Metal grid electrode preparation method of 3D NAND memory

A metal gate and memory technology, applied in the field of metal gate preparation, can solve the problems of gaps in metal gates, affecting the performance of storage devices, hindering subsequent metal dielectric filling, etc., to achieve the effect of reducing possibility and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

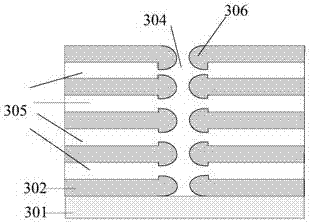

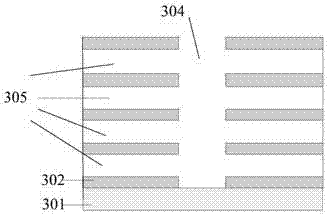

[0027] In order to reduce the influence of the by-product silicon dioxide on the subsequent filling of the metal medium, the embodiments of the present application try to remove the by-product silicon dioxide before filling the metal medium. Based on this, the present application provides a specific implementation of a method for preparing a metal gate of a 3D NAND memory.

[0028] see Figure 2 to Figure 3D . The metal gate preparation method of the 3D NAND memory provided in the embodiment of the present application includes the following steps:

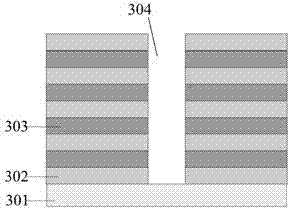

[0029] S201: Provide a substrate 301, on which a silicon oxide 302 / silicon nitride 303 alternate stack structure and a gate line slit (GLS) 304 passing through the stack structure are formed.

[0030] Such as Figure 3A As shown, a substrate 301 is provided, on which a silicon oxide 302 / silicon nitride 303 layer alternate stack structure and gate line gaps 304 passing through the stack structure are formed.

[0031] After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com