Scattered material storage tank tankful detection and control method

A control method and a storage tank technology are applied in the field of bulk material storage and transportation, which can solve the problems of too many connection cables, large maintenance costs, and large maintenance volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

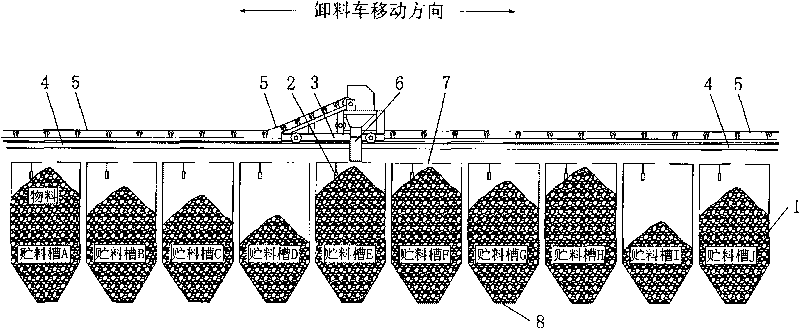

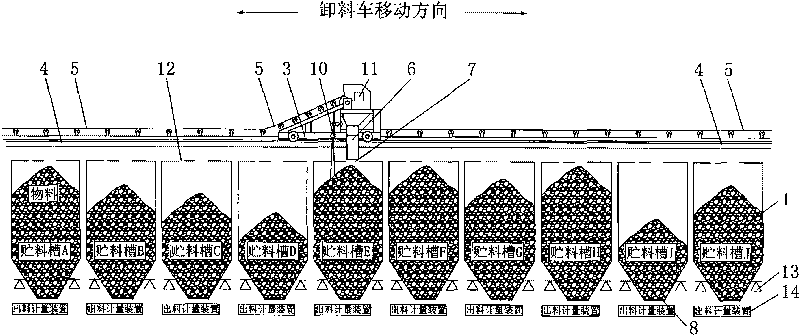

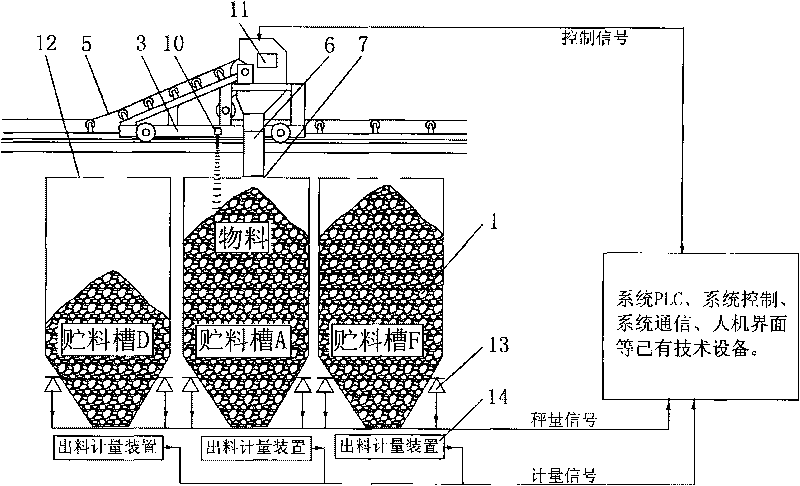

[0029] see figure 2 , a kind of device that implements the full tank detection method of bulk material storage tank is a row of A, B, C, D, E, F, G, H, I, J totally 10 bulk material storage tanks 1, each Each storage tank 1 bottom is respectively equipped with a feed tank scale 13, also can be equipped with discharging metering device 14, present embodiment adopts feed tank scale 13; The rated volume 350m of each feed tank 1 3 ; The upper groove surface of each storage tank 1 has two ports, a feed port 7 and a measuring port 12, and the bottom has a port for the discharge port 8. On the upper trough surface of the storage tank 1, there are facilities such as the loading conveyor belt conveyor 5, the moving track 4 of the storage tank moving unloading vehicle, and the identification mark of the position of the material tank. Can move the unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com