Patents

Literature

640 results about "Molecular beam epitaxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular-beam epitaxy (MBE) is an epitaxy method for thin-film deposition of single crystals. The MBE process was developed in the late 1960s at Bell Telephone Laboratories by J. R. Arthur and Alfred Y. Cho. MBE is widely used in the manufacture of semiconductor devices, including transistors, and it is considered one of the fundamental tools for the development of nanotechnologies. MBE is used to fabricate diodes and MOSFETs (MOS field-effect transistors) at microwave frequencies, and to manufacture the lasers used to read optical discs (such as CDs and DVDs).

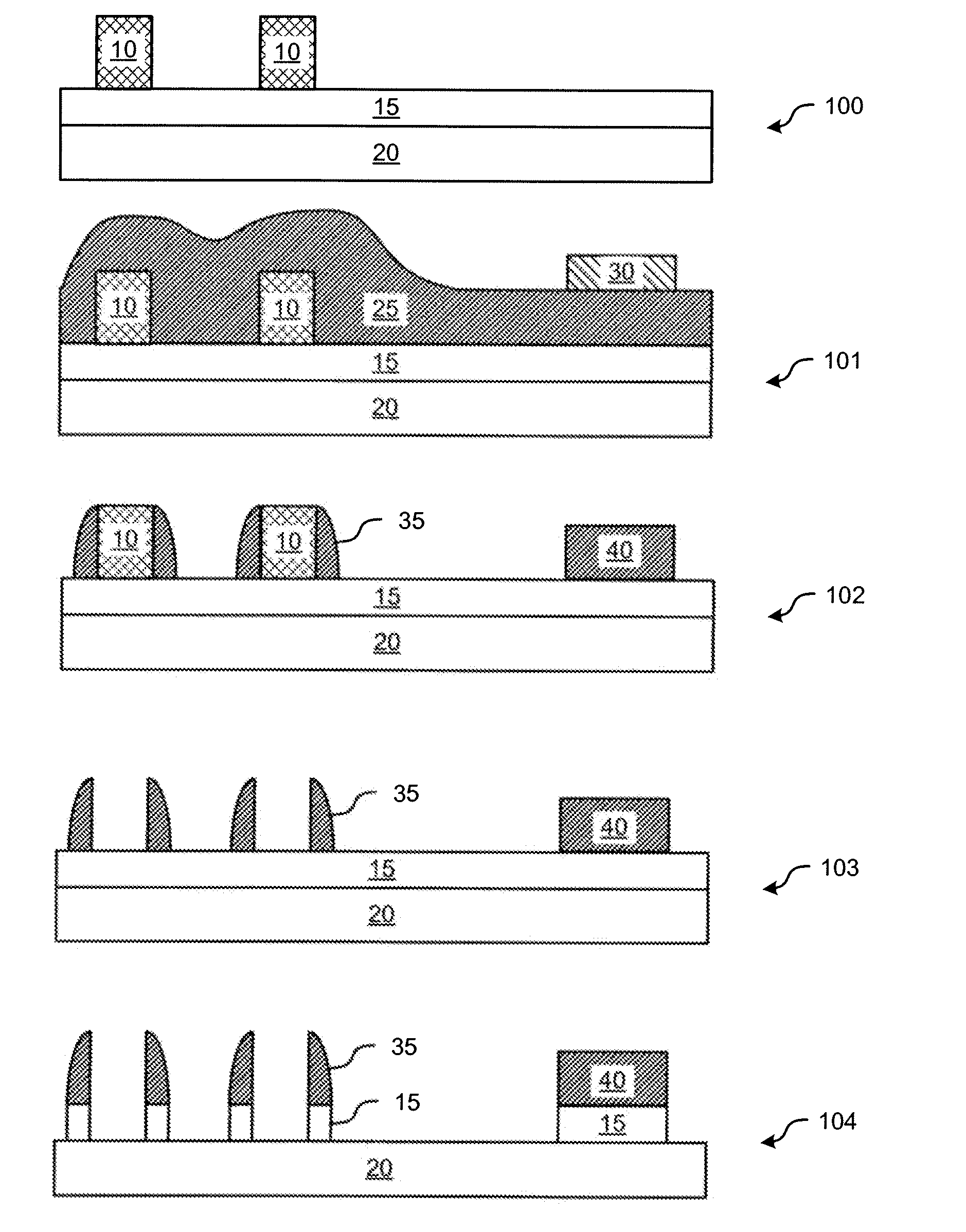

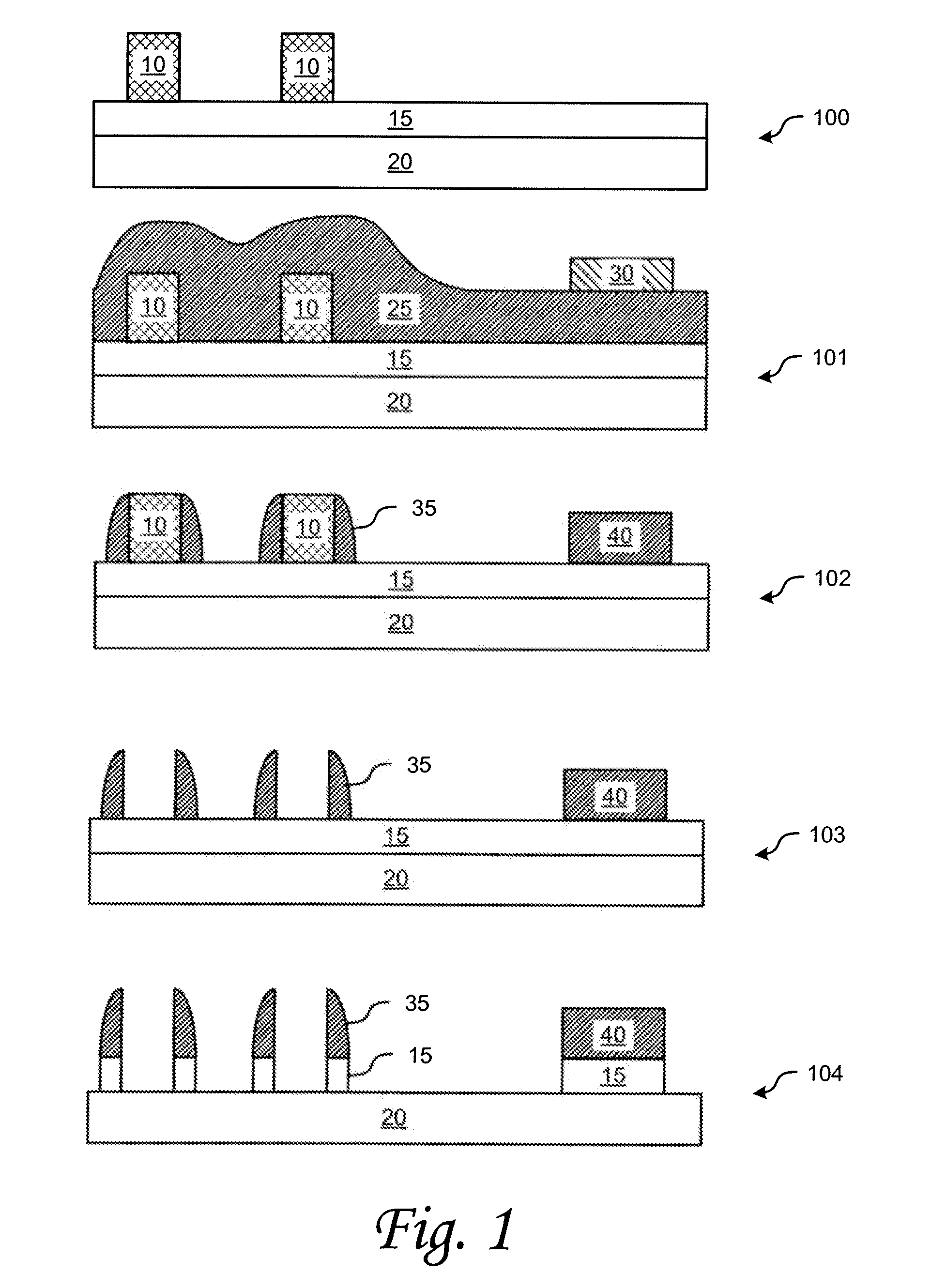

Method of eliminating a lithography operation

ActiveUS20090146322A1Semiconductor/solid-state device detailsSolid-state devicesLithographic artistEngineering

Methods of semiconductor device fabrication are disclosed. An exemplary method includes processes of depositing a first pattern on a semiconductor substrate, wherein the first pattern defines wide and narrow spaces; depositing spacer material over the first pattern on the substrate; etching the spacer material such that the spacer material is removed from horizontal surfaces of the substrate and the first pattern but remains adjacent to vertical surfaces of a wide space defined by the first pattern and remains within narrow a space defined by the first pattern; and removing the first pattern from the substrate. In one embodiment, the first pattern can comprise sacrificial material, which can include, for example, polysilicon material. The deposition can comprise physical vapor deposition, chemical vapor deposition, electrochemical deposition, molecular beam epitaxy, atomic layer deposition or other deposition techniques. According to another embodiment, features for lines and logic device components having a width greater than that of the lines are formed in the spacer material in the same mask layer.

