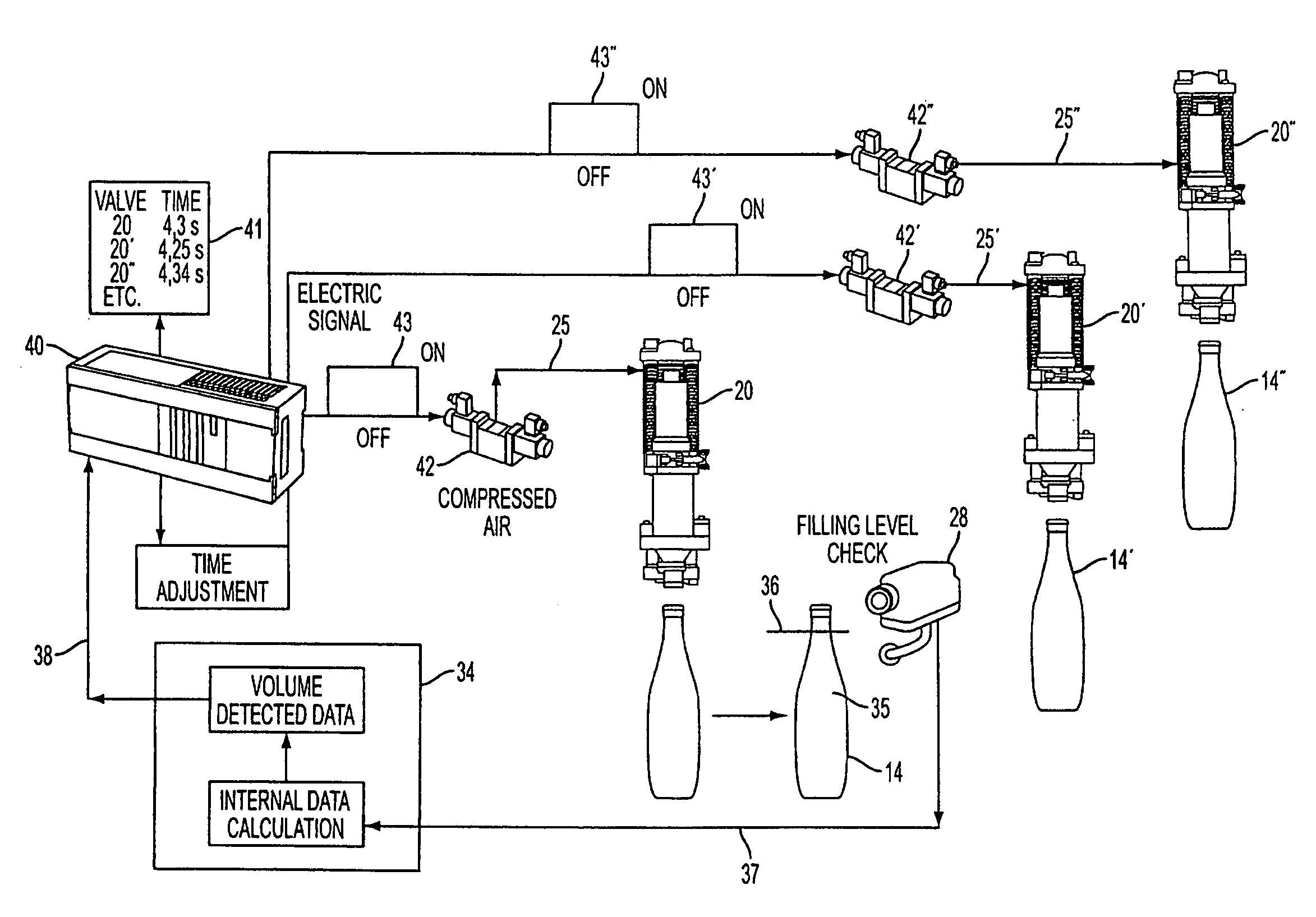

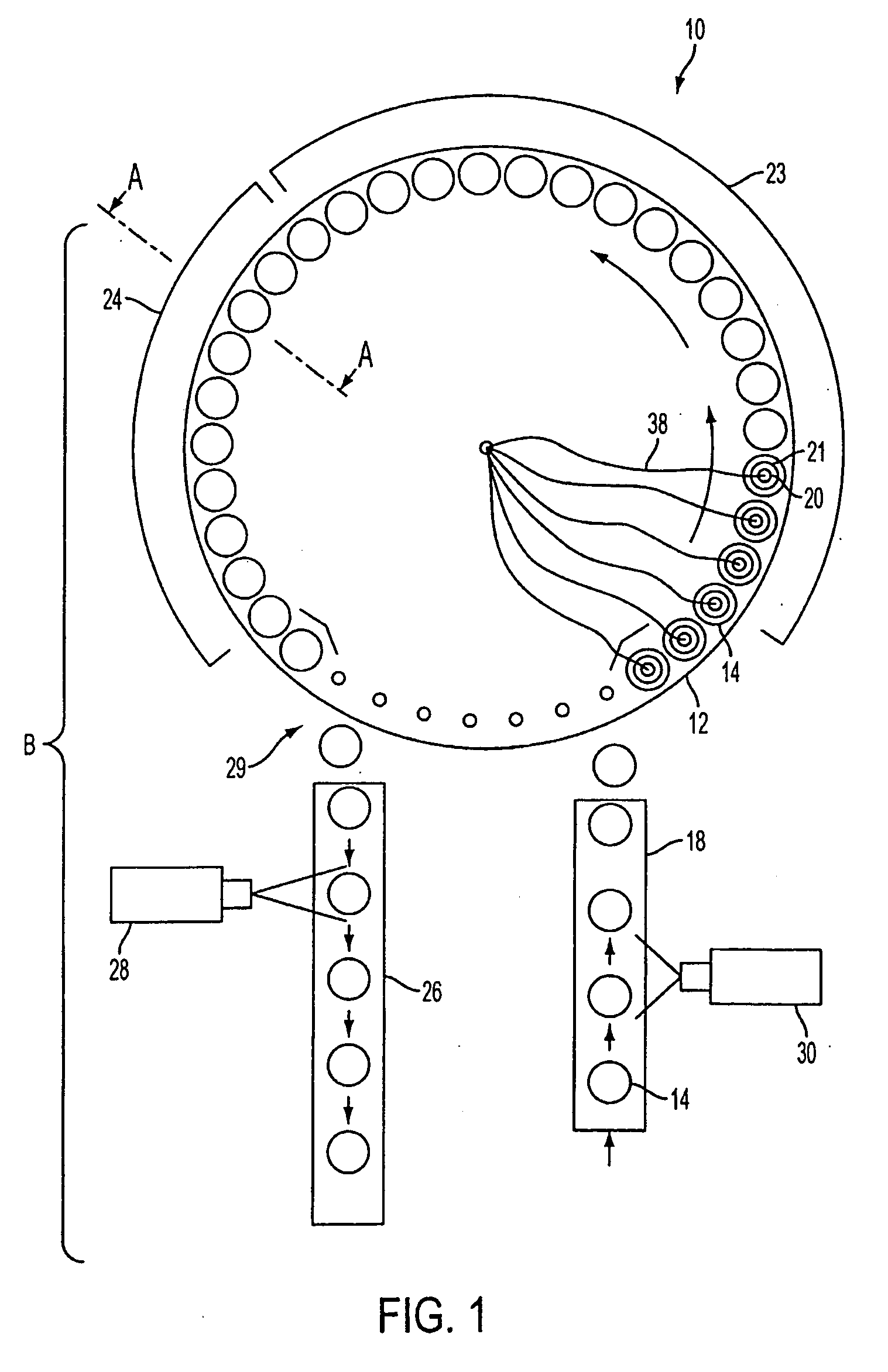

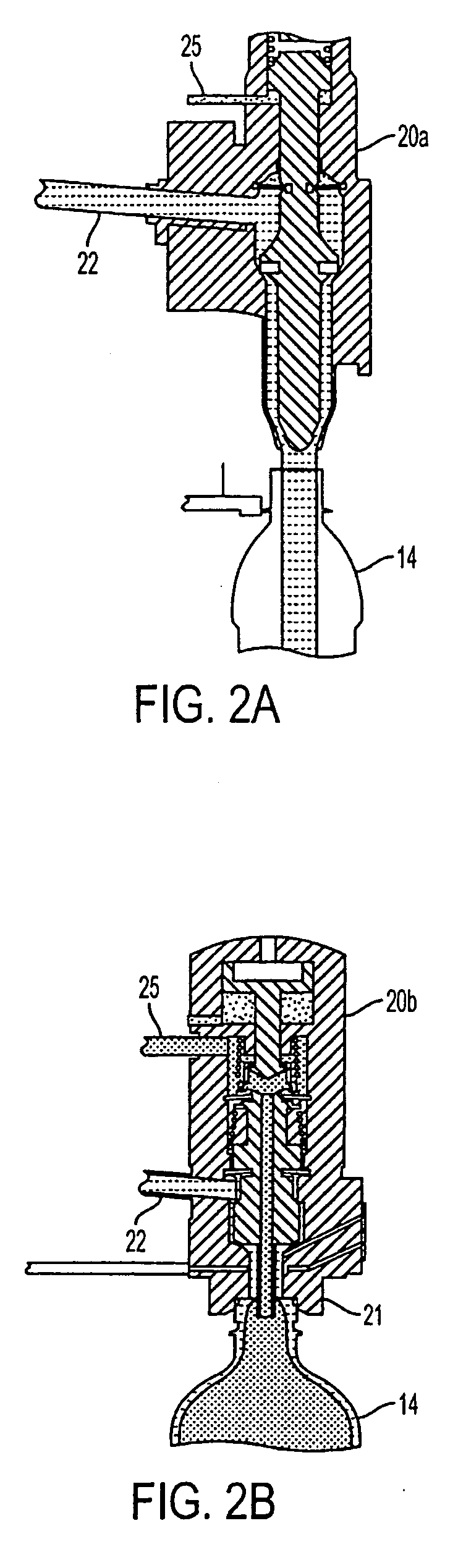

Bottle filling machine with sensor and method thereof

InactiveUS20070107801A1Reduce generationImprove trustVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

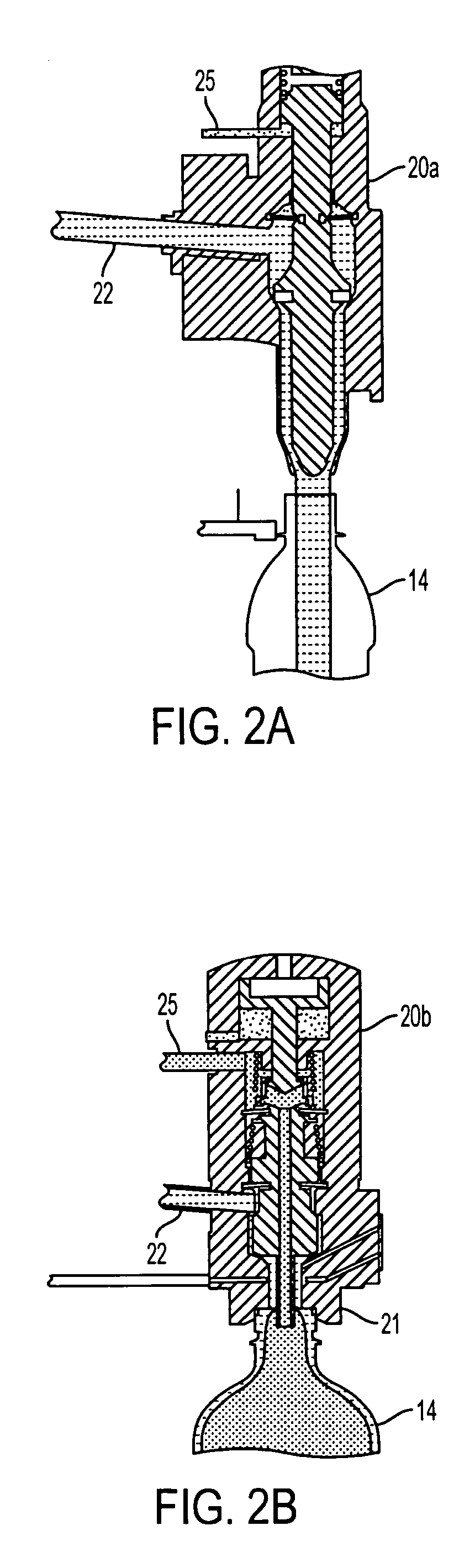

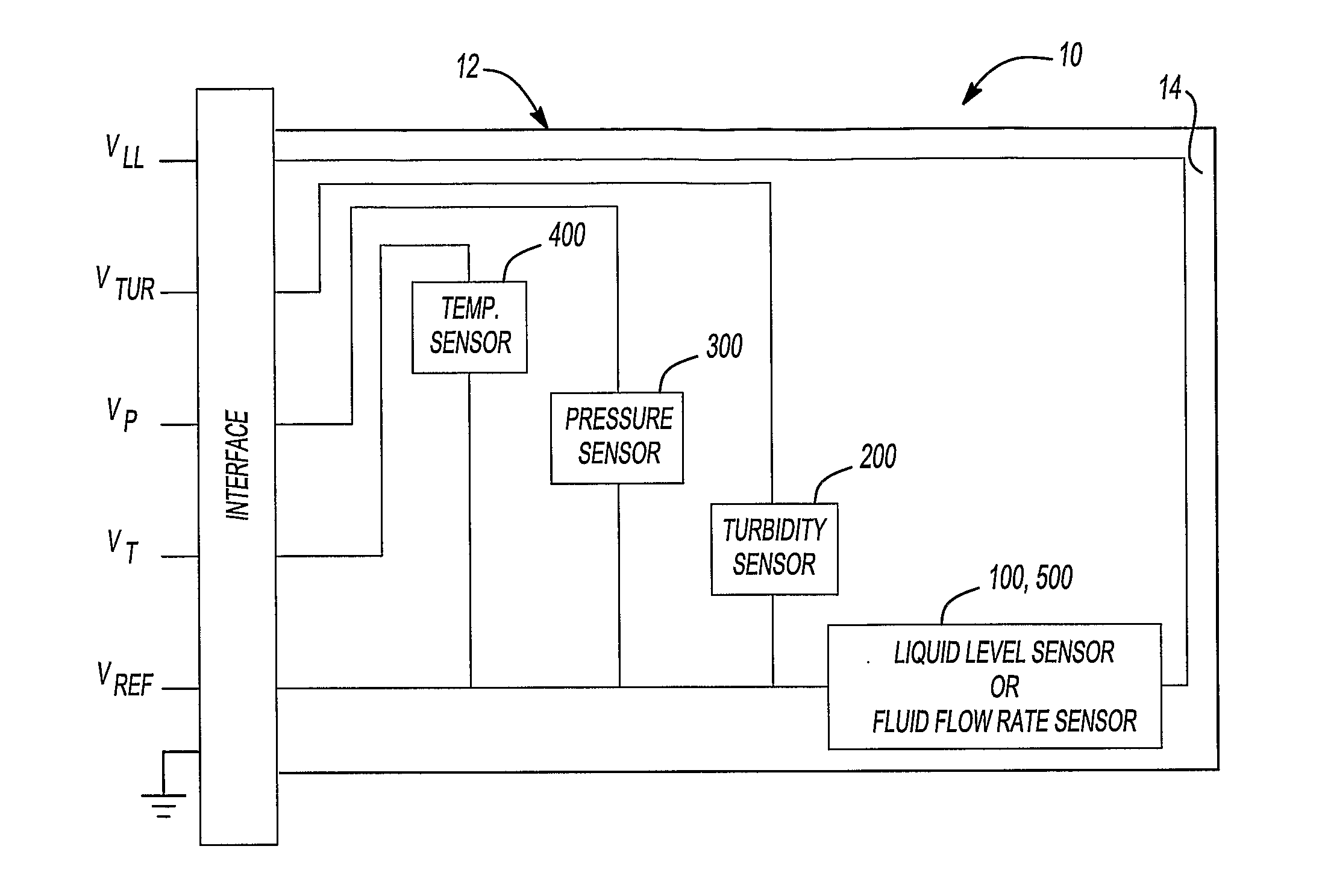

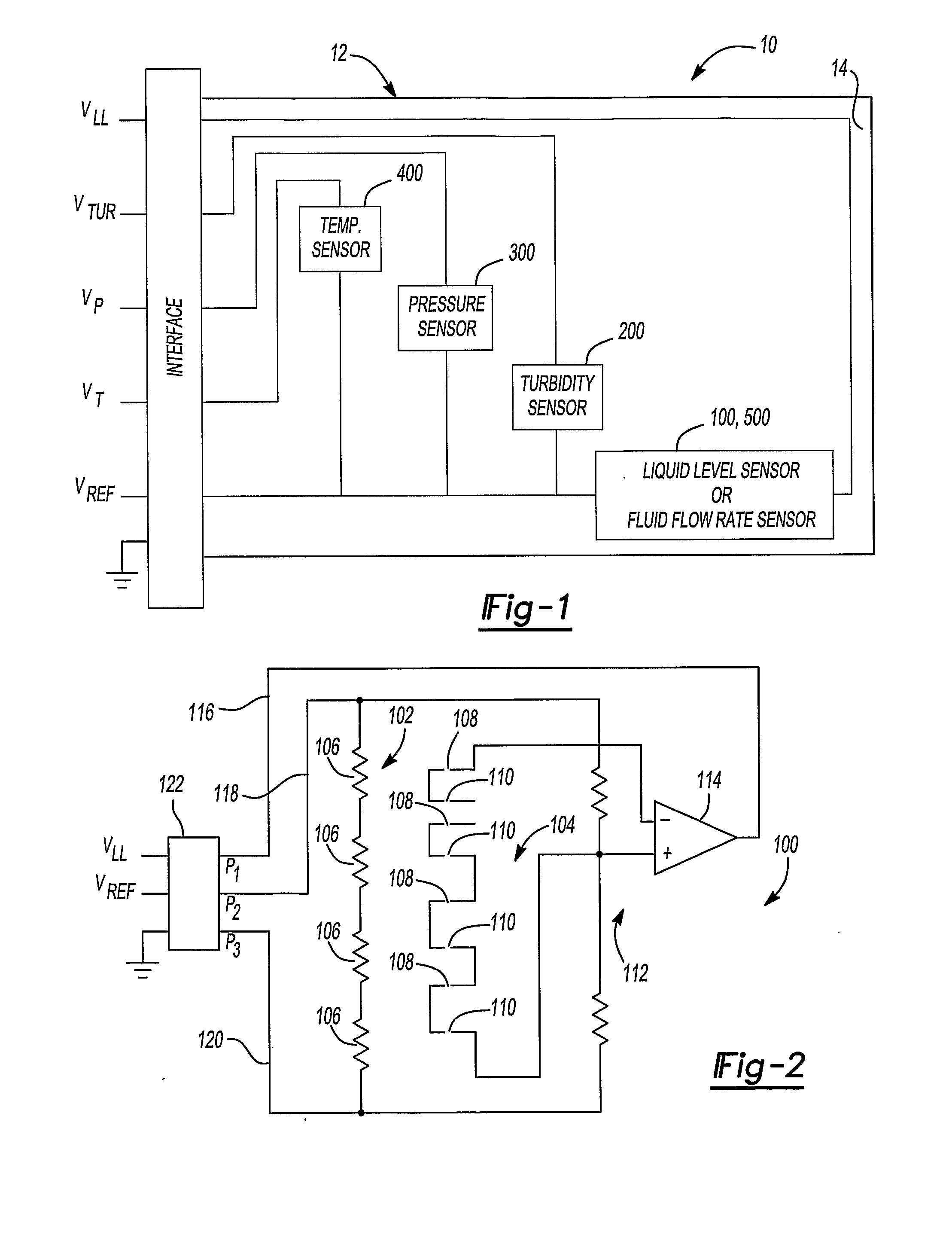

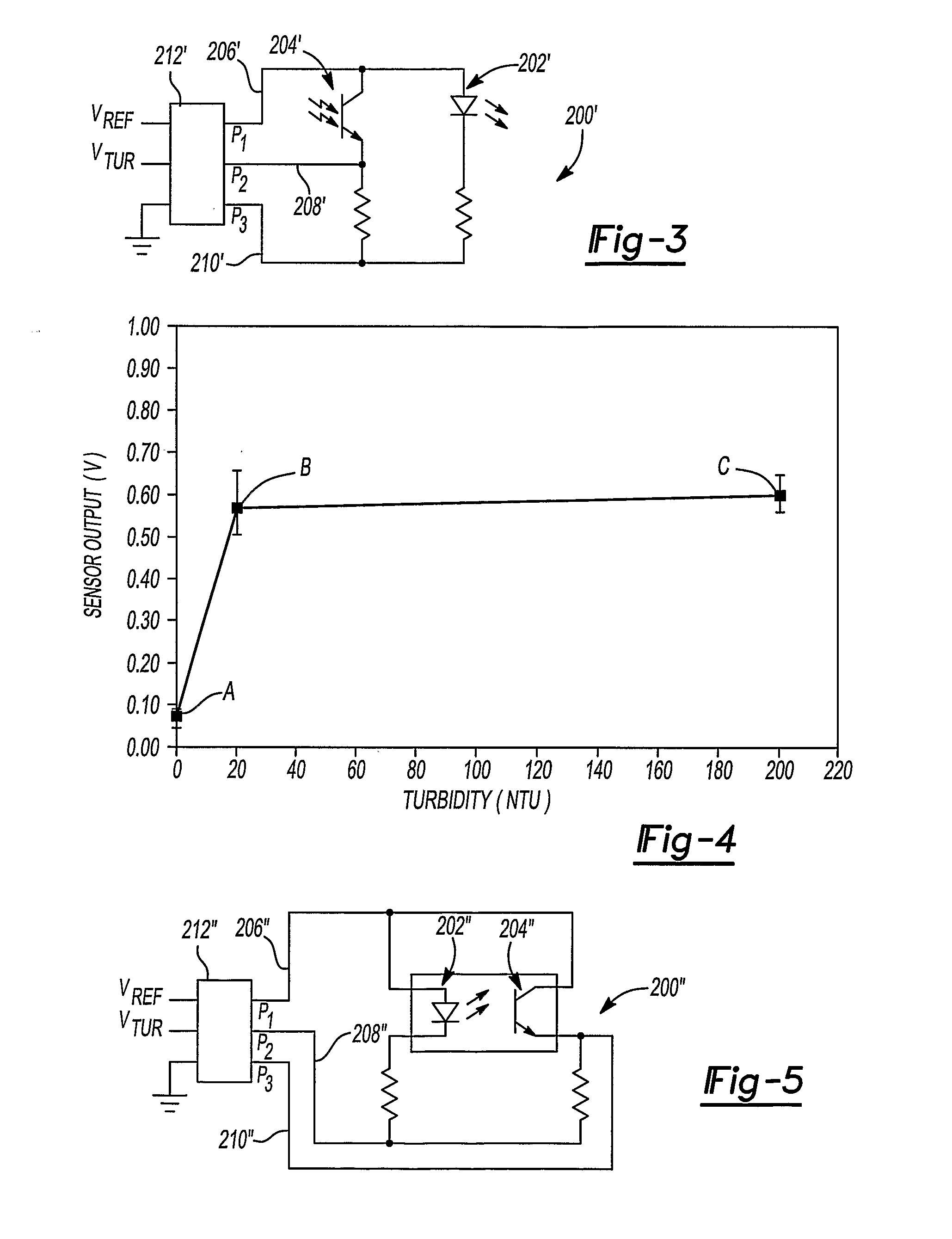

Multi-Function Sensor

InactiveUS20080107151A1Simple and compact designReduce manufacturing costVibration measurement in solidsThermometer detailsTurbidityEngineering

A multi-function sensor is disclosed for measuring the conditions within a container, such as fluid level, turbidity, temperature and pressure. The sensor incorporates a fluid level sensor module, a turbidity sensor module, a temperature sensor module and a pressure sensor module. The fluid level sensor module utilizes a plurality of thermocouple junctions grouped in pairs with the pairs being spaced along a line extending generally in the direction in which the liquid level may vary. The thermocouple junctions are connected in series and produce a signal indicative of the level along the sensor. Turbidity, temperature, and pressure sensor modules may also be incorporated in the multi-function sensor. Alternatively, a fluid flow rate sensor module may be included in place of the liquid level sensor module.

Owner:THERM O DISC

Point of sale inductive systems and methods

InactiveUS20110259960A1Wave amplification devicesStatic indicating devicesLevel sensorDisplay device

Systems and methods for the identification, powering and control of products and product packaging. The systems can include a point of sale display having a contactless power supply. The contactless power supply can provide a source of wireless power for products and product packaging. The products and product packaging can include light emitting diodes, e-ink displays and printed speaker circuits that activate as the operating frequency of the contactless power supply varies. Other embodiments include product level sensors, inductive reader networks, printed temperature sensors, product alignment systems, passive identification circuits and methods for controlling operation of the same.

Owner:PHILIPS IP VENTURES BV

Apparatuses and methods for managing liquid volume in a container

An apparatus and method for managing a liquid volume in a container includes a detector for detecting liquid volume changes in the container during a first preset period, a first determiner for determining whether the changes are lower than the first preset threshold value, and a presenter for presenting the first prompt information in case the changes are lower than the preset threshold value.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Gauge for accurately measuring precipitation

InactiveUS6044699AReduce accumulationGreat up-wellingRainfall/precipitation gaugesMachines/enginesSnowpackElectrical energy consumption

A precipitation gauge that collects liquid and frozen precipitation in a reservoir, suspended by force-sensing transducers, permitting the accurate and precise measurement of accumulated precipitation. A proportionally-heated collector assembly prevents the accumulation of frozen rain or snow on the collector inner surface, converting it into water that enters the reservoir, with minimum electrical energy consumption. The force-sensing transducer may be a programmably excited vibrating strip transducer.

Owner:BELFORT INSTRUMENT COMPANY

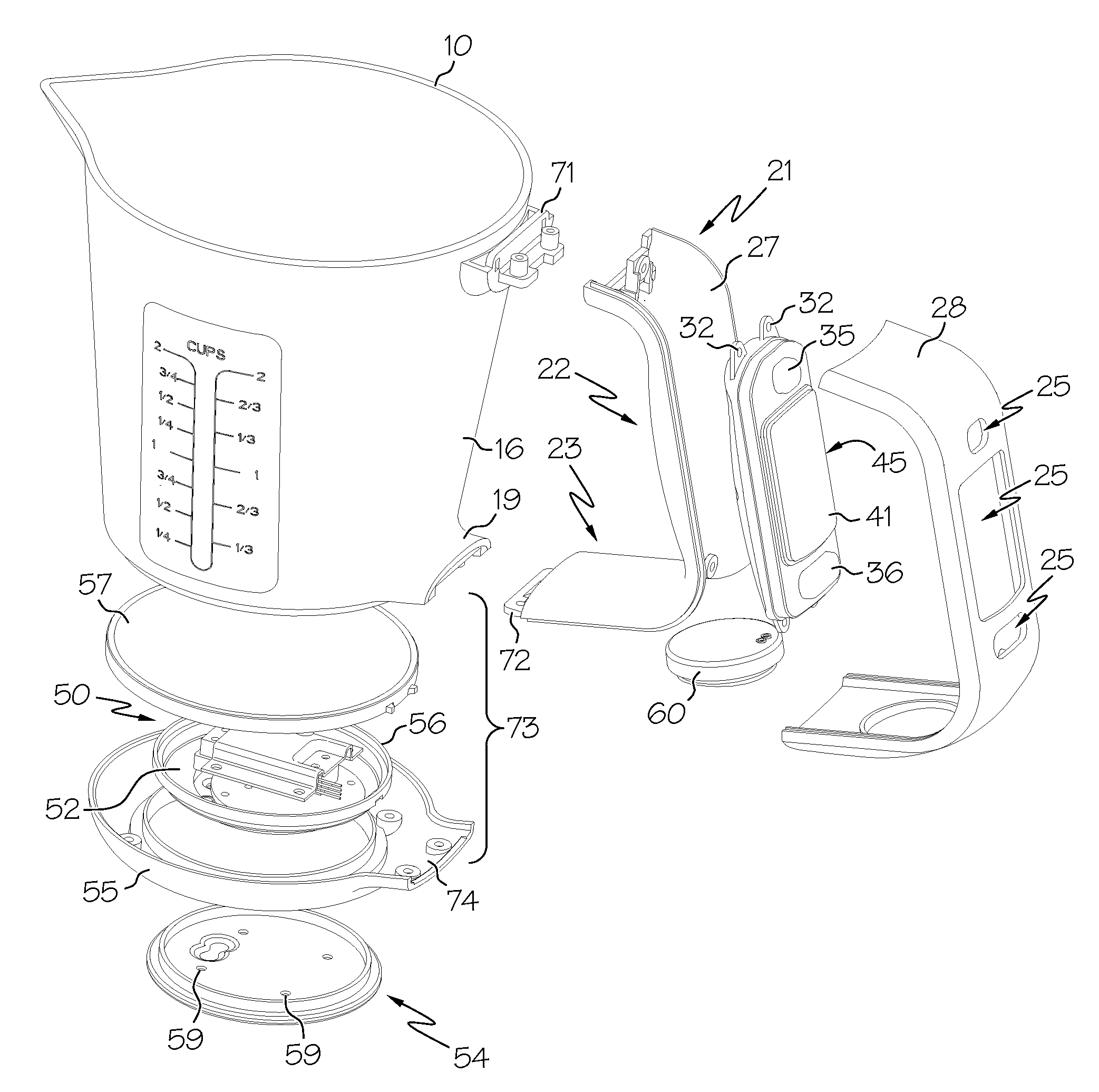

Food product measuring vessel with integrated scale

InactiveUS20100089152A1Easy to manufactureReduce distractionsWeighing auxillary devicesCapacity measurement calibrationEngineeringLoad cell

The present invention comprises a portable measuring vessel with a removably attached digital measuring device. The digital measuring device includes one or more load cells, one or more processors, an input unit, and an output unit. Preferably the input unit is one or more finger-actuatable switches and the output unit is a visual display, such as an LCD. The processor is connected to the input, output, load cell and power source, thereby making a convenient, portable and easily used product.

Owner:PRIORITY WORX

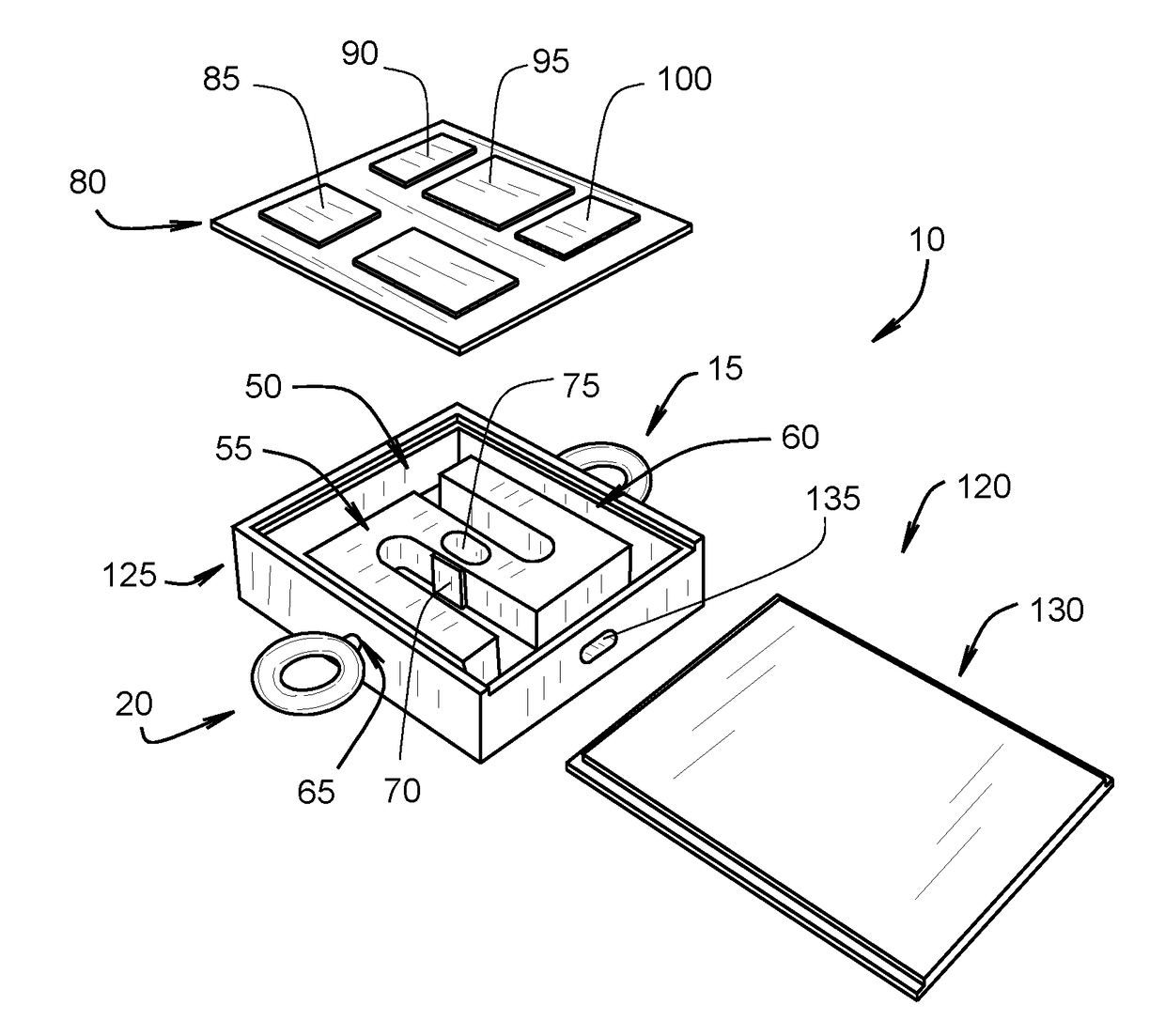

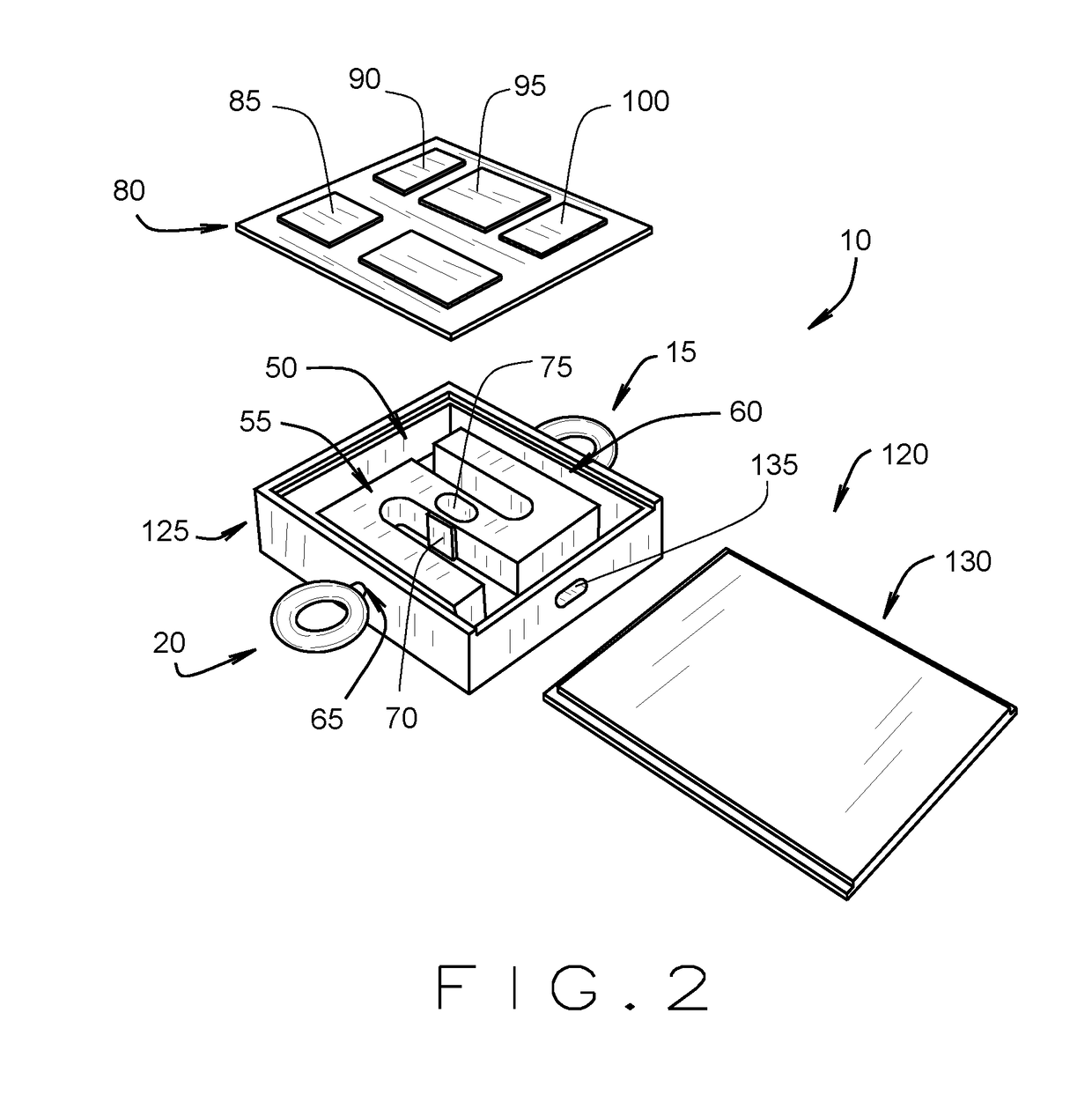

Device for measuring and displaying the amount of beer in a keg

InactiveUS7255003B2Weighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDisplay deviceEngineering

A scale for determining a quantity of material in a container such as a keg. The scale may include a support member configured to be placed under a portion of the container, a display to indicate the quantity of material in the container, and a weight sensor positioned underneath the support member to determine the quantity of material in the container and to provide a signal to the display.

