Semimetal/semiconductor Schottky junction, method for fabricating same, and Schottky diode

A Schottky diode and Schottky junction technology, applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the problems of interface diffusion and interface reaction, easy formation of defects, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

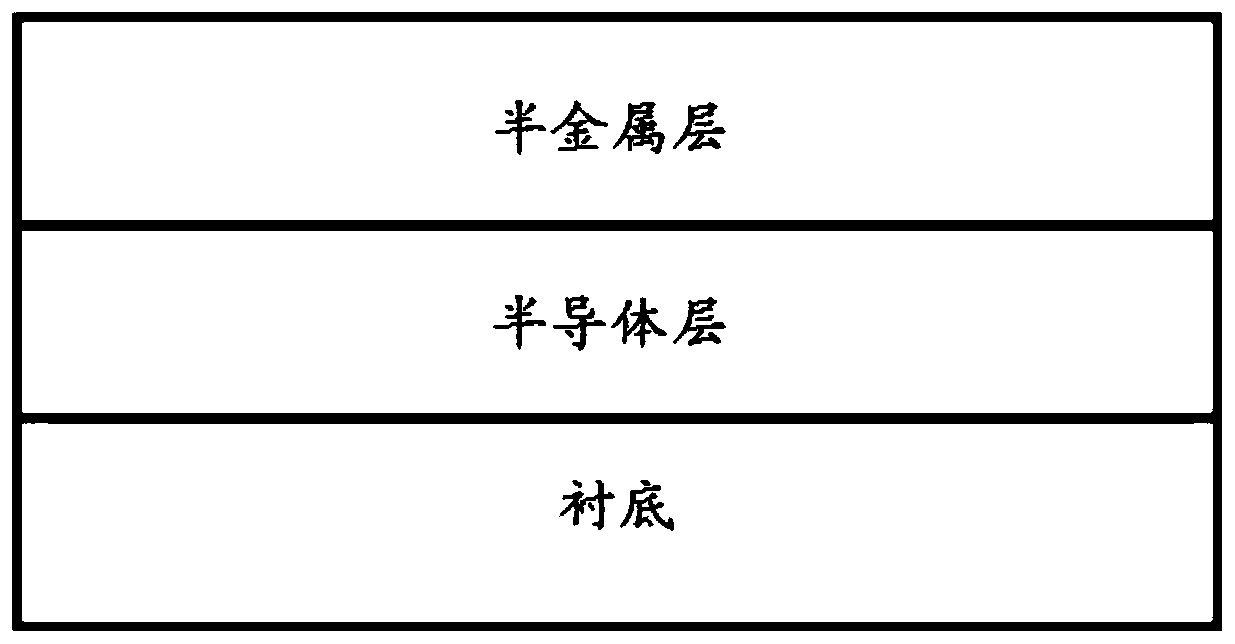

[0043] In the present invention, the preparation method of the Schottky diode preferably comprises the following steps:

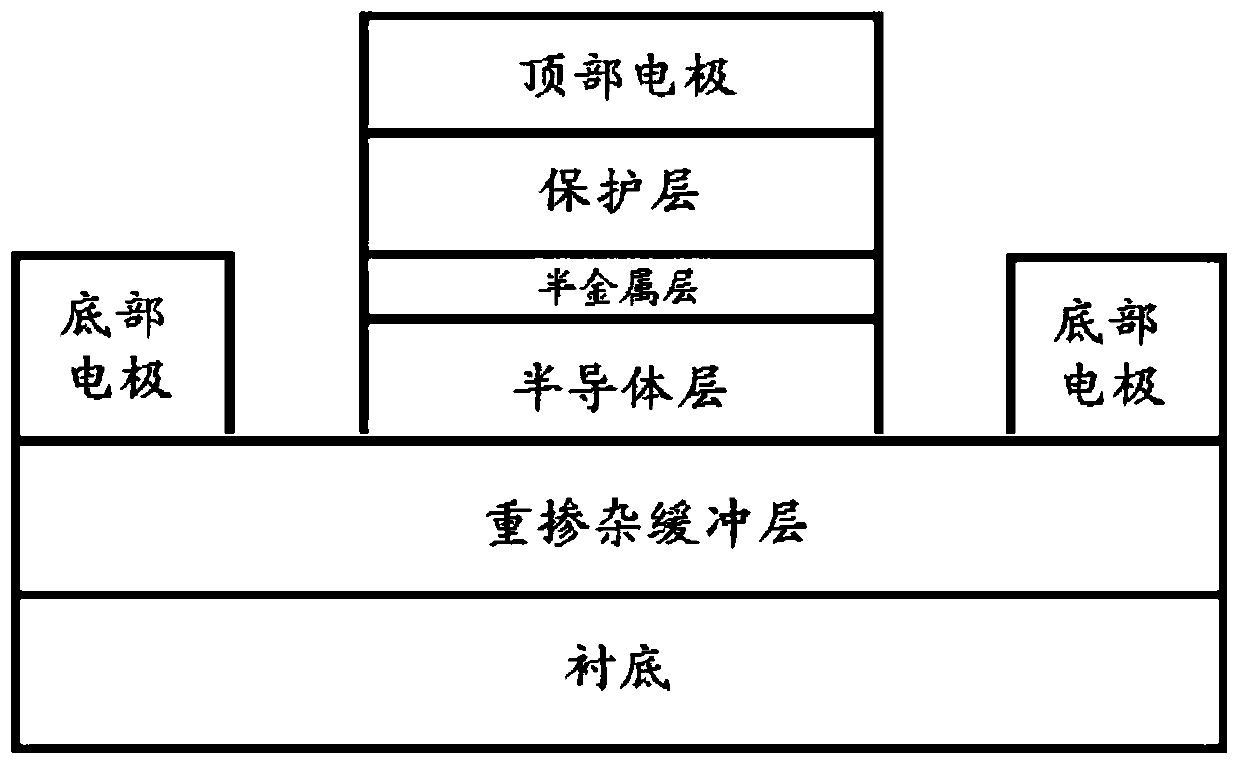

[0044] A material containing a heavily doped buffer layer, a semiconductor layer, a semi-metal layer and a protective layer is prepared on a substrate by molecular beam epitaxy, wherein the semi-metal / semiconductor Schottky junction formed by the semiconductor layer and the semi-metal layer For the half-metal / semiconductor Schottky junction of the above technical solution, an ohmic contact is formed between the protective layer and the half-metal layer; the position of the electrode is determined by photolithography, and the etching depth reaches the heavily doped buffer layer of the obtained material ; The top electrode is prepared on the protective layer by evaporation method; the bottom electrode is prepared on the etched heavily doped buffer layer to form a mesa structure, and an ohmic contact is formed between the bottom electrode and the heavily doped ...