Owner:CADENCE DESIGN SYST INC

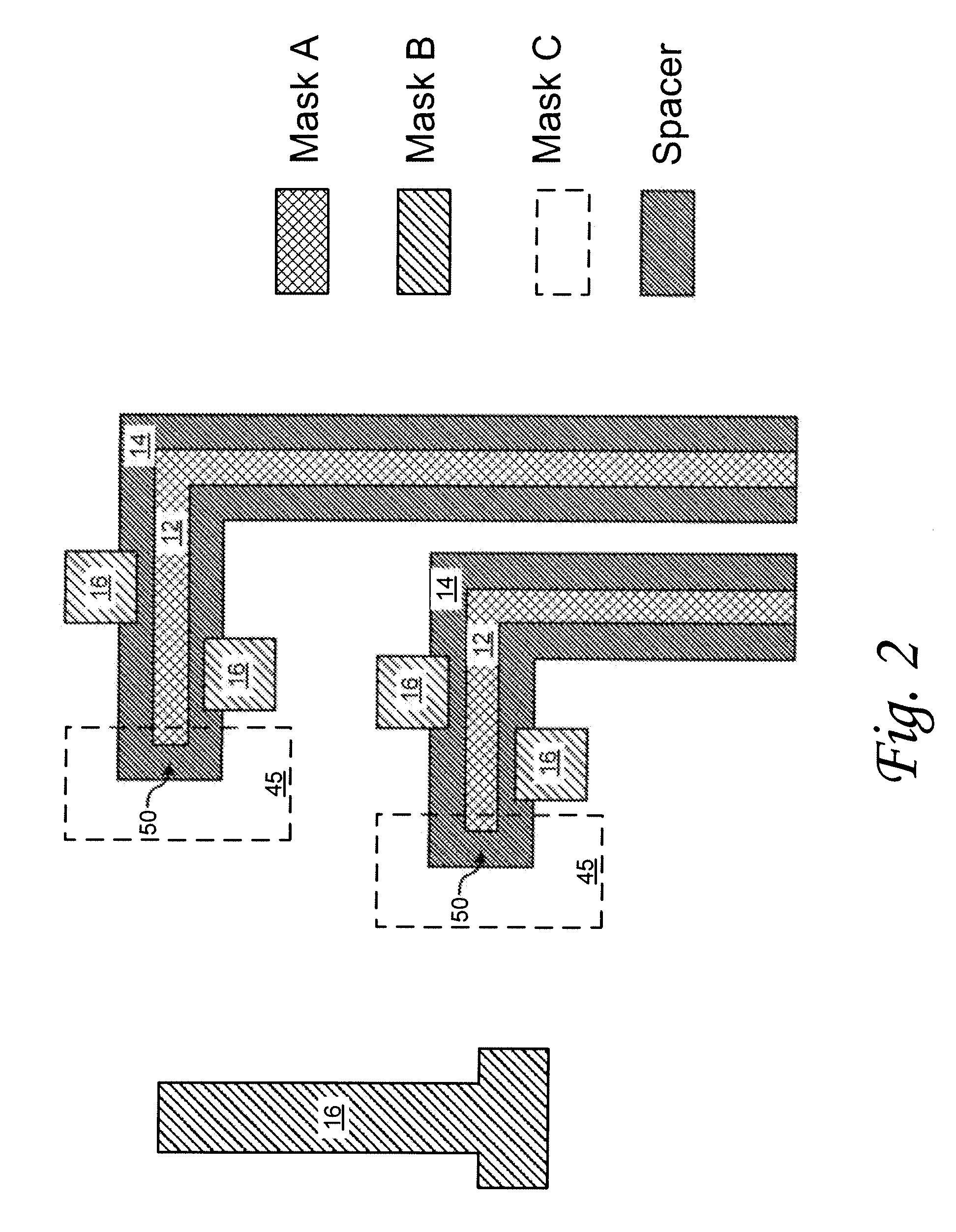

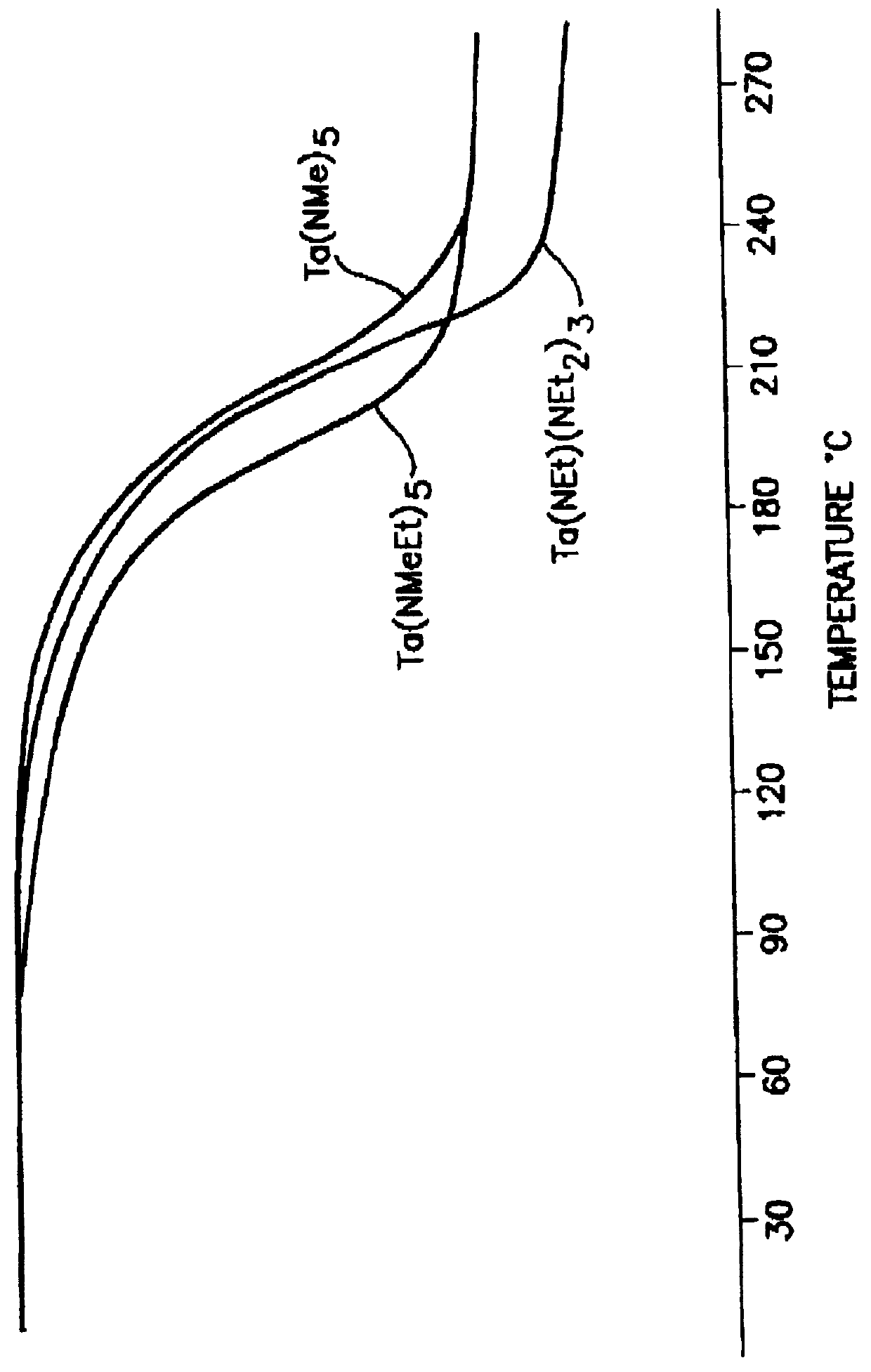

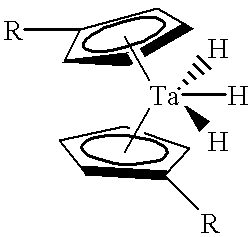

Tantalum amide precursors for deposition of tantalum nitride on a substrate

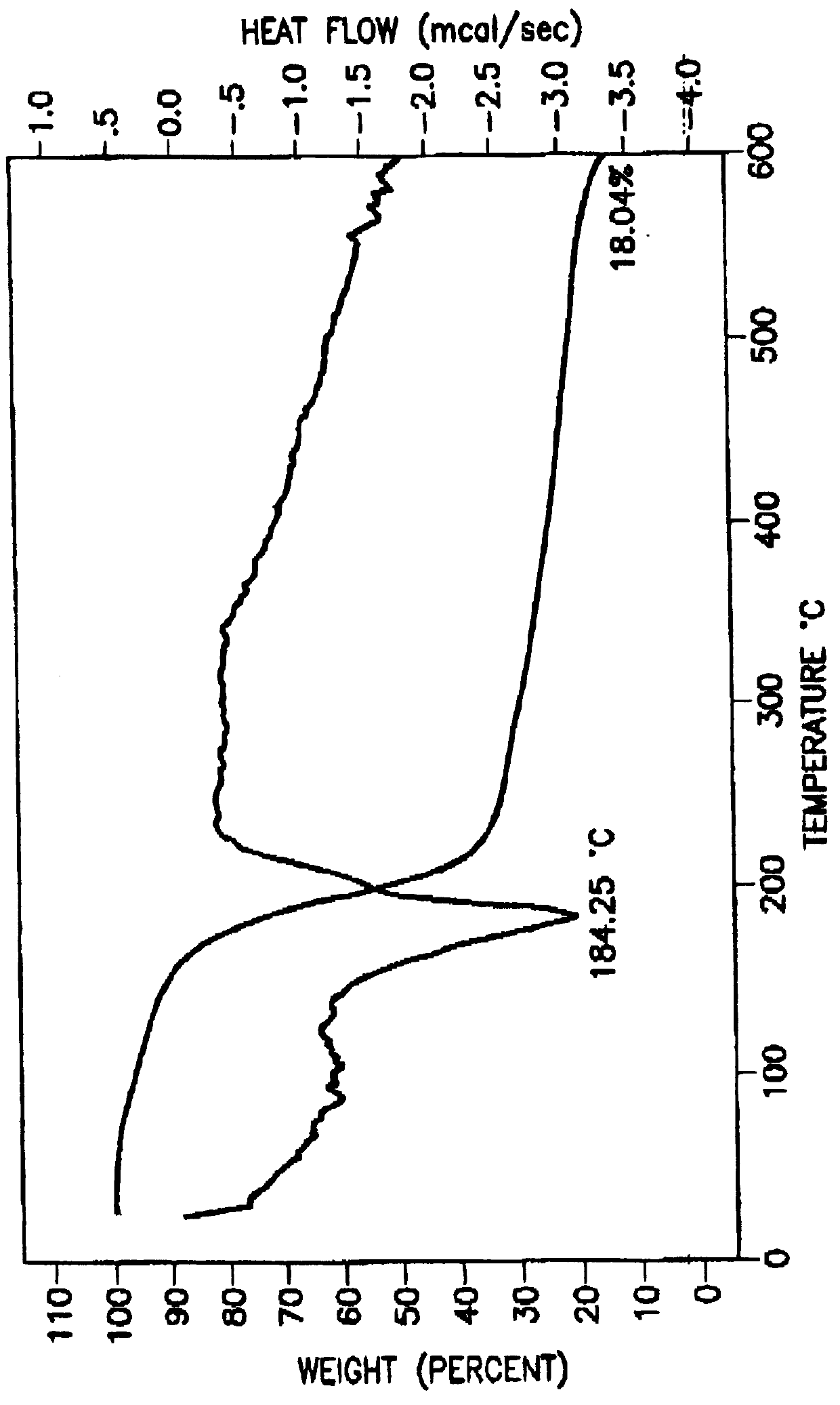

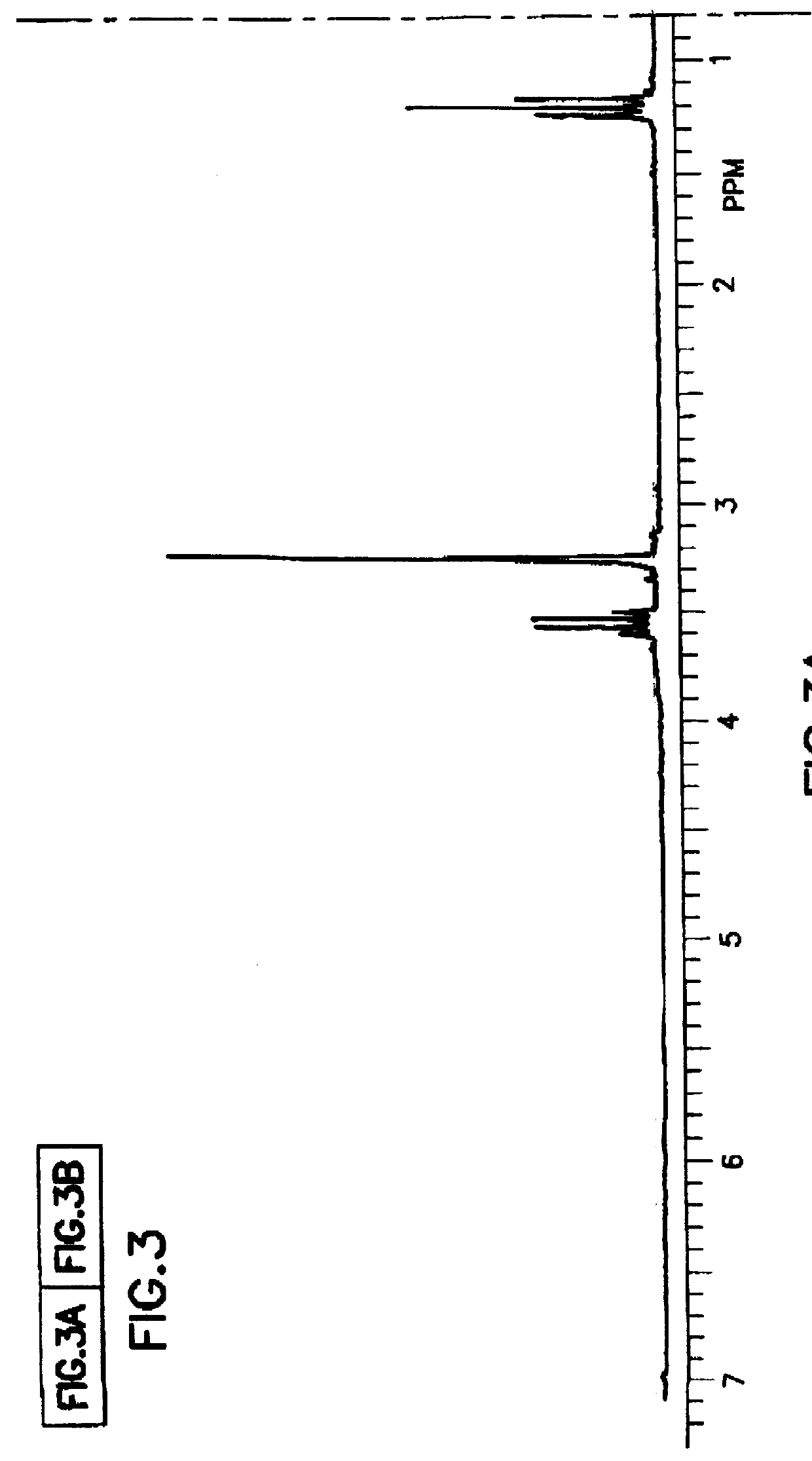

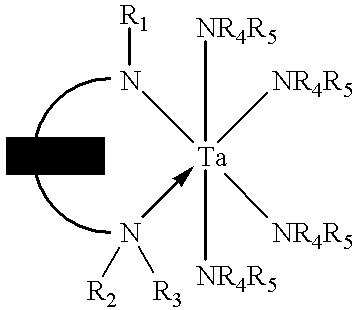

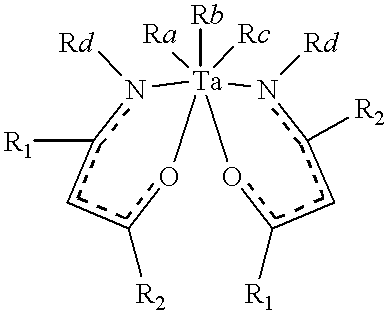

InactiveUS6015917ARapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microlectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ENTEGRIS INC

Tantalum amide precursors for deposition of tantalum nitride on a substrate

InactiveUS6379748B1Rapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microelectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ADVANCED TECH MATERIALS INC