Owner:SCHNEITER CALVIN R

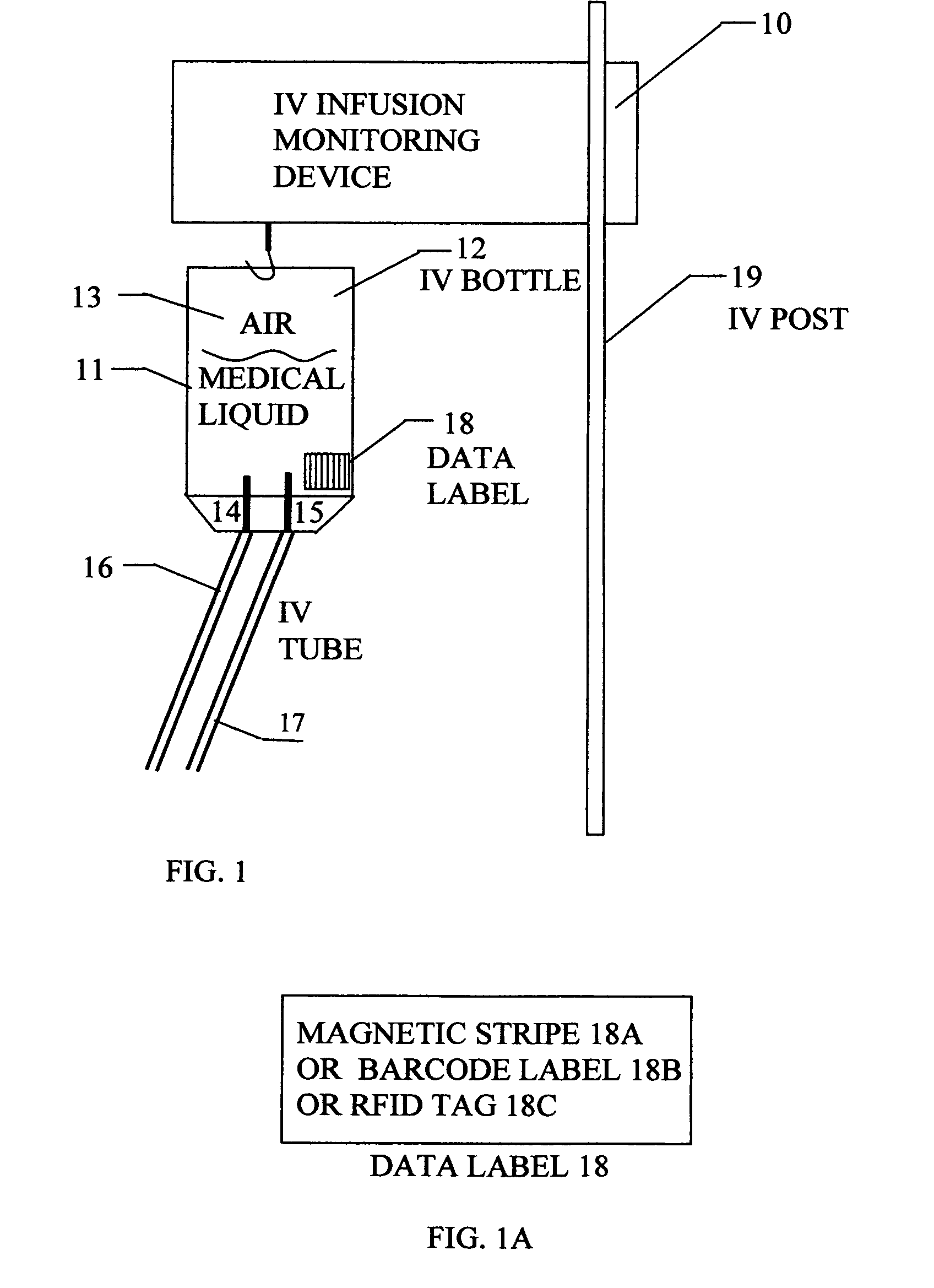

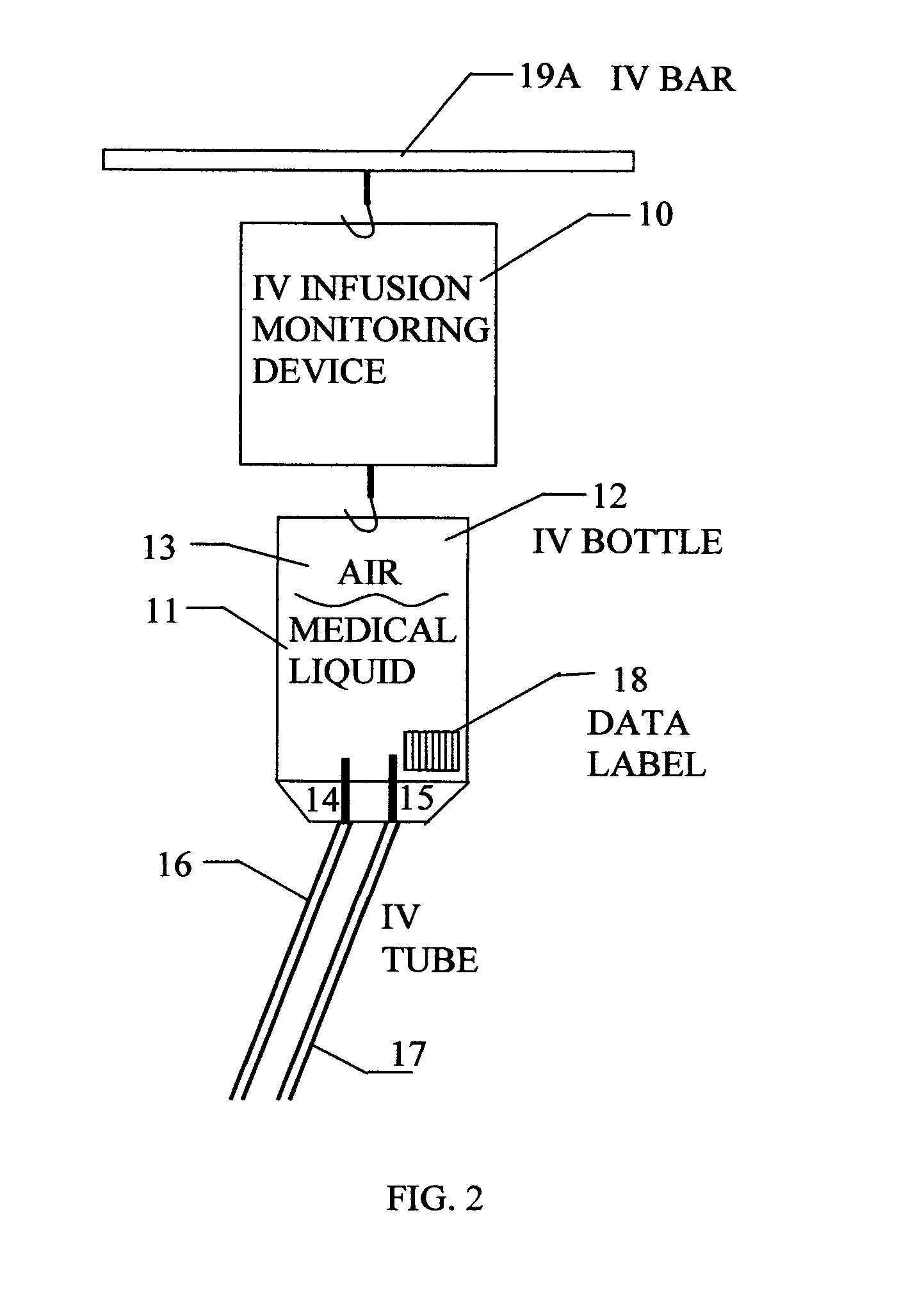

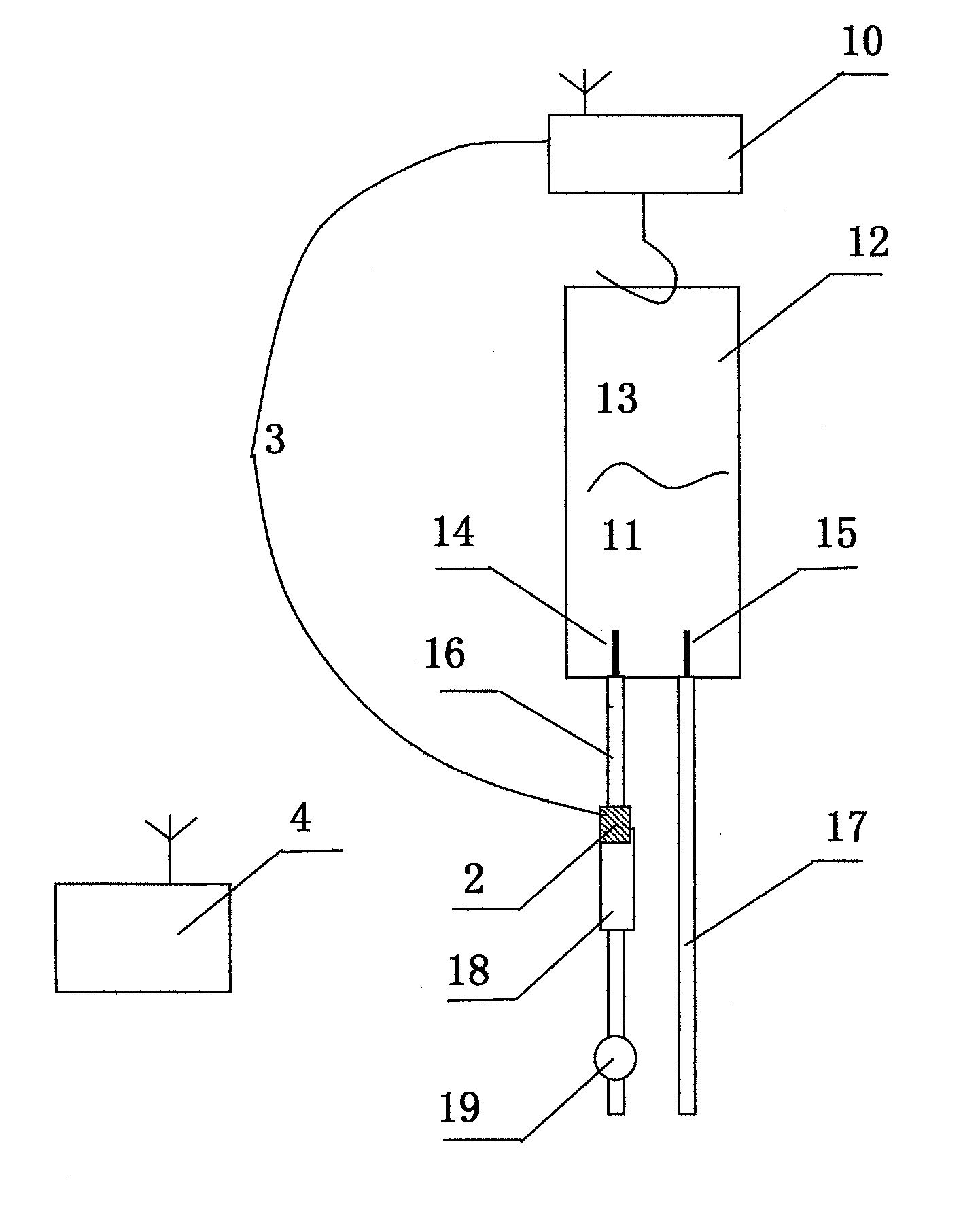

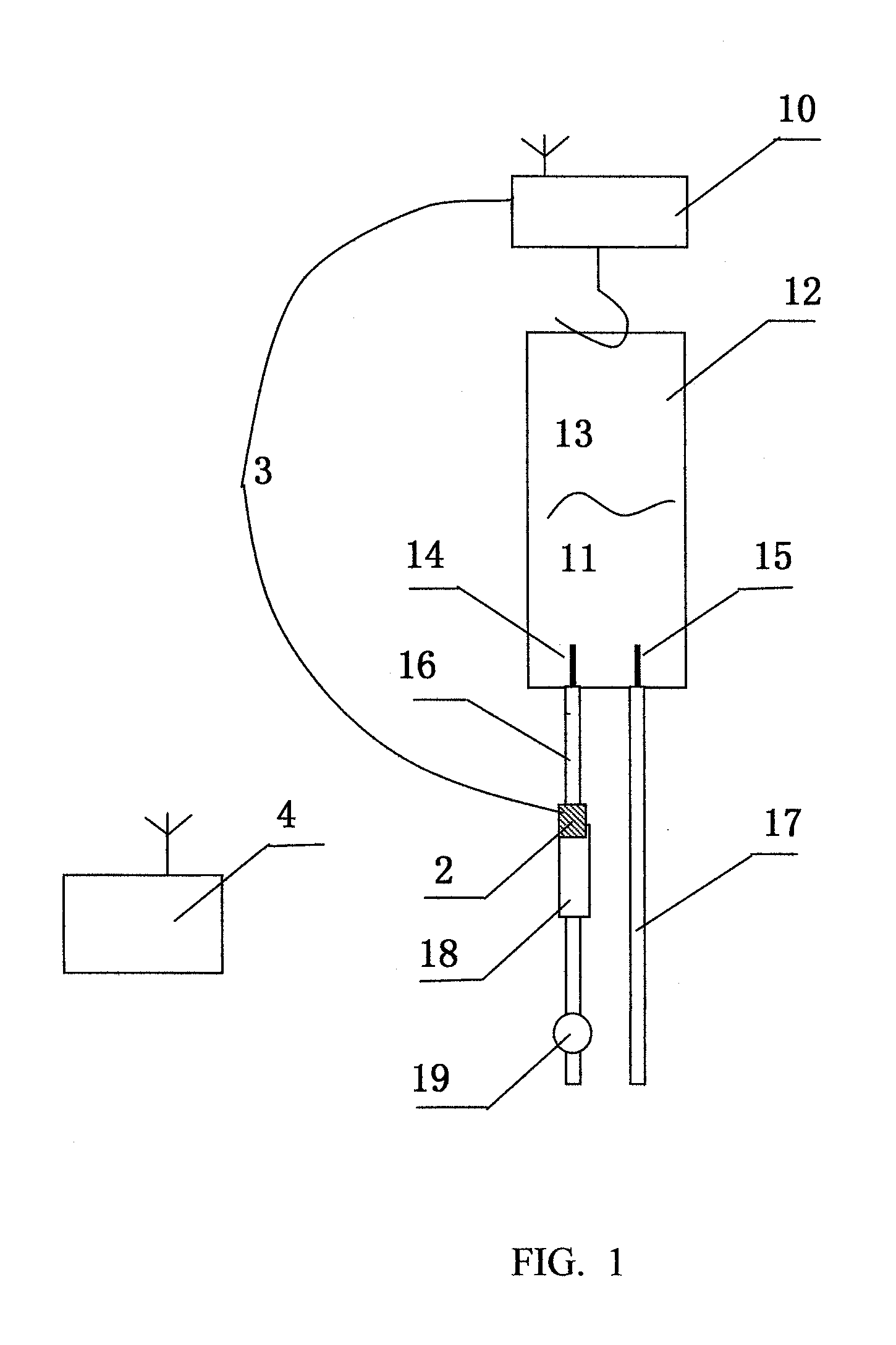

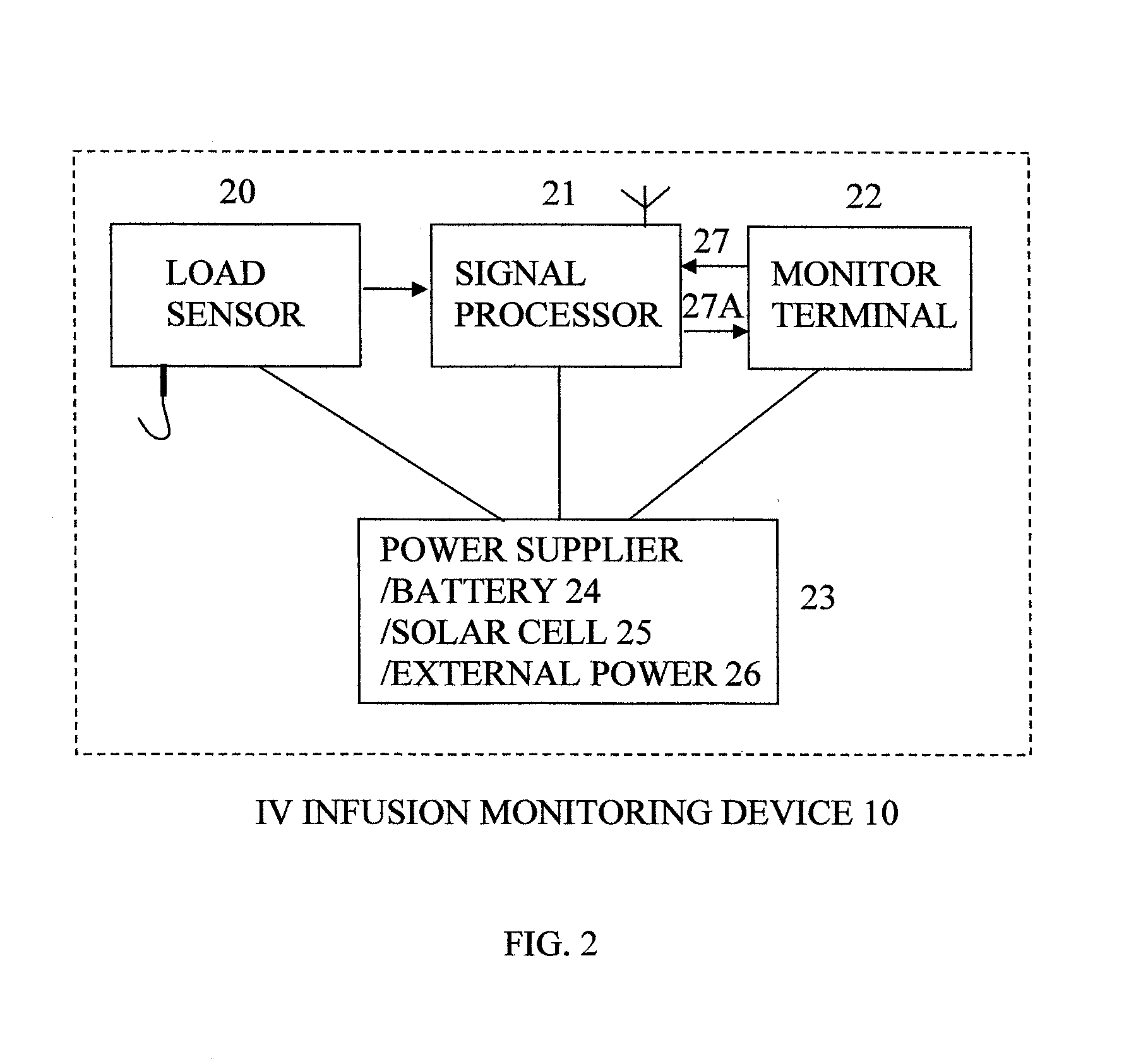

IV infusion monitoring device

InactiveUS20110205074A1Easy to useDrug and medicationsVolume/mass flow measurementMonitoring systemIV Infusion

An IV infusion monitoring device is provided to measure and to display, during whole infusion process, the liquid level data including the weight of remaining medical liquid in an IV bottle, the liquid flow rate and the remaining time from the completion of an IV infusion process. It also gives alarm as the medical liquid in an IV bottle drops to a predetermined low level. The IV infusion monitoring system comprises an electric load sensor, a signal processor, a monitor terminal and a power provided preferably by a battery. The load sensor measures the weight of the medical liquid in the IV bottle. The measured signal is then transmitted to the signal processor for processing and generating the liquid level data, which are then sent to the monitor terminal for display. The monitor terminal can also generate an alarm if the liquid level drops to the predetermined value. Furthermore, the monitoring device combines with a server and a plurality of PDA devices to form a communication network so that a nurse can monitor the IV infusion process from a remote location.

Owner:FENG JUN +1

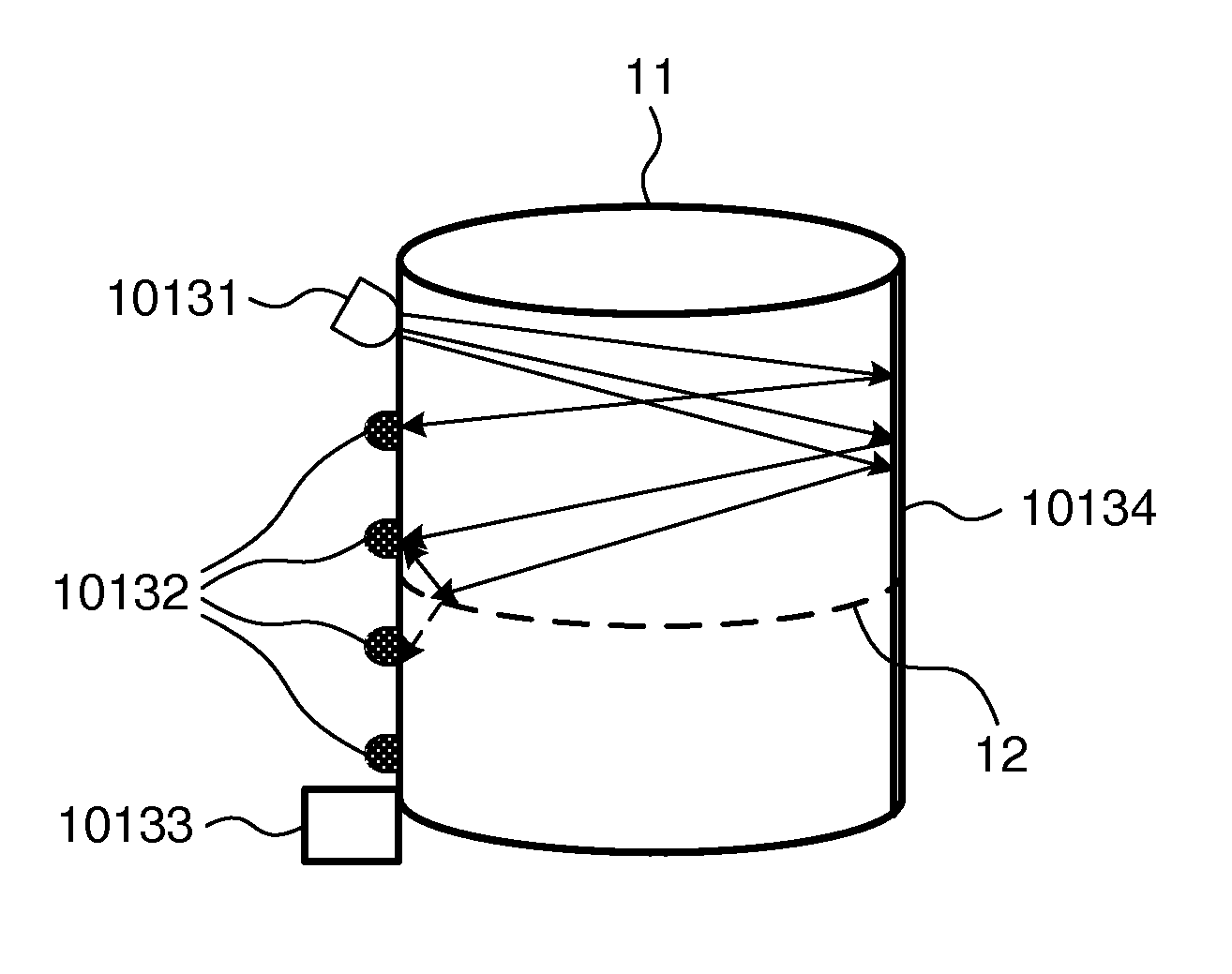

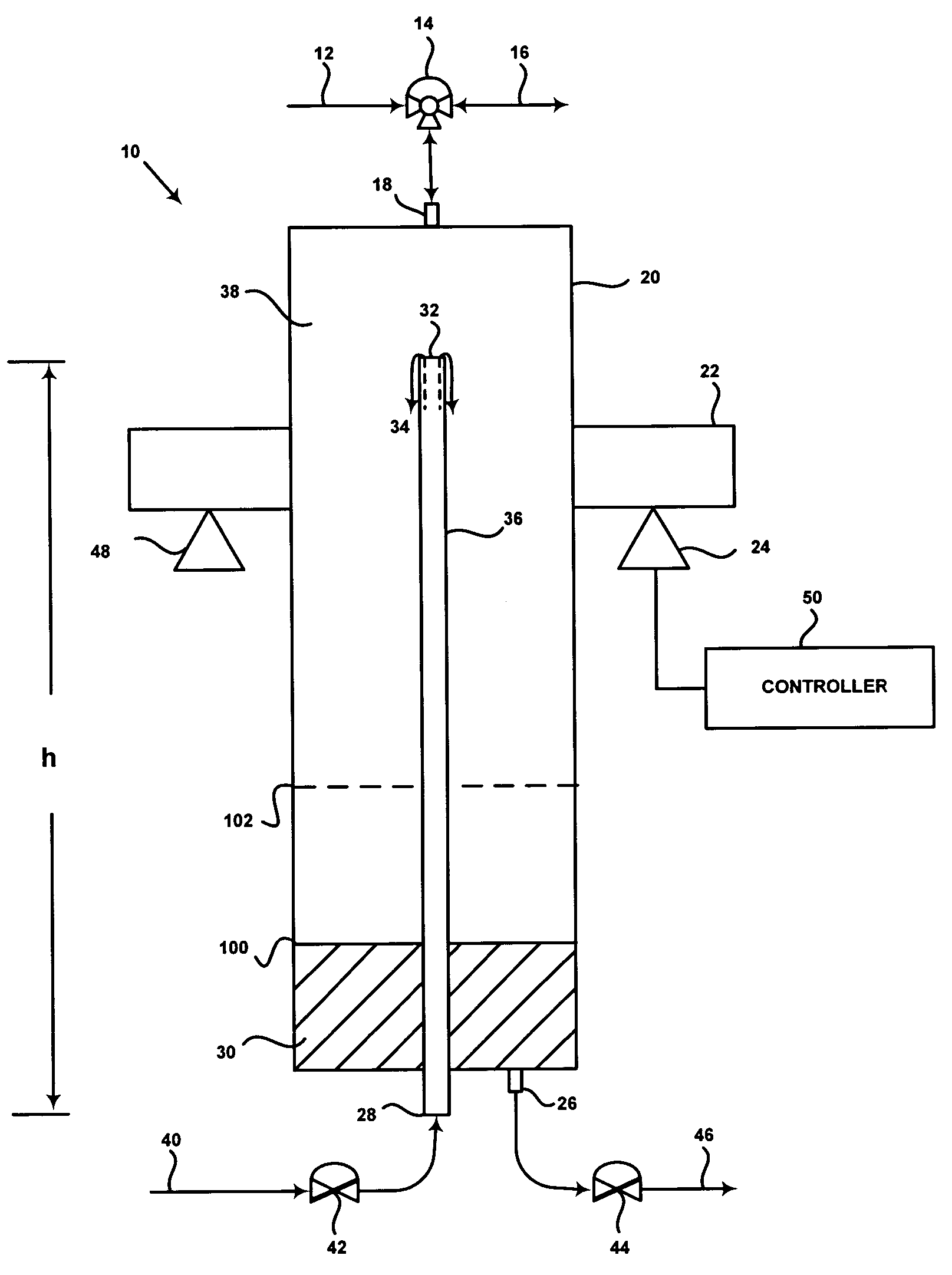

Weight measurements of liquids in flexible containers

InactiveUS20080213874A1Bioreactor/fermenter combinationsBiological substance pretreatmentsControl systemContinuous flow

Articles and methods for measuring weight of a liquid in a disposable bag bioreactor are presented. In certain embodiments, bioreactor systems described herein include a supported container (e.g., a flexible bag in a reusable housing) for containing a liquid, and at least two pressure indicating sensors operatively associated with the container. A first pressure indicating sensor can be placed near the bottom of the container to measure the total downward force within the container, including the liquid head in the container and the gas pressure above the liquid. The second pressure indicating sensor can be placed near the top of the container to measure only the pressure at the top of or above the liquid. Signals from the pressure indicating sensors can be directed to a control system that receives the signals and calculates a difference between the signals. This difference can be used to determine a volume or a weight of the liquid in the container. Advantageously, real-time weight measurements can be obtained while the system is in operation and continuous flow processes can be monitored. Moreover, in some embodiments, the pressure indicating sensors are isolated from contact with any fluid (e.g., liquid) in the container and, therefore, do not require cleaning after processing of each batch of reactants. Contamination of the process fluid by contact with the pressure indicating sensors can also be avoided.

Owner:XCELLEREX INC

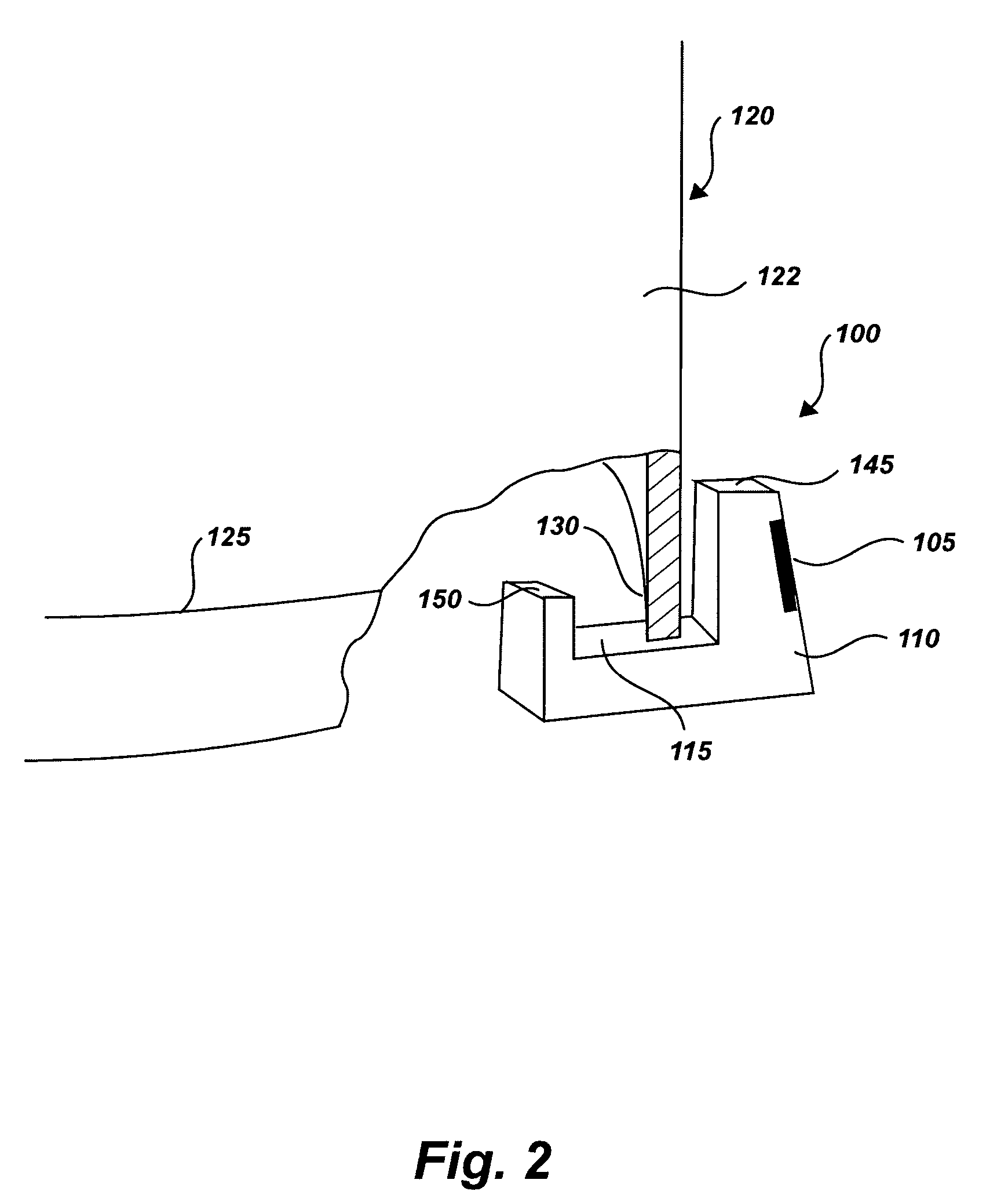

Method for Determining the Empty State of an IV Bottle in an IV Infusion Monitoring Device

InactiveUS20150346013A1Accurately determinedNeed can be replacedFlow propertiesDrug and medicationsMonitoring systemIV Infusion

A method for determining the empty state of an IV bottle is provided in an IV infusion monitoring device or in a networking monitoring system, which is cable to monitor the infusion data during whole infusion process. The infusion data includes the weight of remaining medical liquid in the IV bottle, the infusion rate and the remaining time from completion as well as the empty state. It also gives alarm as the measured gross weight of the IV bottle drops to the empty state. The empty state is determined preferably in terms of necking effect and needle tip effect, or their combination.

