Weight measurements of liquids in flexible containers

a flexible container and liquid technology, applied in the field of flexible containers, can solve the problems of large scales, vibration and shock, and later systems are not well suited for measuring the weight and/or volume of liquids in flexible containers, such as disposable bags, and require cumbersome scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

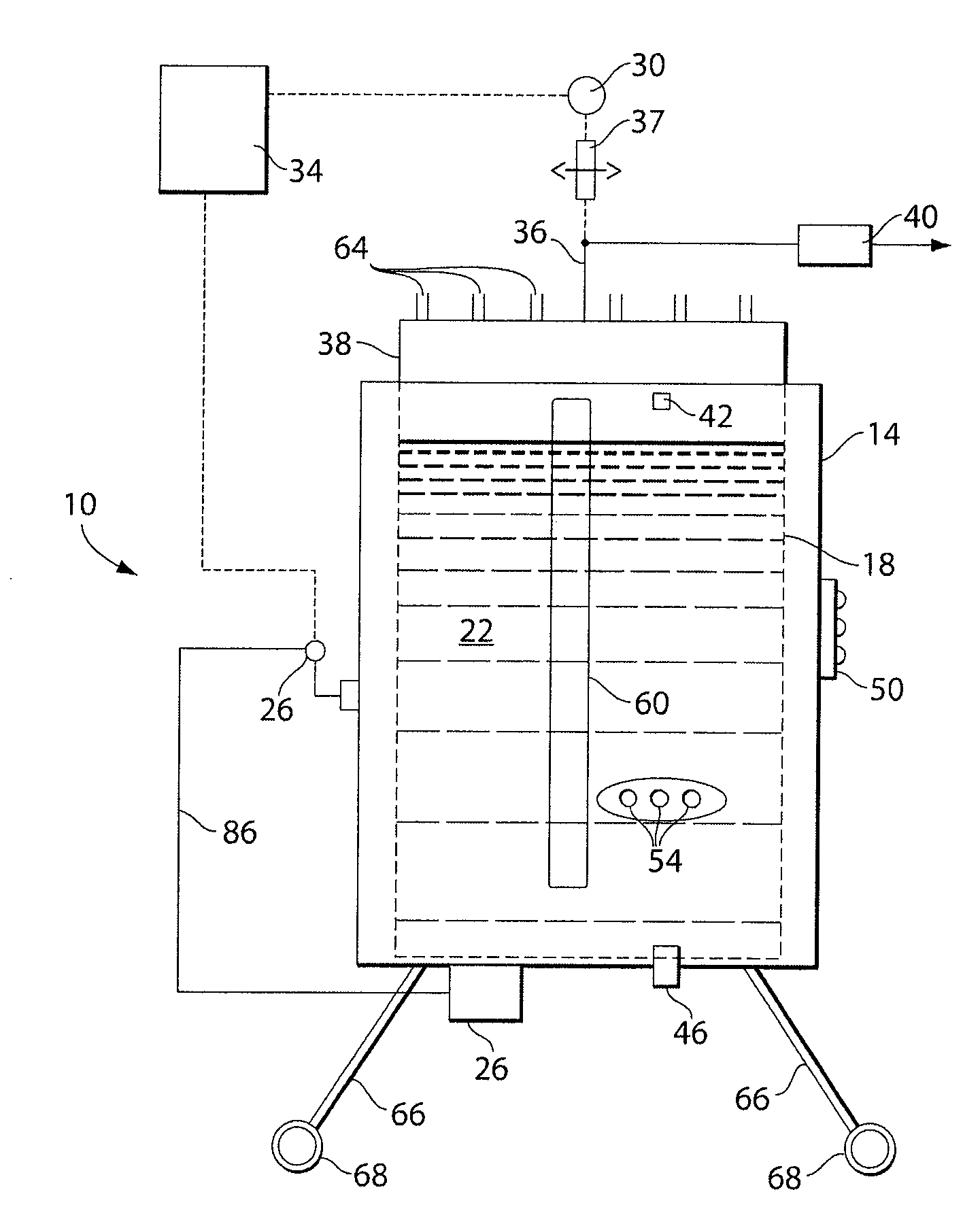

[0054]This example describes a configuration of a bioreactor including a disposable, flexible container with pressure indicating sensors that can be used for determining a weight and / or volume of a fluid in the container.