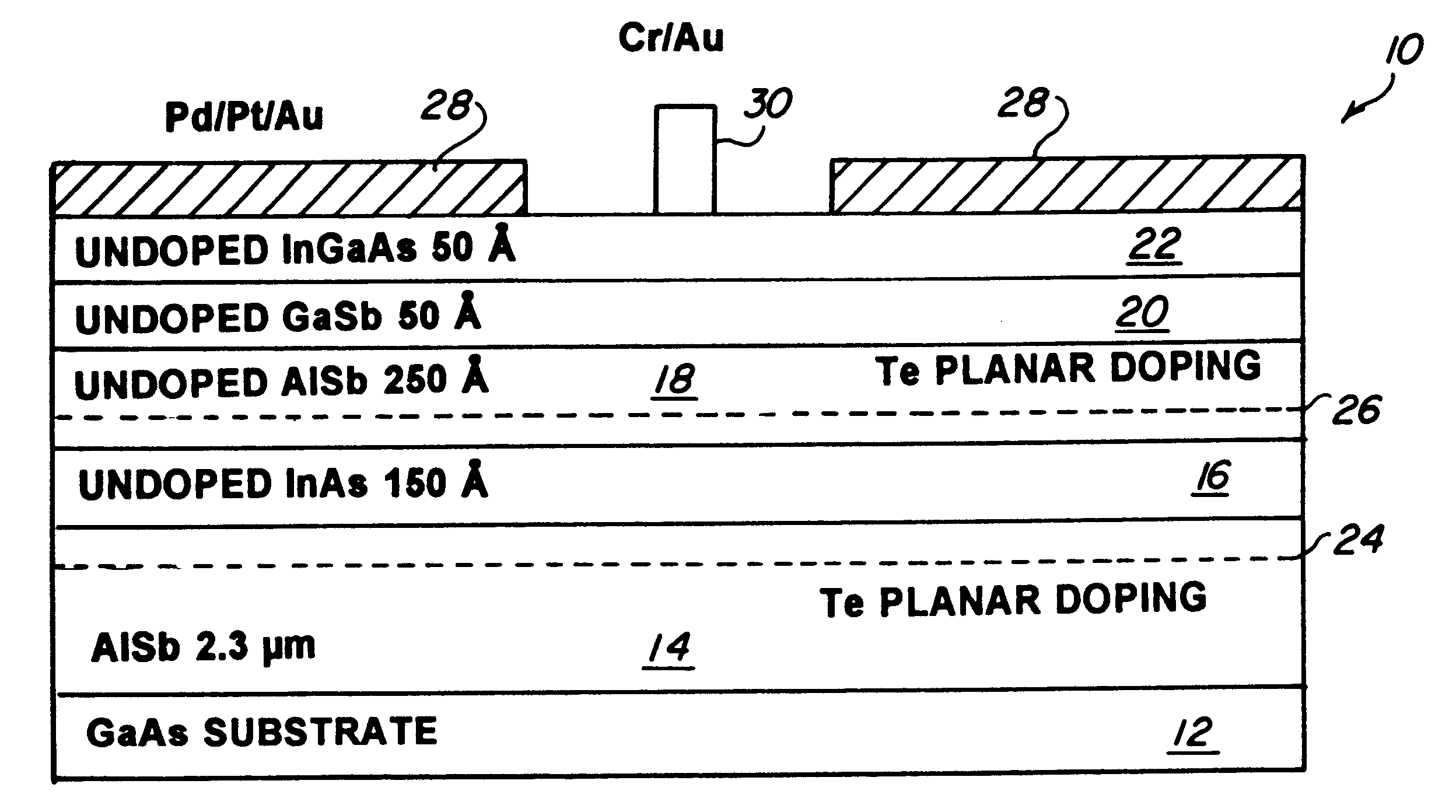

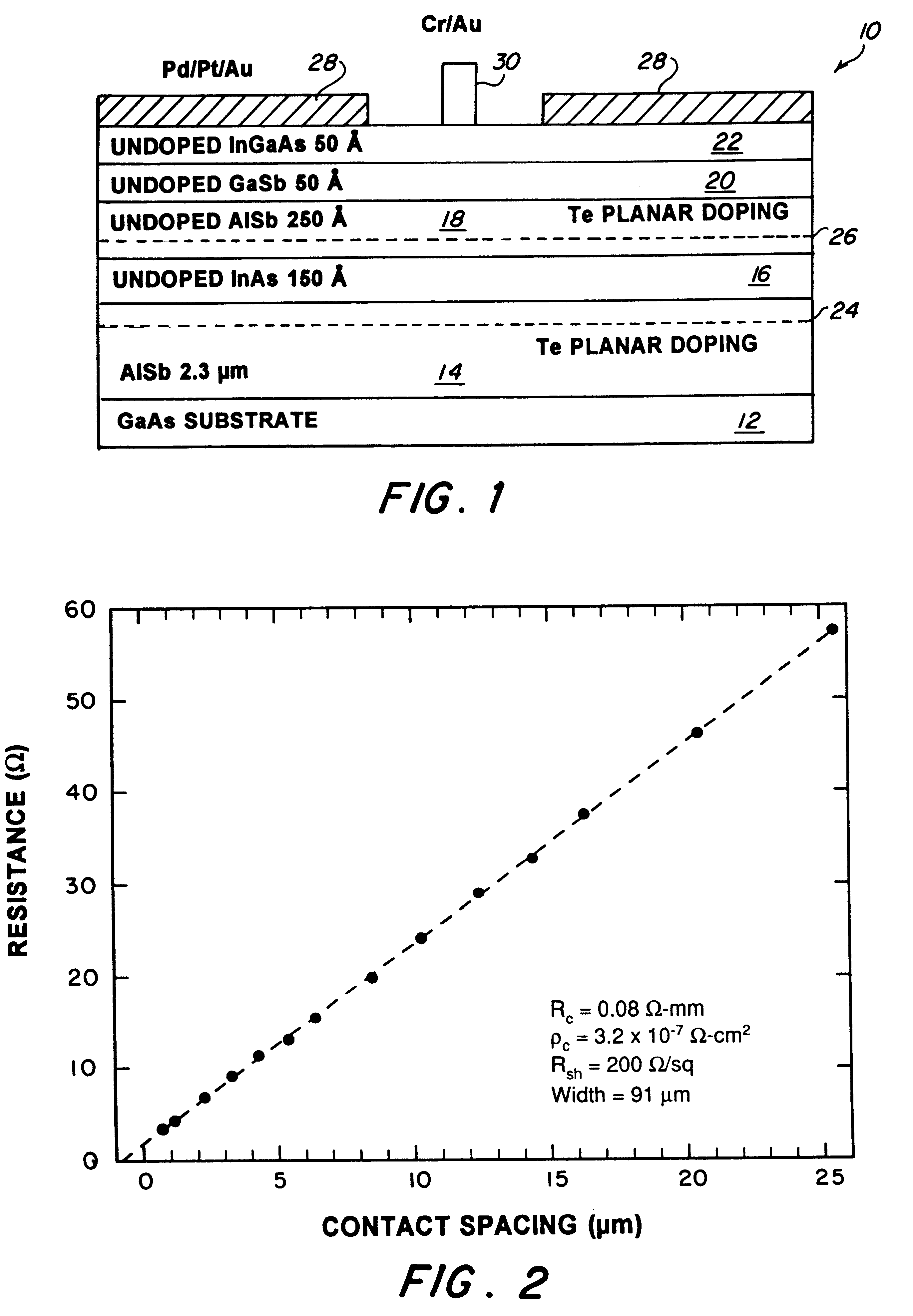

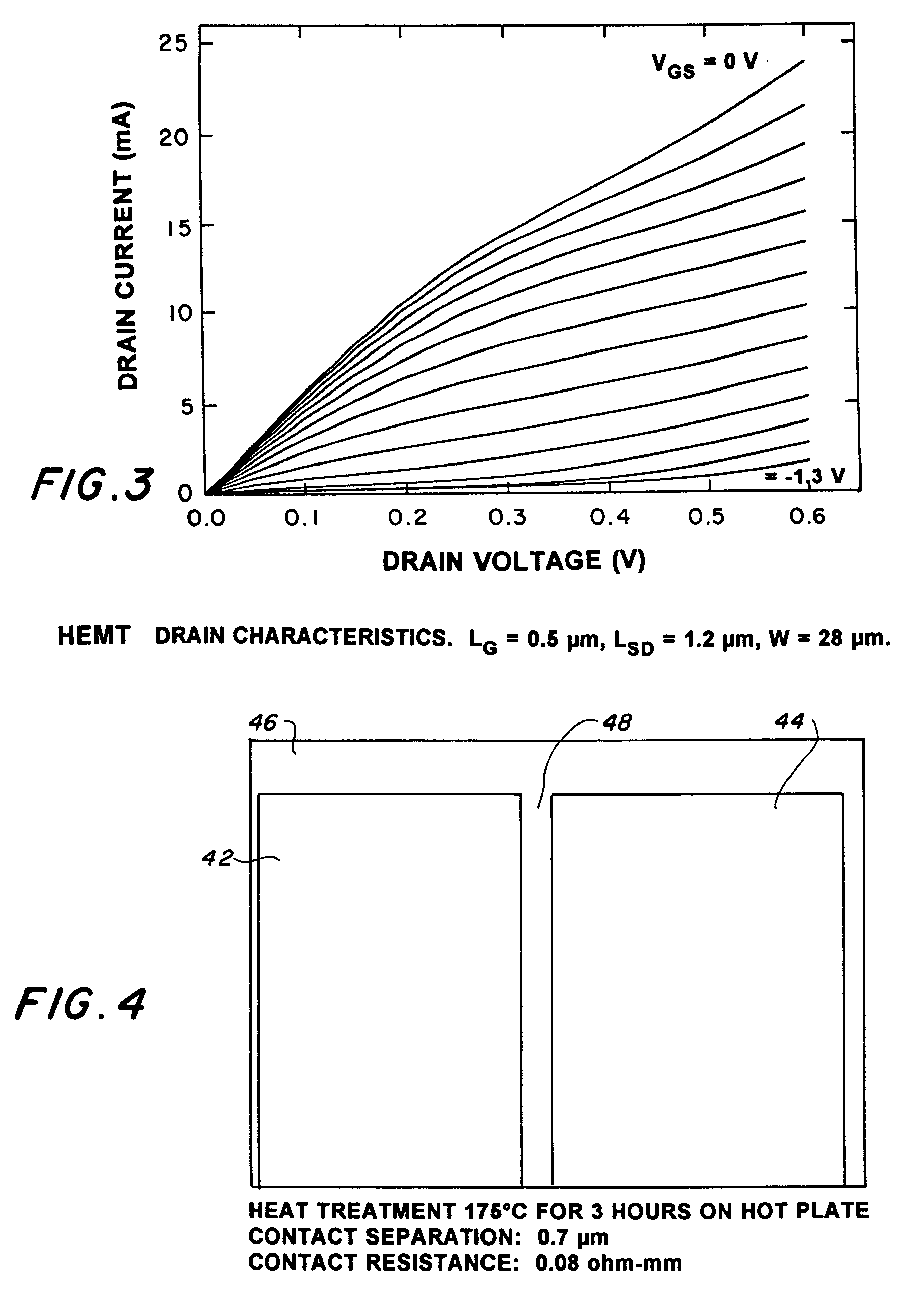

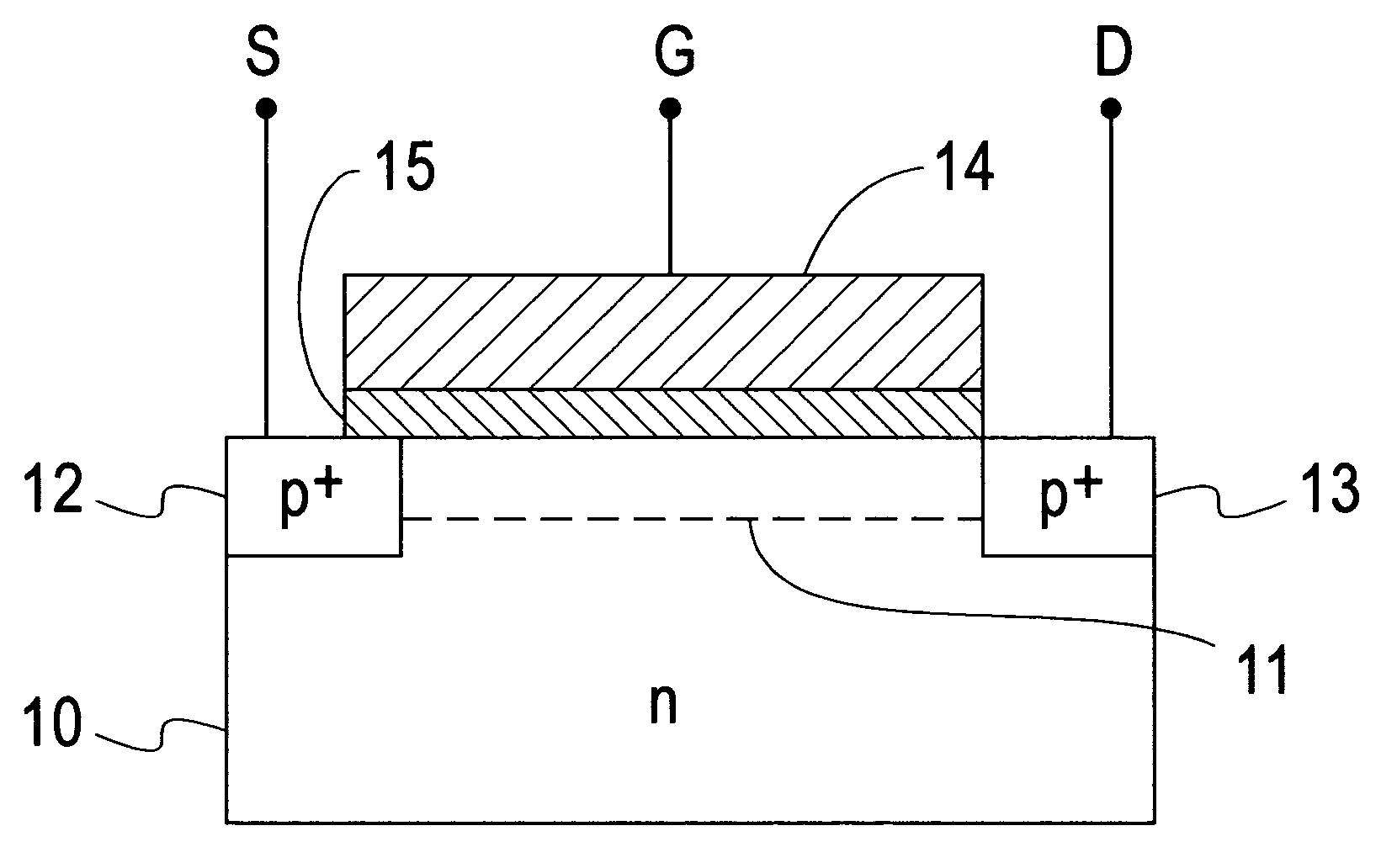

Metalization of electronic semiconductor devices

InactiveUS6448648B1Avoids material deteriorationPrevent materialSemiconductor/solid-state device detailsSolid-state devicesAccess resistanceDevice material

An electronic semiconductor device comprising a semiconductor base deposited on a semiconductor substrate by means of molecular beam epitaxy and source, drain and gate disposed on the base in a spaced relationghip to each other, the source and the drain comprising Pd / barrier / Au layers with the palladium layer being in contact with the device. The device is fabricated conventionally except the heat treating is at above about 170° C. for ¼-10 hours sufficient for the palladium layer to react with the base yielding reduced contact and access resistances and a narrower spacing between source and drain.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method of manufacturing an ultraviolet light emitting AlGaN composition and ultraviolet light emitting device containing same

InactiveUS7498182B1Laser optical resonator constructionSemiconductor/solid-state device manufacturingCharge carrierUltraviolet lights