Owner:FENG JUN +1

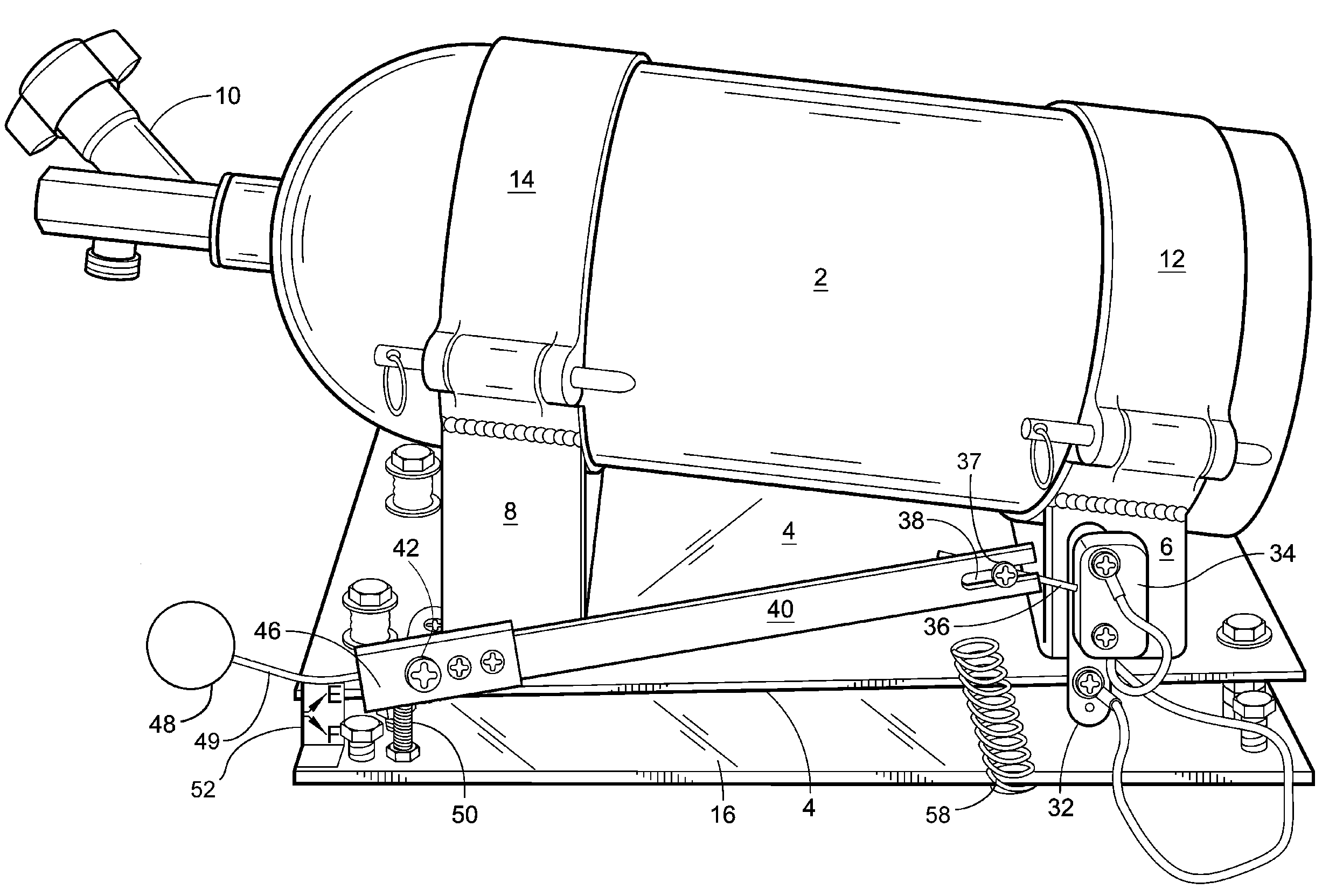

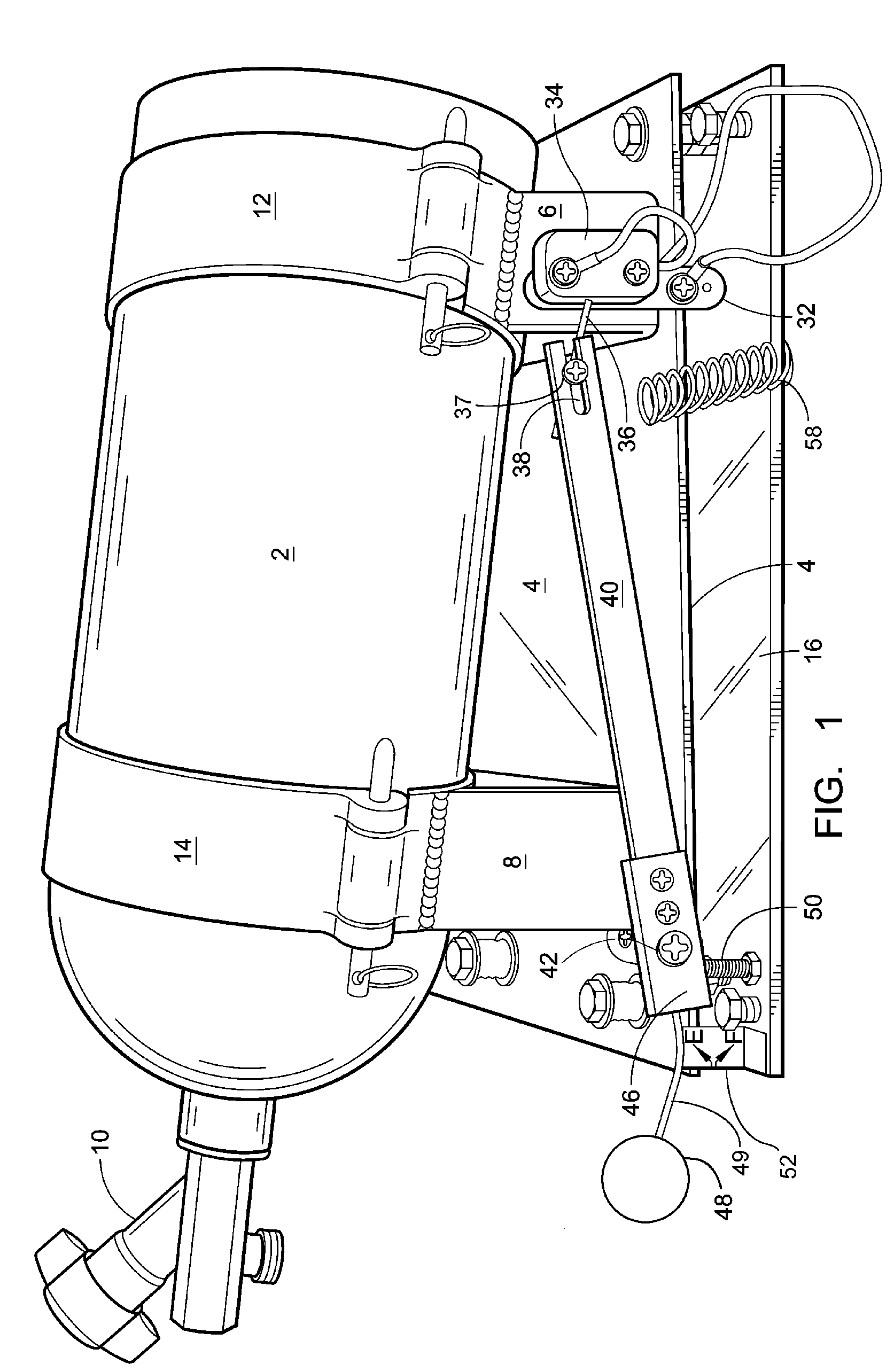

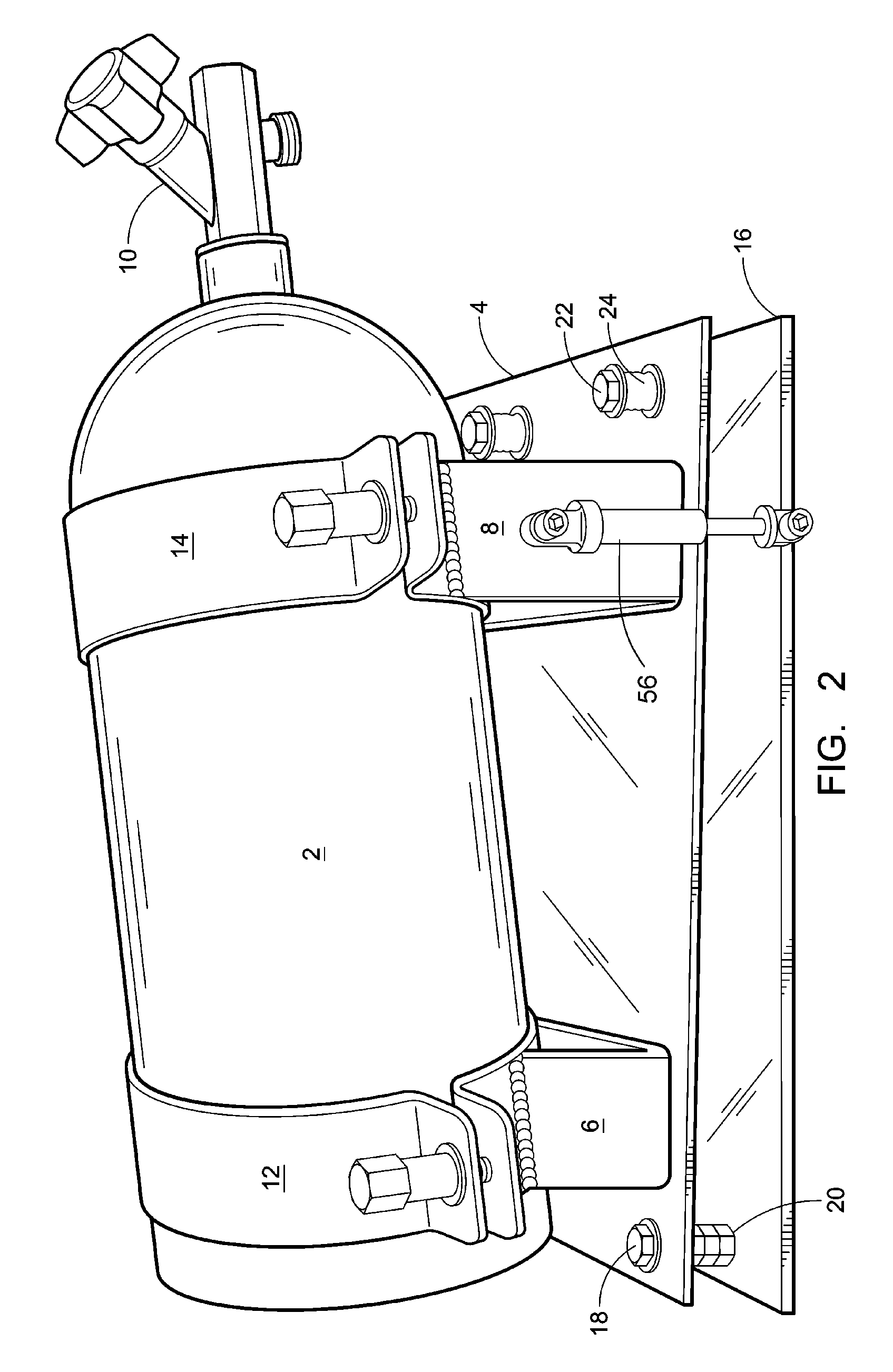

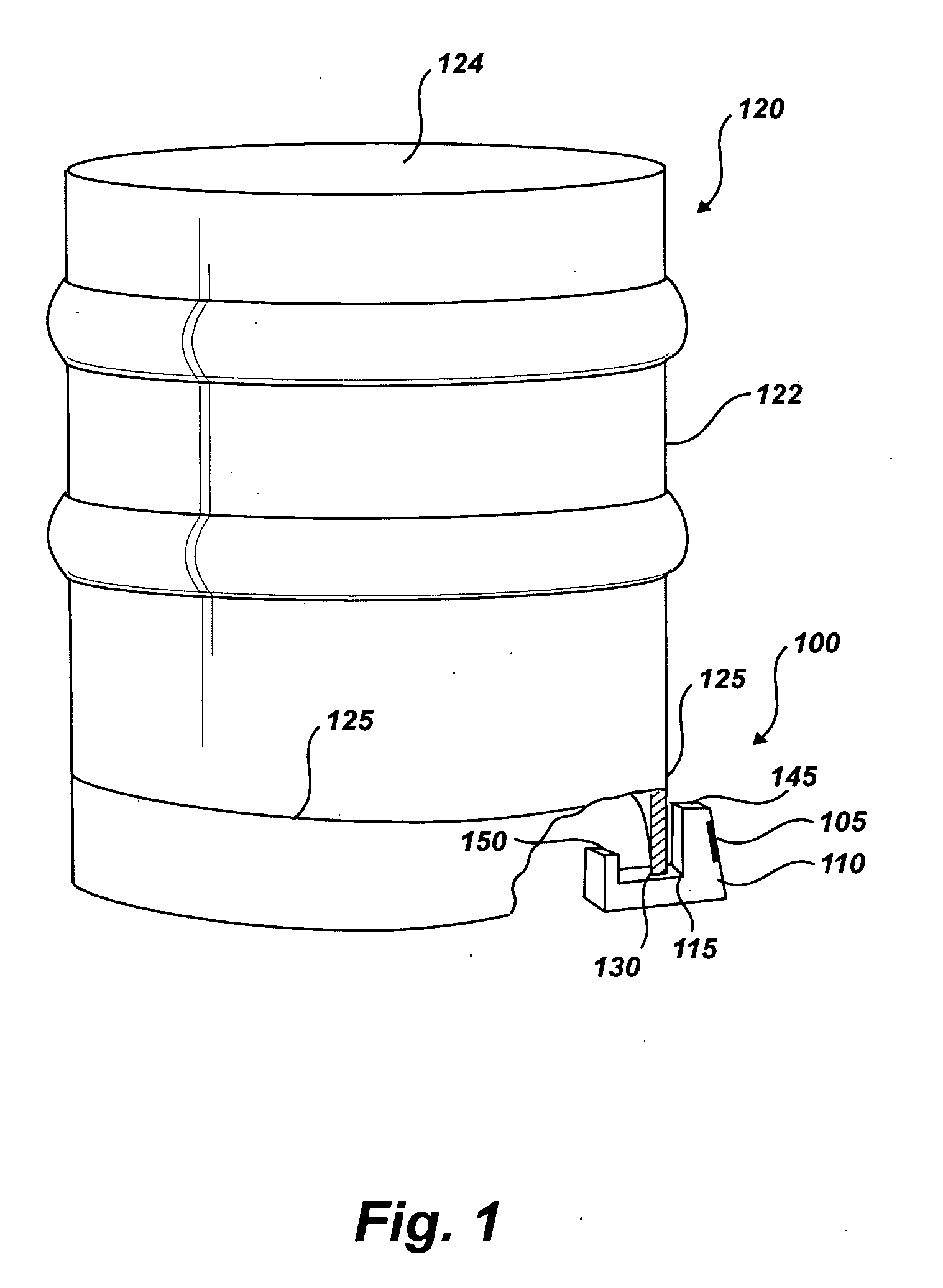

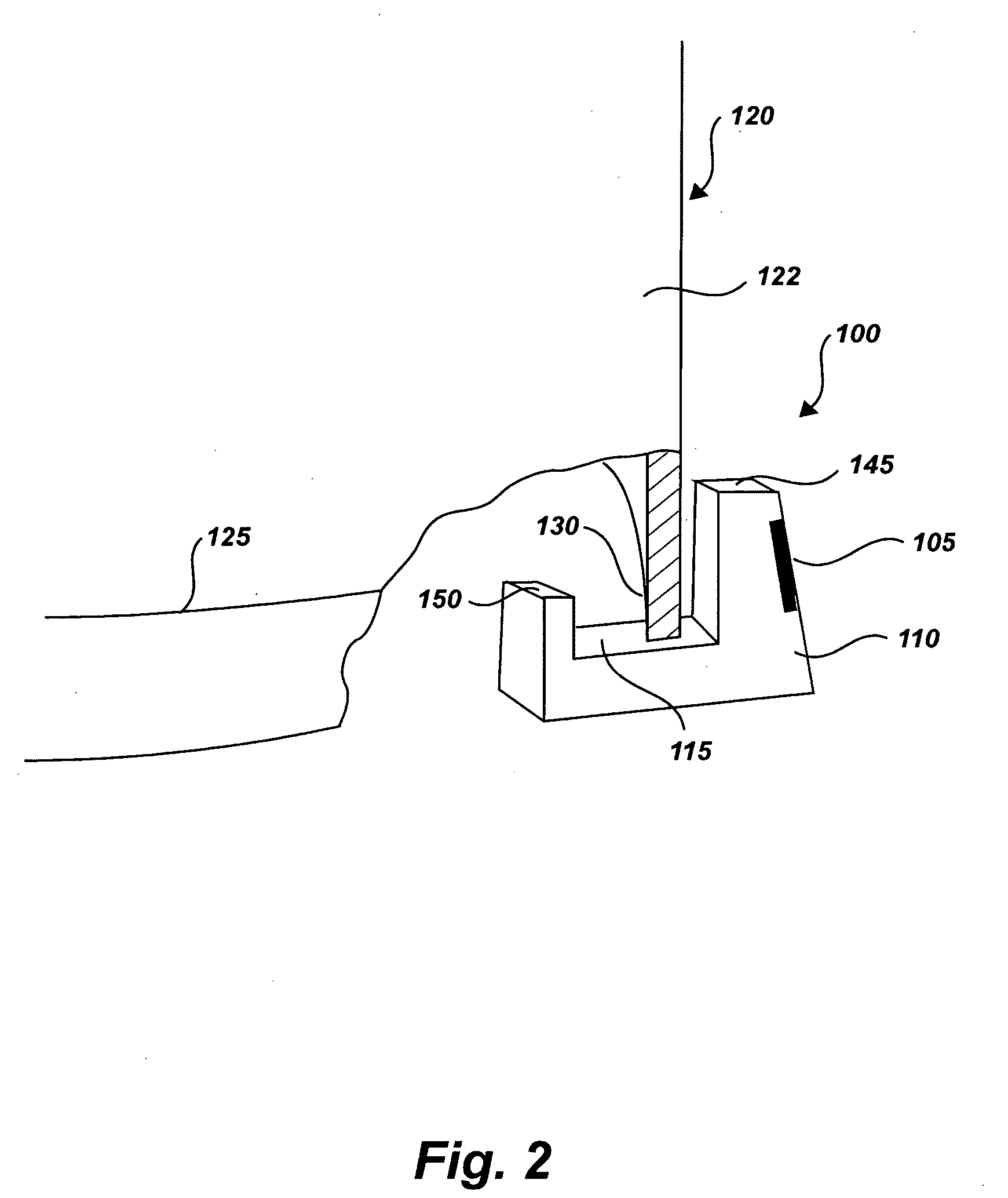

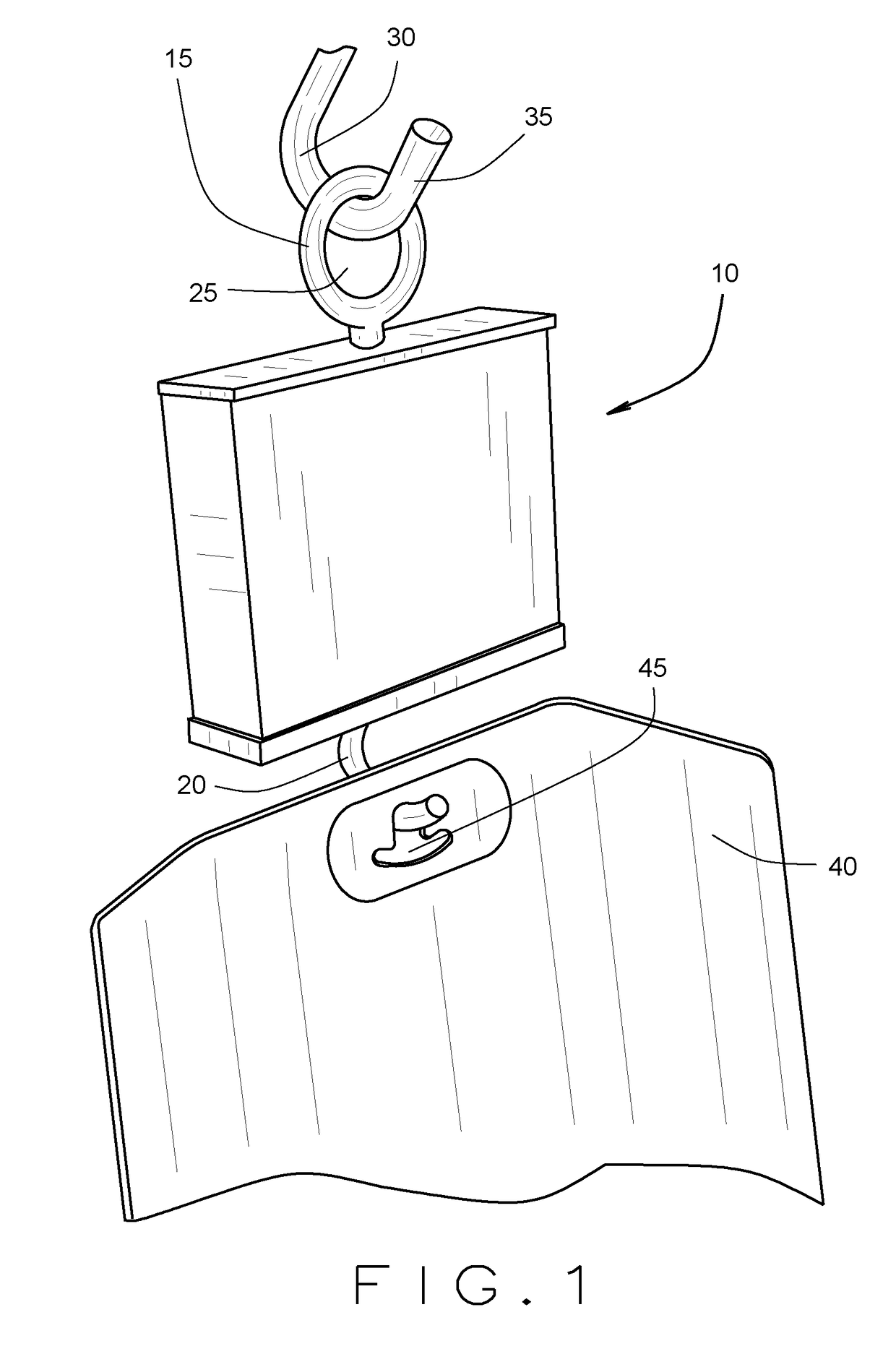

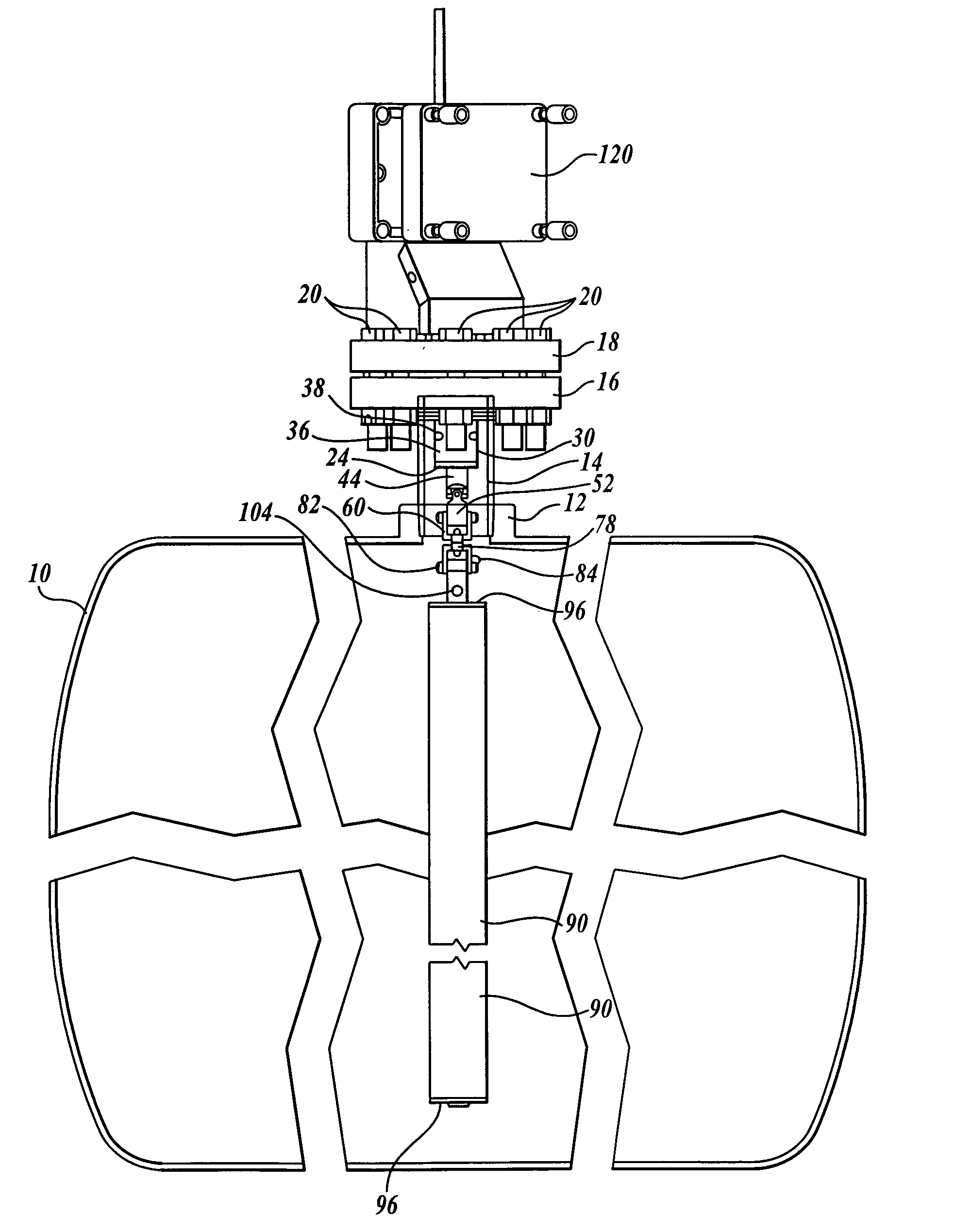

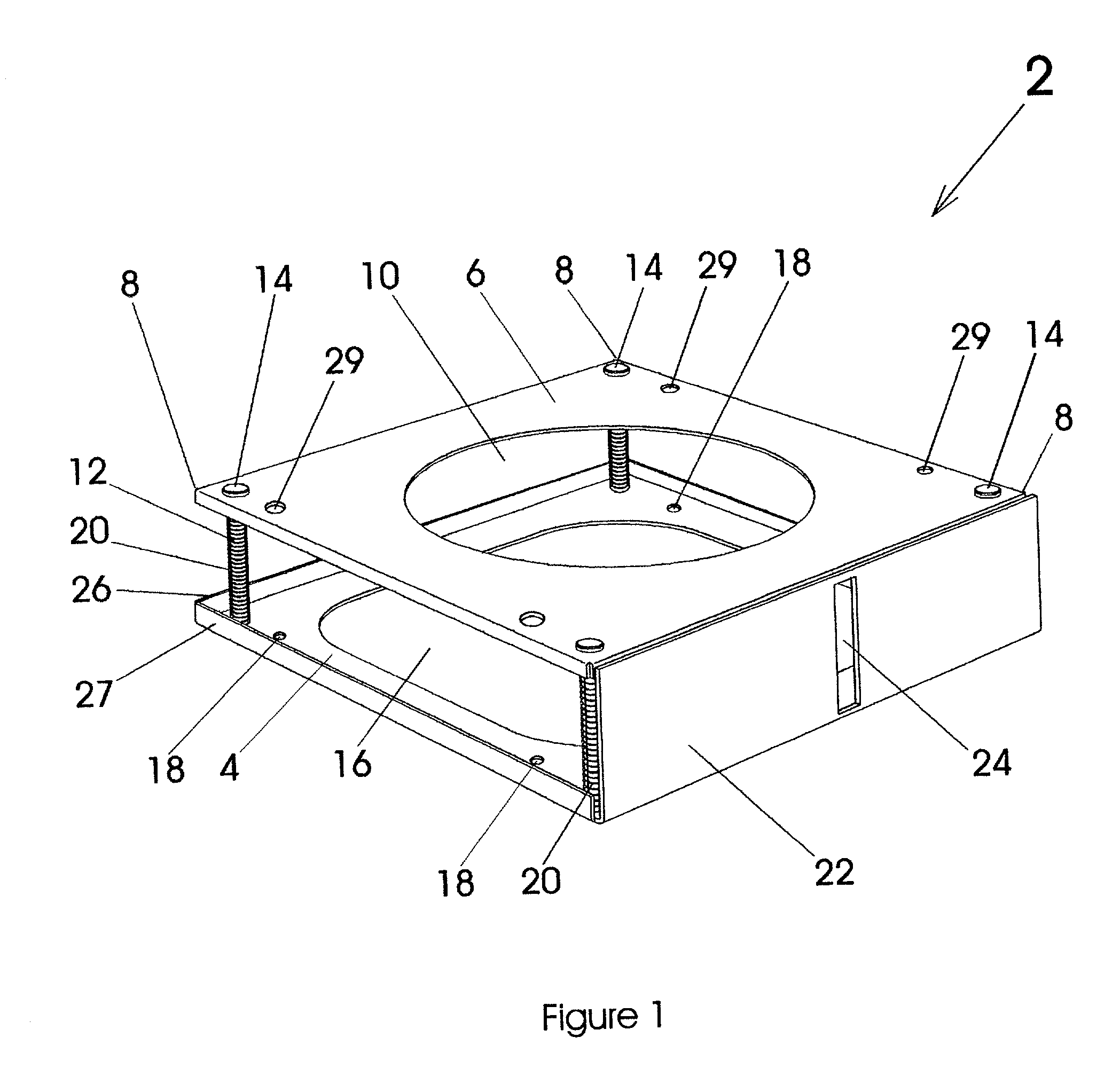

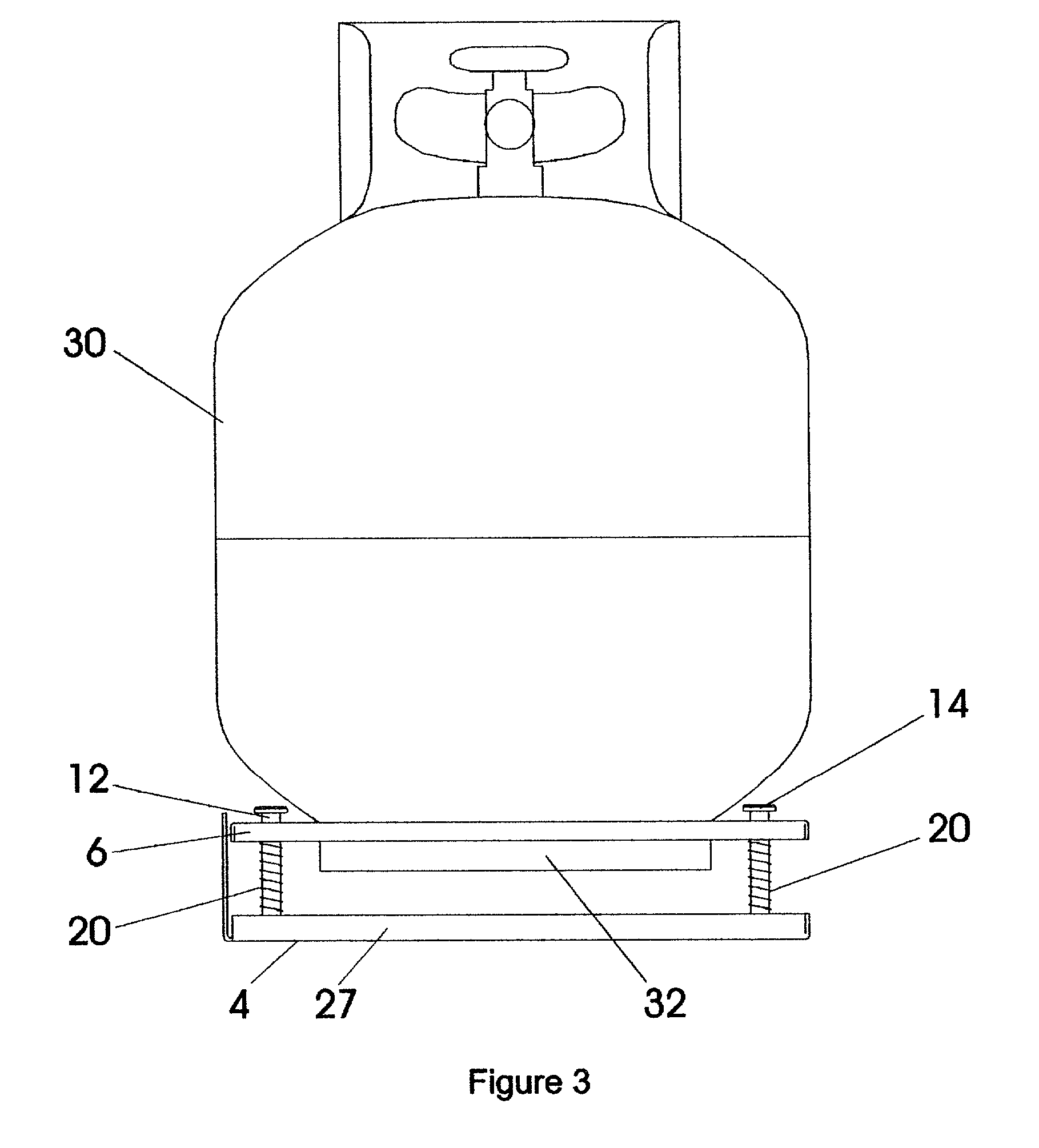

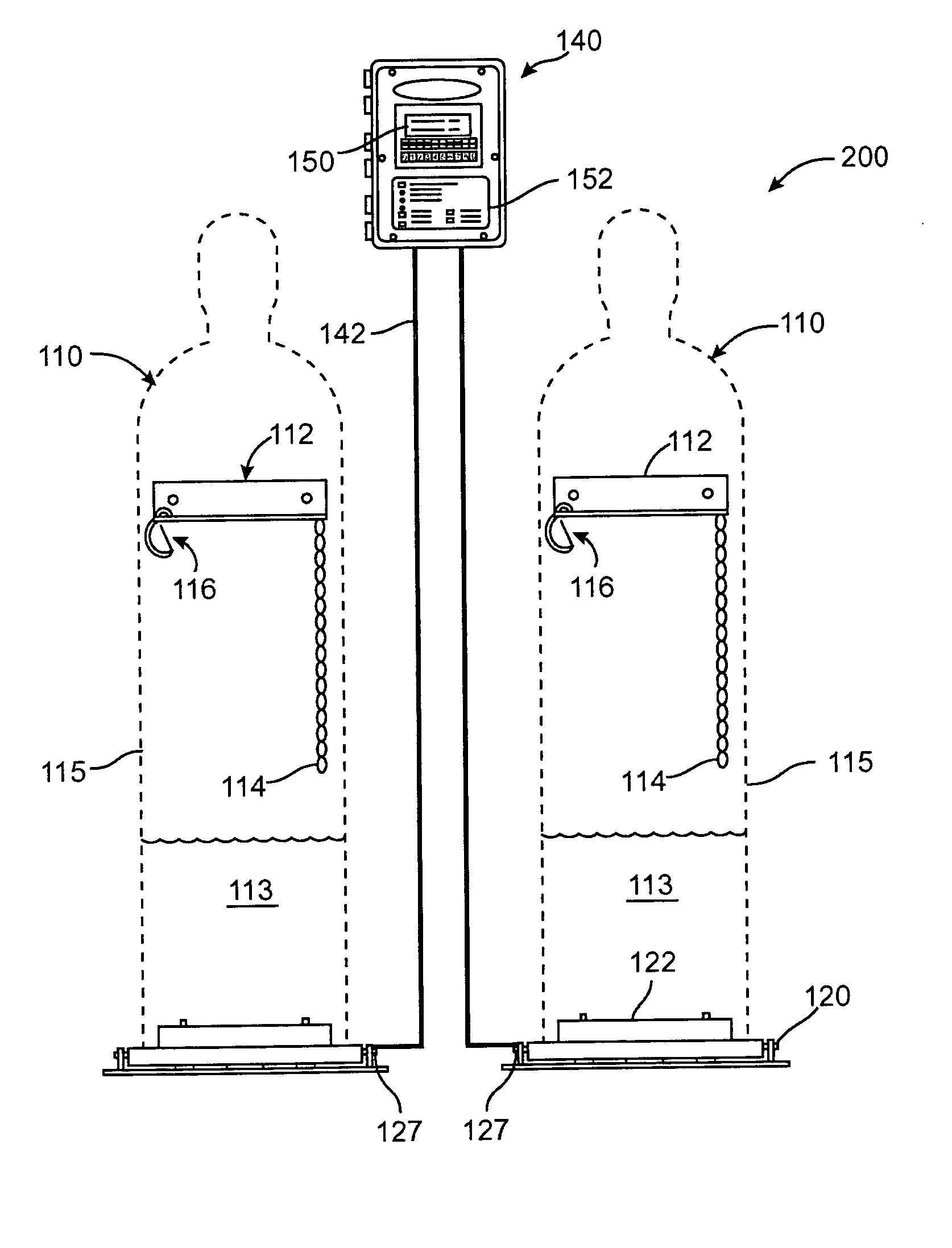

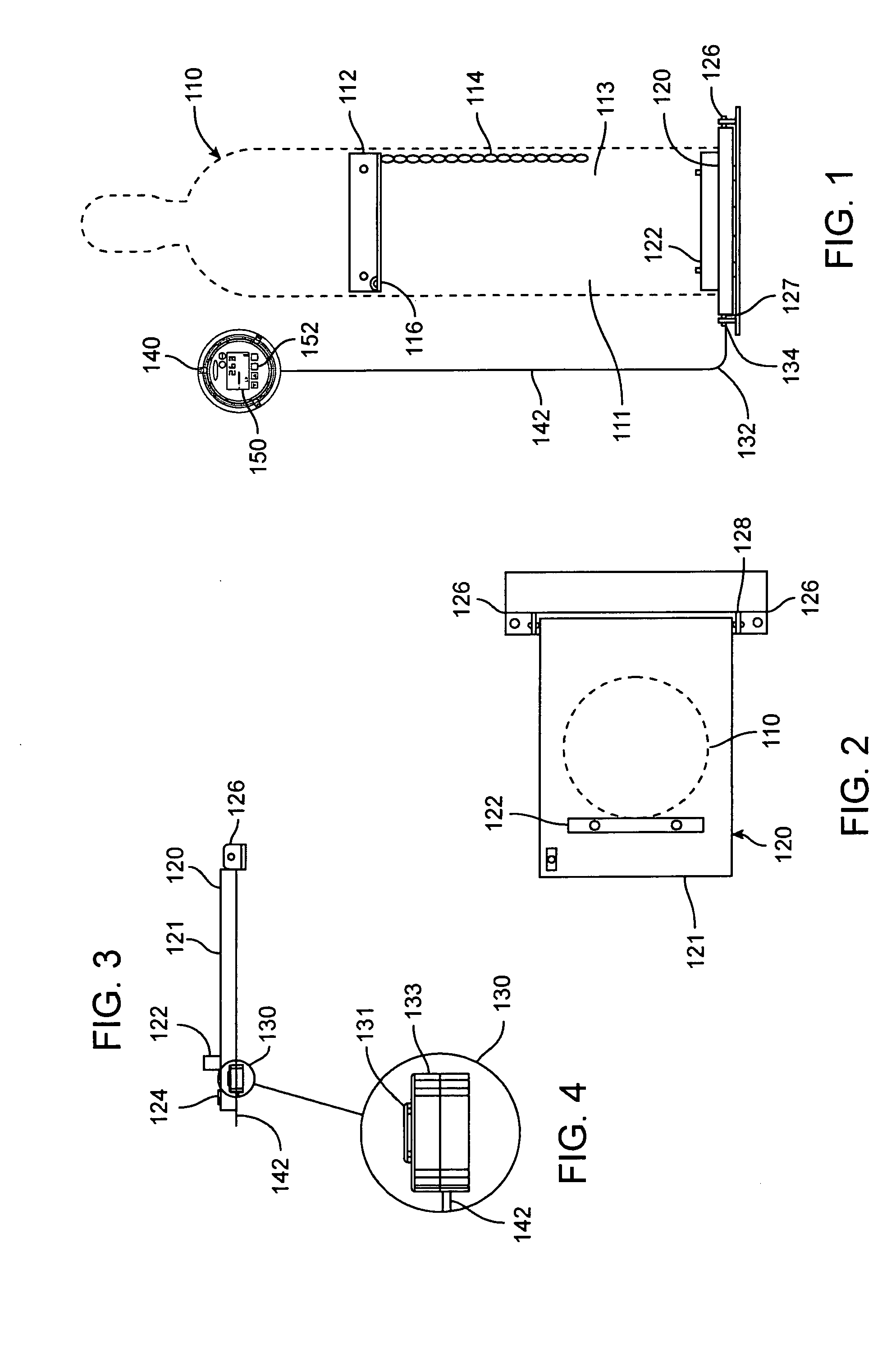

Apparatus for securely mounting and continuously monitoring the weight of a liquified gas tank

InactiveUS7267001B1Continuous monitoringEasy to installMachines/enginesWeighing apparatus for materials with special property/formGas cylinderDisplay device

A bottle plate mates or is integrated with brackets for mounting a gas bottle atop the plate. An aft end of the bottle plate is spacedly affixed to a top of a base plate, the bottle plate being bendable about its aft end corresponding to the weight of a bottle mounted thereon. A plurality of guide pins disposed at a fore end of the bottle plate prevents lateral movement of the fore end with respect to the base plate, but allows to a limited extent displacement of the fore end due to bottle weight. Any displacement of the fore end due to bottle weight is converted to a corresponding bottle weight and a display indicates same to a user. The base plate is used to securely mount the apparatus.

Owner:STEIN DANIEL J

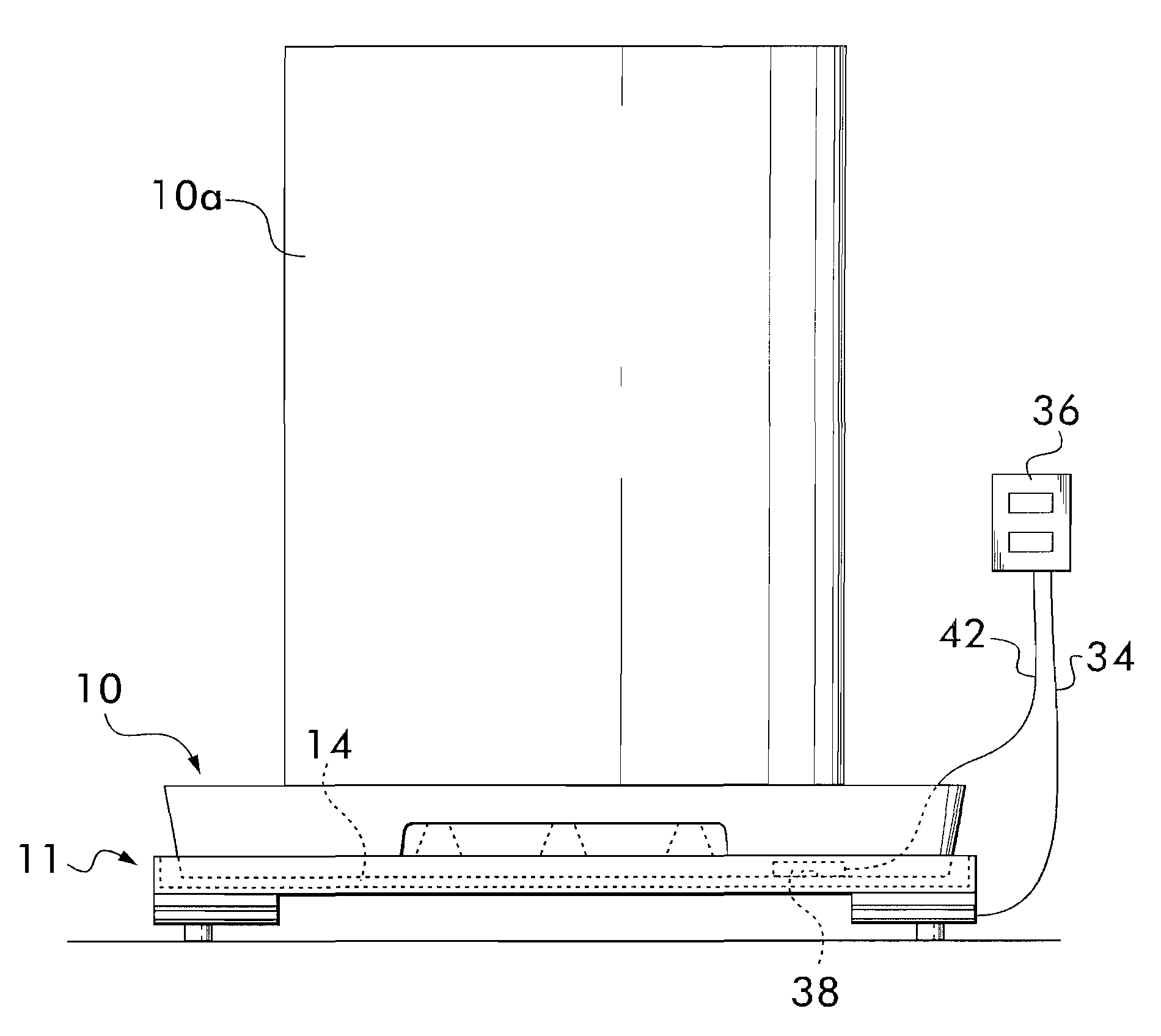

Leak and spill containment scale

ActiveUS7737372B2Major catastrophes can be avoidedPotential for harm can be assessedProtective foundationMachines/enginesLoad cellSpillage