Embodiment 1

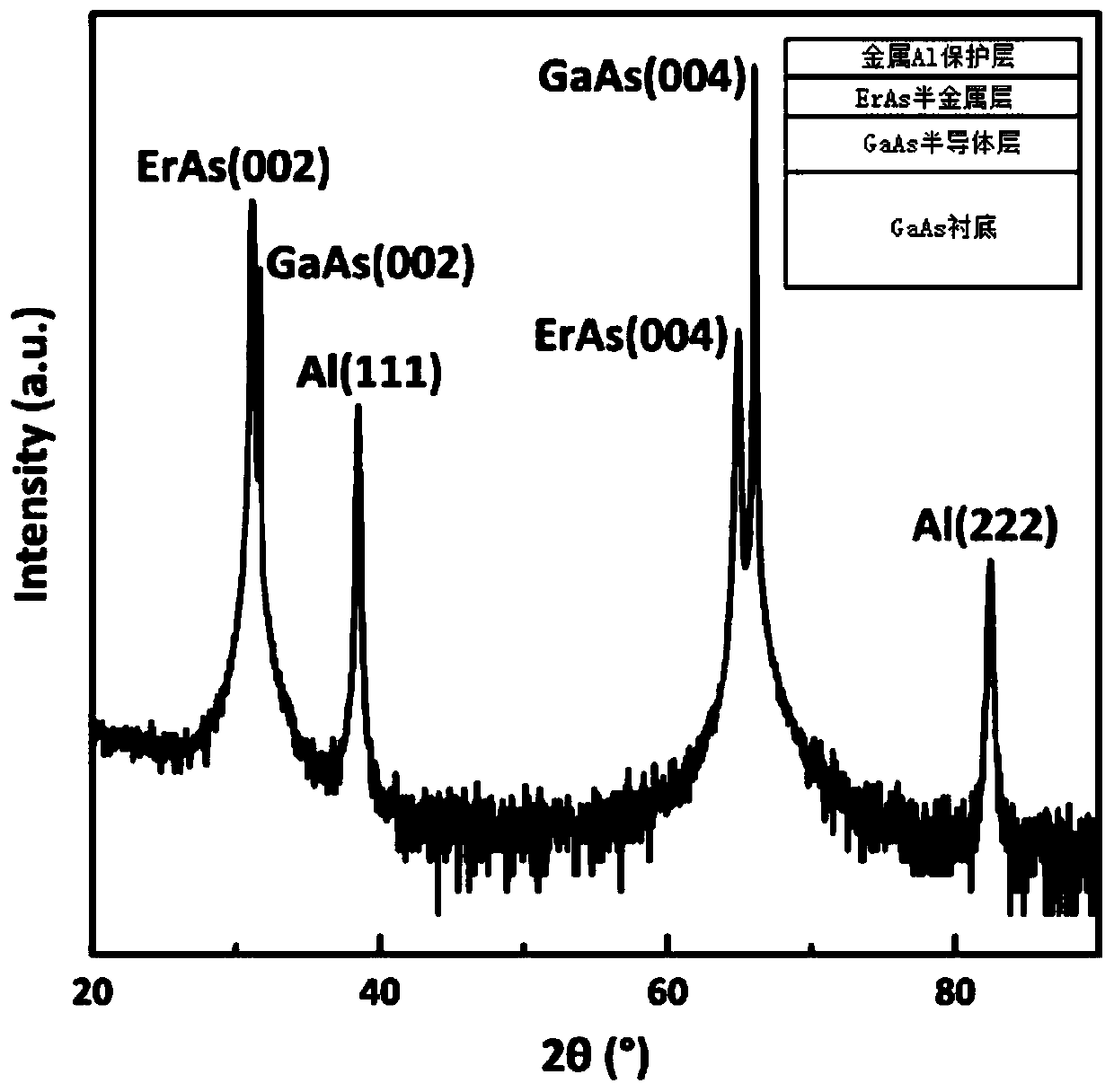

[0052] (1) Deoxidize the GaAs substrate on the (001) crystal plane for 15 minutes. During the deoxidization process, the surface temperature of the GaAs substrate is 600°C;

[0053] (2) Using the molecular beam epitaxy method, the background vacuum is 1×10 -7 ~1×10 -8 Epitaxial growth of a GaAs semiconductor layer (non-doped semiconductor layer, that is, no dopant source) on a GaAs substrate under torr and 580°C, with a thickness of 100 nm and a growth rate of 1 μm / h;

[0054] (3) Reduce the temperature of the obtained material to 455°C at a cooling rate of 30°C / min, and the background vacuum is 1×10 -7 ~1×10 -8 Under torr conditions, an ErAs semi-metal layer is epitaxially grown on the GaAs semiconductor layer by molecular beam epitaxy, with a thickness of 125 nm and a growth rate of 170 nm / h;

[0055] (4) Reduce the temperature of the obtained material to 50°C at a cooling rate of 30°C / min, and the background vacuum is 5×10 -10 When the Torr is lower than that, a metal A...

Embodiment 2

[0059] (1) After deoxidizing the GaAs substrate on the (001) crystal plane (the surface temperature of the GaAs substrate is 600°C, and the processing time is 15 minutes), molecular beam epitaxy is used in a background vacuum of 1×10 -7 ~1×10 -8 Under the conditions of torr and 580°C, taking the GaAs substrate as the reference, the GaAs heavily doped buffer layer (thickness: 100nm) and GaAs concentration gradient layer (thickness: 300nm) were epitaxially grown sequentially, the growth rate was 1μm / h, and the dopant source was Si, the content of the dopant source in the GaAs heavily doped buffer layer is 1×10 18 cm -3 , the content of the dopant source in the GaAs concentration gradient layer is 5×10 17 cm -3 ;

[0060] (2) Using the molecular beam epitaxy method, the background vacuum is 1×10 -7 ~1×10 -8 Under the condition of torr and 580°C, epitaxially grow a GaAs semiconductor layer on the GaAs concentration gradient layer (it is a doped semiconductor layer, the dopin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com