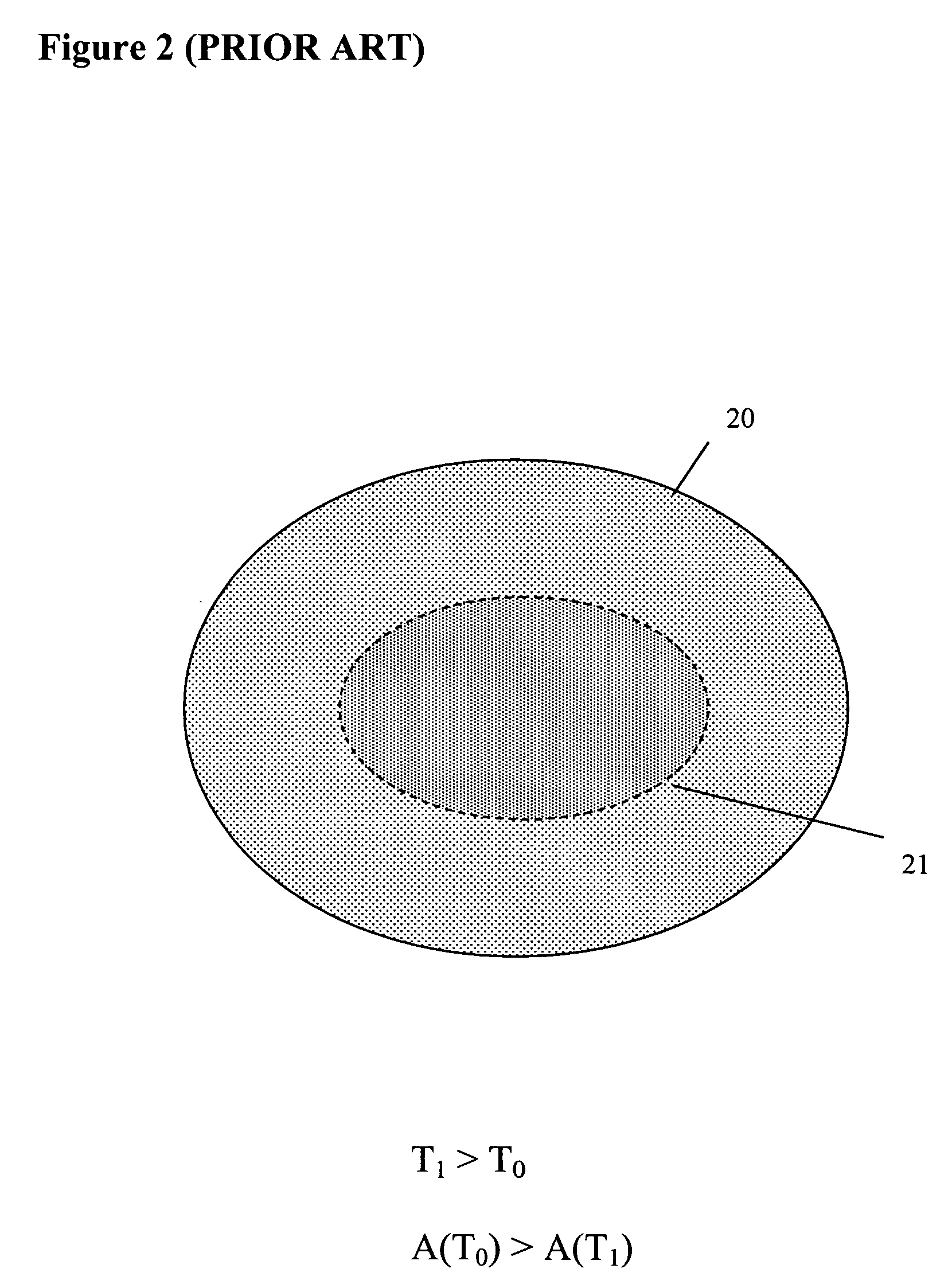

An AlGaN composition is provided comprising a group III-Nitride active region layer, for use in an active region of a UV light emitting device, wherein light-generation occurs through radiative recombination of carriers in nanometer scale size, compositionally inhomogeneous regions having band-gap energy less than the surrounding material. Further, a semiconductor UV light emitting device having an active region layer comprised of the AlGaN composition above is provided, as well as a method of producing the AlGaN composition and semiconductor UV light emitting device, involving molecular beam epitaxy.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Dielectric materials

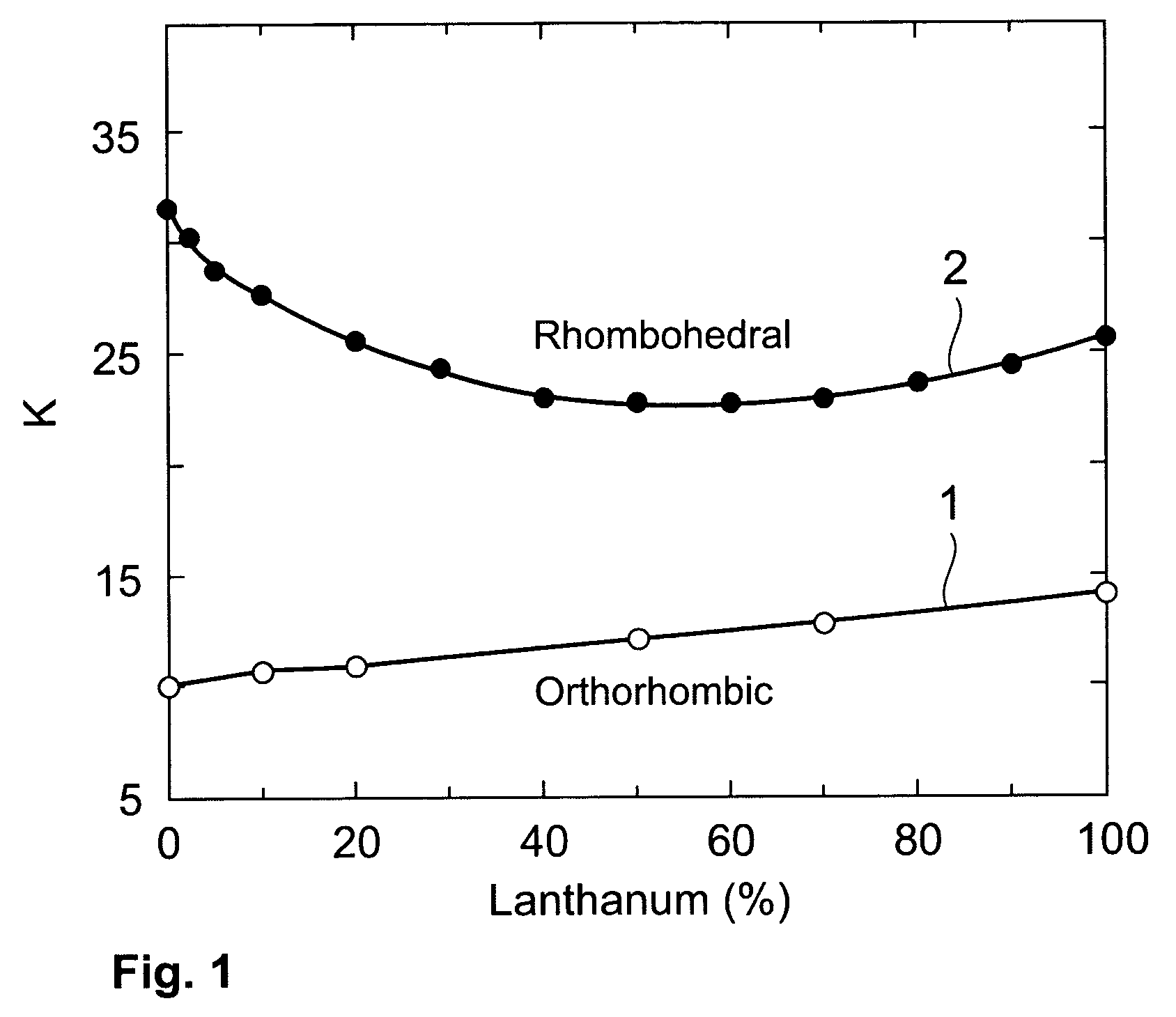

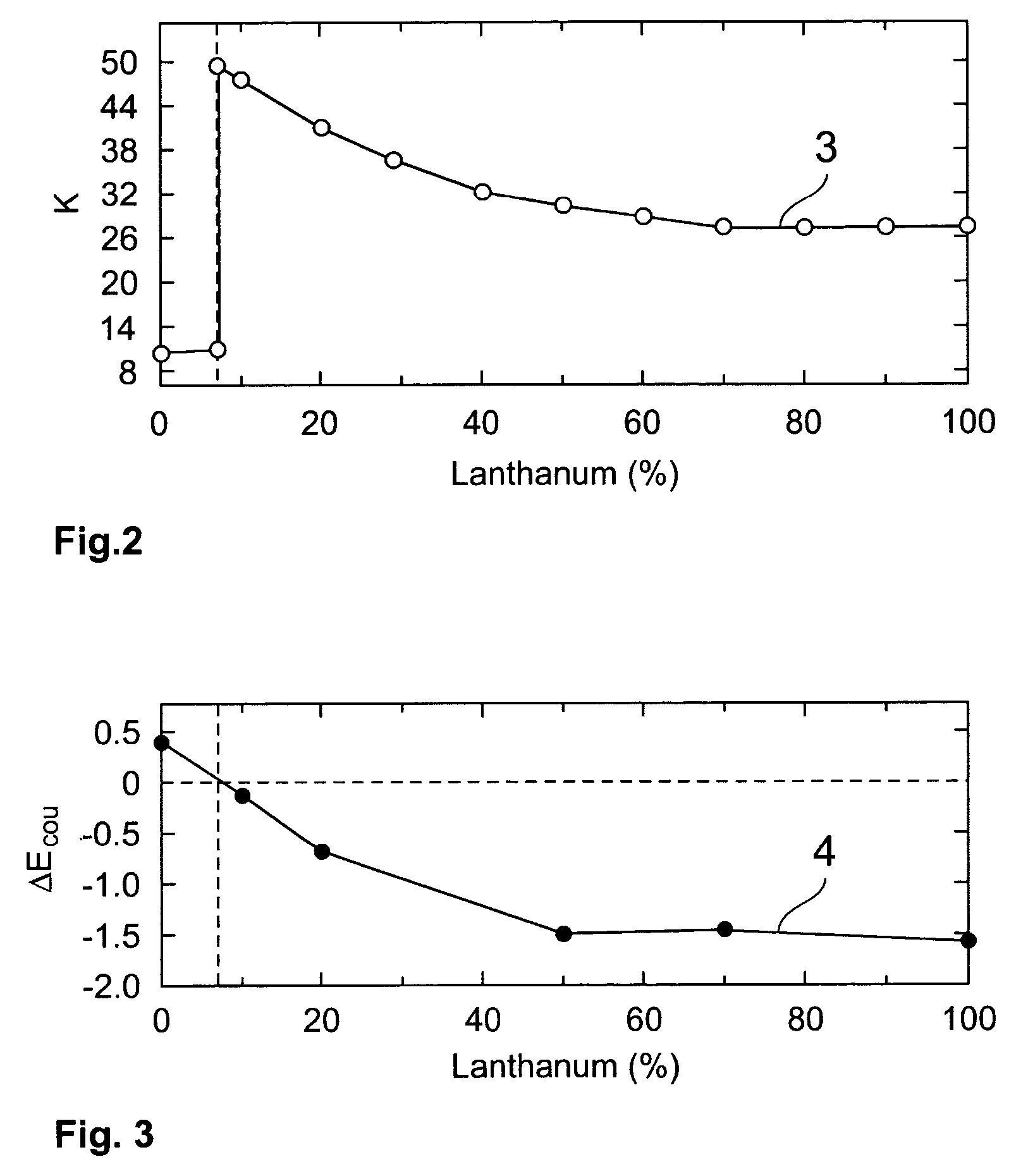

InactiveUS7057244B2High spatial anisotropyHigh thermodynamic stabilityPolycrystalline material growthCeramicsOptoelectronicsField-effect transistor

An article of manufacture comprises a substrate and a layer of N(x)Y(1−x)AlO3 on the substrate where x is a molar fraction greater than zero and less than one, and N is an element selected from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu. The article may be an electronic device further comprising an electrode electrically isolated from the substrate by the layer. In particular, the dielectric properties of the layer are such that the layer is especially although by no means exclusively useful for electrically isolating gate electrodes in field effect transistor devices. The layer may be formed on the substrate via molecular beam epitaxy.