A scale assembly for weighing potentially hazardous materials comprise a containment deck designed to support a container from which materials are dispensed. The containment deck is preferably provided with sufficient storage capacity to capture spillage or leaks from the container and is supported on a low-profile platform supported in turn by load cells which generate signals indicative of the weight of the contents of the container and of any spillage within the containment deck. The containment deck is further equipped with a level detector typically positioned near the bottom of the deck for generating signals indicating the presence of leakage or spillage from the container.

Owner:SCALETRON INDS

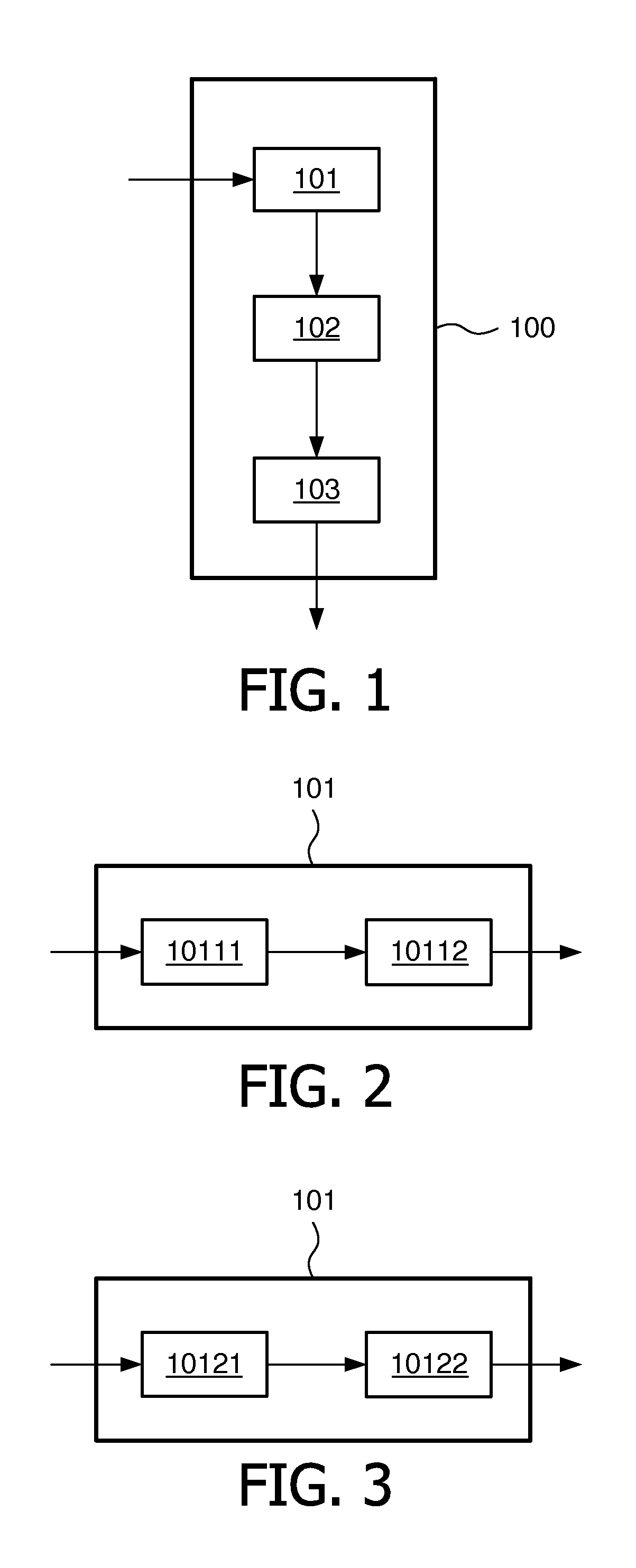

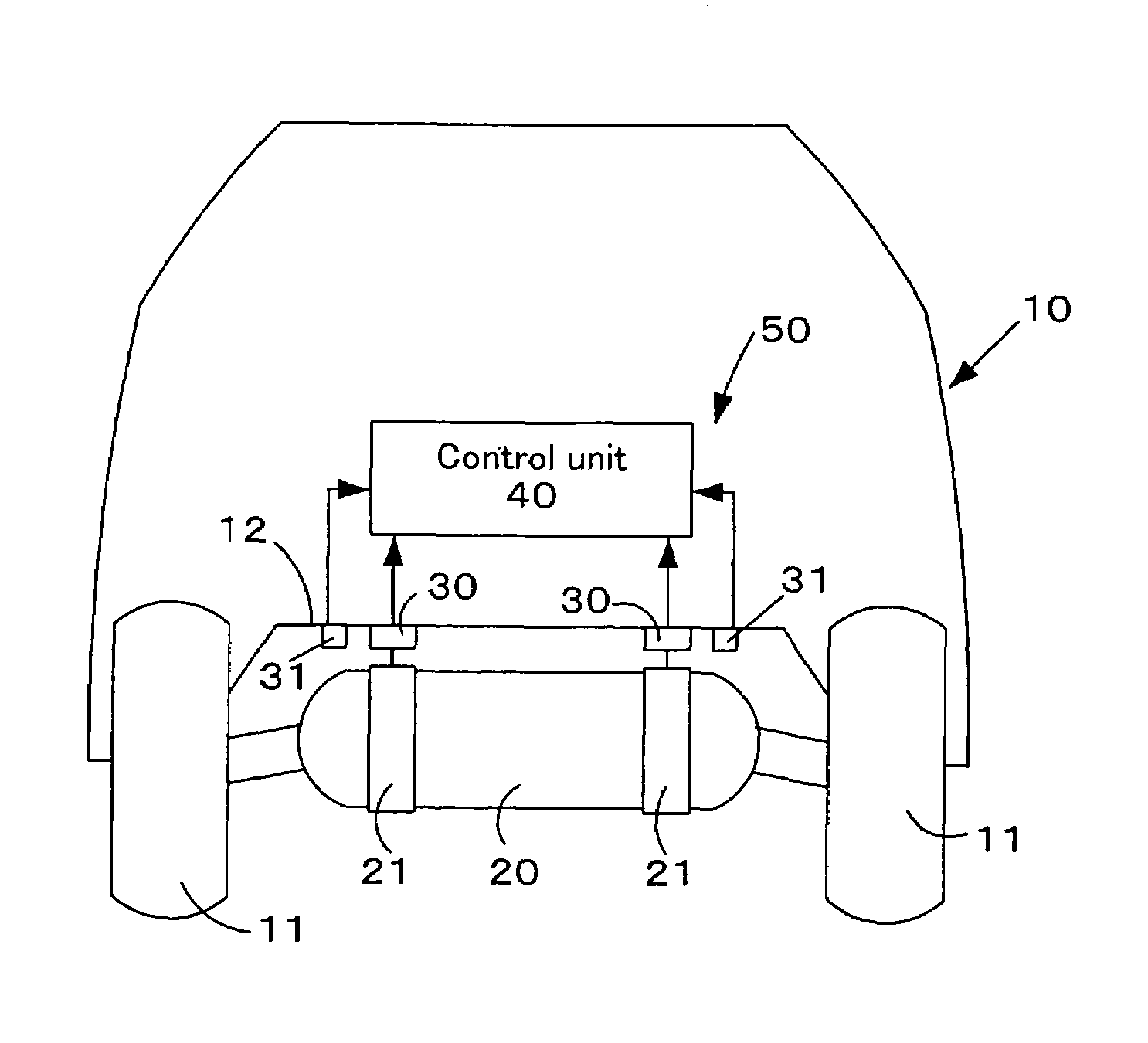

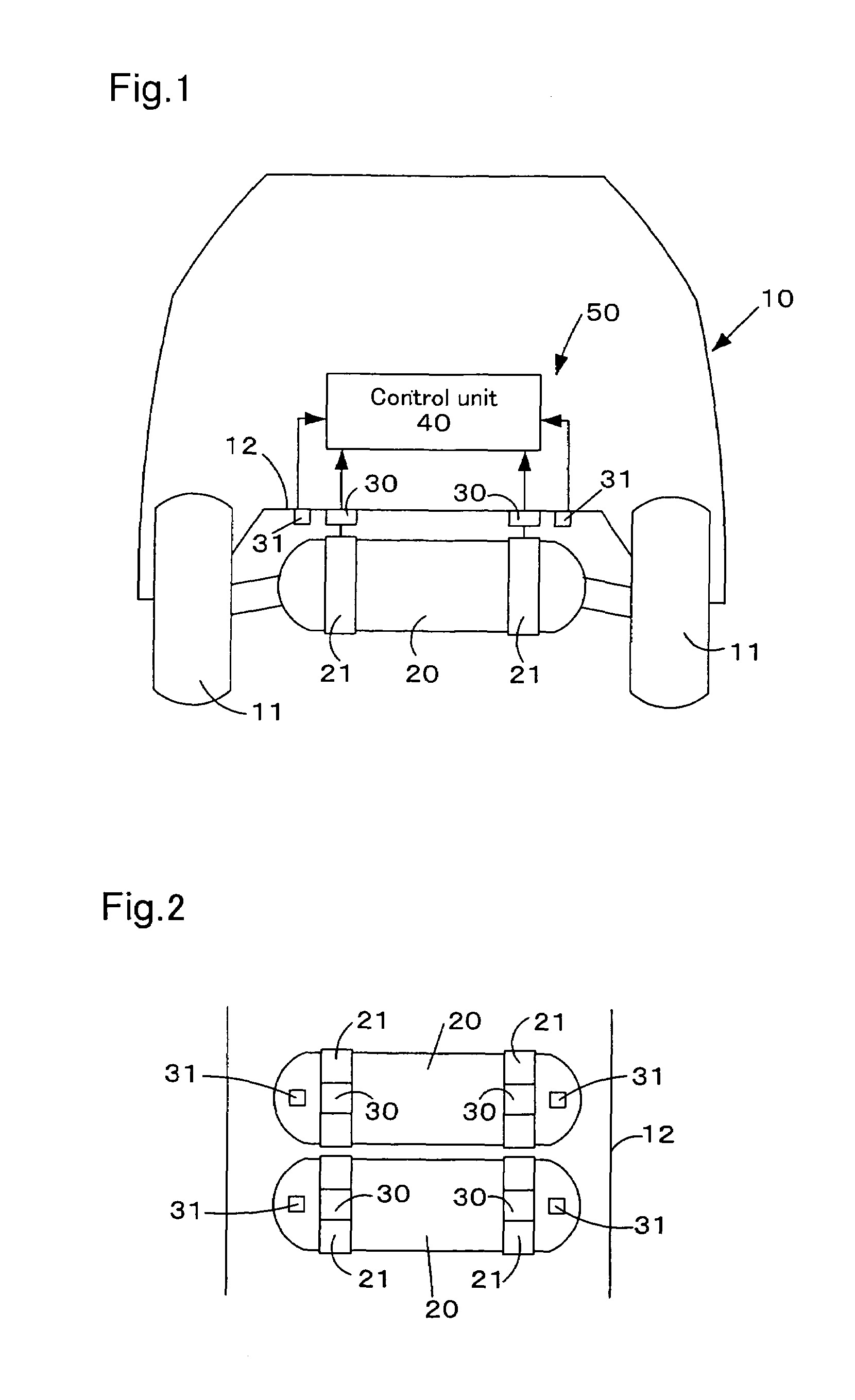

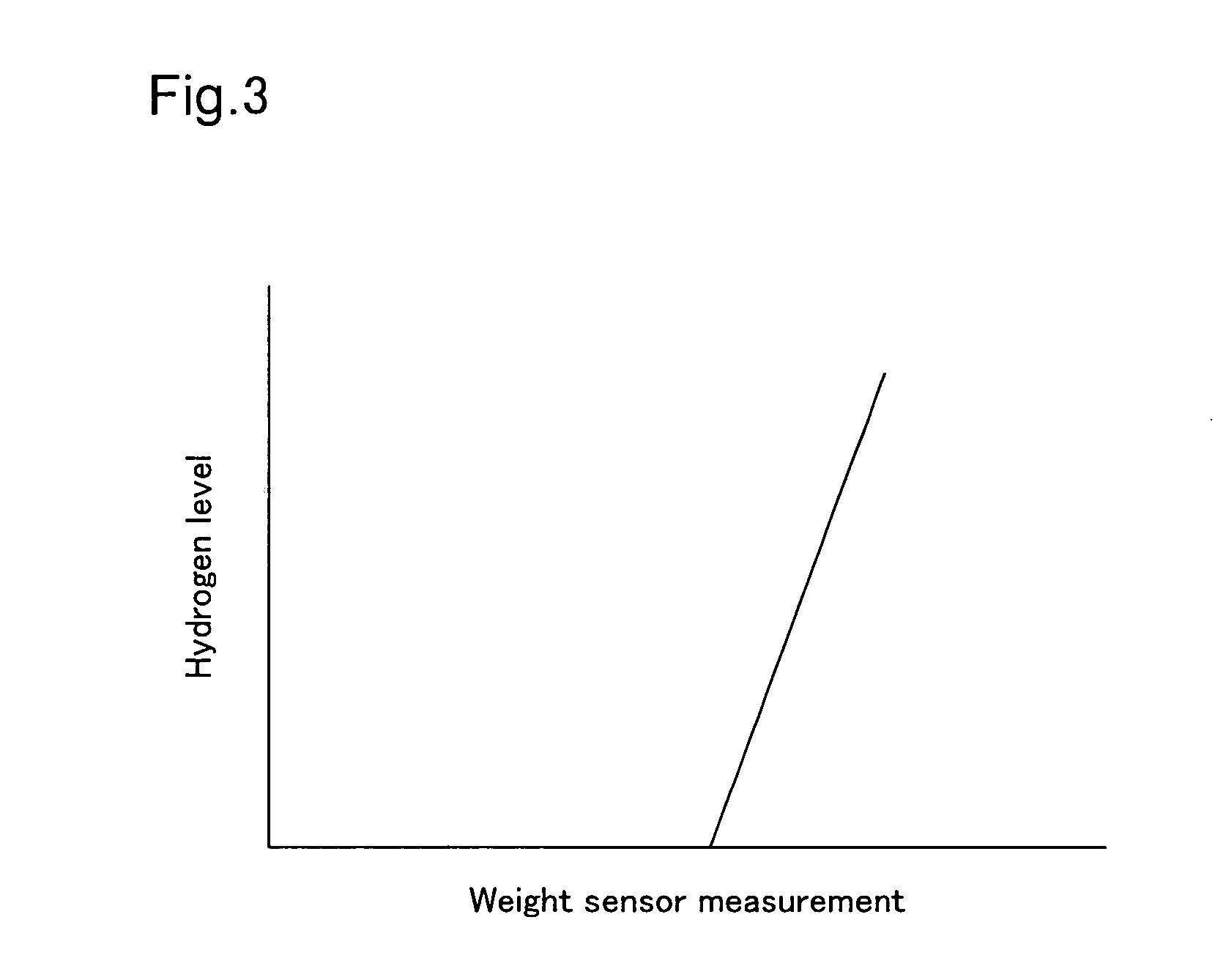

Measurement of gas fuel amount

InactiveUS7240549B2High measurement accuracyAccurate measurementElectrical controlDigital computer detailsHydrogenEngineering

A control unit 40 acquires acceleration α sensed by an acceleration sensor 31, and if the control unit 40 determines that acceleration α does not equal zero, the control unit 40 again acquires acceleration α. In the event that the control unit 40 decides that acceleration α equals zero, the control unit 40 acquires the weight M sensed by the weight sensor 30. The control unit 40 continues sampling of weight M until a predetermined sampling period has elapsed. Once the sampling period has elapsed, the control unit 40 calculates the average of weight M obtained through sampling, and uses the calculated average and a map to determine hydrogen amount.

Owner:TOYOTA IND CORP

Systems and methods for measurement of low liquid flow rates

InactiveUS6997053B2Accurate measurementImmune to environmental change and minor physical perturbationVolume measurement and fluid deliveryMachines/enginesCollection periodEngineering

