Bottle filling machine with sensor and method thereof

a technology of a filling machine and a sensor, which is applied in the direction of liquid handling, instruments, packaged goods, etc., can solve the problems of increased labor, increased costs, and inconvenient filling levels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

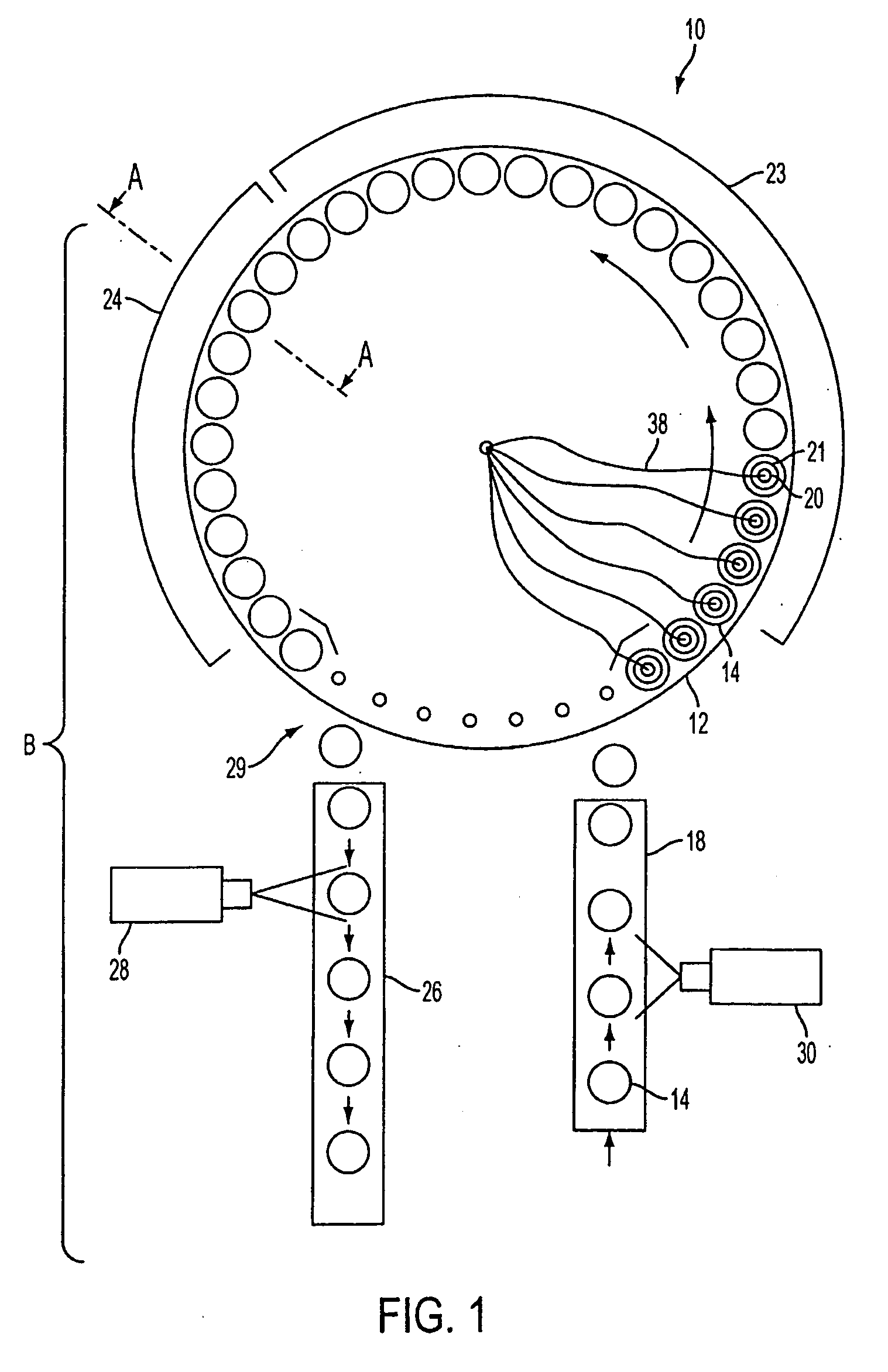

[0030]FIG. 1 is a top view of a filling machine 10 having a rotatable carrier or carousel 12 for transporting containers 14. A wide variety of containers may be used in the present apparatuses and methods, such as glass, plastic, metal, paperboard or the like. For example, the apparatuses and methods may be used to measure liquids or granular solid materials, such as fine chemicals, pharmaceuticals or foodstuffs, or materials comprising solids suspended in liquids. The containers themselves can also vary widely in size and shape and may have the form of, for example, drums, carboys, flasks, cartons, jars, cans, and bottles. However, an exemplary embodiment of the present invention is intended for use with containers containing liquids and, accordingly, the detailed description of the processes hereinafter will mainly be with reference to such bottles of liquid, since the necessary modifications of the apparatus and method for use with other types of containers and contents will be r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filling speeds | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com