Owner:IBM CORP

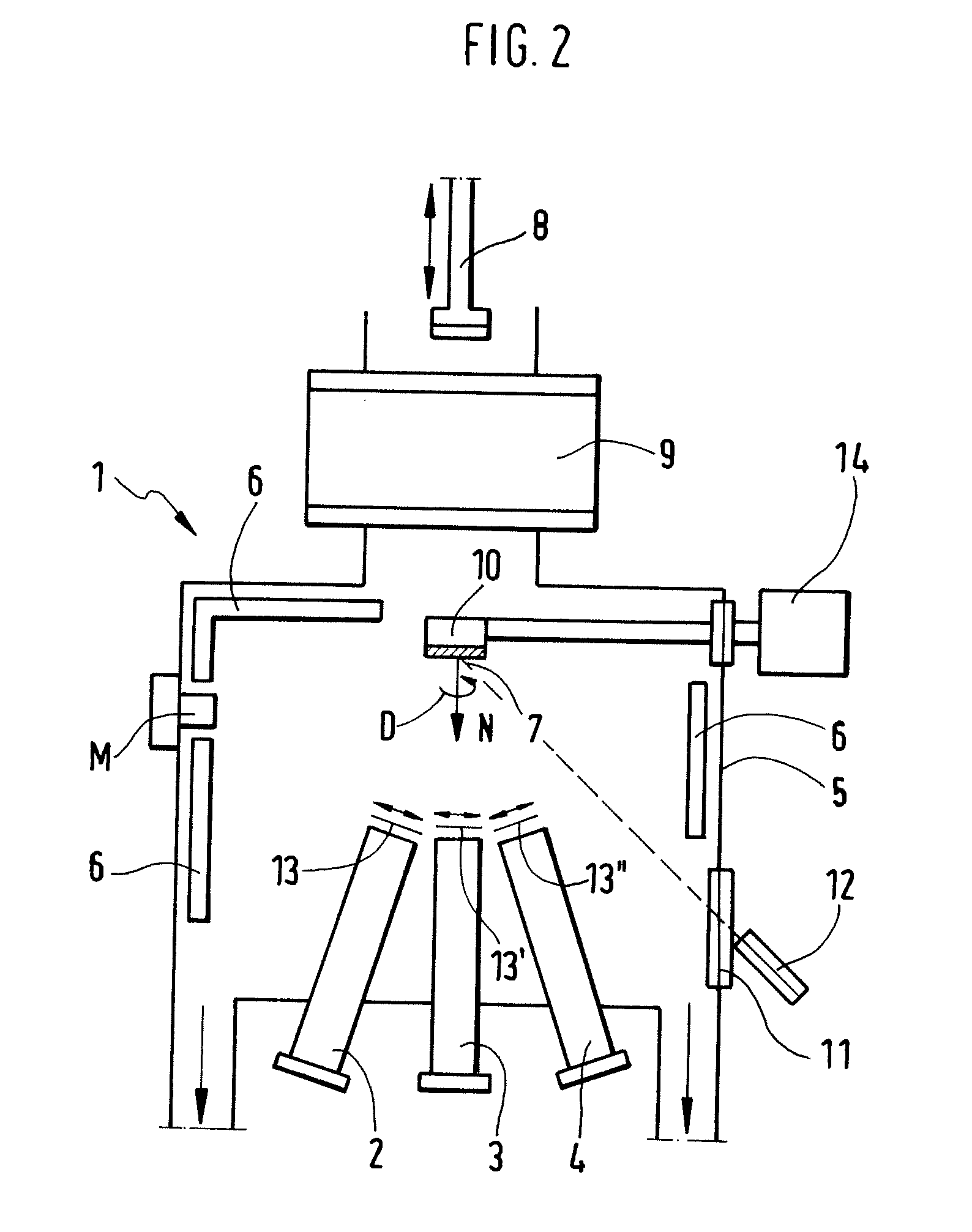

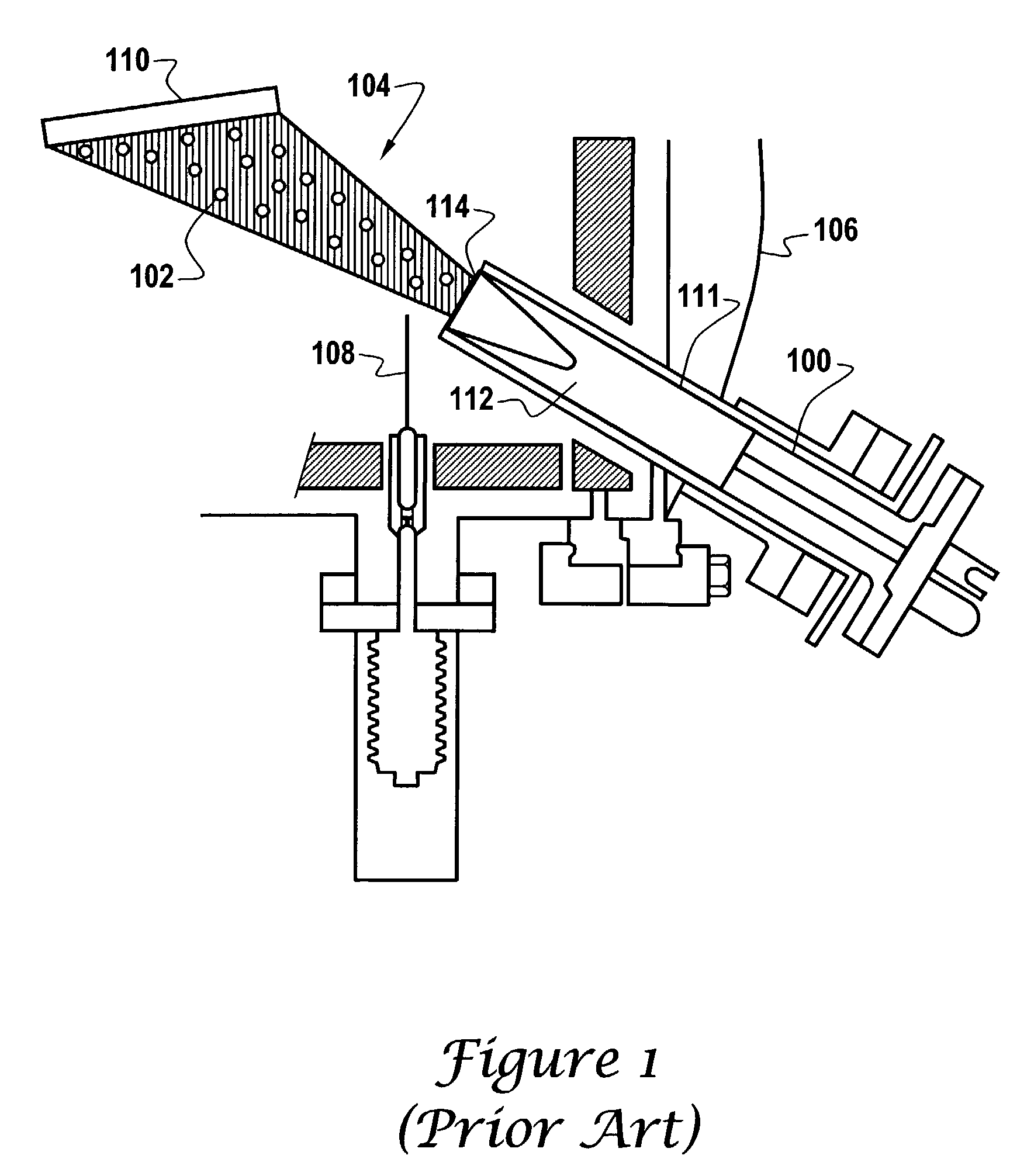

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

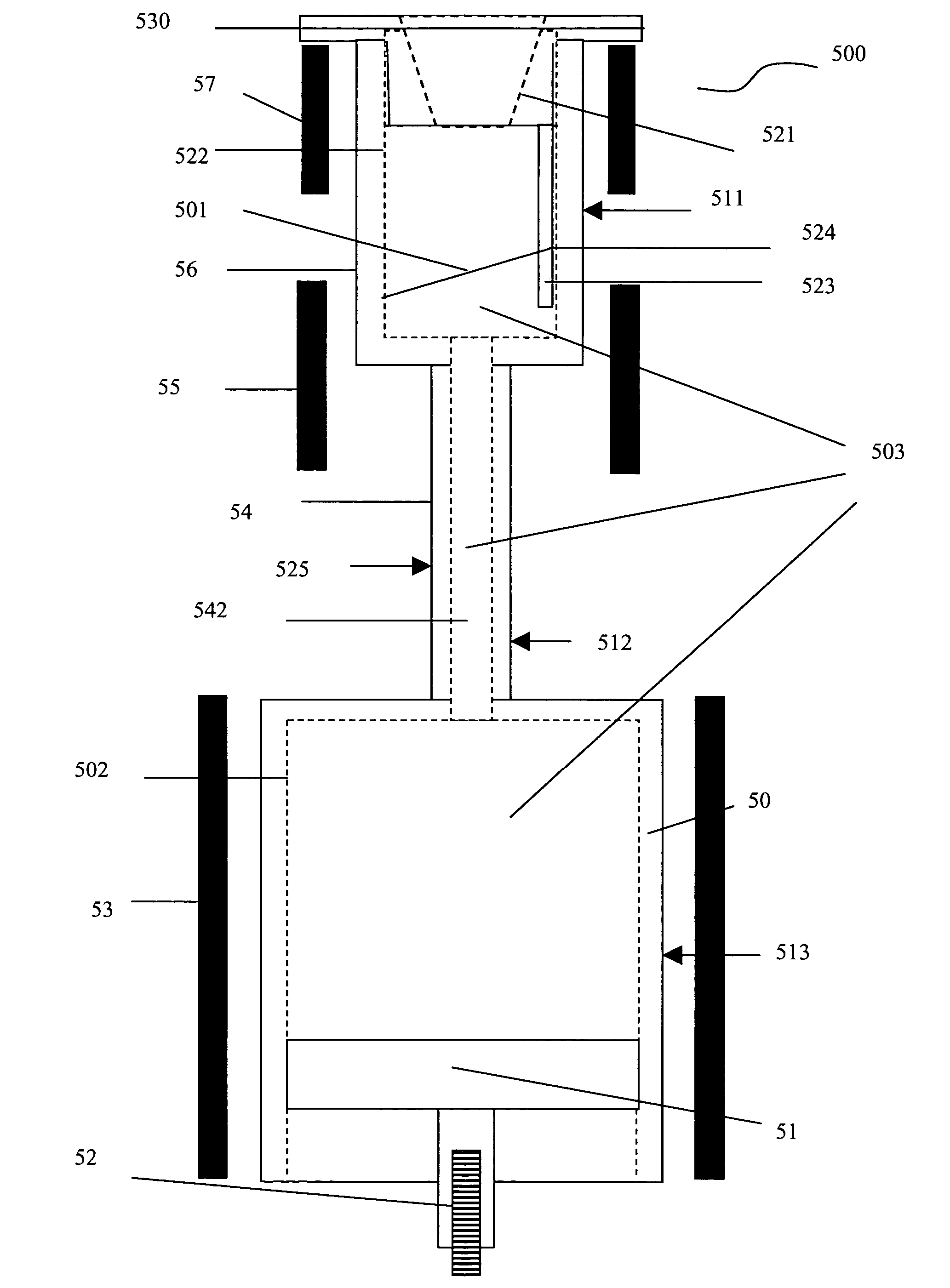

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

Homoepitaxial layers of p-type zinc oxide and the fabrication thereof

InactiveUS6624441B2Reduces and limits diffusionImprove crystal qualityPolycrystalline material growthSolid-state devicesLithiumDopant

A semiconductor structure for providing an epitaxial zinc oxide layer having p-type conduction for semiconductor device manufacture and methods of depositing the p-type zinc oxide layer. A zinc oxide layer is deposited epitaxially by molecular beam epitaxy on a crystalline zinc oxide substrate. The zinc oxide layer incorporates a p-type dopant, such as nitrogen, in an atomic concentration adequate to provide p-type conduction. The p-type zinc oxide layer may further incorporate an atomic concentration of a compensating species, such as lithium, sufficient to electronically occupy excess donors therein so that the efficiency of the p-type dopant may be increased.