Owner:AIR LIQUIDE ELECTRONICS US LP

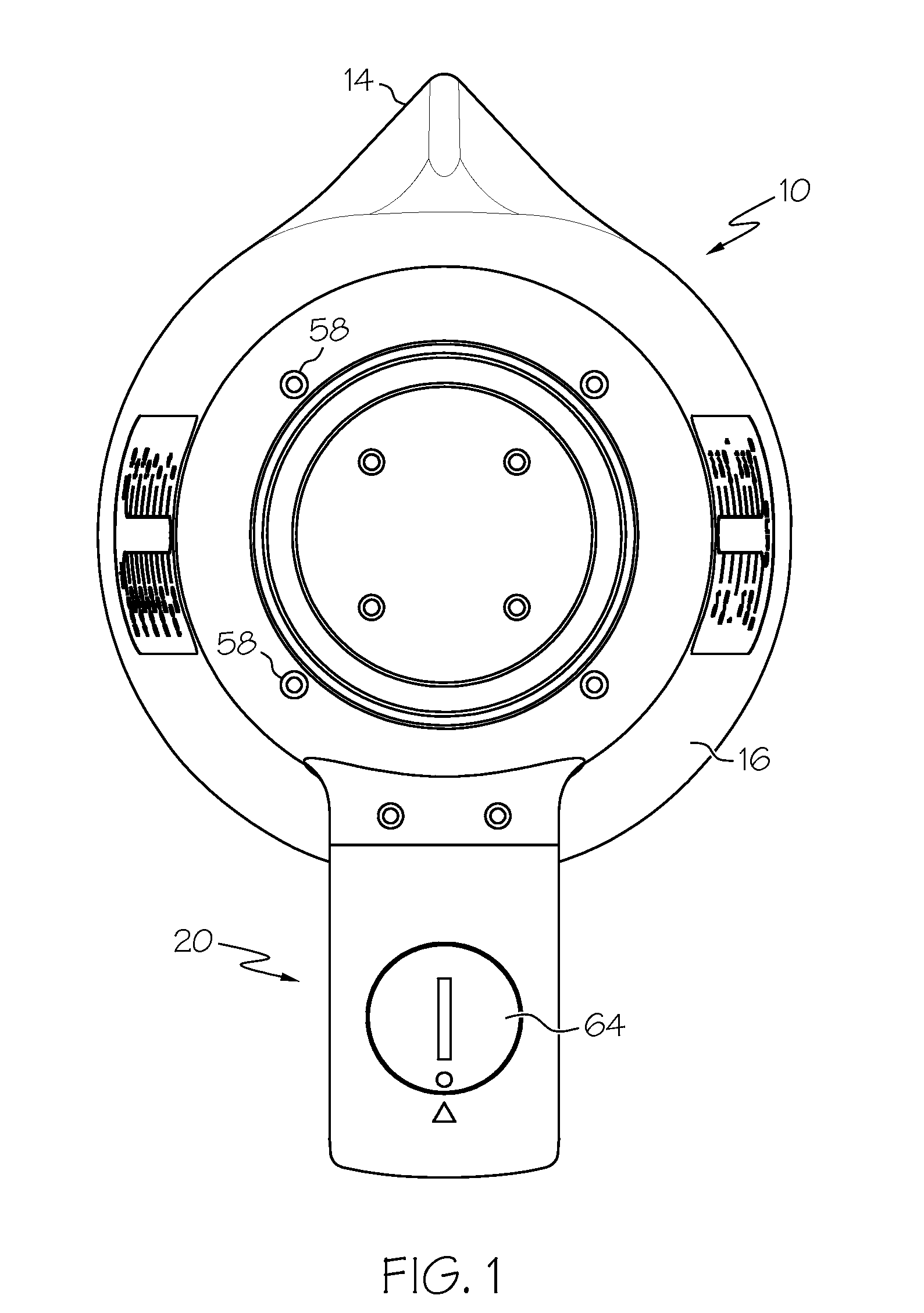

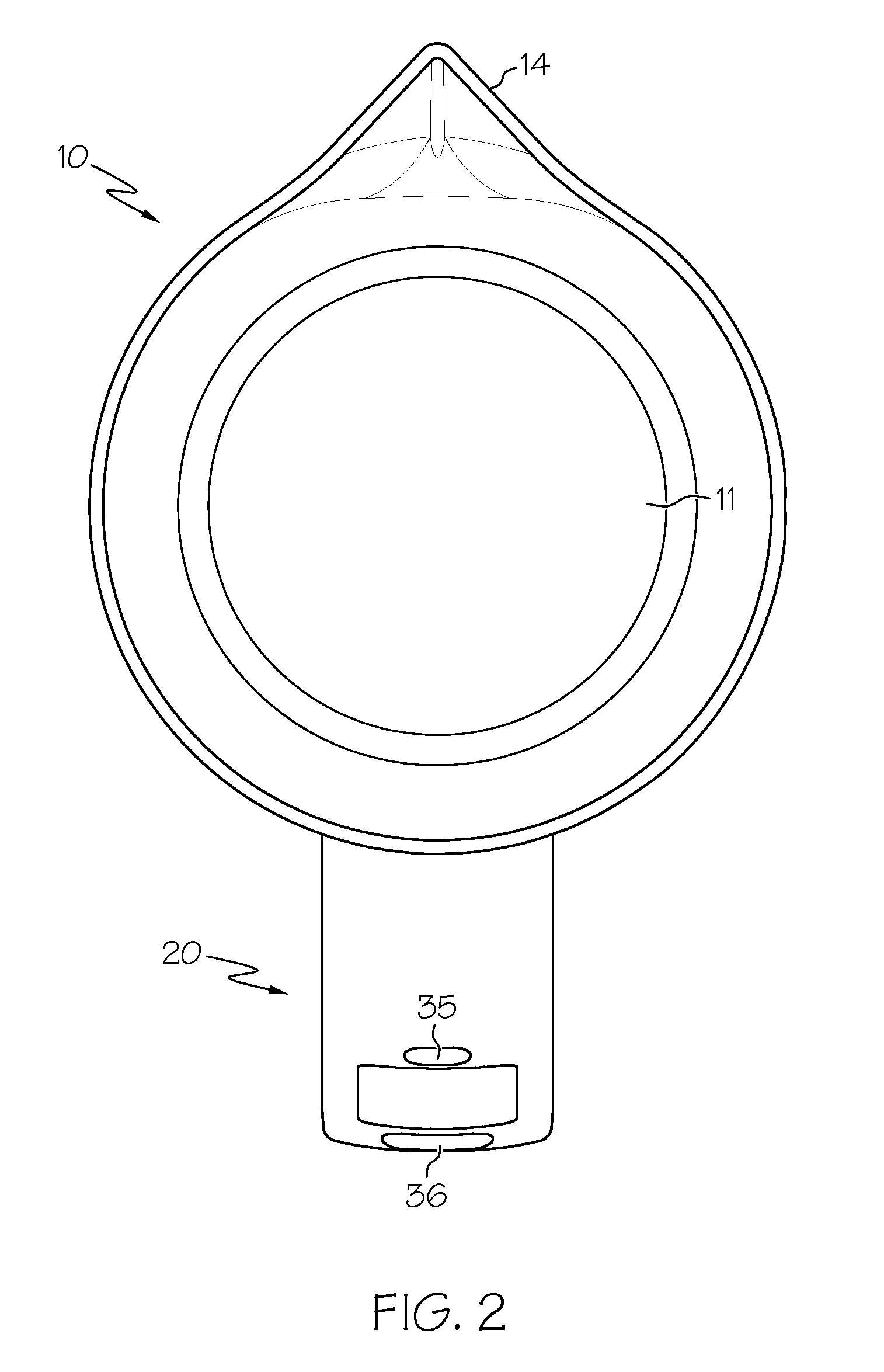

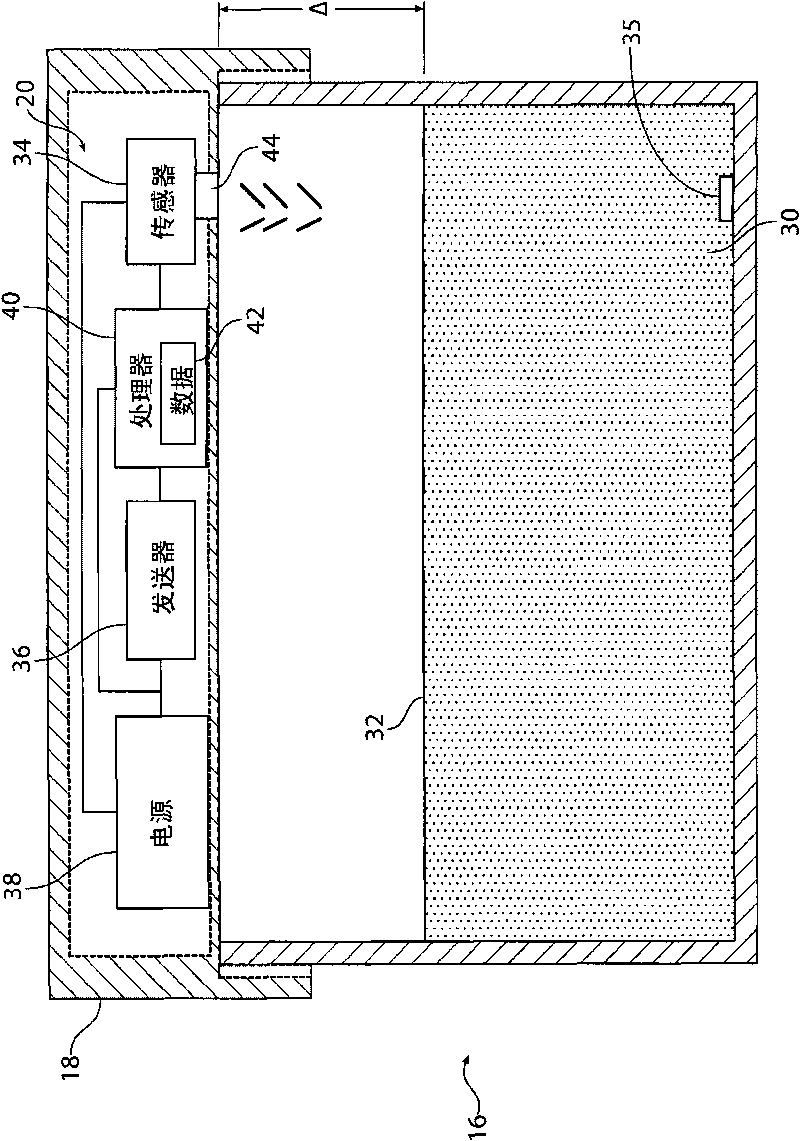

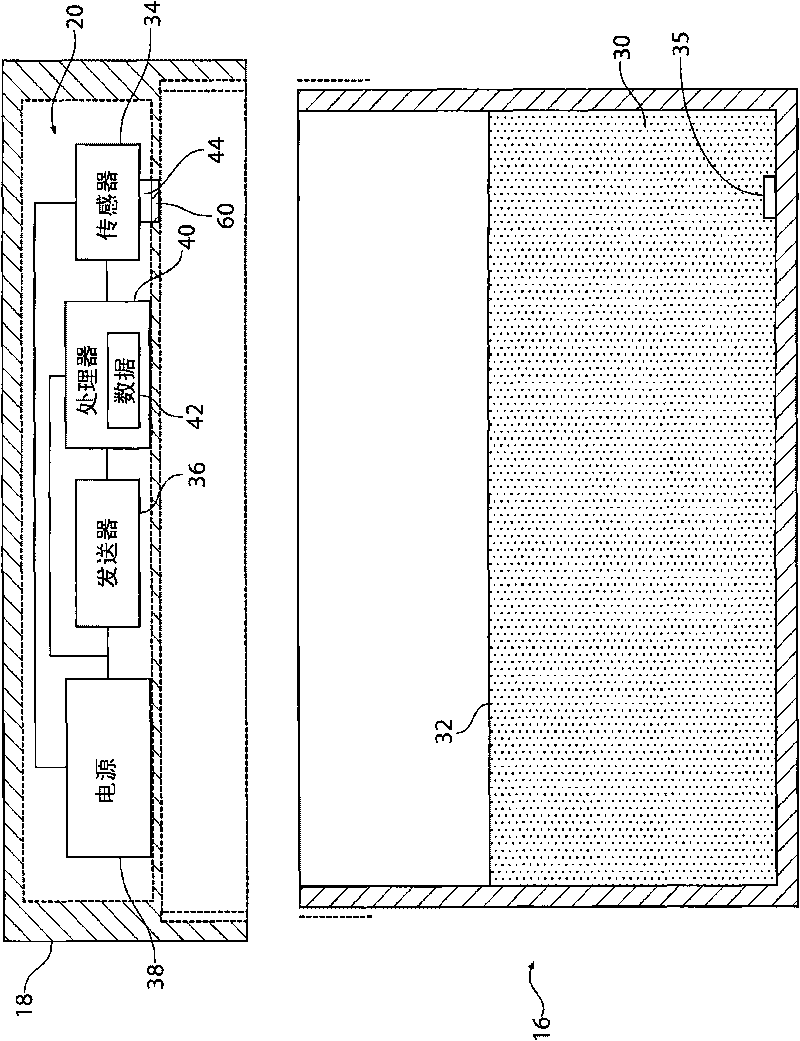

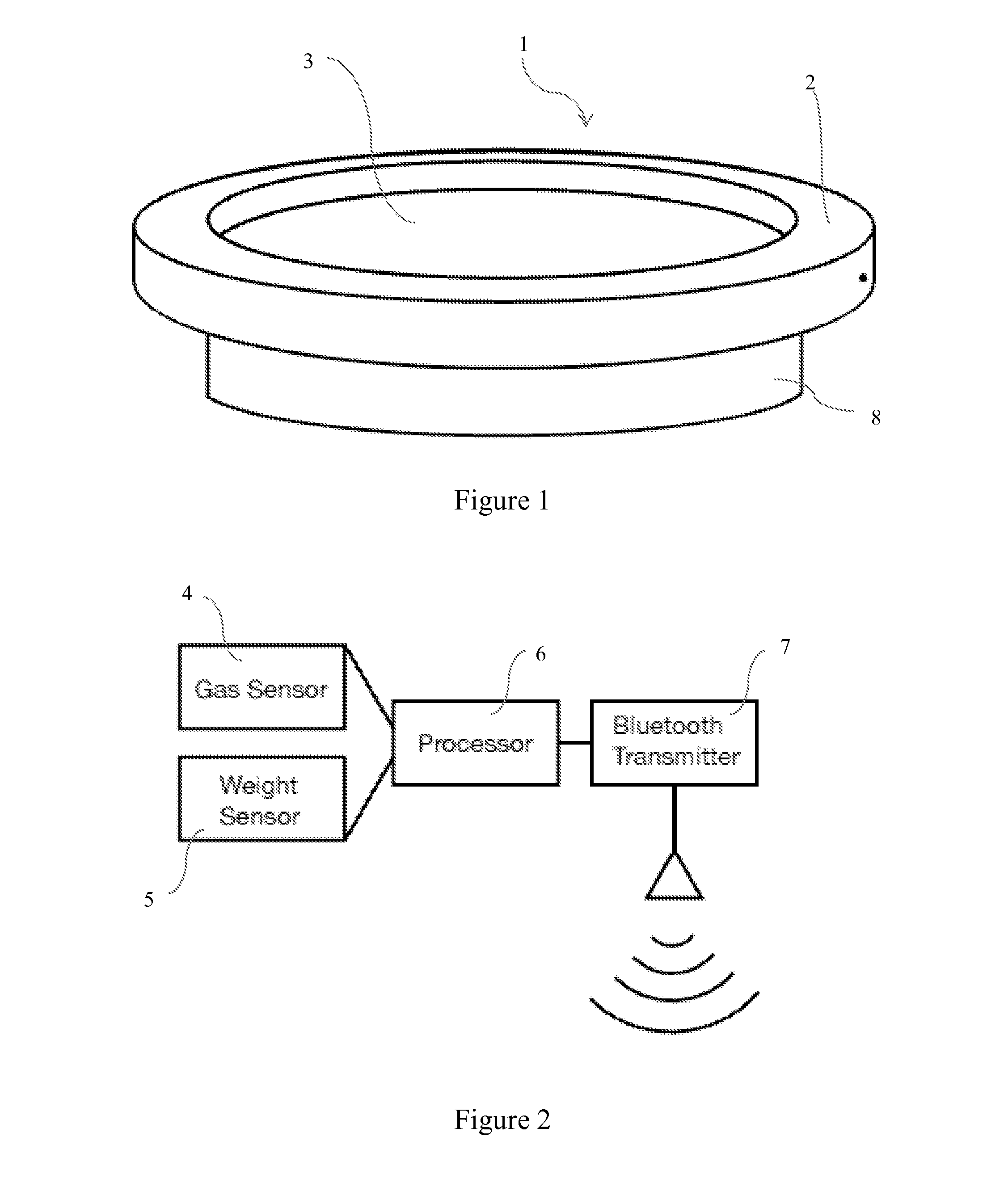

Lid based amount sensor

A device for determining the amount of a substance in a container includes an amount sensor disposed within the container, a transmitter coupled to the sensor and configured to transmit an output thereof, and an electrical power source powering the sensor and the transmitter.

Owner:WHIRLPOOL CORP

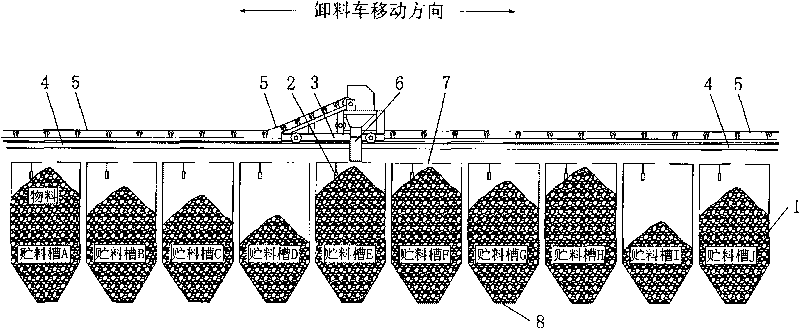

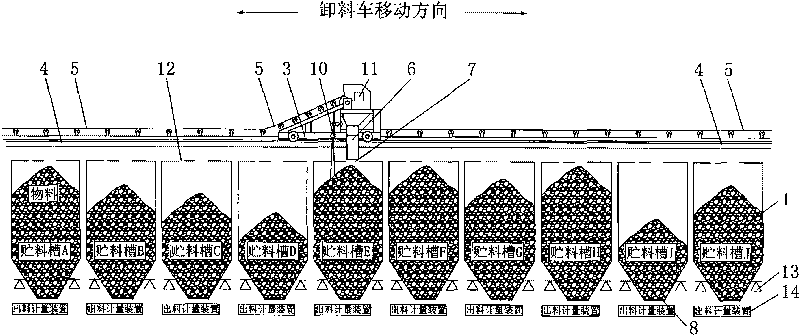

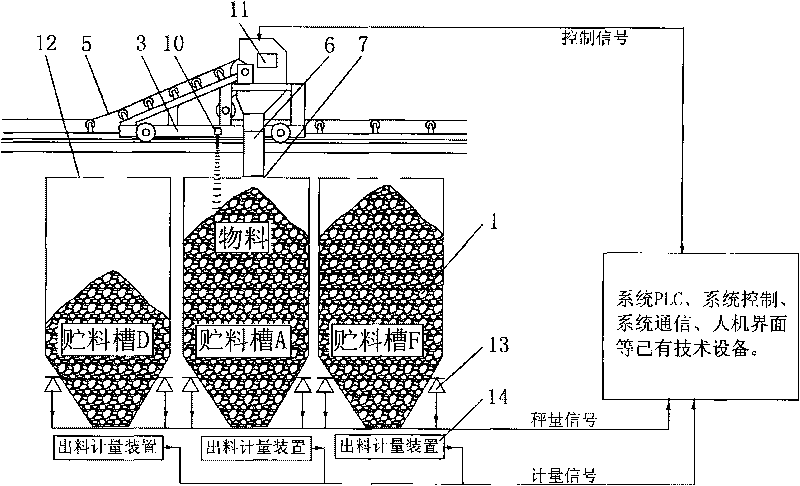

Scattered material storage tank tankful detection and control method

InactiveCN101723183AReduce in quantityEasy to controlLoading/unloadingLevel indicators by weight measurementFailure rateGround system

The invention relates to a scattered material storage and transportation technology in a physical distribution storage and transportation system. The invention discloses a scattered material storage tank tankful detection and control method which is realized in a way that: a tankful level detection device and an arithmetic control unit, which are arranged on a storage tank moving discharging car, are provided; the tankful level detection device moves among charging tanks along with the discharging car; the tankful level detection is carried out on the material storage tanks in the charging process, so that the tankful detection can be carried out on all the material storage tanks by using only one tankful level detection device; and the arithmetic control unit is used for control; and the arithmetic control unit can process, calculate and control the data detected by the tankful level detection device, and carries out the data communication with a ground system PLC or computer. Compared with the traditional scattered material storage tank tankful detection system, the detection and control method of the invention has the advantages of convenient detection, easy control, simple structure of devices for implementing the detection method, small quantity of the devices and cables, low failure rate of the system equipment, and small maintenance quantity.