[0055]A flexible, disposable bag was installed in a reusable support structure with pressure indicating sensors installed within the sparge air supply line (e.g., at the top of the flexible container), and within a harvest line (e.g., a tubing connected to an outlet port at the bottom of the flexible container). The disposable, flexible bag was formed of a plastic sheet welded together in a designed configuration to result in an enclosed bag design. Hose barb ports were welded on the bag and hoses were installed on these hose barb ports. The number of ports used was dependent on the configuration of the bag necessary to operate a specific bioreactor process. The sensors had a flow-through design to measure pressure of a liquid or gas flowing through them (e.g., a De...

example 2

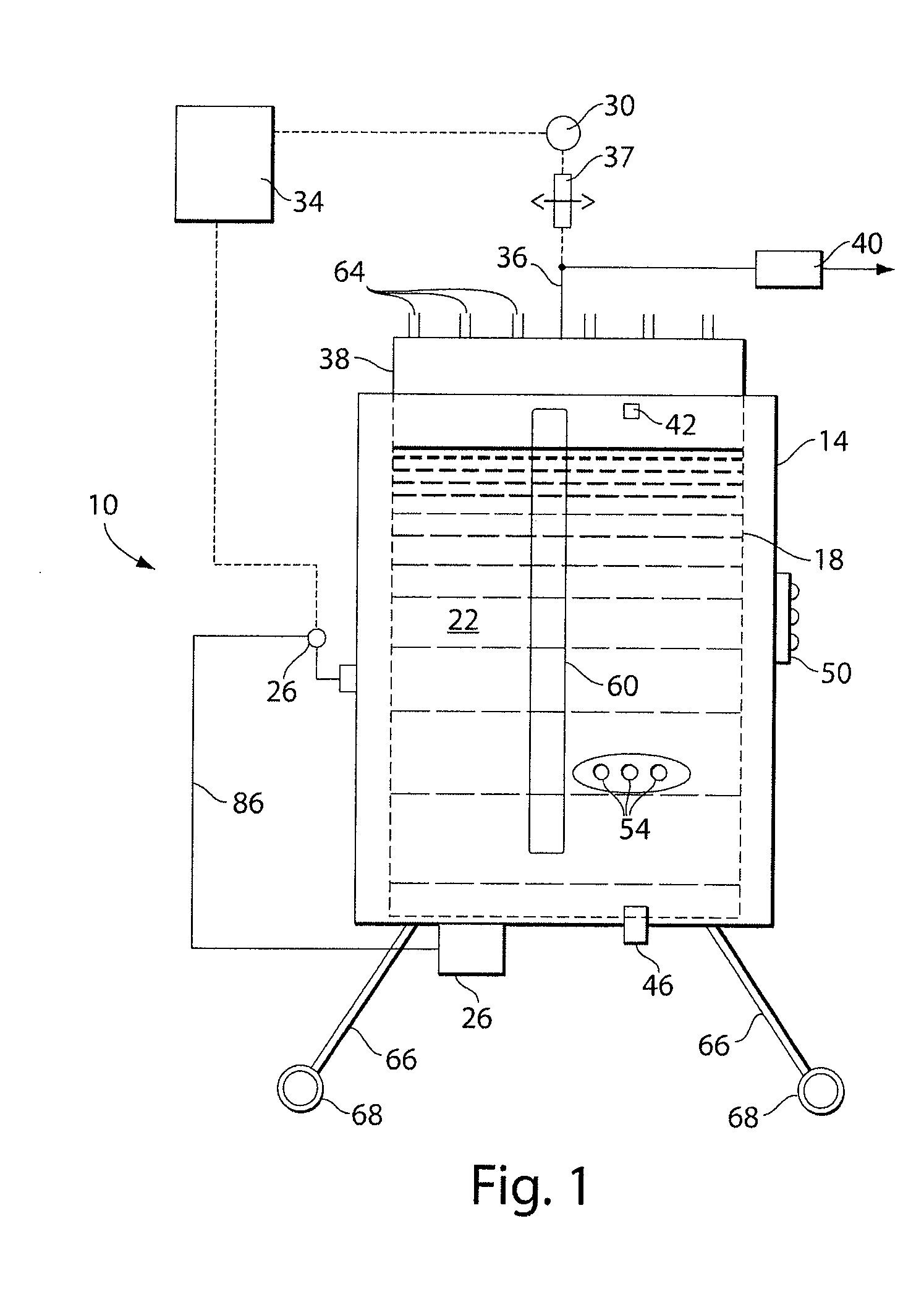

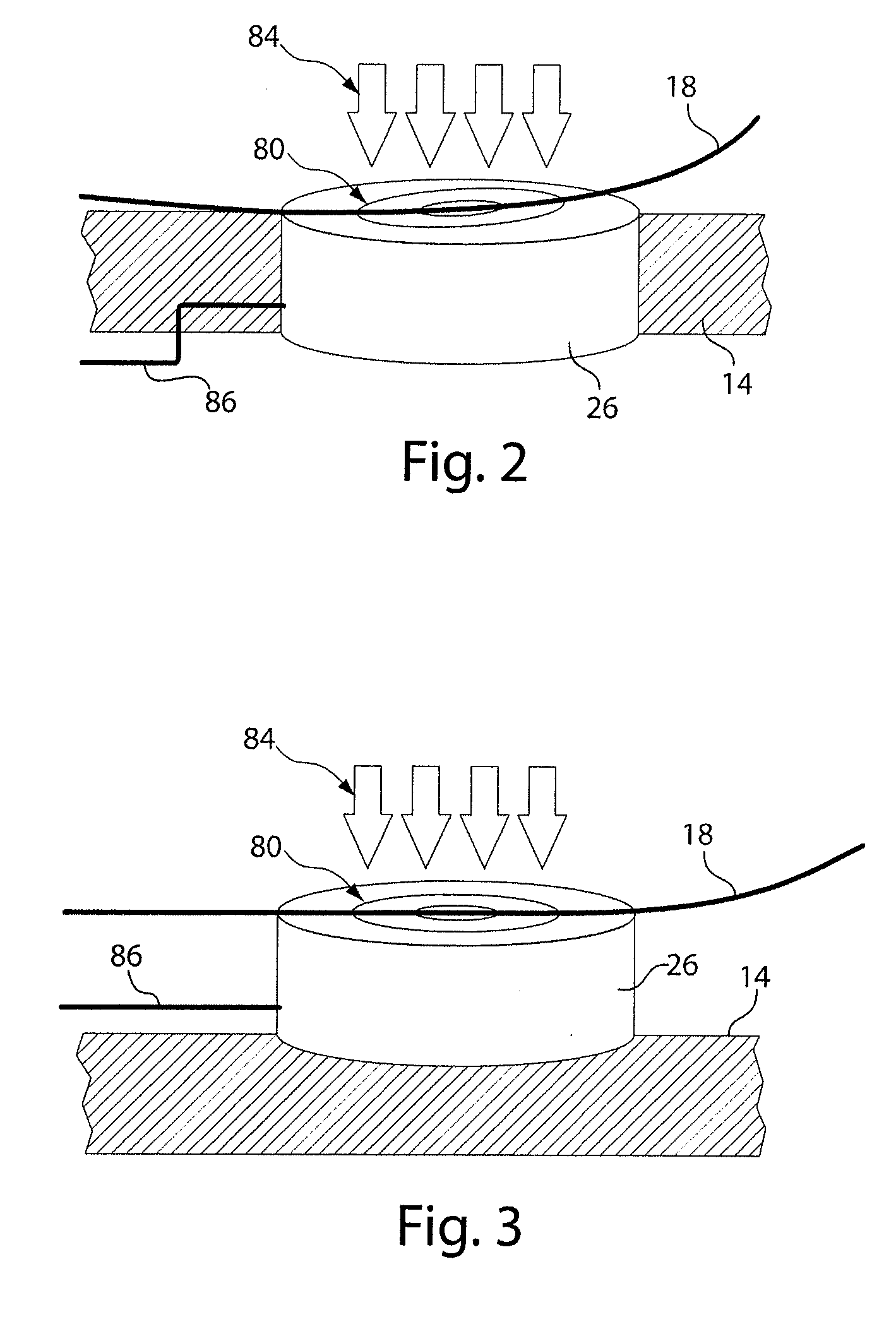

[0059]This prophetic example describes a configuration of a bioreactor including a disposable, flexible container with a first pressure indicating sensor positioned near the bottom of the flexible container that is not in fluid contact with any fluid in the flexible container, and a second pressure indicating sensor positioned near the top of the flexible container and operatively associated with the container via a sparge air supply line. The pressure indicating sensors are used for determining a weight and / or volume of a fluid in the container.

[0060]A disposable, flexible container for containing materials for performing biological and / or chemical reaction is supported by a reusable support structure. A first, non-flow through pressure indicating sensor is positioned between the bottom of the flexible container and a wall of the reusable support structure as shown in FIG. 2 and / or 3 (e.g., the pressure indicating sensor is not attached to harvest line). The pressure indicating sen...

example 3

[0062]This prophetic example describes a configuration of a bioreactor including a disposable, flexible container with a first pressure indicating sensor positioned near the bottom of the flexible container and operatively associated with the container via a harvest line, and a second pressure indicating sensor positioned near the top of the flexible container and operatively associated with the container via a sparge air supply line. The pressure indicating sensors are used for determining a weight and / or volume of a fluid in the container.

[0063]Pressure indicating sensors are interconnected with a disposable, flexible container in the manner described in Example 1. A first pressure indicating sensor is positioned at the bottom of the disposable, flexible container in the harvest line and is used to measure the total downward force / pressure within the container, including the force / pressure due to the weight of the liquid in the container and also any gas pressure present above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com