Owner:NEW EAGLEPICHER TECH

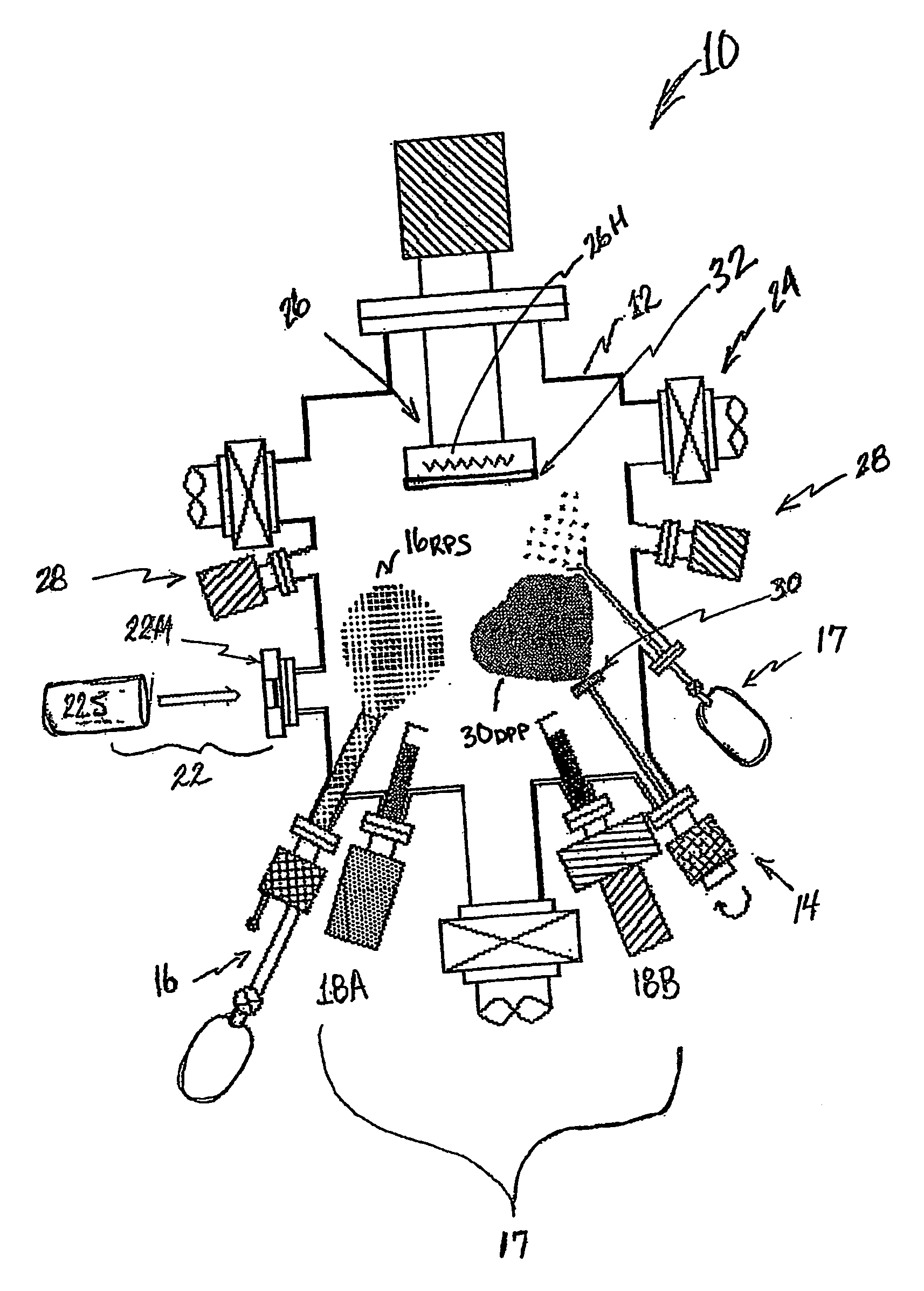

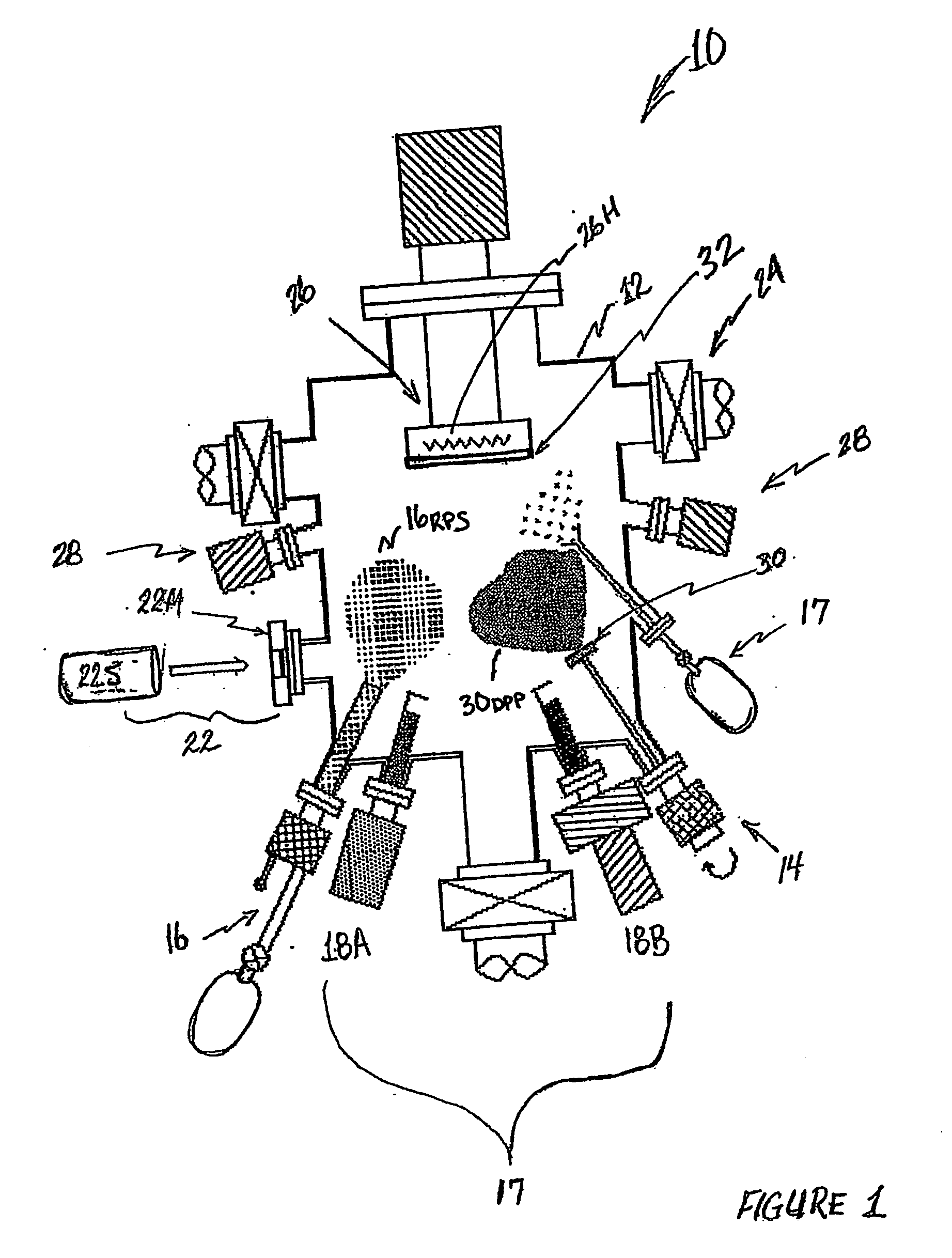

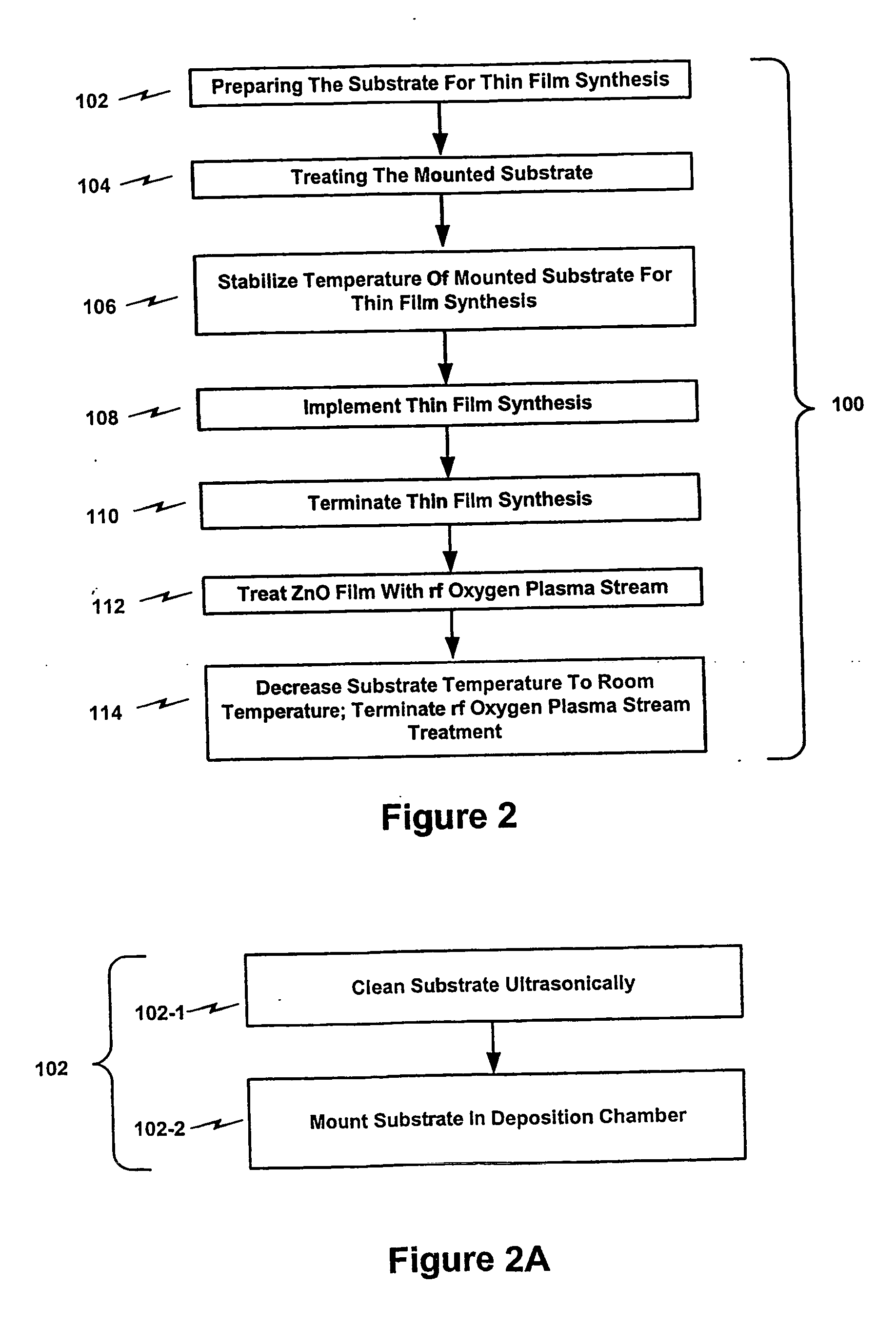

Hybrid beam deposition system and methods for fabricating metal oxide-zno films, p-type zno films, and zno-based II-VI compound semiconductor devices

InactiveUS20060233969A1Increase flux densityVacuum evaporation coatingSputtering coatingSource materialAlloy thin film

A hybrid beam deposition (HBD) system and methods according to the present invention utilizes a unique combination of pulsed laser deposition (PLD) technique and equipment with equipment and techniques that provide a radical oxygen rf-plasma stream to effectively increase the flux density of available reactive oxygen at a deposition substrate for the effective synthesis of metal oxide thin films. The HBD system and methods of the present invention further integrate molecular beam epitaxy (MBE) and / or chemical vapor deposition (CVD) techniques and equipment in combination with the PLD equipment and technique and the radical oxygen rf-plasma stream to provide elemental source materials for the synthesis of undoped and / or doped metal oxide thin films as well as synthesis of undoped and / or doped metal-based oxide alloy thin films.

Owner:MOXTRONICS

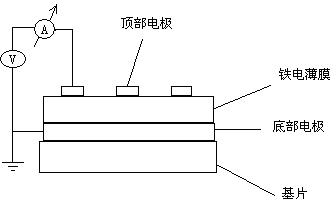

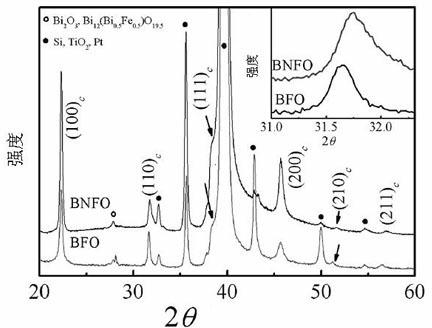

One-phase ferroelectric film and preparing method thereof as well as effective resistance regulation mode

InactiveCN102157682AWith ferroelectricityWith semiconductor performanceElectrical apparatusVacuum evaporation coatingLead zirconate titanateSputtering

The invention discloses a one-phase ferroelectric film capable of regulating effective resistance by ferroelectric polarization, a preparing method of the one-phase ferroelectric film and an effective resistance regulation mode. The one-phase ferroelectric film comprises B-bit-doped Bal-xSrxTil-yByO3, Pb(Fe1-yBy)O3, Pb(Co1-yBy)O3, (Pb1-xAx)(ZryTi1-y)O3, A-bit-doped Y1-xAxMnO3, Bil-xAxFeO3, and Bi4-xAxTi3O12. The one-phase ferroelectric film is prepared by using film preparing methods, such as pulsed laser deposition (PLD), laser molecular beam epitaxy (LMBE) and magnetron sputtering. The prepared ferroelectric film is 0.4-1000 nanometer in the thickness and has larger conductance and leakage current, as well as ferroelectricity and semiconductor performance. The invention provides a method for improving the antifatigue performance of the one-phase ferroelectric film. Turning frequency (x) of the ferroelectric polarization in the method can be increased to 102-1010; and the ferroelectric polarization is turned to regulate the effective resistance of the one-phase ferroelectric film.