Owner:BAOSHAN IRON & STEEL CO LTD +1

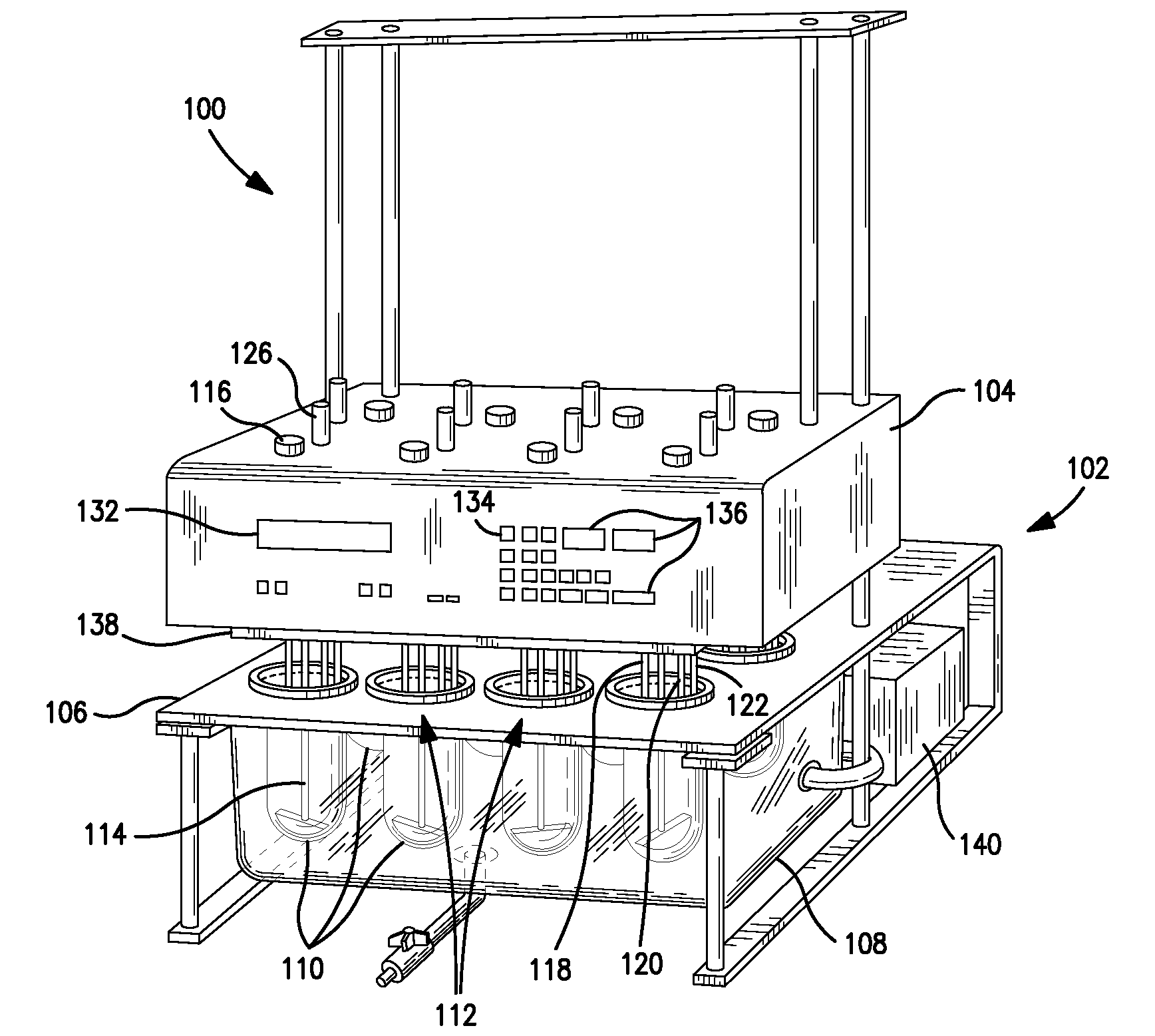

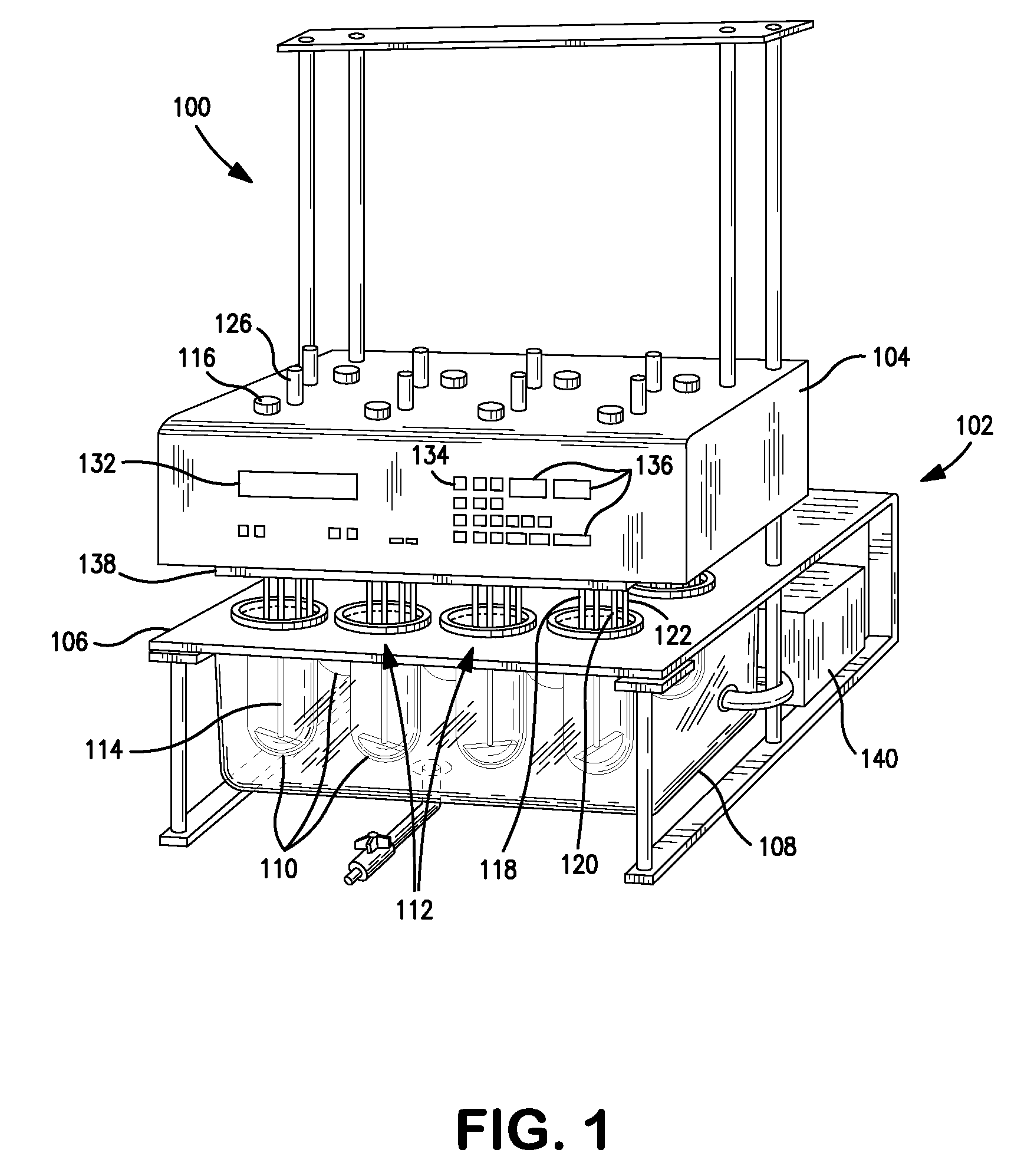

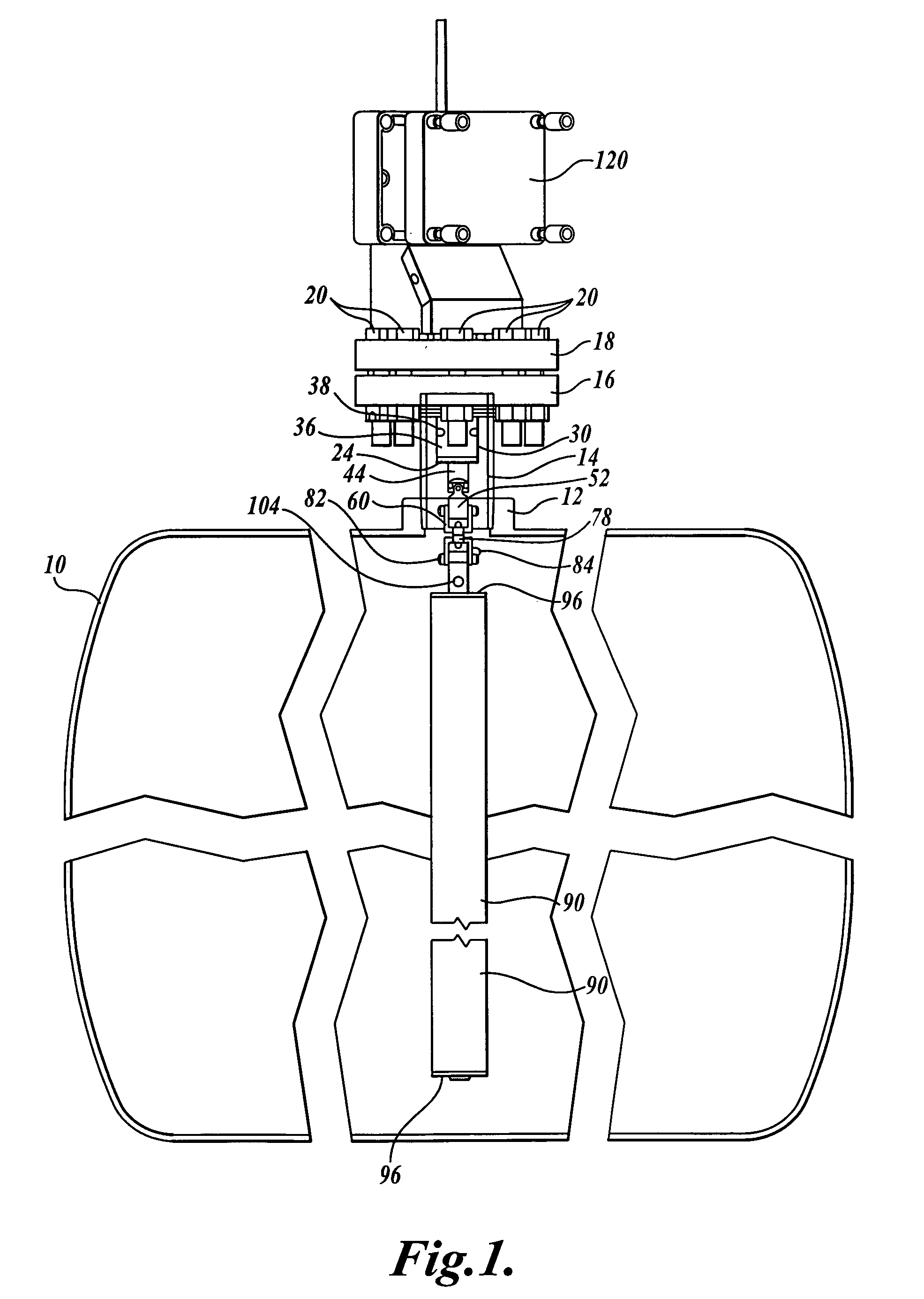

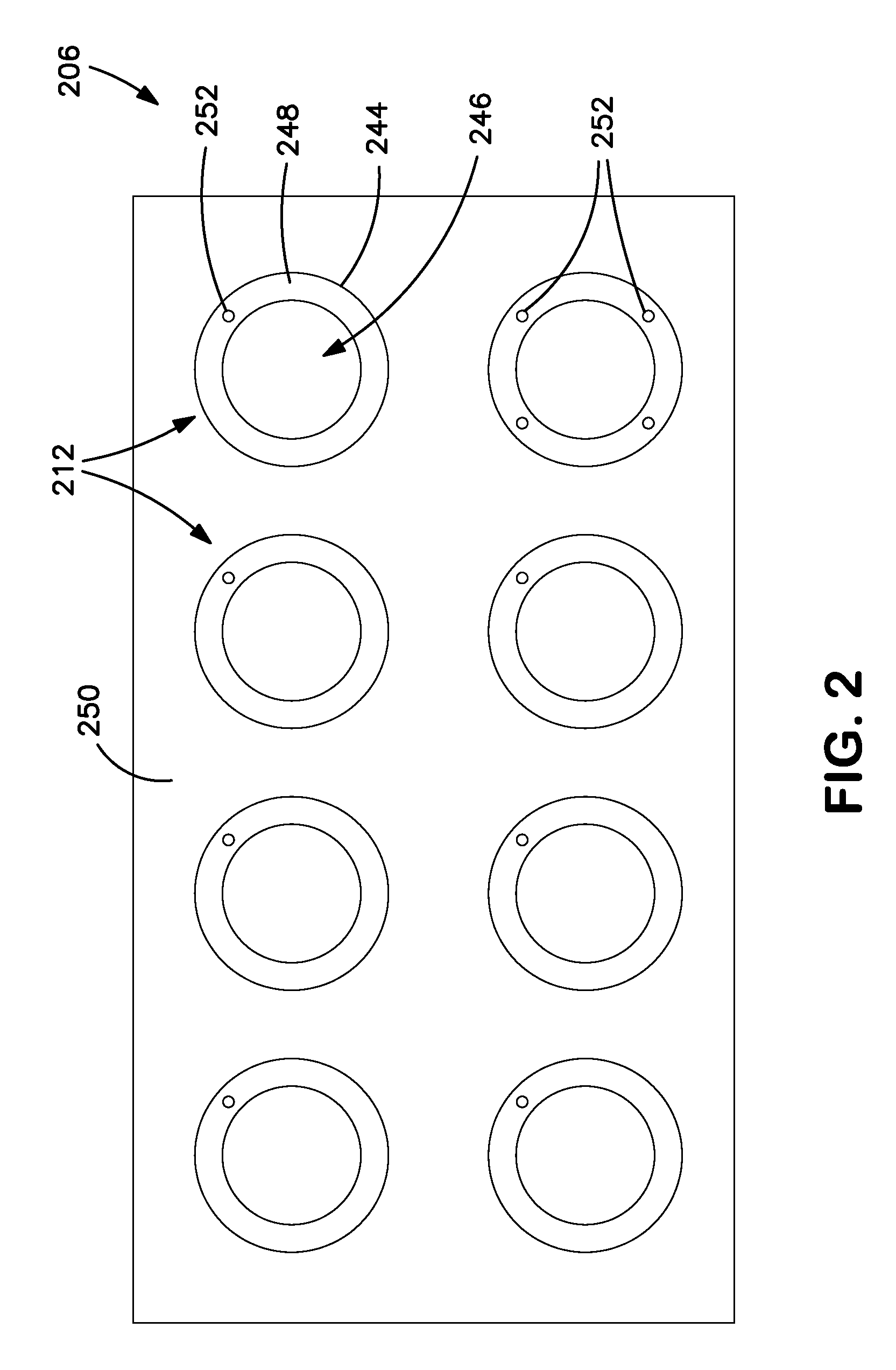

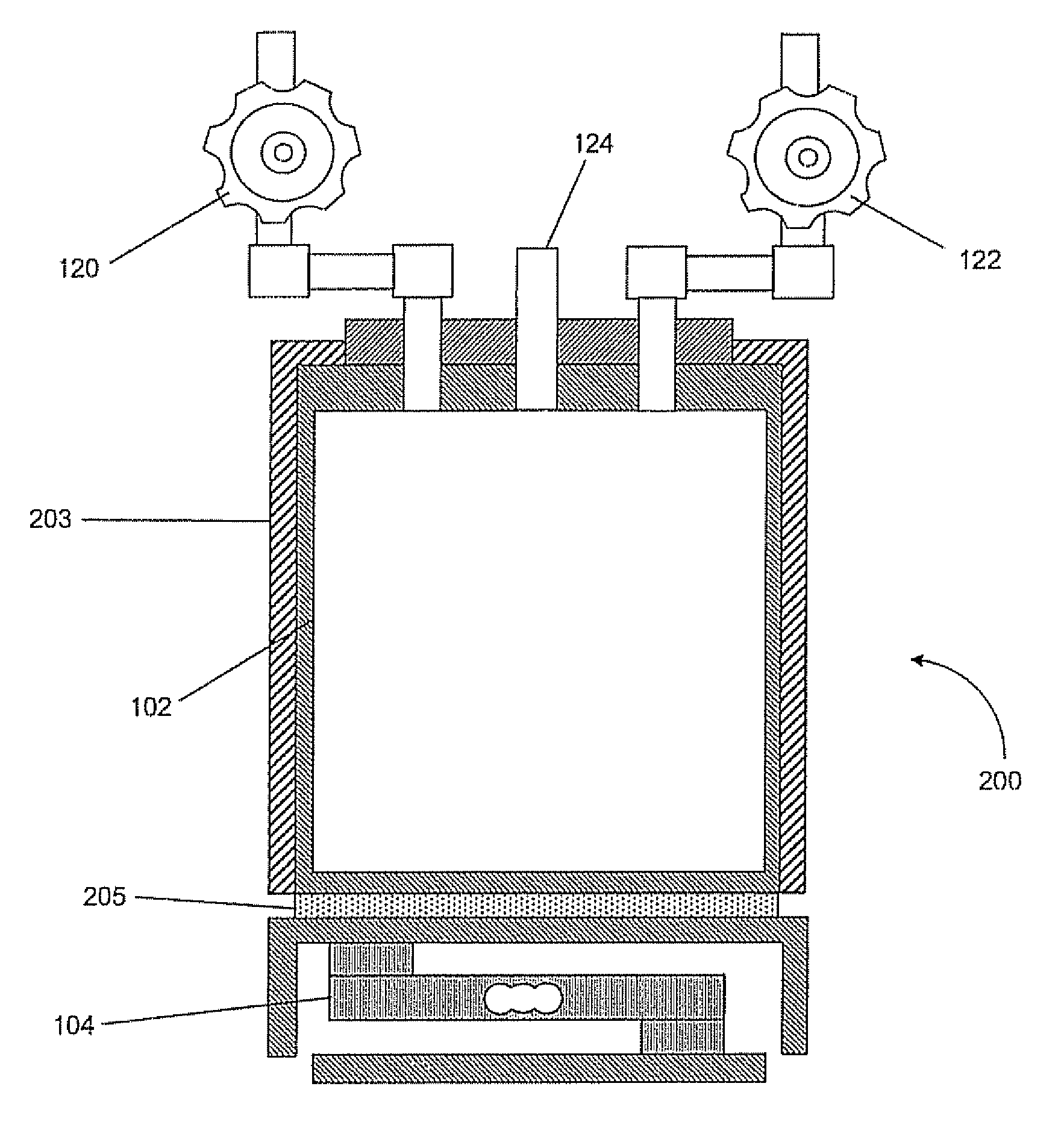

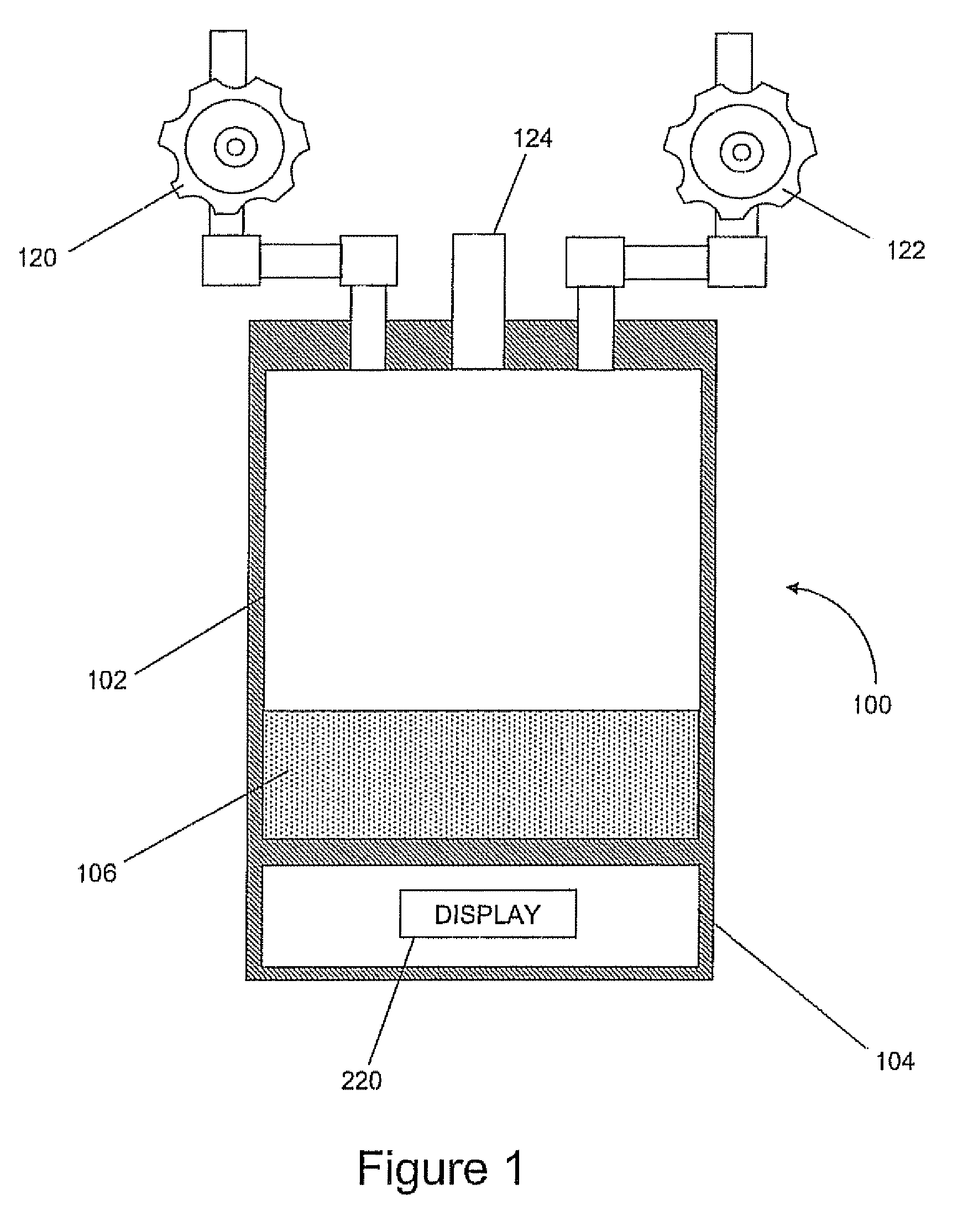

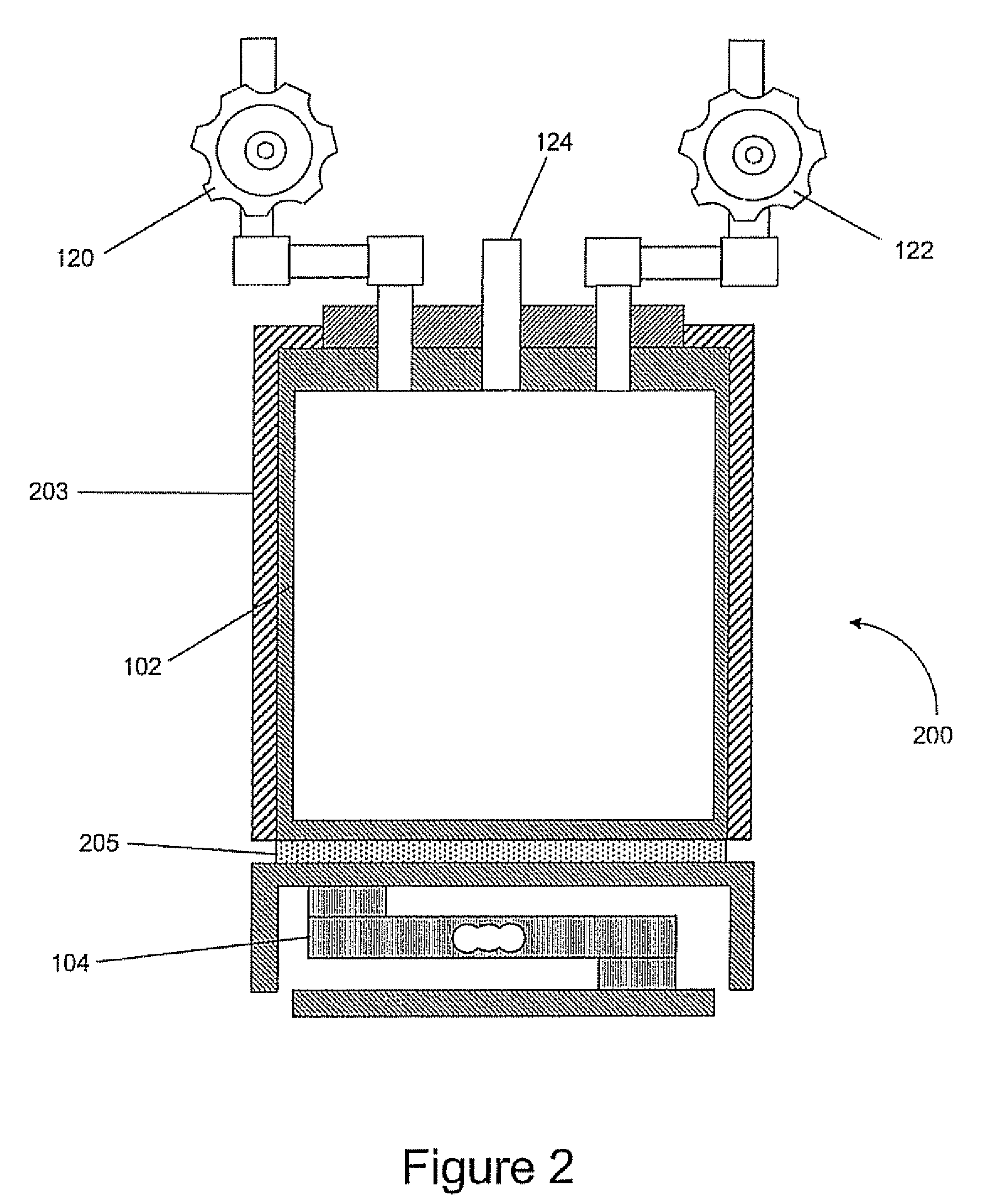

Dissolution testing with in-situ gravimetric volume measurement

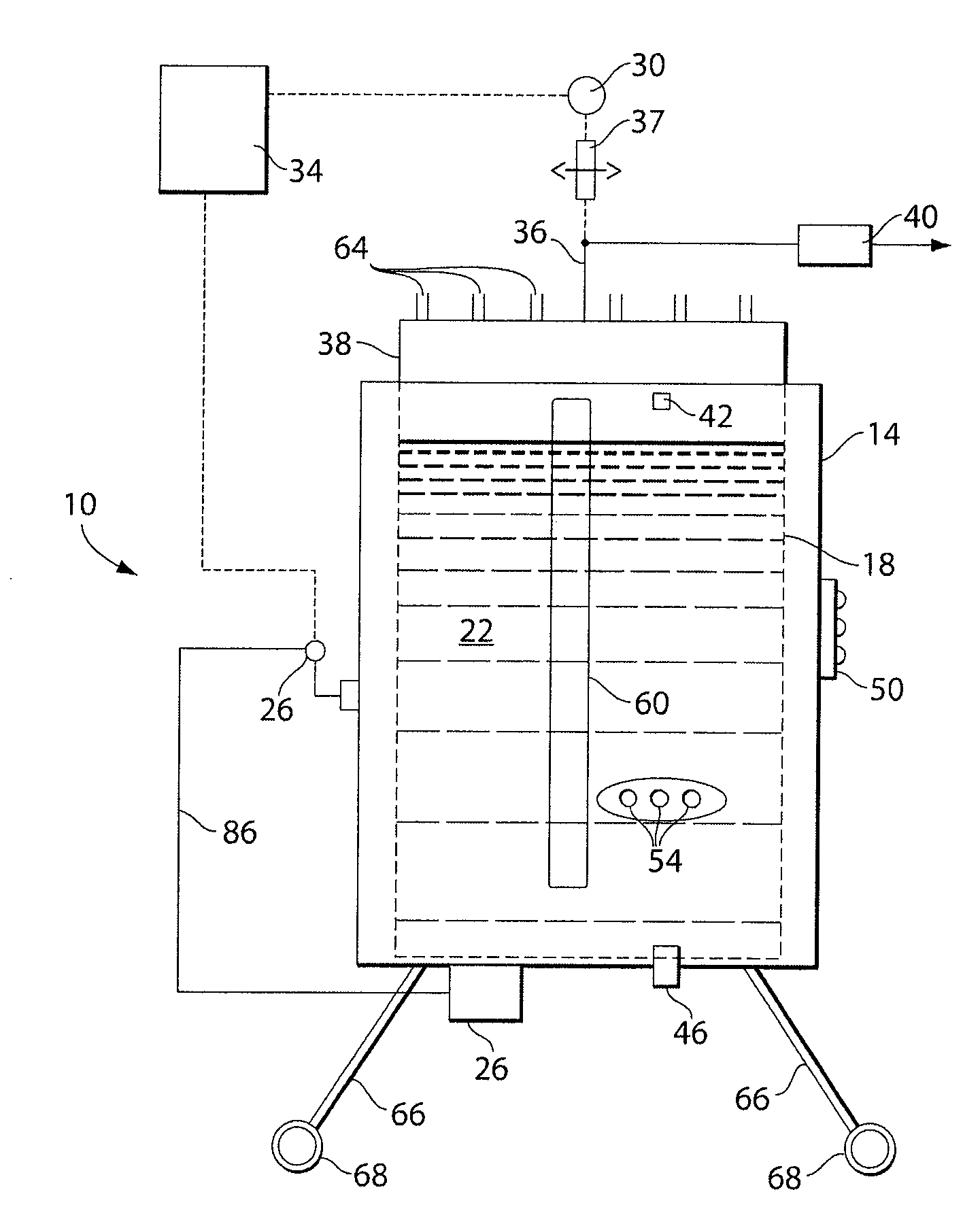

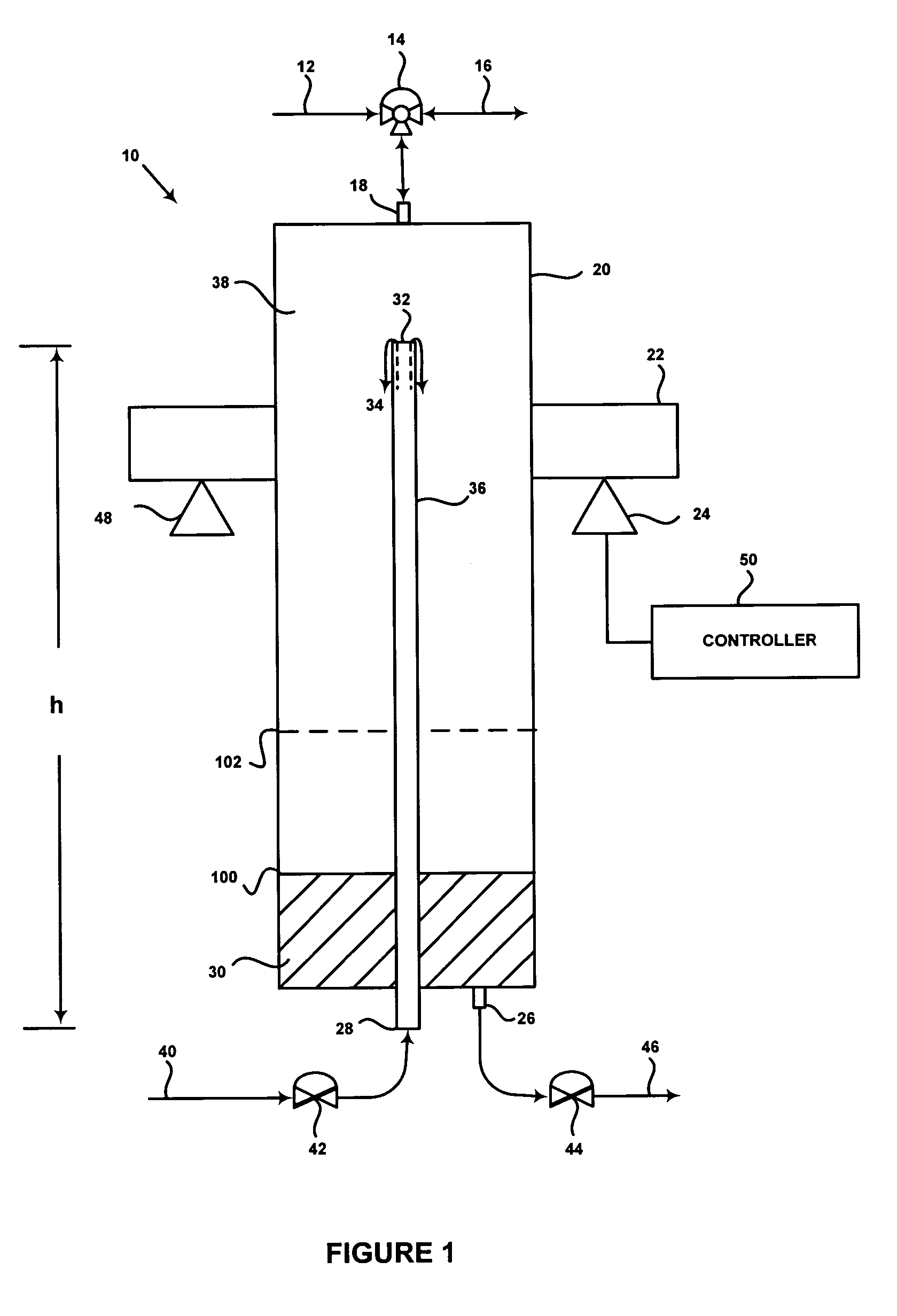

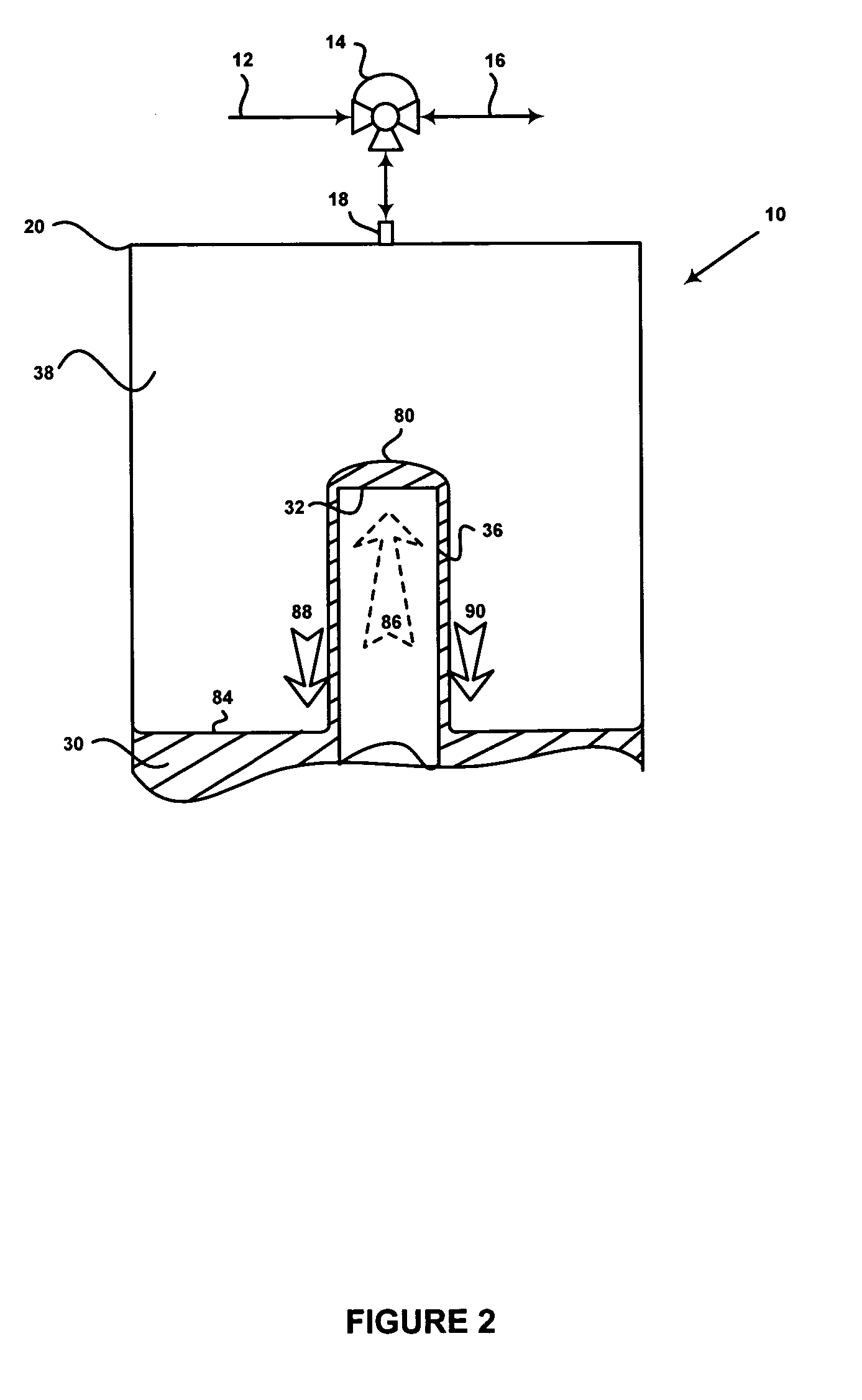

InactiveUS20100107752A1Shaking/oscillating/vibrating mixersWeather/light/corrosion resistanceElectronic controllerControl signal

A dissolution test apparatus includes a vessel support member, weight sensors, a movable component, a media transport cannula, a pump, and an electronic controller. The vessel support member receives vessels. A weight sensor is located at each vessel site. Each weight sensor contacts a vessel and transmits a measurement signal indicative of the weight of the vessel and any contents therein. The movable component moves the media transport cannula toward a vessel site. The pump establishes media flow between the media transport cannula and the selected vessel. The controller communicates with the weight sensors and may also communicate with the pump. Based on the measurement signals received from the weight sensors, the electronic controller may calculate the volume of media in a given vessel. The electronic controller may also control media flows to or from the vessels by transmitting control signals to the pump assembly.

Owner:AGILENT TECH INC

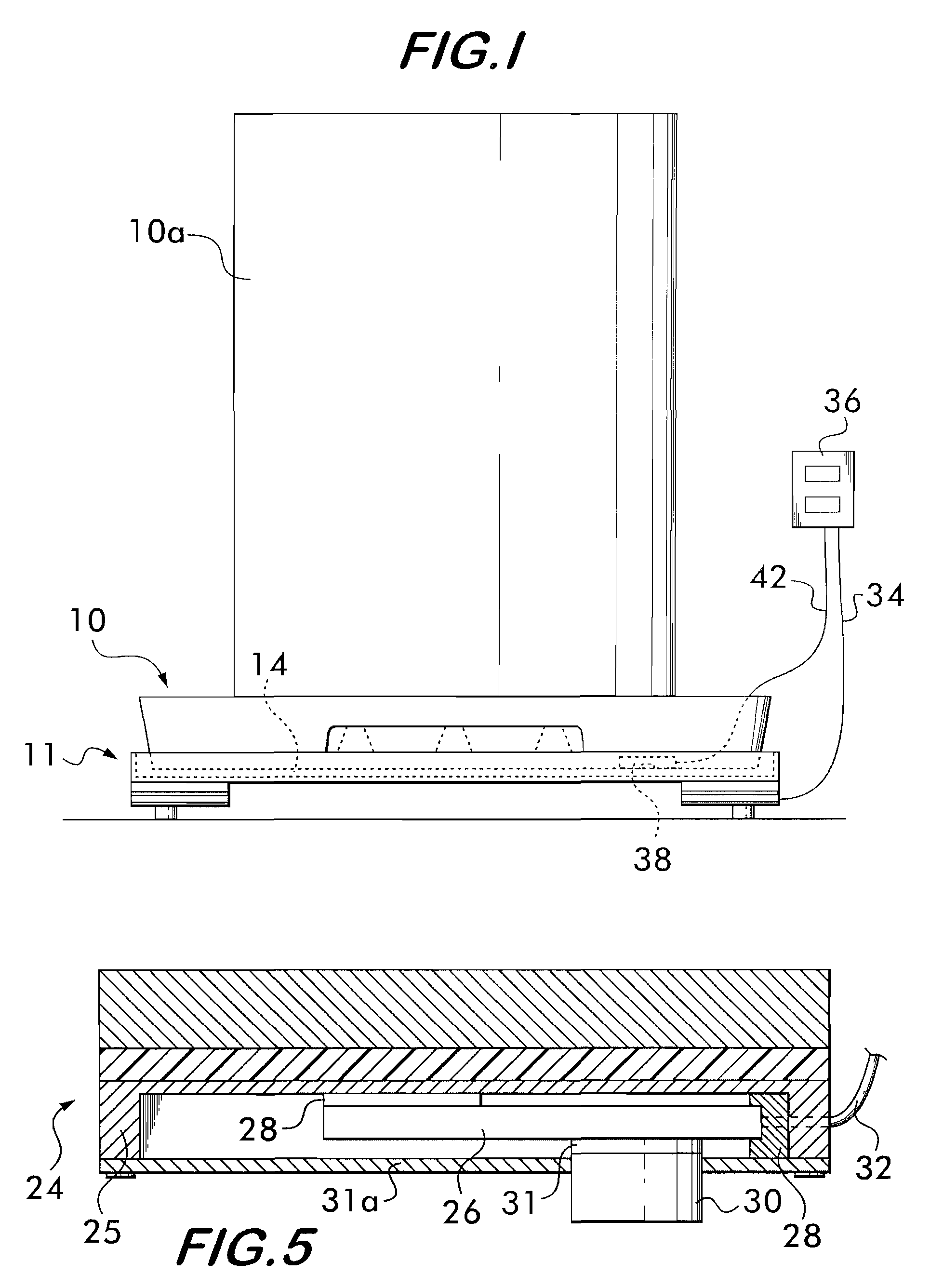

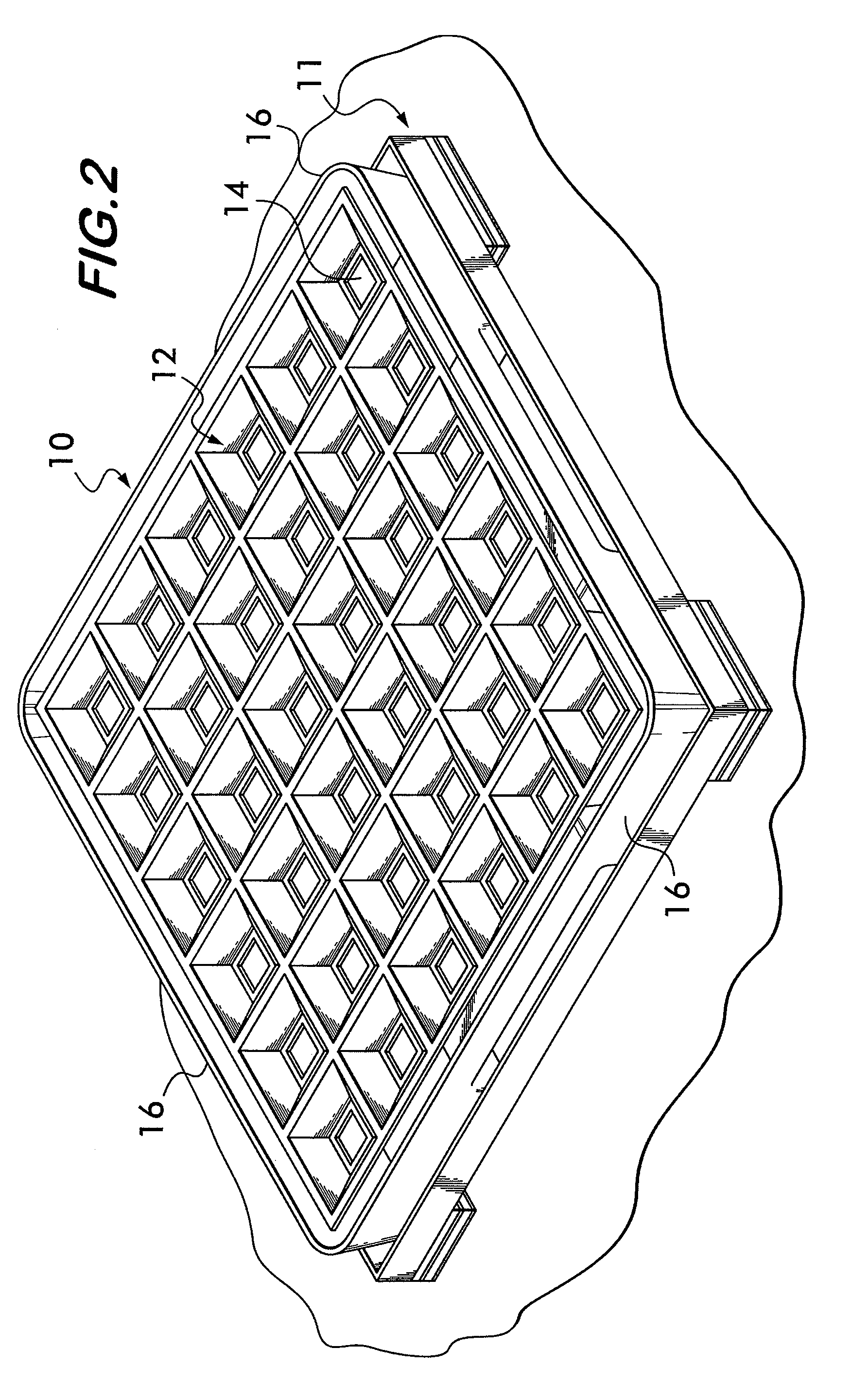

Device for measuring and displaying the amount of beer in a keg

InactiveUS20070056368A1Weighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDisplay deviceMechanical engineering

A scale for determining a quantity of material in a container such as a keg. The may include a support member configured to be placed under a portion of the container, a display to indicate the quantity of material in the container, and a weight sensor positioned underneath the support member to determine the quantity of material in the container and to provide a signal to the display.

Owner:SCHNEITER CALVIN R

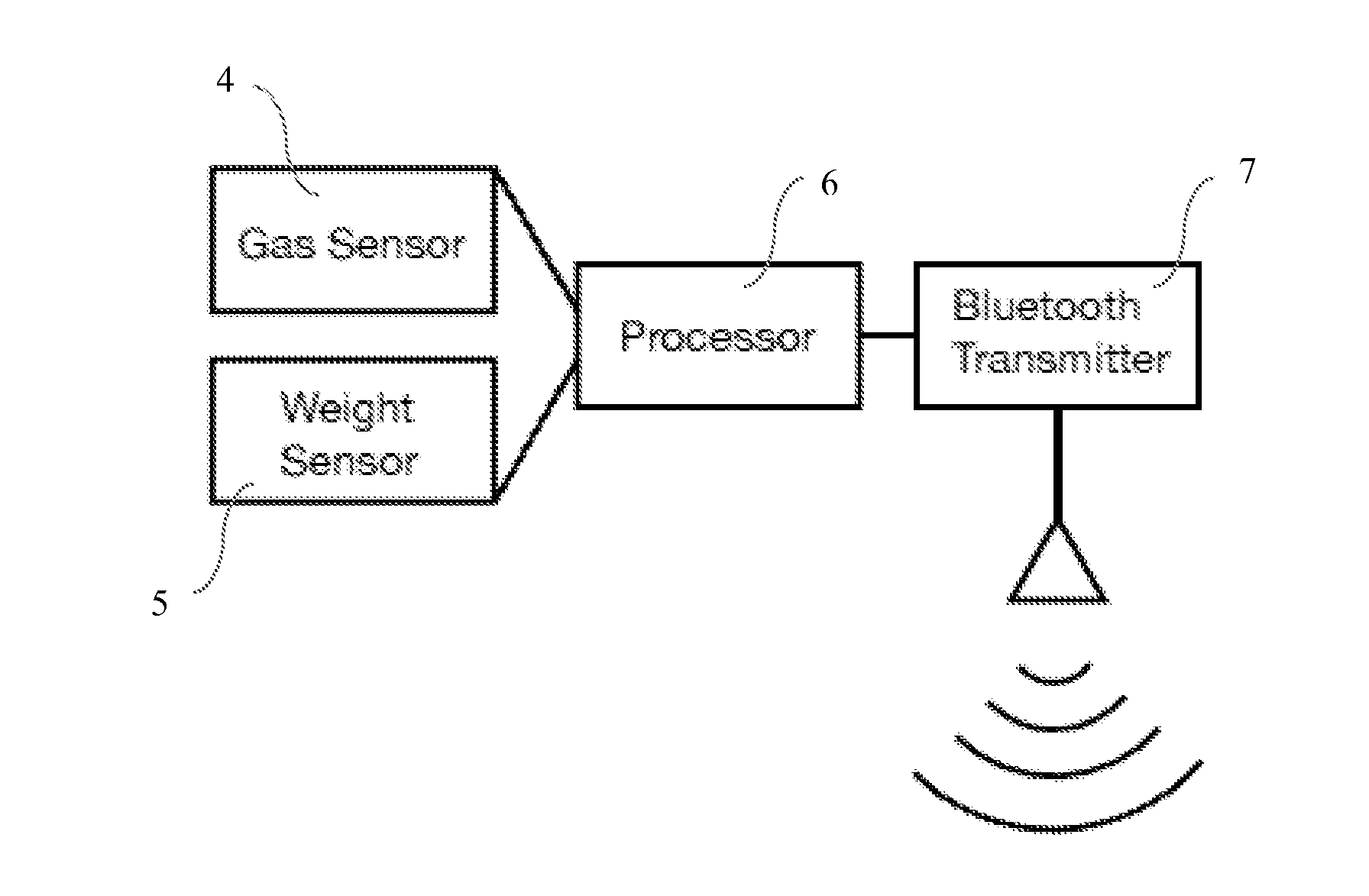

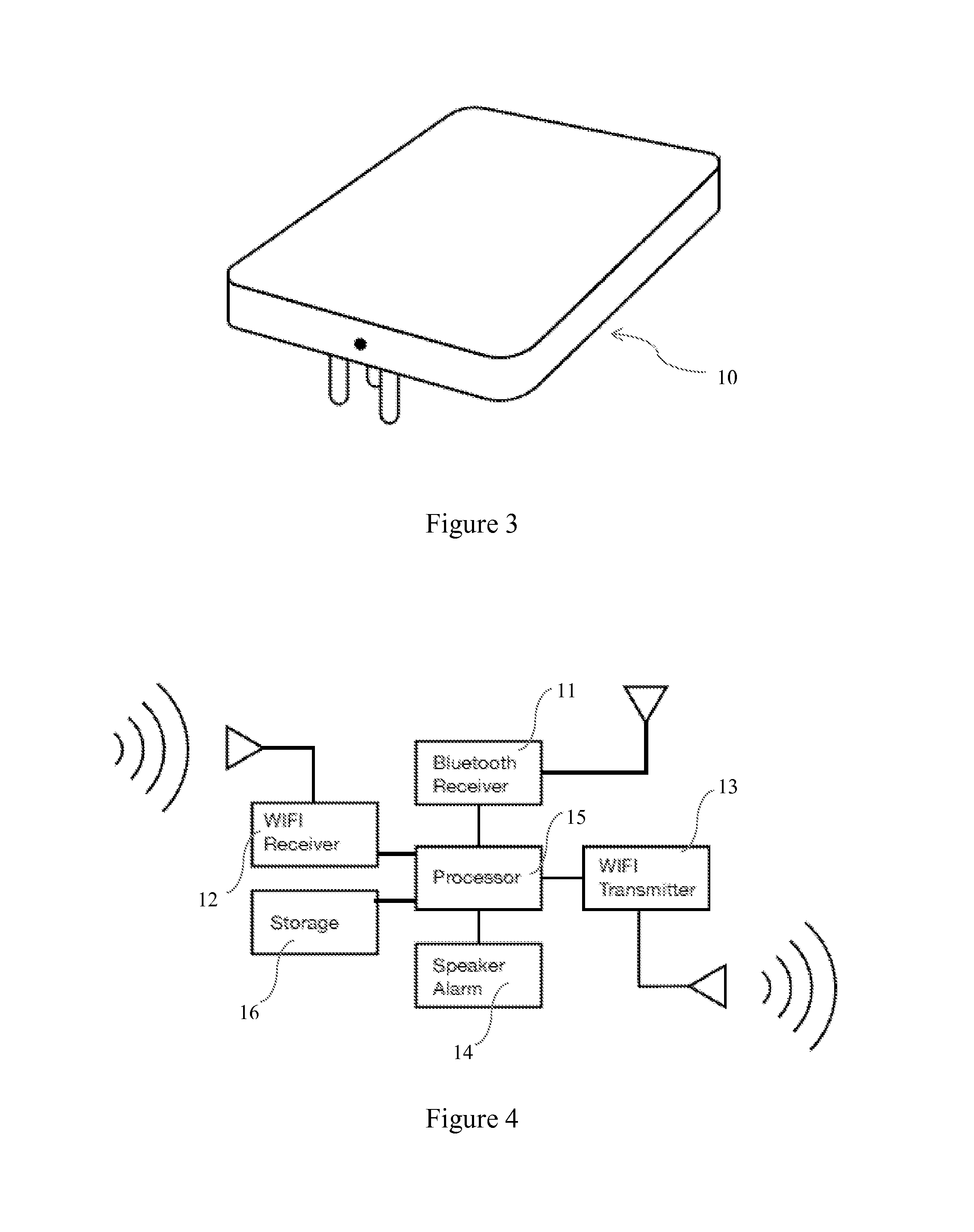

Safety and fuel level communication system

InactiveUS20160163175A1Electric signal transmission systemsFuel testingCommunications systemWireless transceiver

Provided herein are, among other things, an electronic pad comprising a weight sensor, a gas sensor, a processor and a wireless transmitter. Also provided herein is a safety and fuel level communication system comprising the electronic pad disclosed herein and a wireless transceiver. The electronic pad disclosed herein or the system disclosed herein can automatically provide a low gas level alert when the gas amount remained in a gas container on the electronic pad is below a pre-determined level and / or a gas leak alert when a gas leak is detected. Also provided herein is a method of providing a low gas level alert and a gas leak alert.

Owner:BOND MFG CO

System for automated measurement of fluid output

InactiveUS20170307423A1Accurate measurementInformed decisionWeighing apparatus using elastically-deformable membersDiagnostic recording/measuringMedical recordEngineering

A system for automatically measuring and recording when fluid such as urine is introduced to a fluid collection container is provided. The system includes a measuring device that includes a load cell in communication with other various electronic components. The load cell is attached on one end to a fixed object like a hospital bed. At its other end, it is attached to a fluid collection container such as a urine collection bag. When fluid is introduced into the container, the load cell detects a stress change. A strain gauge (or gauges) on the load cell detects a resistance change and reads the change as a voltage change. That voltage change is amplified and digitized and converted to a weight, volume, and flow rate, before being transmitted to a recordkeeping system like electronic medical records. The system thus provides for real time measurement of fluid output collected in the container.

Owner:UROSTAT LLC

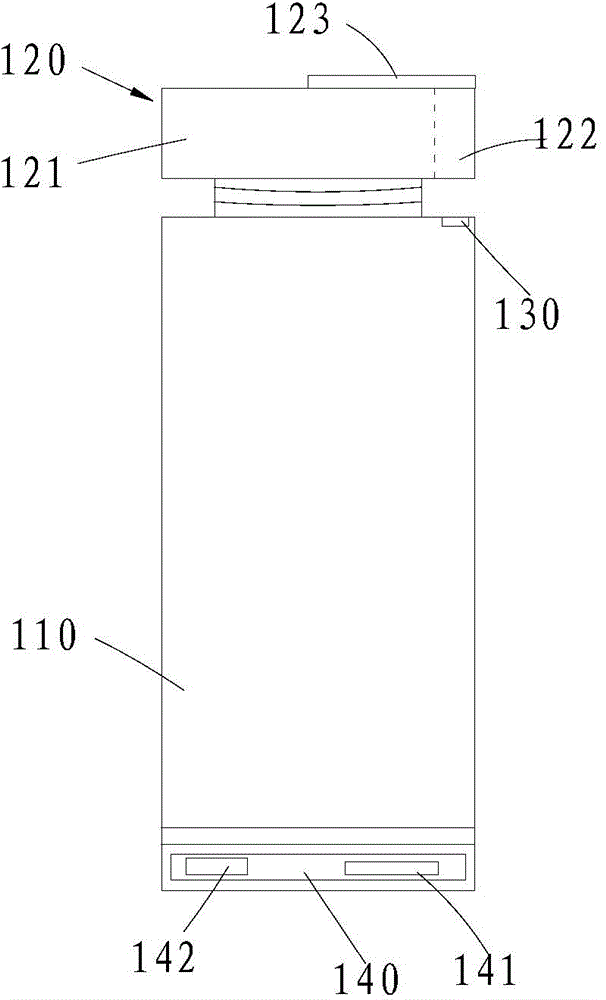

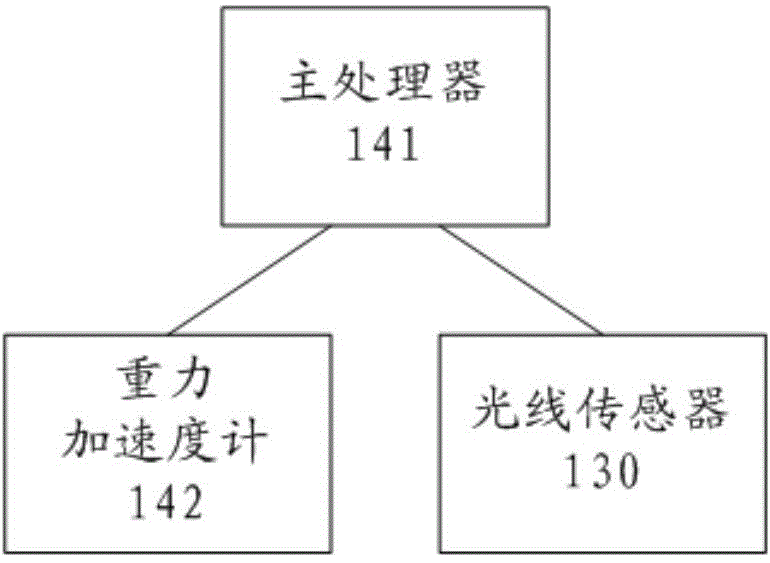

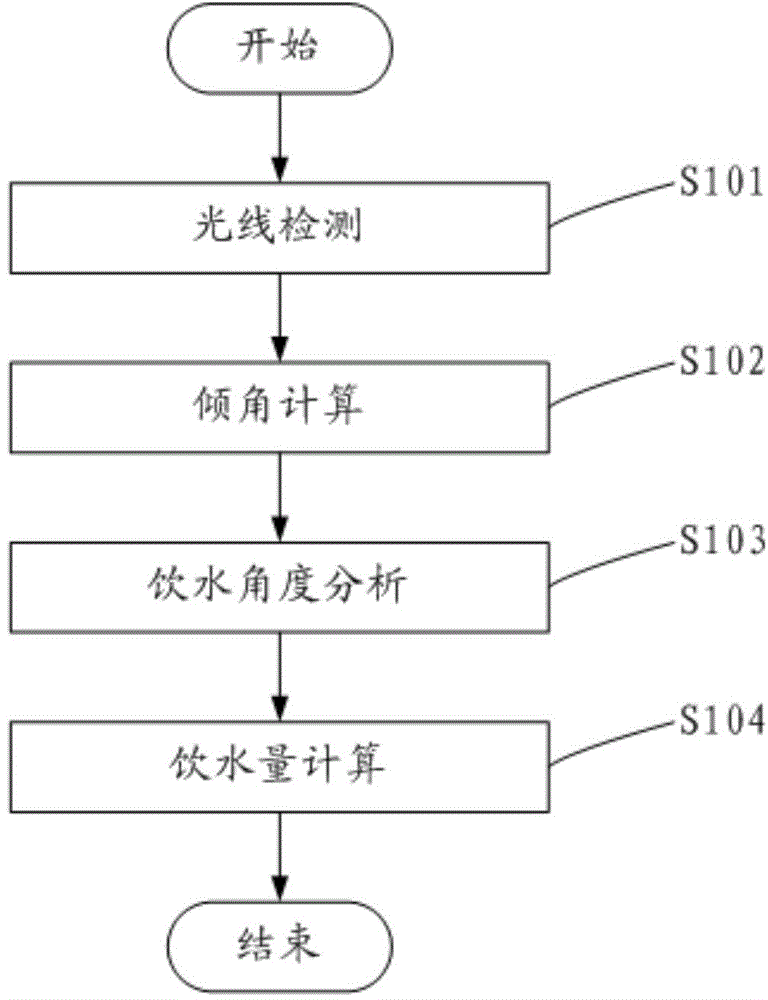

Intelligent water cup and method and system for detecting water intake of intelligent water cup

ActiveCN104643829AReal-time measurementMeasuring safety and hygieneVolume measurement apparatus/methodsDwelling equipmentAccelerometerEngineering

The invention relates to an intelligent water cup. The intelligent water cup comprises a cup body, a cup cover, a light sensor and a main board, wherein the cup cover is arranged on the cup body, the light sensor is arranged on the cup body and is covered by the cup cover, the light sensor can be exposed by opening the cup cover, the main board is arranged at the bottom of the cup body and is isolated from an inner cavity of the cup body, a main processor and a gravity accelerometer are arranged on the main board, and the light sensor and the gravity accelerometer are respectively connected with the main processor. The intelligent water cup has the advantages that the water intake can be measured in real time, the intelligent water cup can not be in a static state, a measuring element does not contact with drinking water, and the measurement is safe and hygienic.

Owner:上海诺饮智能科技有限公司

Method and system for remotely processing volumetric data

InactiveUS20060142974A1Effectively efficiently readingLevel indicator with buoyant probesError detection/correctionVolumetric dataEngineering

In accordance with an aspect of the present invention, a system for providing storage tank measurements to a remote location is provided. The system includes a control box configured to take a plurality of readings from within the storage tank and transmit those readings to a master computer. The master computer is configured to receive and store the plurality of readings, and in response to receiving a request for a measurement for the storage tank, calculate the requested measurement utilizing the received readings. The calculated measurements are then transmitted to the device requesting the measurements.

Owner:FUELING TECH

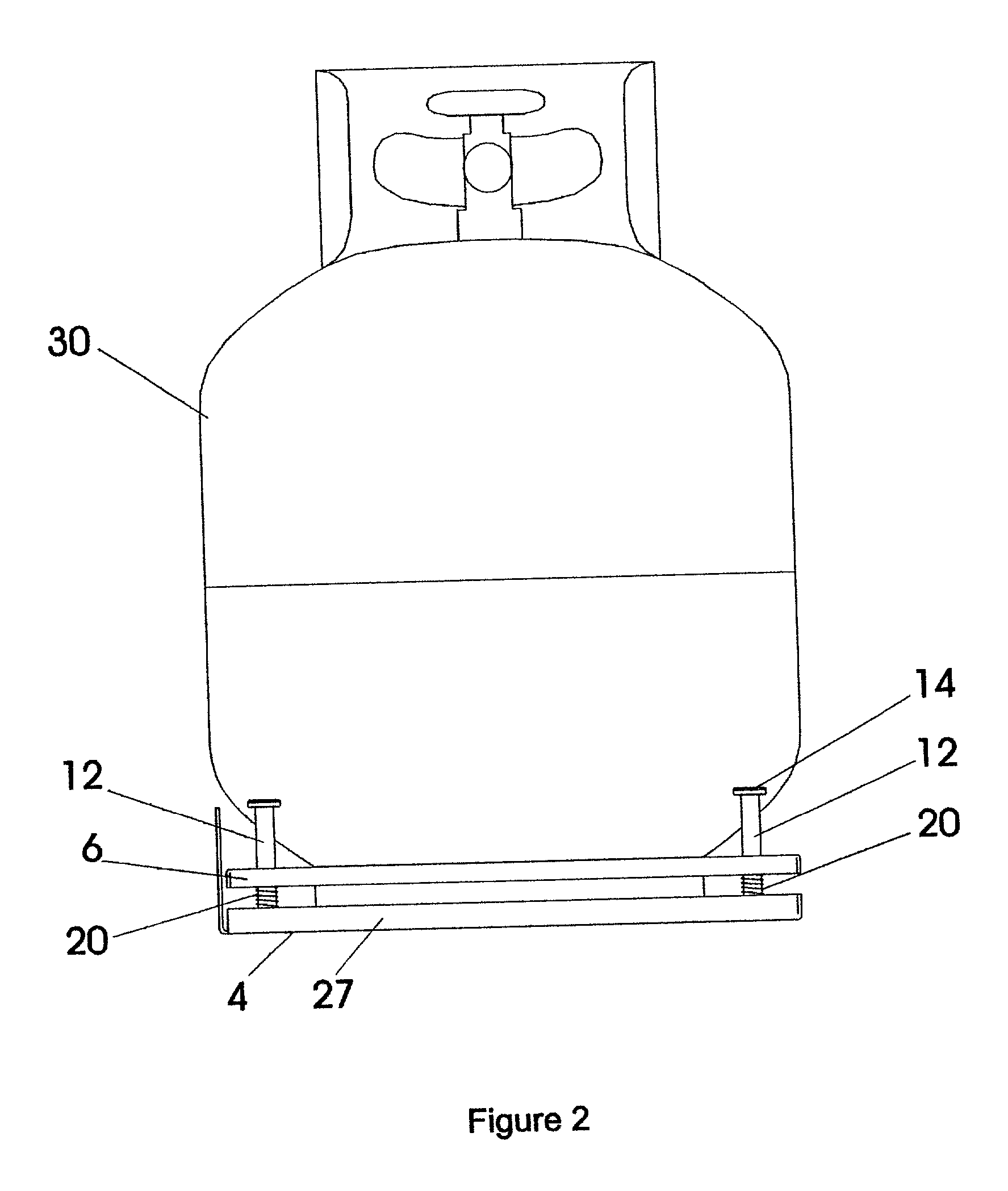

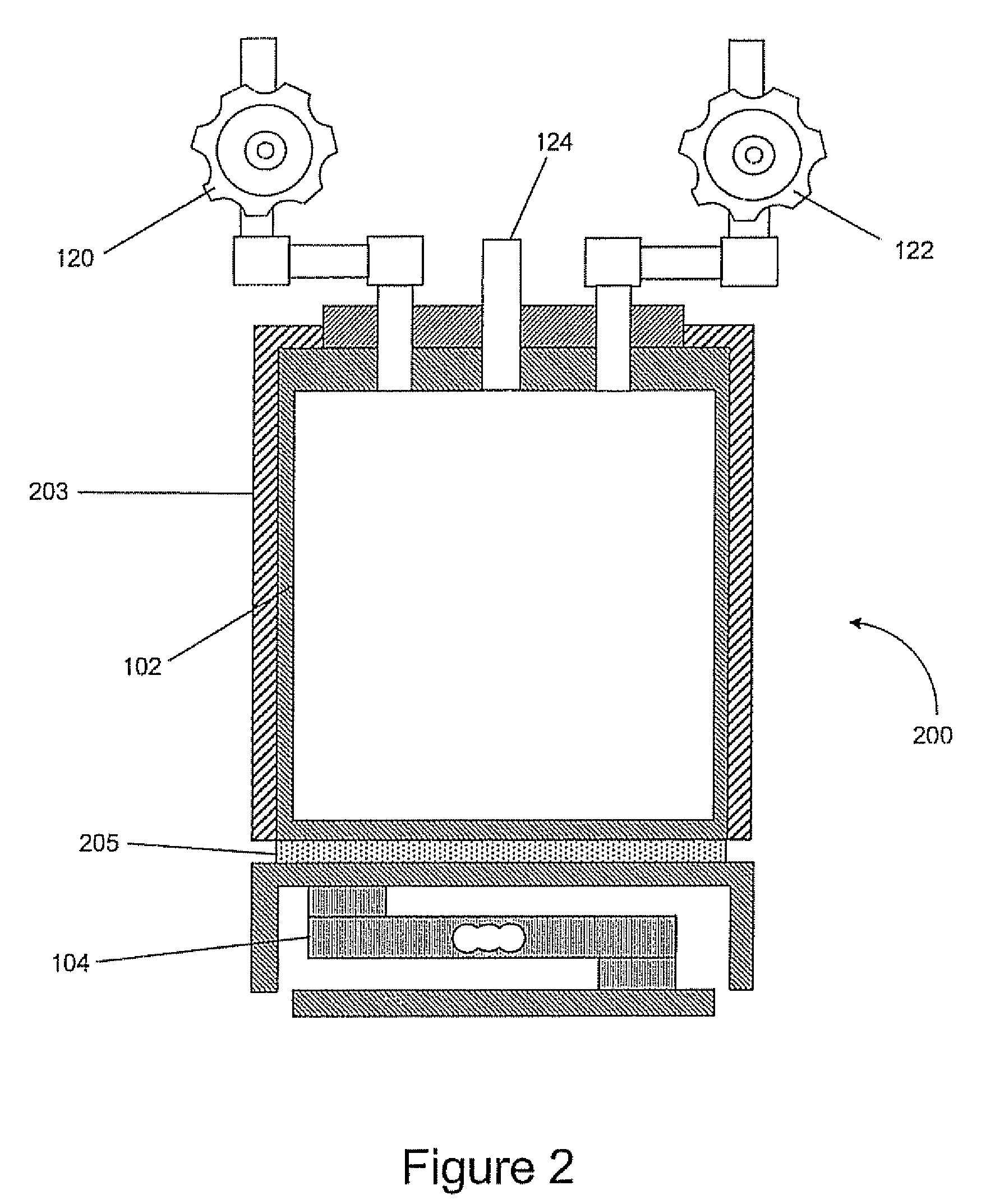

Fuel level indicator for propane tank on a barbecue

InactiveUS20010032504A1Machines/enginesWeighing apparatus for materials with special property/formMechanical engineeringPropane

A fuel level indicator for a propane tank has a top and a base. The top has means to receive and support a propane tank. The top is spring mounted to a base by bolts surrounded by springs. The top moves downward when a full propane tank is mounted thereon. As the tank empties, the top moves upward from the force of the springs. A level indicator is located on the device to indicate the level of the top above the base. In a further embodiment a remote fuel level indicator is used.

Owner:MOSELEY C WILLIAM

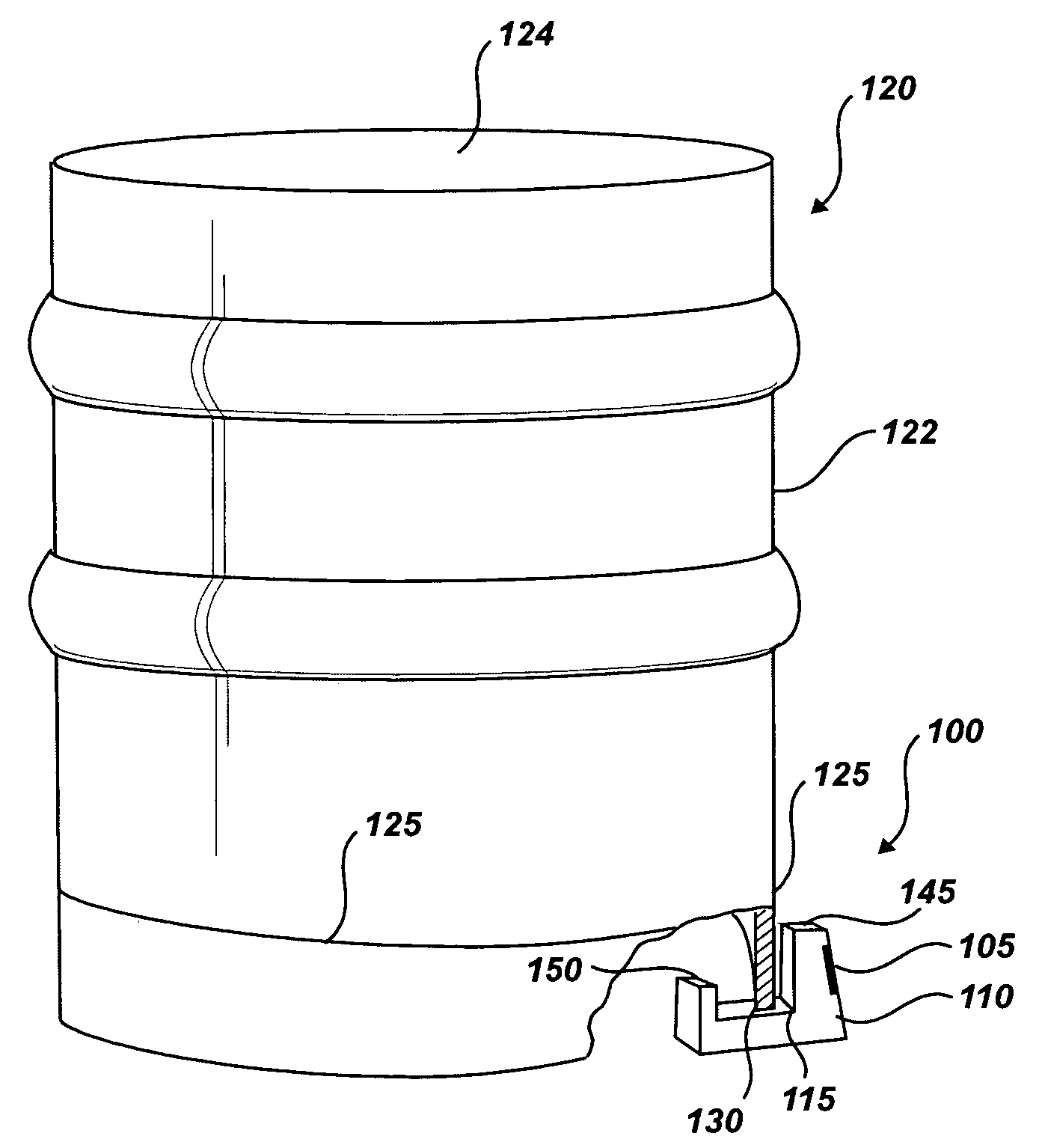

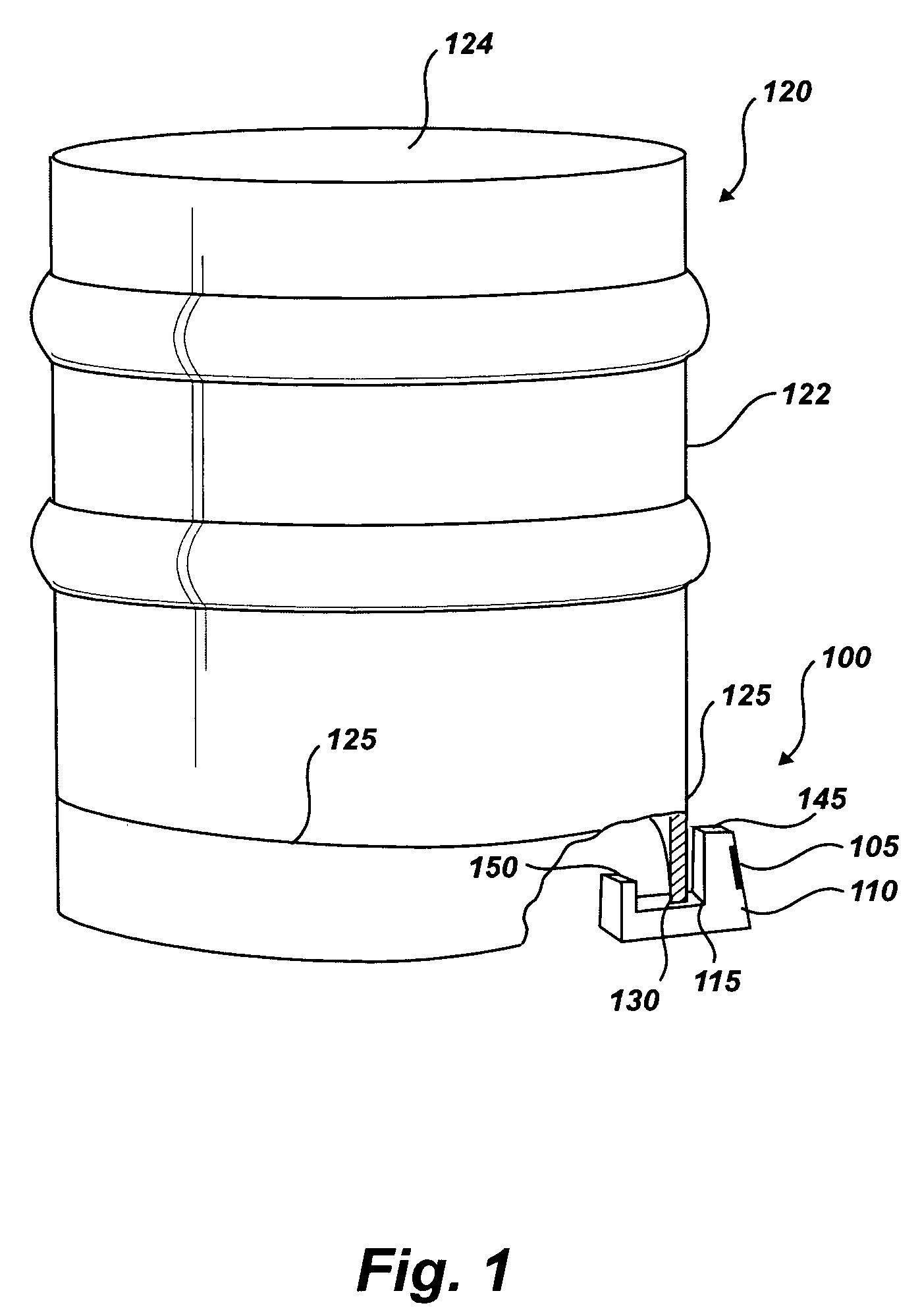

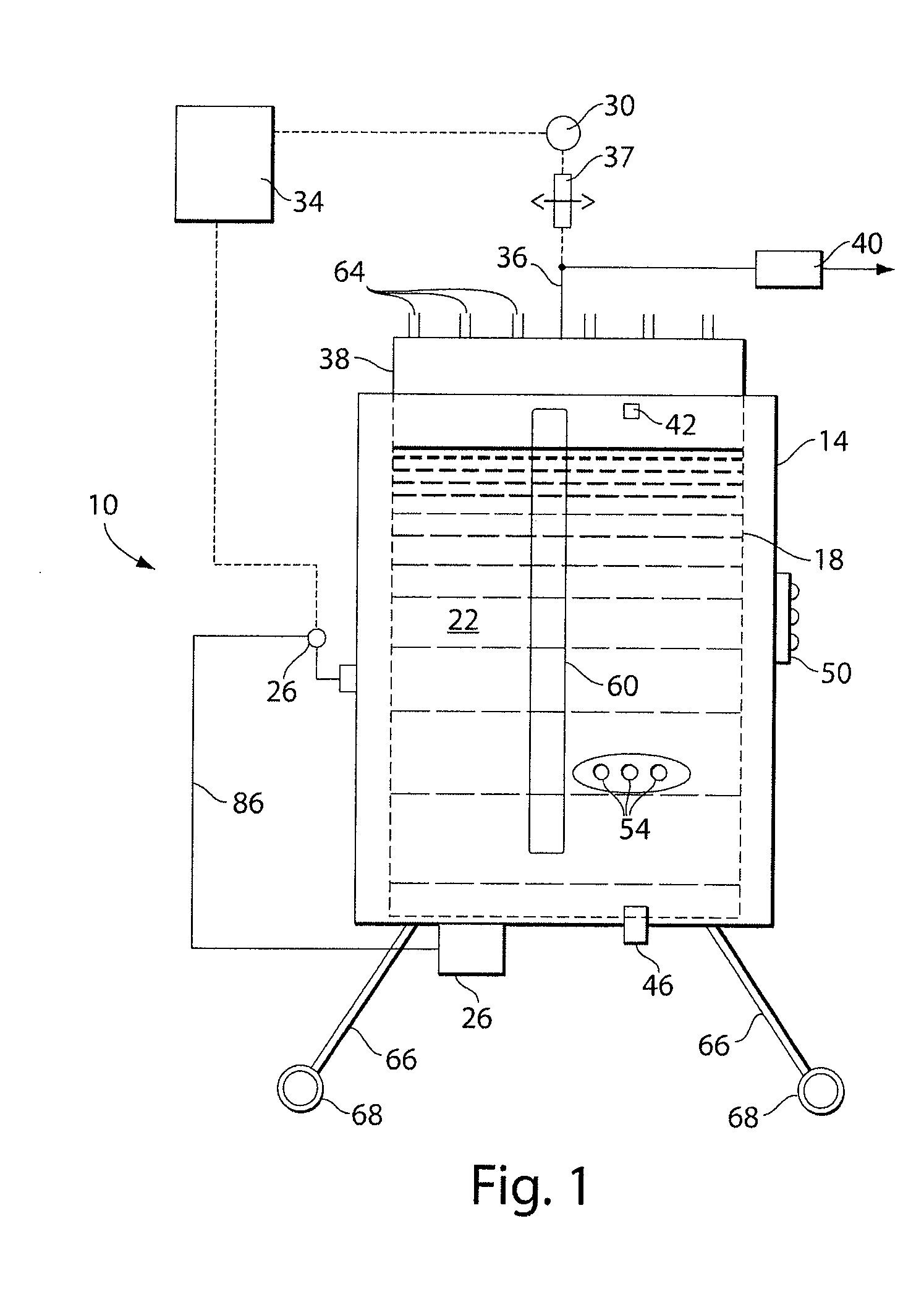

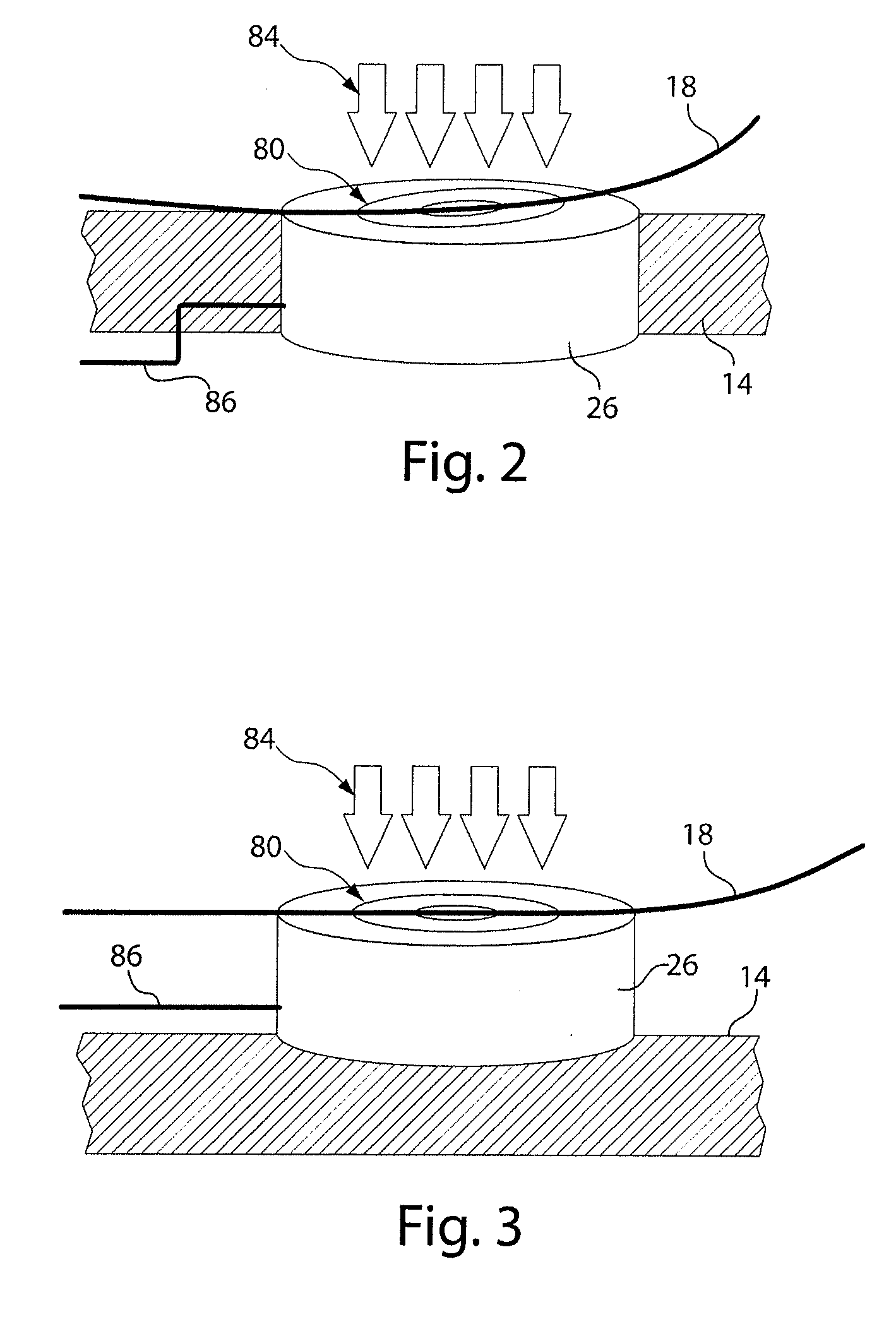

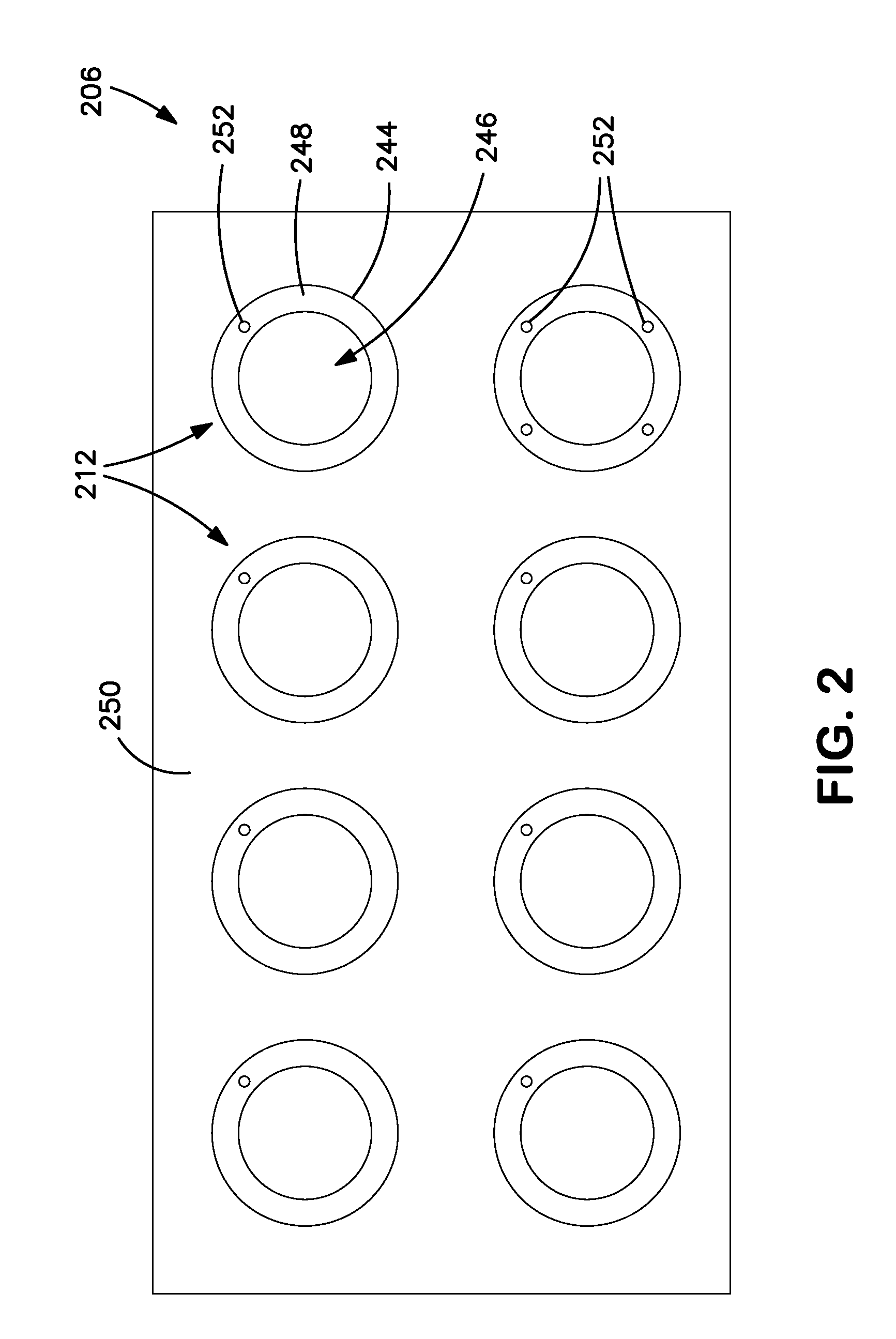

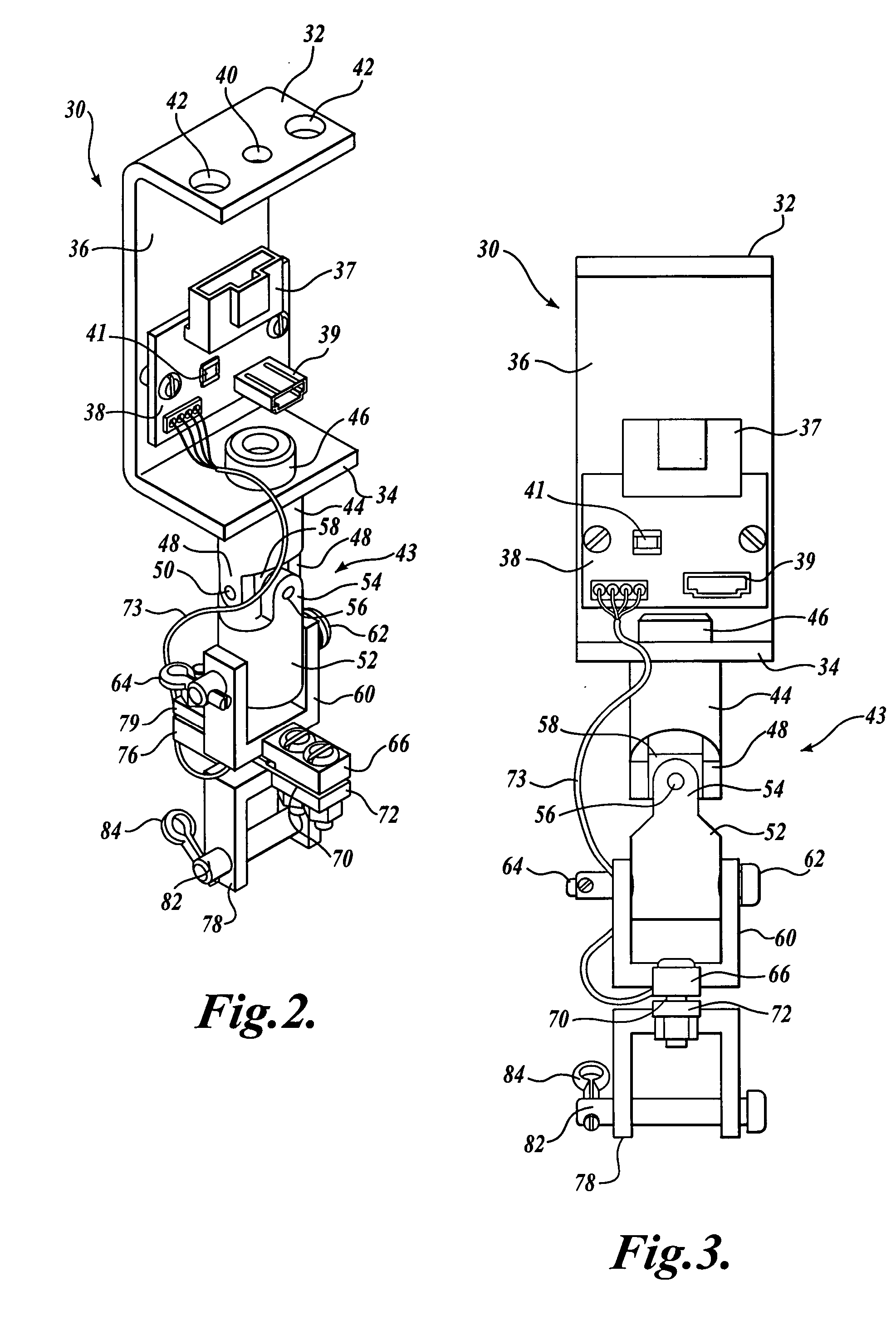

Chemical storage device with integrated load cell

ActiveUS20070062270A1Weight increaseEasy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageCompound (substance)