Owner:NANJING UNIV OF SCI & TECH

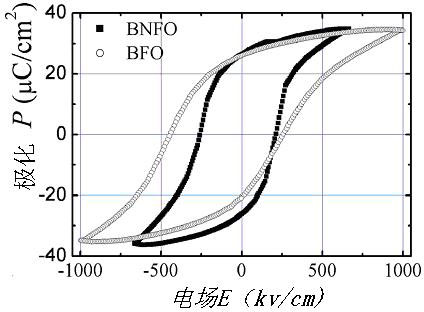

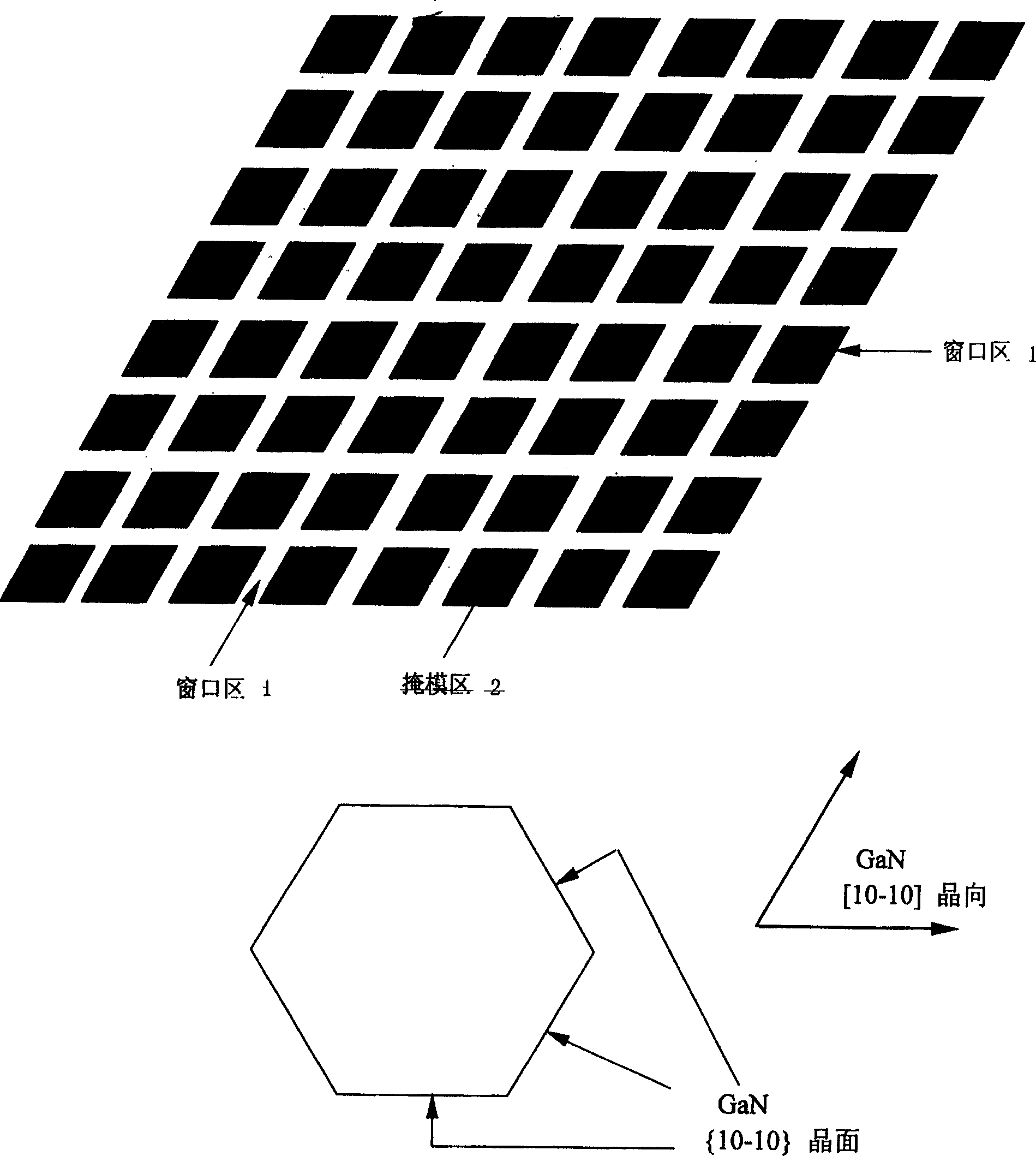

Horizontal epitaxial growth of gallium nitride and its compound semiconductor

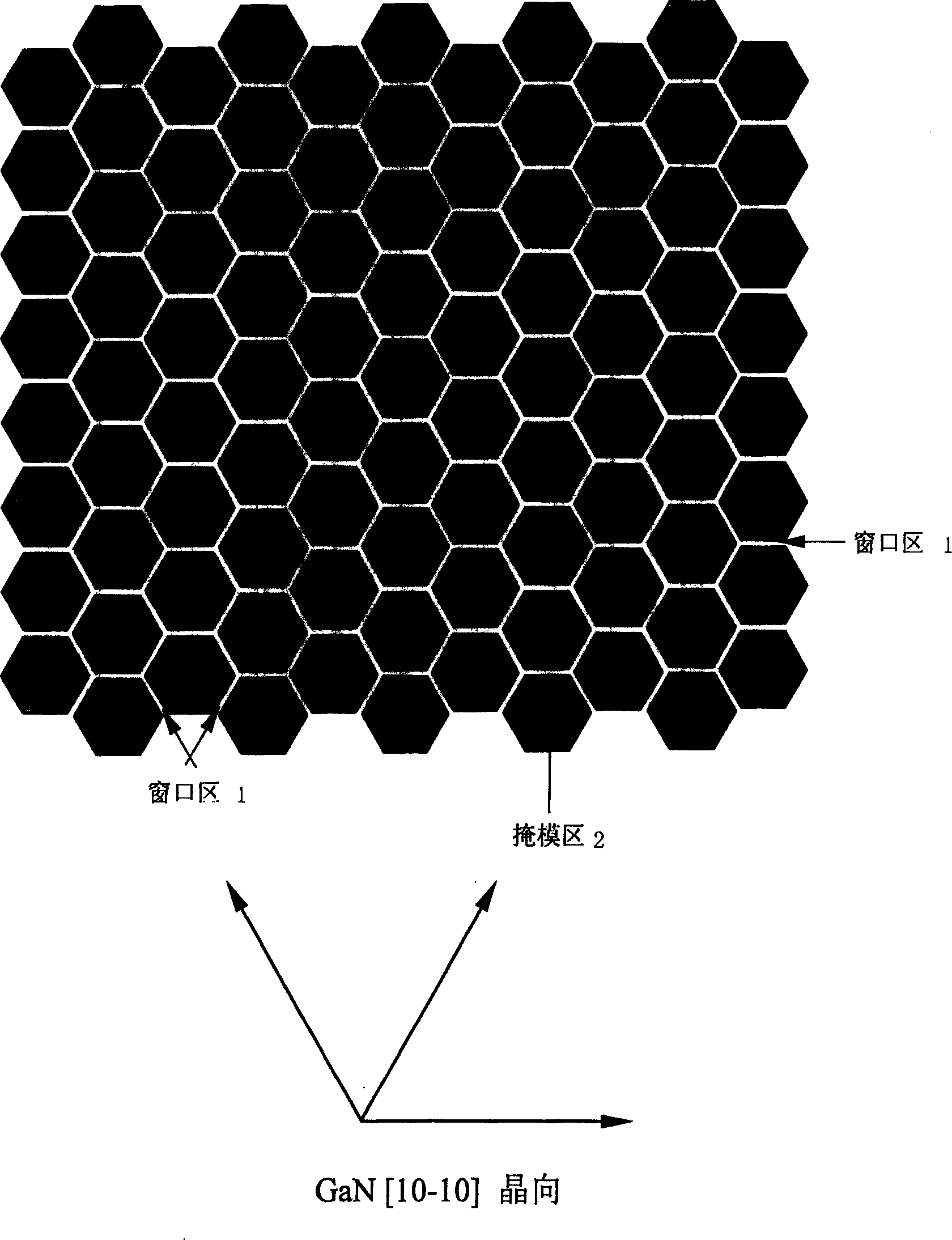

InactiveCN1490844AOvercome MisorientationQuick mergeSemiconductor/solid-state device manufacturingGas phaseGallium nitride

The present invention provides a method for growing a lateral epitaxy of the gallium nitride and its compound semiconductors, comprising the following steps: growing an intrinsic gallium nitride on the ( 0001 ) crystal face of sapphire or the ( 111 ) of silicon or the ( 0001 ) of silicon carbide using the metal organic chemical vapor deposition or the molecule beam epitaxy or the hydride vapor epitaxy; then depositing on it a layer of silicon nitride or silicon dioxide or silicon nitride-oxide as the mask area; patterning the mask area using the photolithography and wet or dry etch techniques, the pattern of the mask area being designed into the pattern structure of the triangle or parallelogram or rhombus or hexagon with the included angles of 60 or 120 degrees or the combination of above shapes which are constituted of the [ 10 - 10 ] crystal direction of gallium nitride on the edge of the adjacent windows; and finally growing the secondary epitaxy, that is, lateral epitaxy of gallium nitride and its compound using the metal organic vapor deposition or the molecule beam epitaxy or the hydride vapor epitaxy.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

4H-polytype gallium nitride-based semiconductor device on a 4H-polytype substrate