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

Bottle filling machine with sensor and method thereof

InactiveUS20090178728A1Good filling effectFunction increaseVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

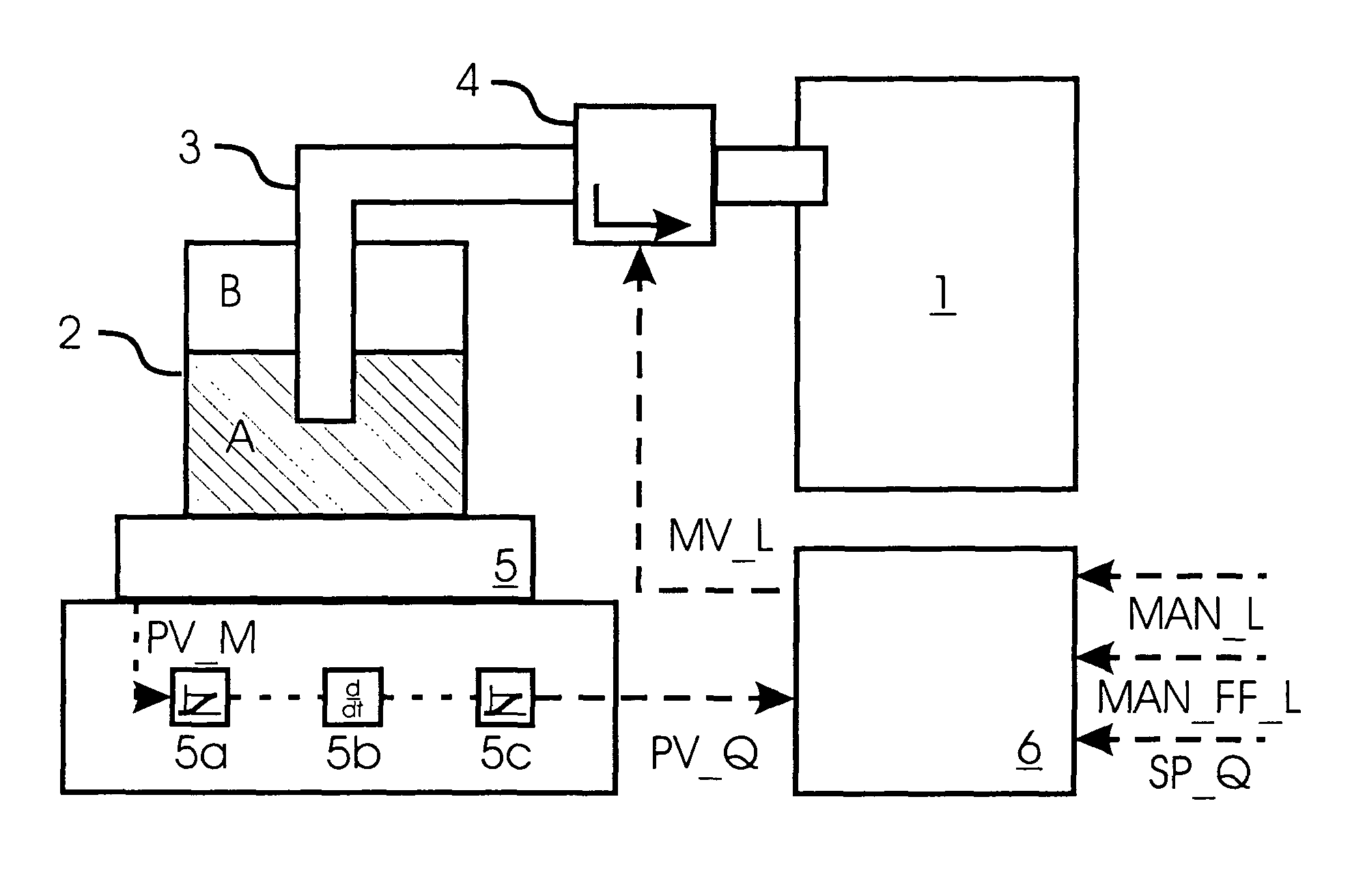

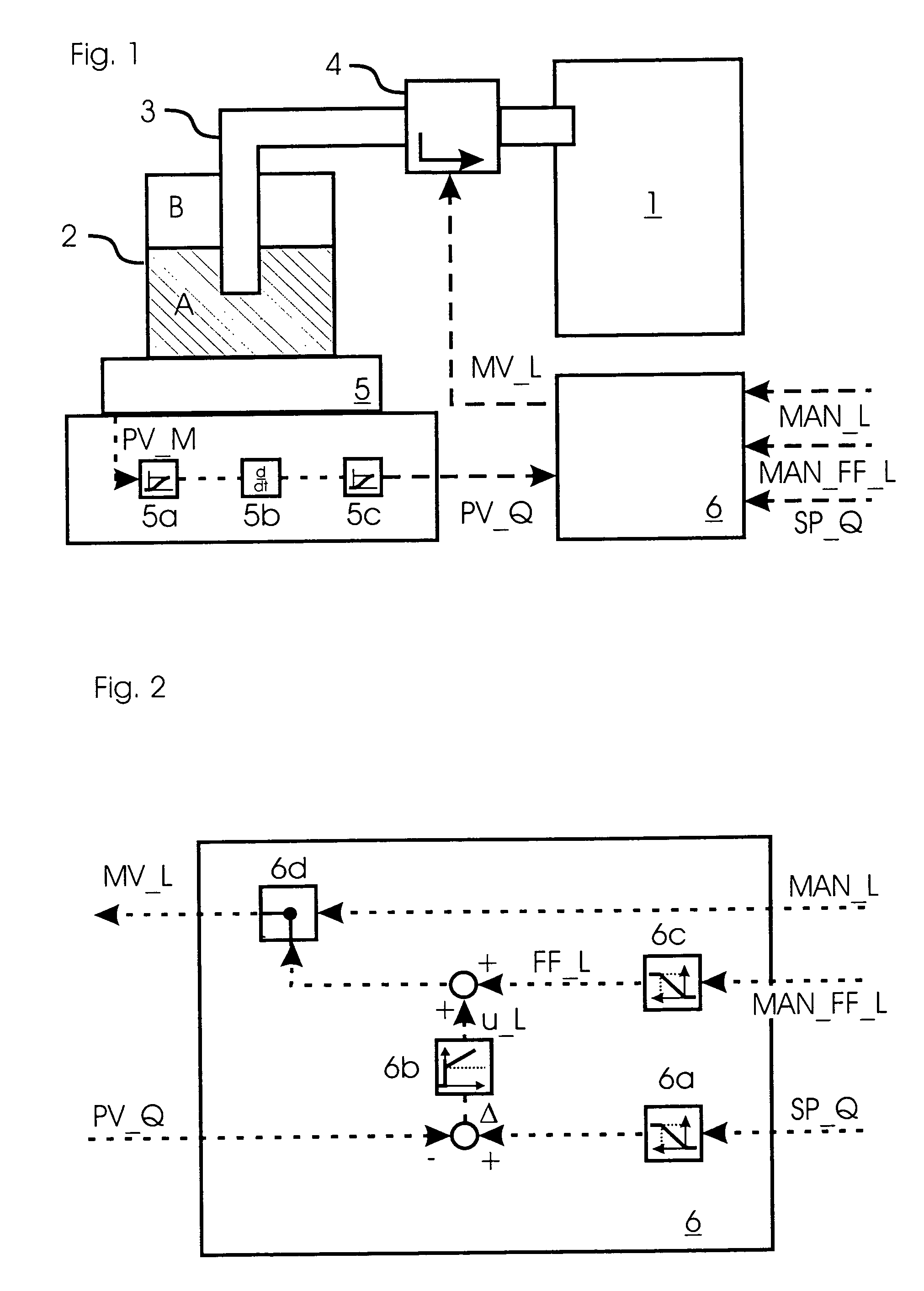

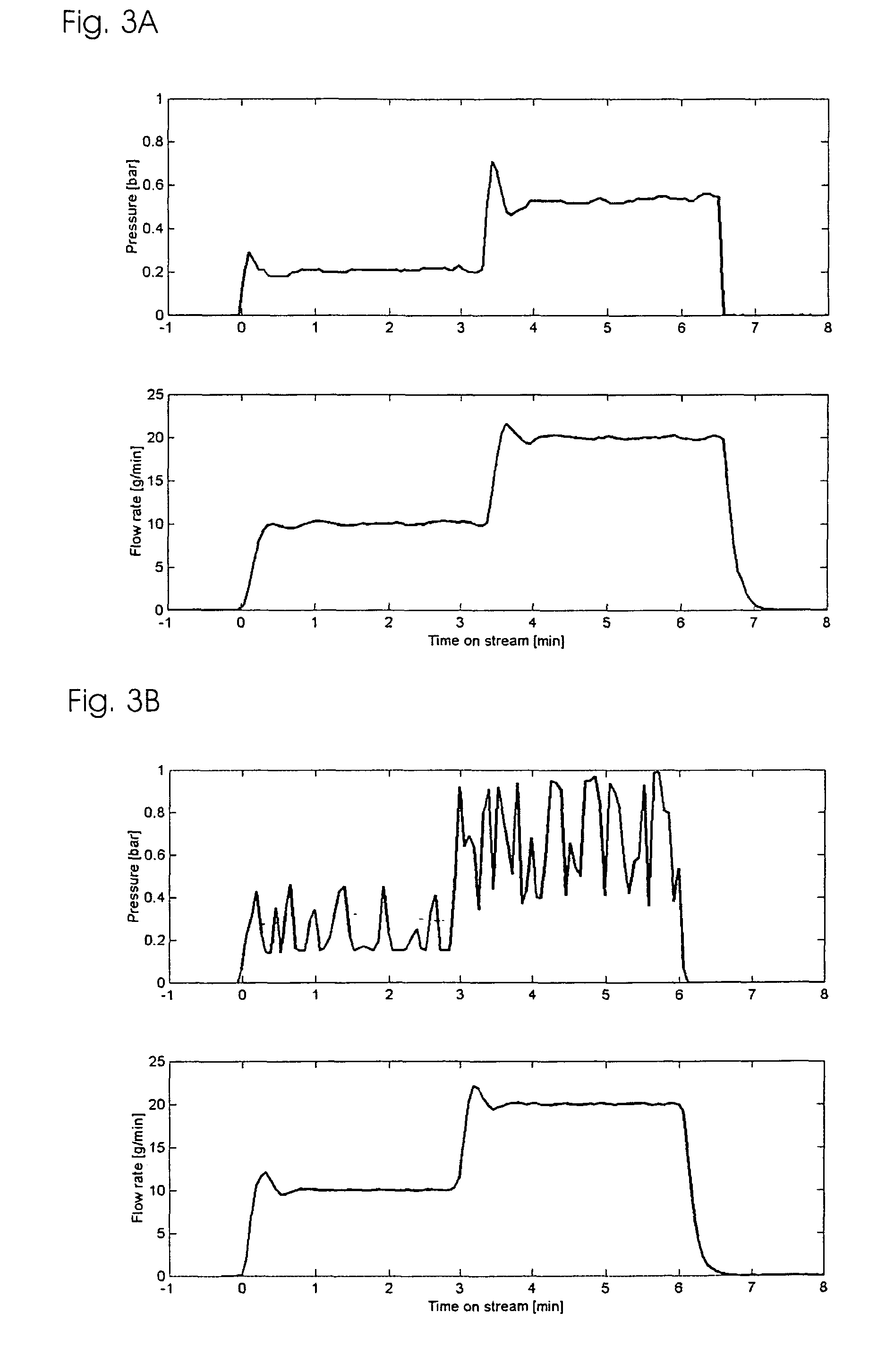

Mass flow rate control system

ActiveUS8230877B2Smooth transferSimple and cheap elementOperating means/releasing devices for valvesLiquid transferring devicesControl systemControl signal

A dosage system for feeding a fluid (A) to a static mixer (1), said system comprising a tank (2) containing said fluid (A) at a predetermined pressure, a fluid passage (3) connecting said container (1) and tank (2), a control valve (4) provided within said fluid passage (3) to control the flow of said fluid (A) from said tank into said container; and a controller (6) for receiving a target flow rate (SP_Q) of said fluid (A), and an actual flow rate (PV_Q) of said fluid (A), and for outputting a control signal (MV_L) to said control valve (4) indicating a valve position to adjust the flow rate. Further provided is a method for controlling said dosage system.

Owner:LONZA AG

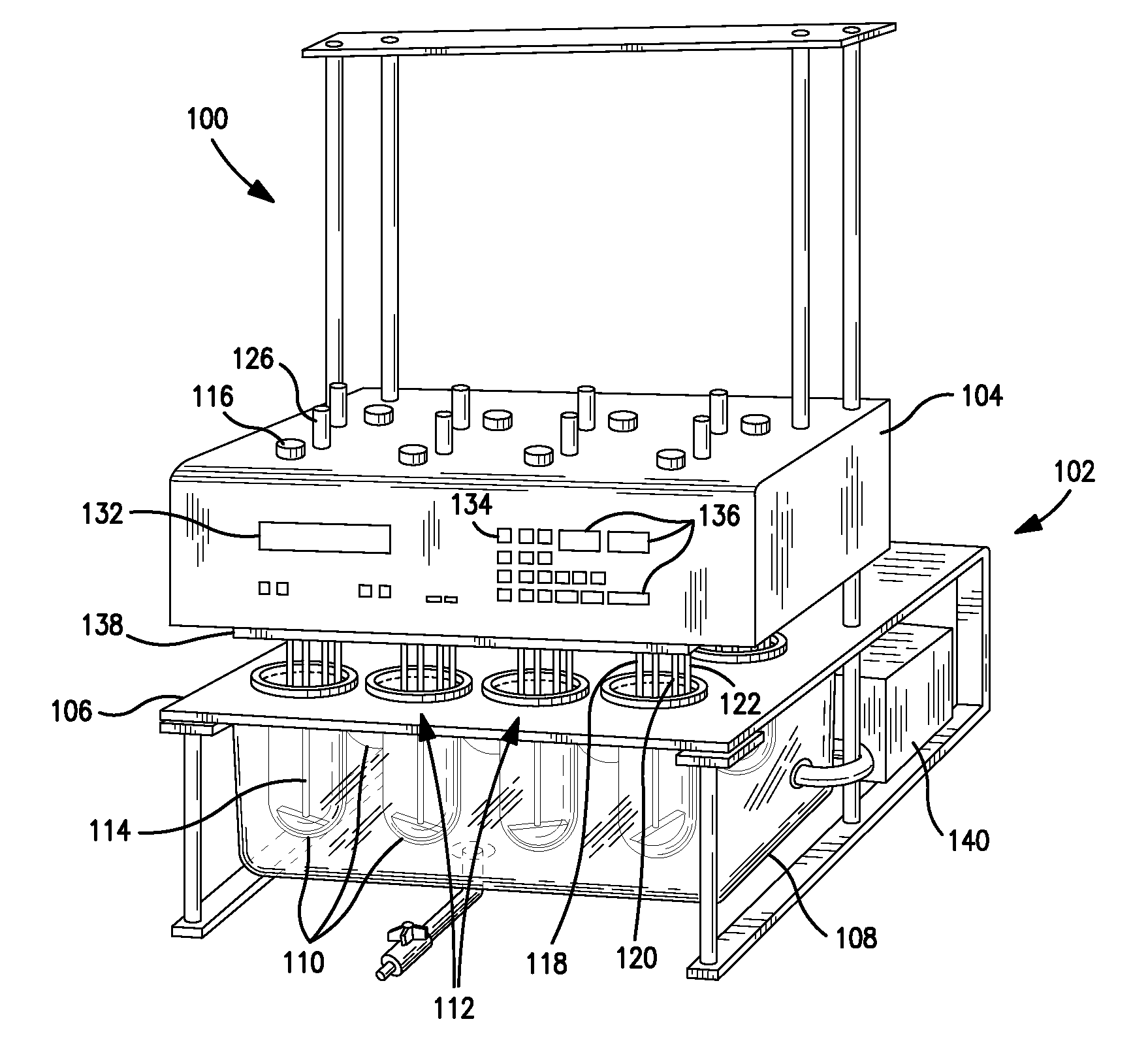

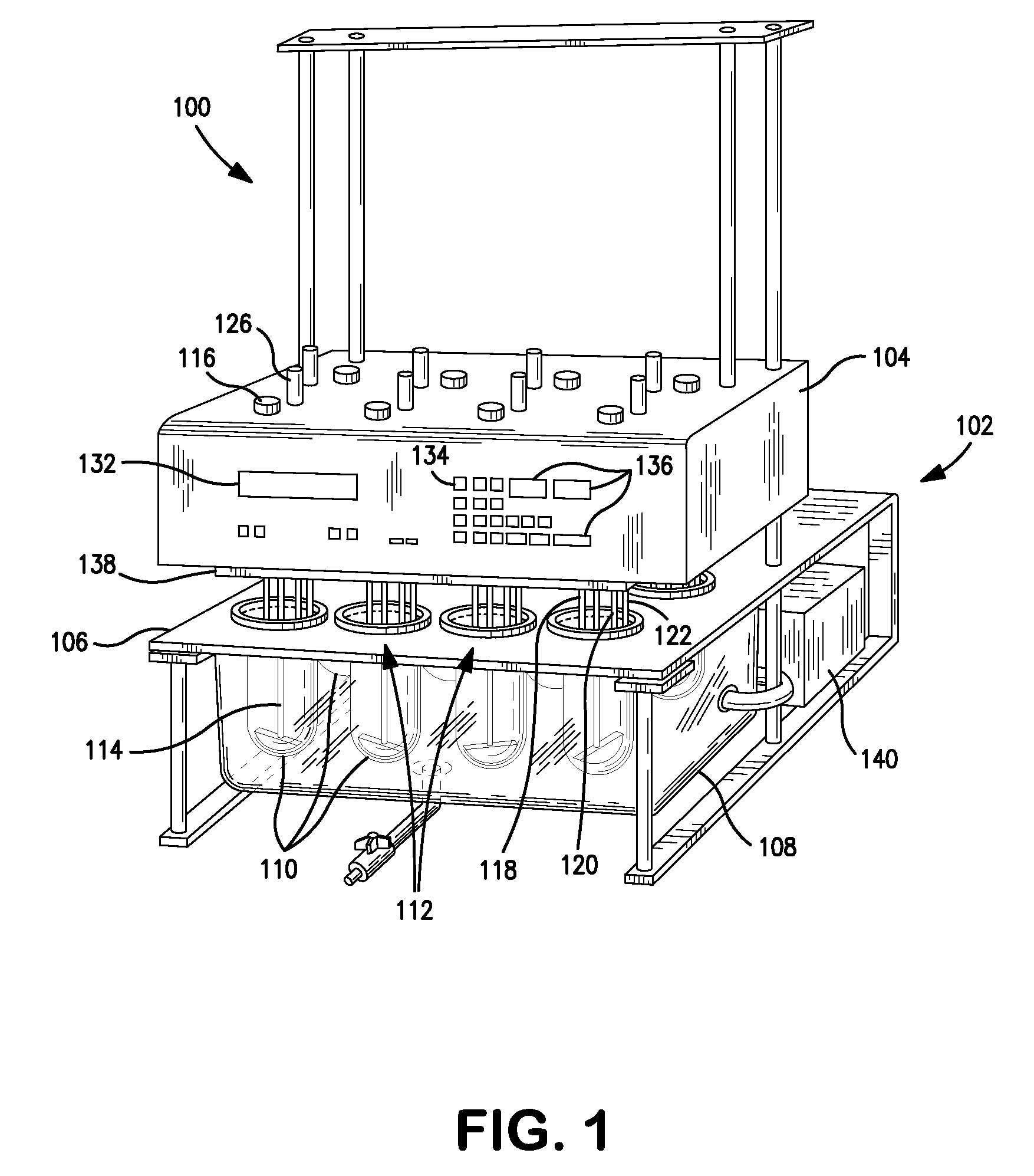

Dissolution testing with in-situ gravimetric volume measurement

InactiveUS7938032B2Shaking/oscillating/vibrating mixersWeather/light/corrosion resistanceElectronic controllerControl signal

A dissolution test apparatus includes a vessel support member, weight sensors, a movable component, a media transport cannula, a pump, and an electronic controller. The vessel support member receives vessels. A weight sensor is located at each vessel site. Each weight sensor contacts a vessel and transmits a measurement signal indicative of the weight of the vessel and any contents therein. The movable component moves the media transport cannula toward a vessel site. The pump establishes media flow between the media transport cannula and the selected vessel. The controller communicates with the weight sensors and may also communicate with the pump. Based on the measurement signals received from the weight sensors, the electronic controller may calculate the volume of media in a given vessel. The electronic controller may also control media flows to or from the vessels by transmitting control signals to the pump assembly.

Owner:AGILENT TECH INC

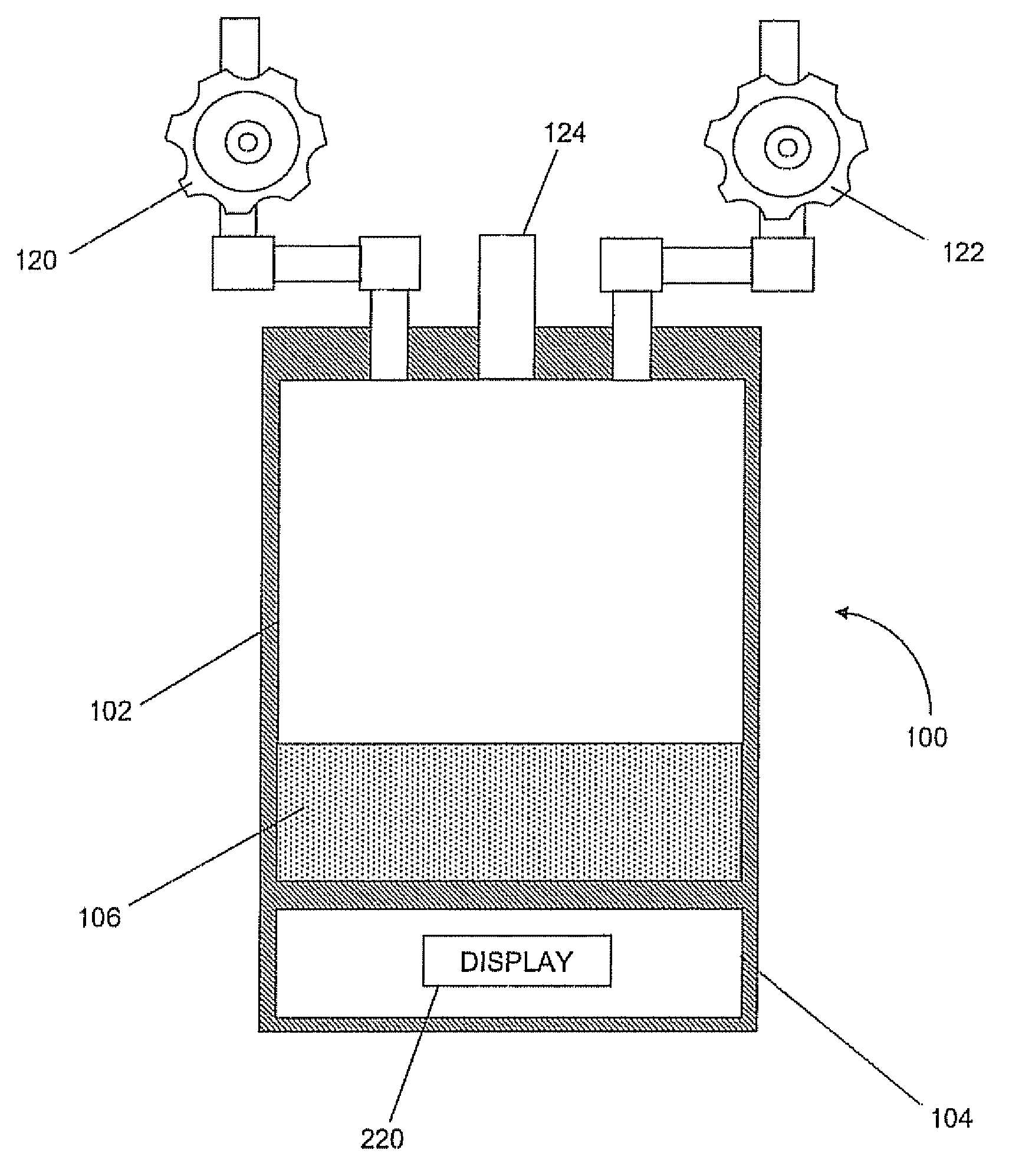

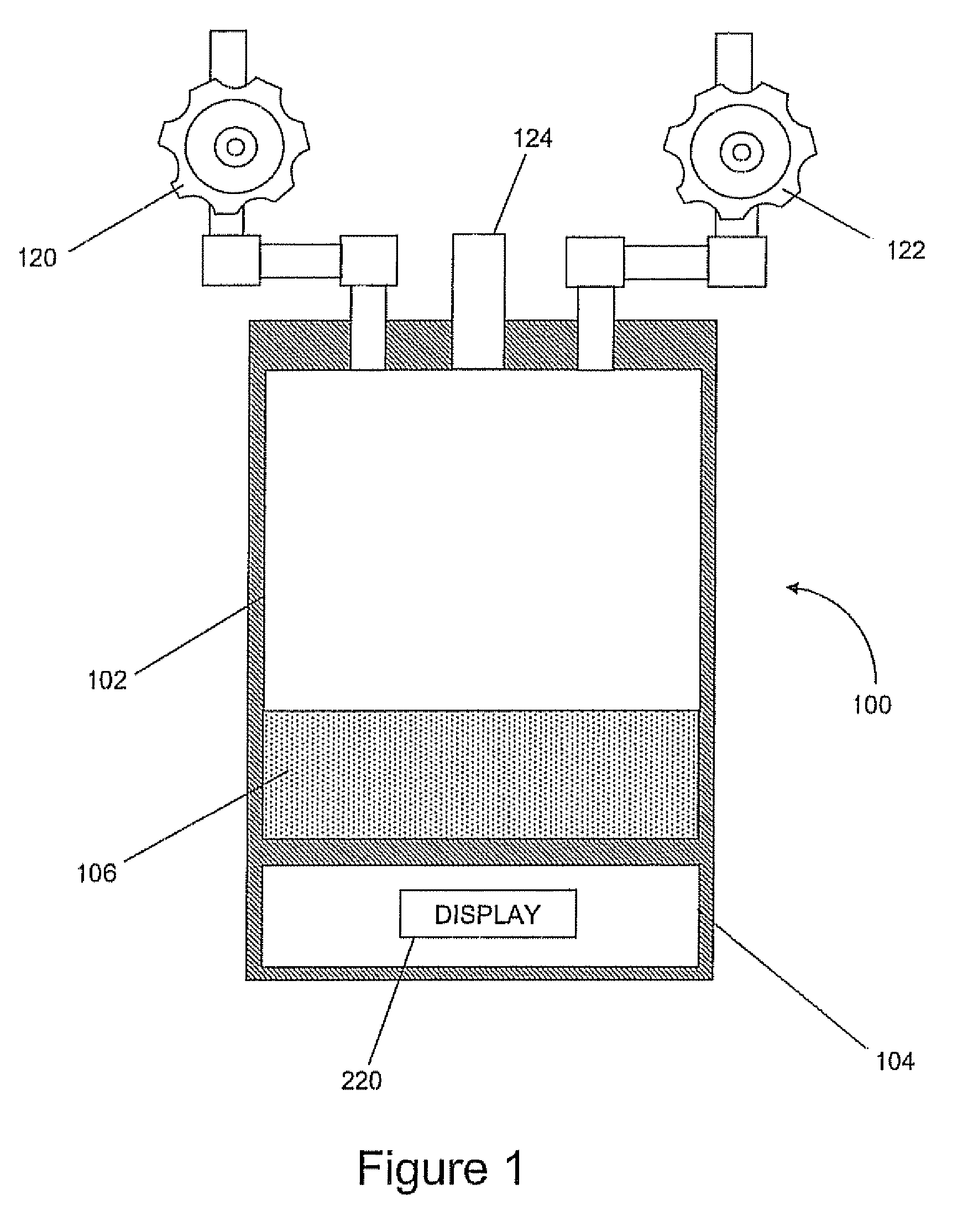

Chemical storage device with integrated load cell

ActiveUS7770448B2Easy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageLoad cell

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

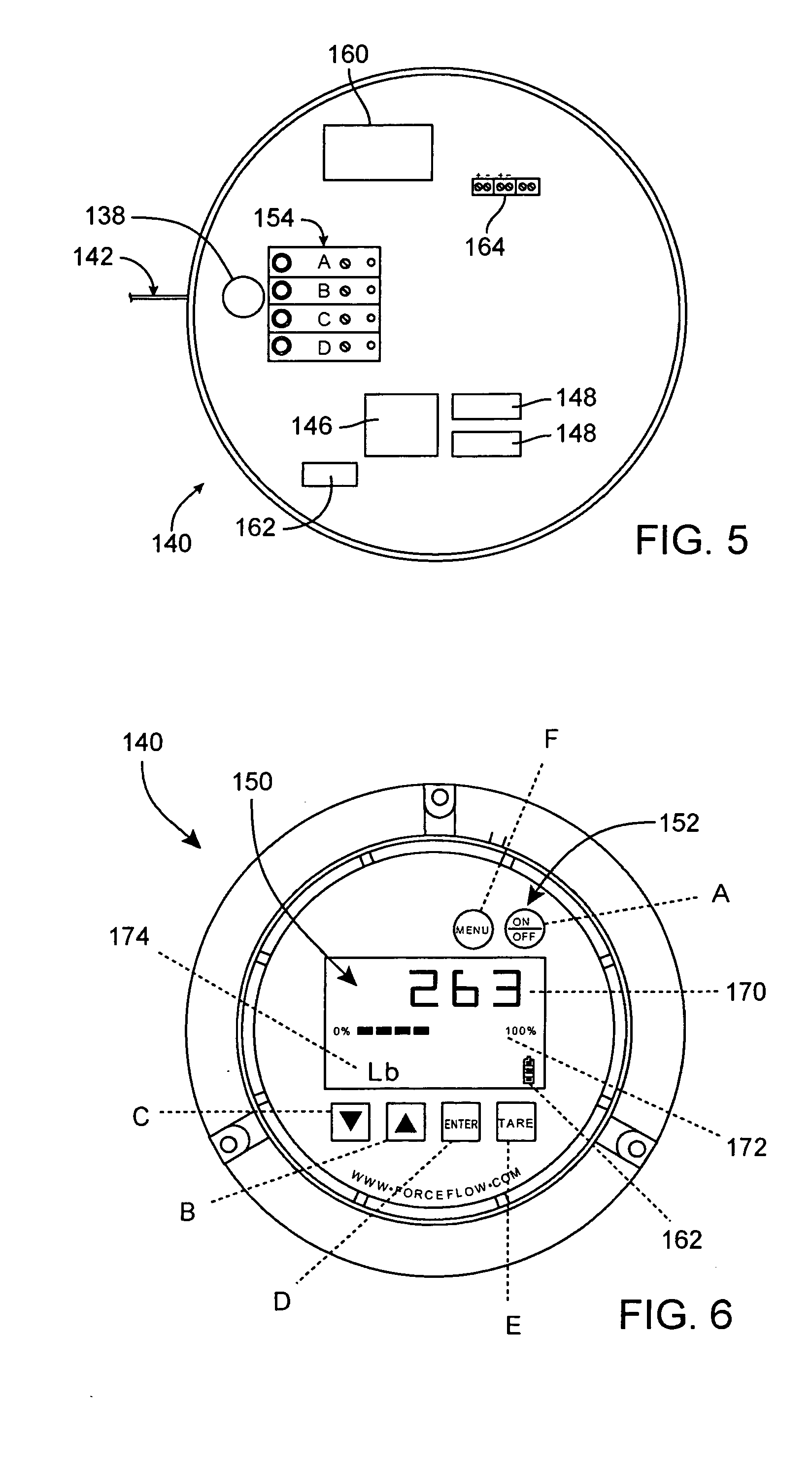

System and method for detecting and displaying an amount of chemical in a cylinder or vessel

ActiveUS20050126277A1Weighing apparatus using fluid action balancingContainer/cavity capacity measurementMarine engineeringTransducer

A system and method for detecting and displaying the amount of chemical in a vessel. The system includes a vessel with a variable quantity of gas supported upon a moveable platform. A hydraulic load cell is positioned under the platform, and generates a hydraulic pressure signal, which is a function of the variable quantity of gas in the vessel. An electrical signal transducer converts the pressure signal to an electrical signal which is transmitted to a battery powered microprocessor / display capable of converting the electrical signal into a displayable signal indicative of an amount of gas remaining in the vessel.

Owner:FORCE FLOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com