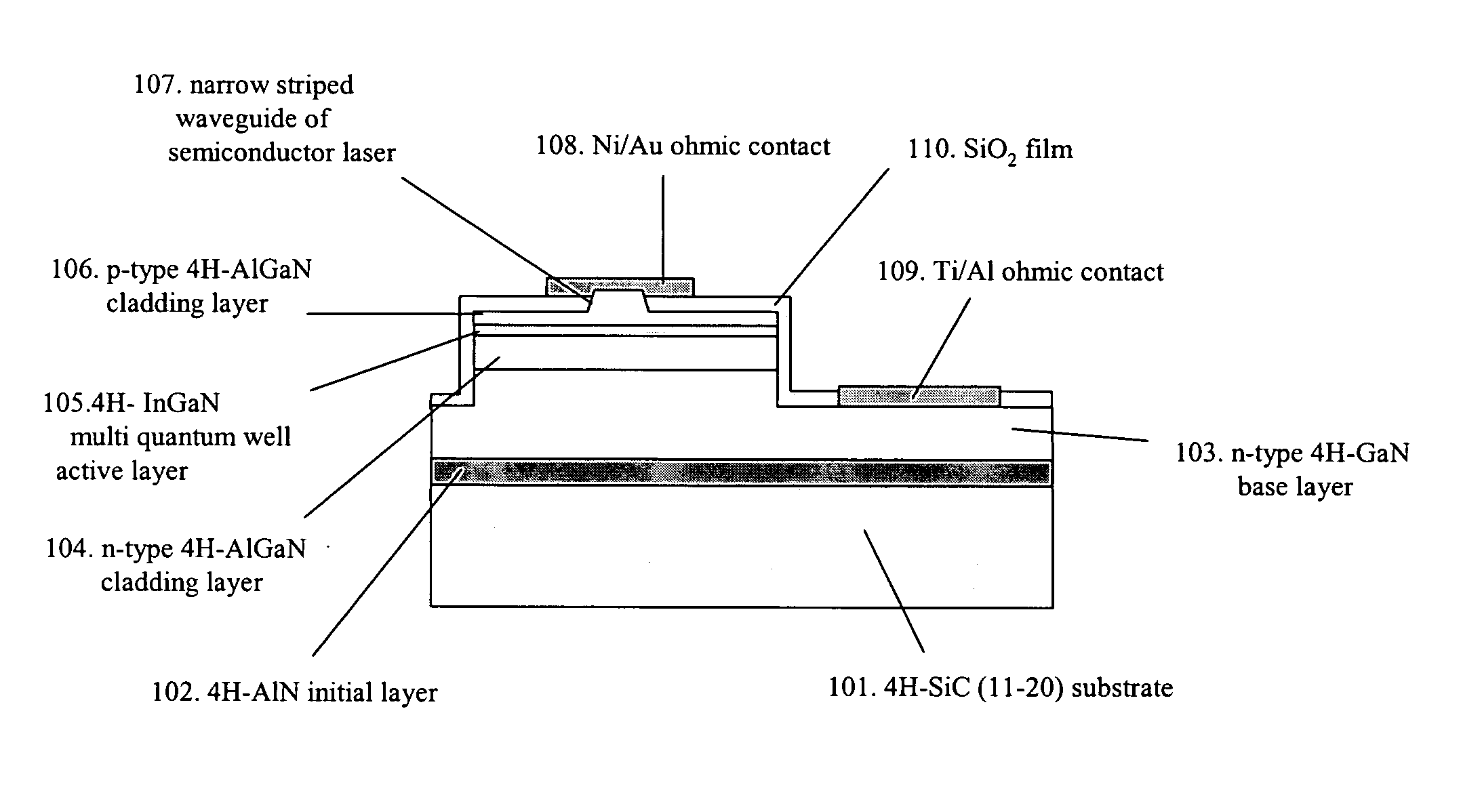

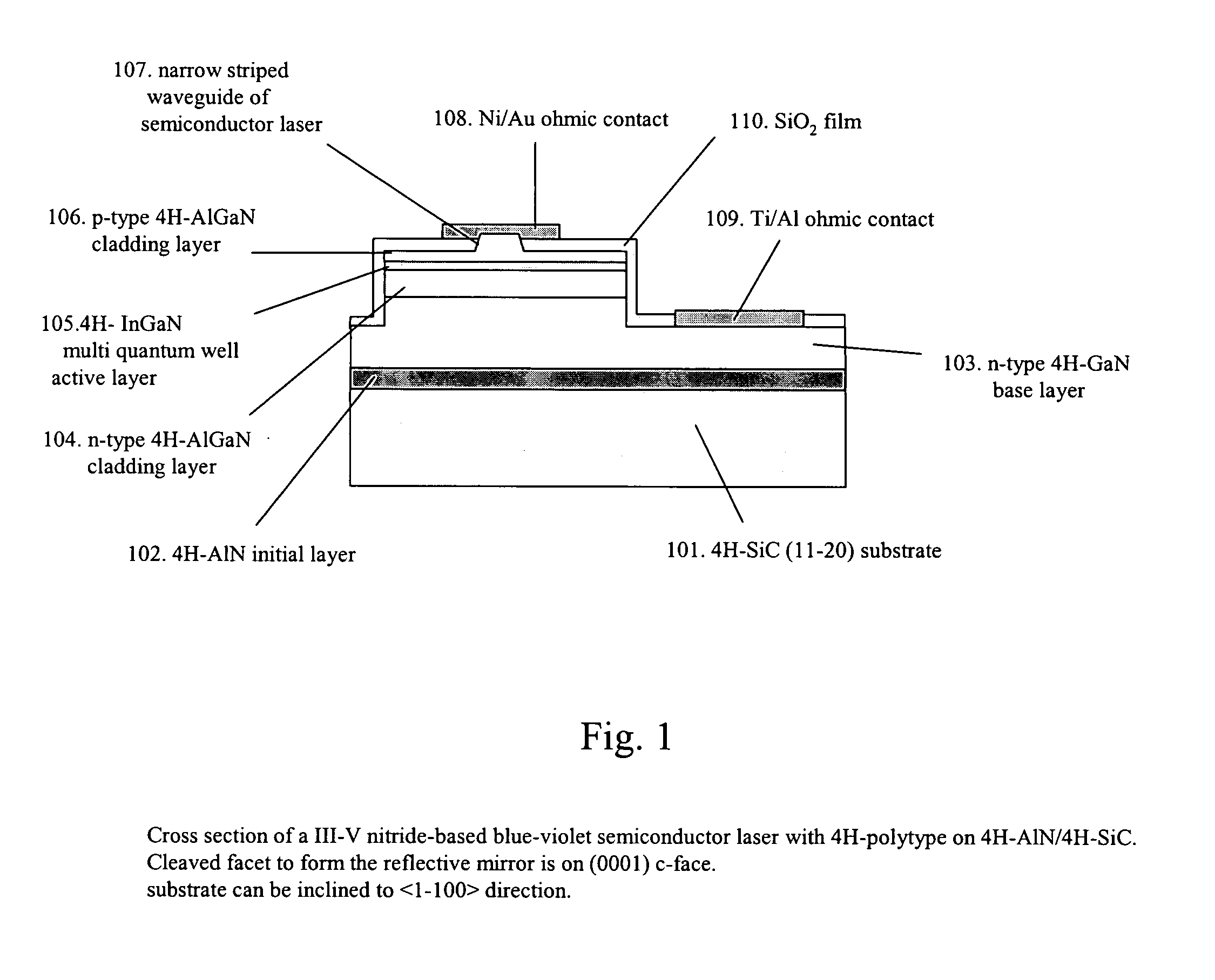

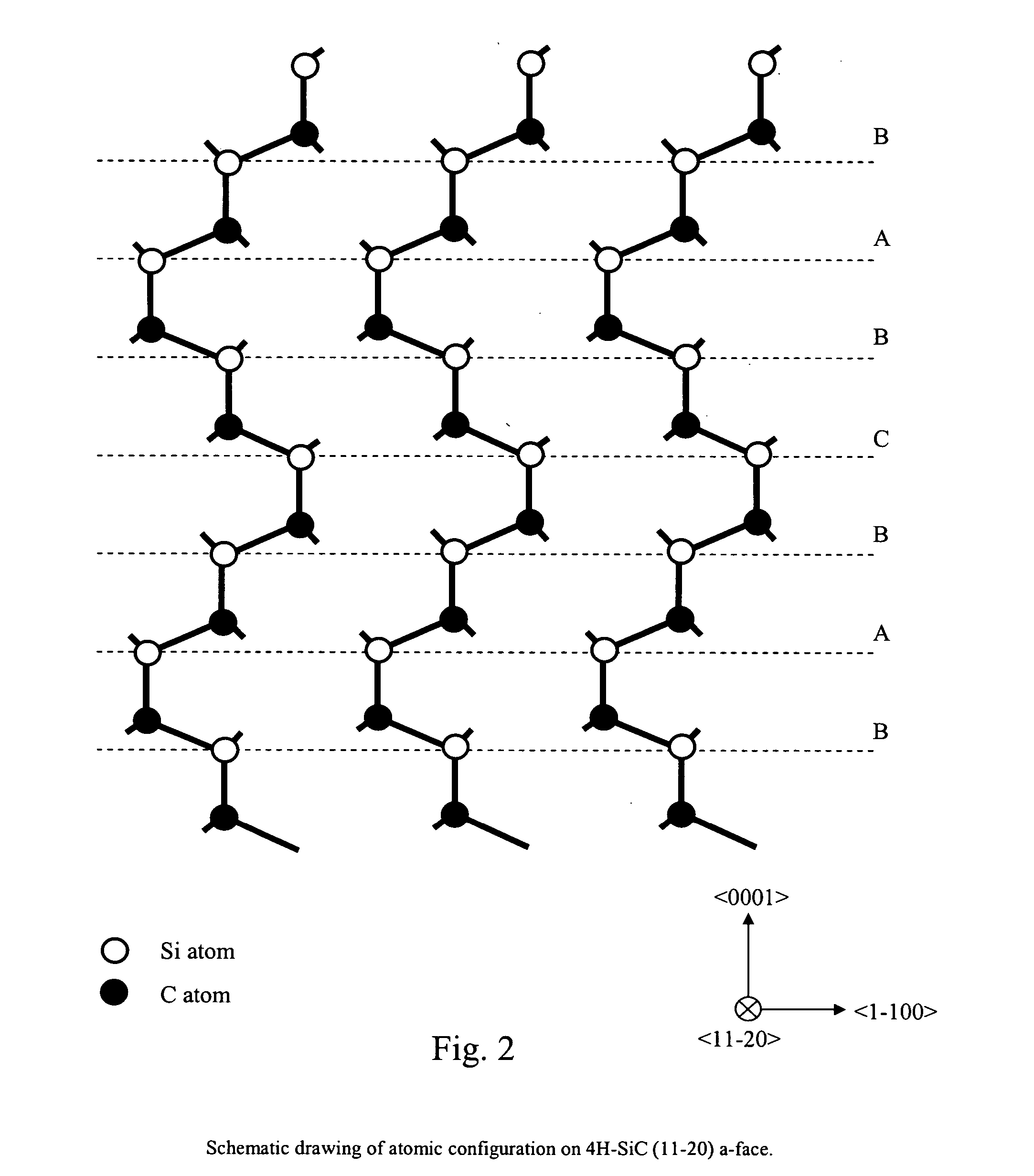

InactiveUS20050218414A1Laser detailsSemiconductor/solid-state device manufacturingDevice materialAlloy

4H-InGaAlN alloy based optoelectronic and electronic devices on non-polar face are formed on 4H-AlN or 4H-AlGaN on (11-20) a-face 4H-SiC substrates. Typically, non polar 4H-AlN is grown on 4H-SiC (11-20) by molecular beam epitaxy (MBE). Subsequently, III-V nitride device layers are grown by metal organic chemical vapor deposition (MOCVD) with 4H-polytype for all of the layers. The non-polar device does not contain any built-in electric field due to the spontaneous and piezoelectric polarization. The optoelectonic devices on the non-polar face exhibits higher emission efficiency with shorter emission wavelength because the electrons and holes are not spatially separated in the quantum well. Vertical device configuration for lasers and light emitting diodes(LEDs) using conductive 4H-AlGaN interlayer on conductive 4H-SiC substrates makes the chip size and series resistance smaller. The elimination of such electric field also improves the performance of high speed and high power transistors. The details of the epitaxial growth s and the processing procedures for the non-polar III-V nitride devices on the non-polar SiC substrates are also disclosed.

Owner:PANASONIC CORP

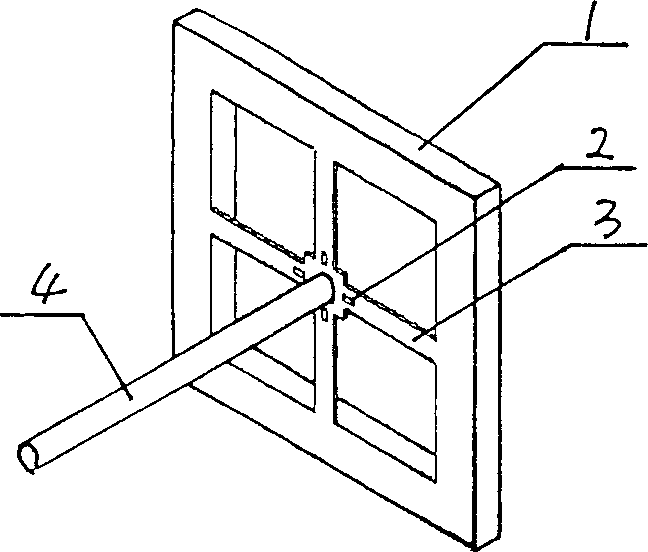

Resonant tunnelling bionic vector underwaster sensor

InactiveCN1912554AHigh sensitivityHigh microvolumeWave based measurement systemsSubsonic/sonic/ultrasonic wave measurementImage resolutionUnderwater

A vector underwater sound transducer of resonant tunneling bionic type is prepared as applying semiconductor etching technique to each bottom-middle part of semiconductor substrate to be structure of cross cantilever beam, fixing micro cylindrical body at center of cross cantilever beam and setting resonant tunneling diode separately at end portions of four beams on cross cantilever beam.

Owner:ZHONGBEI UNIV

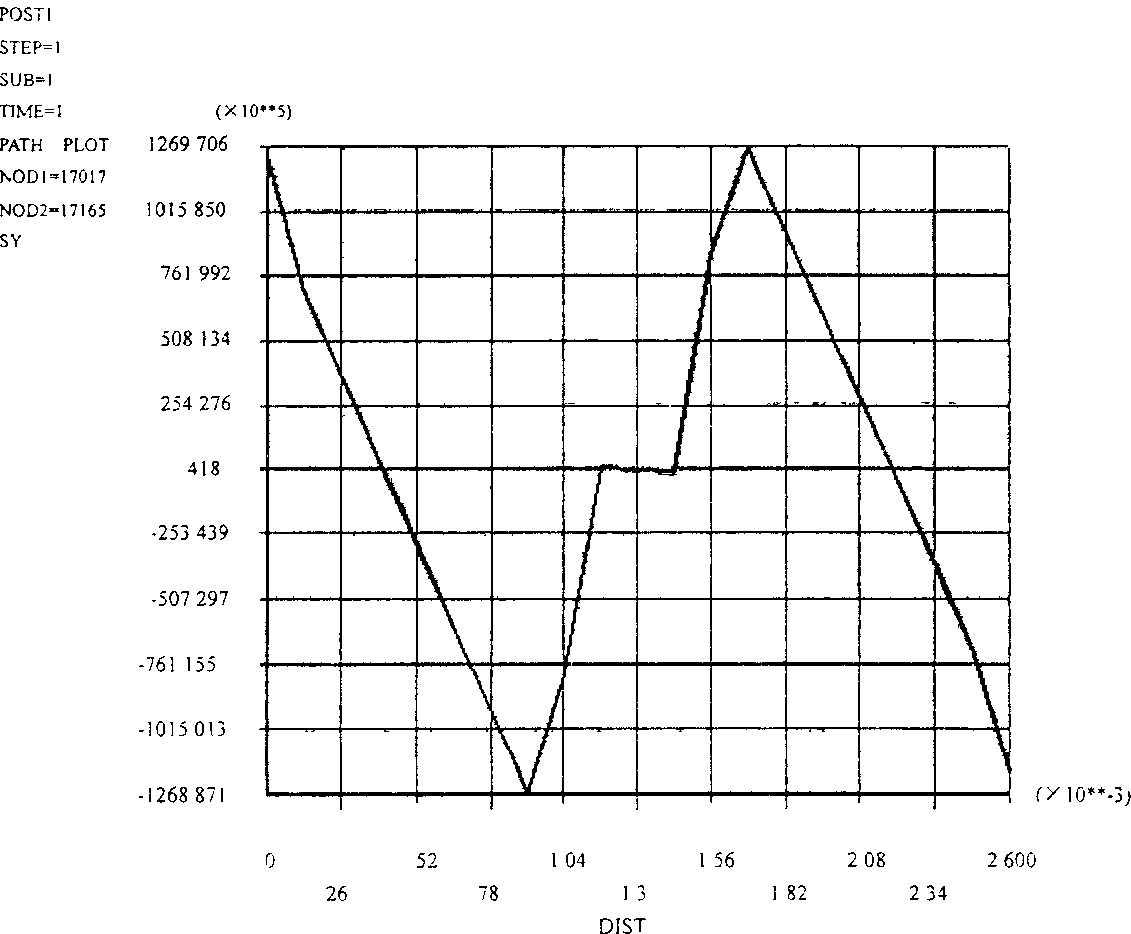

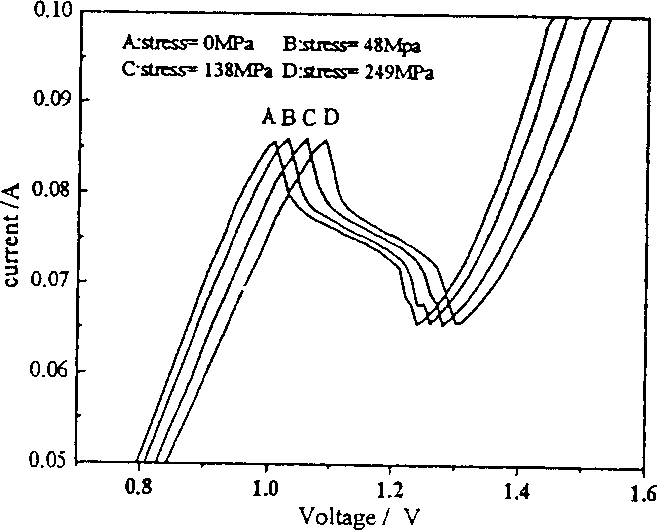

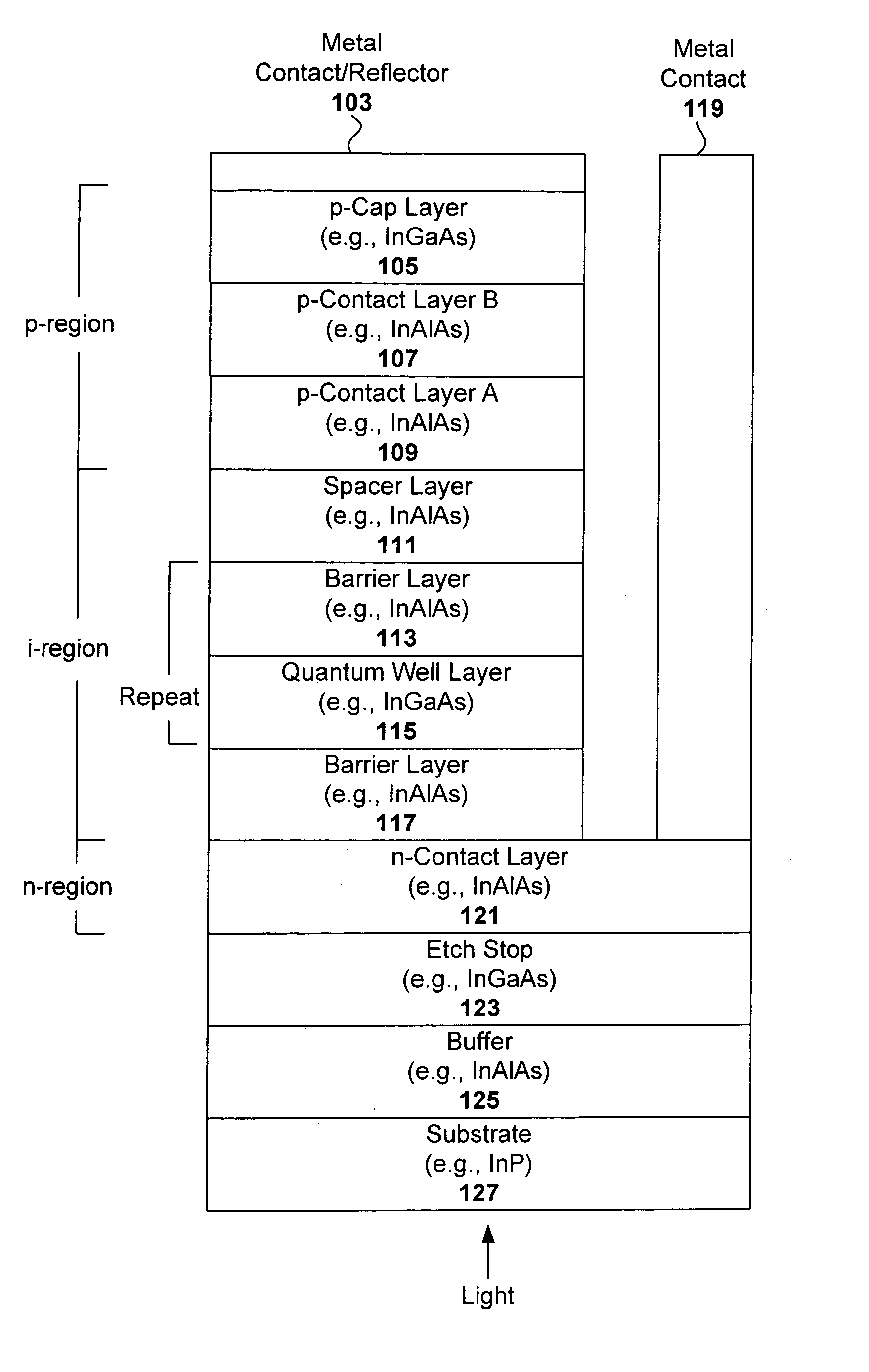

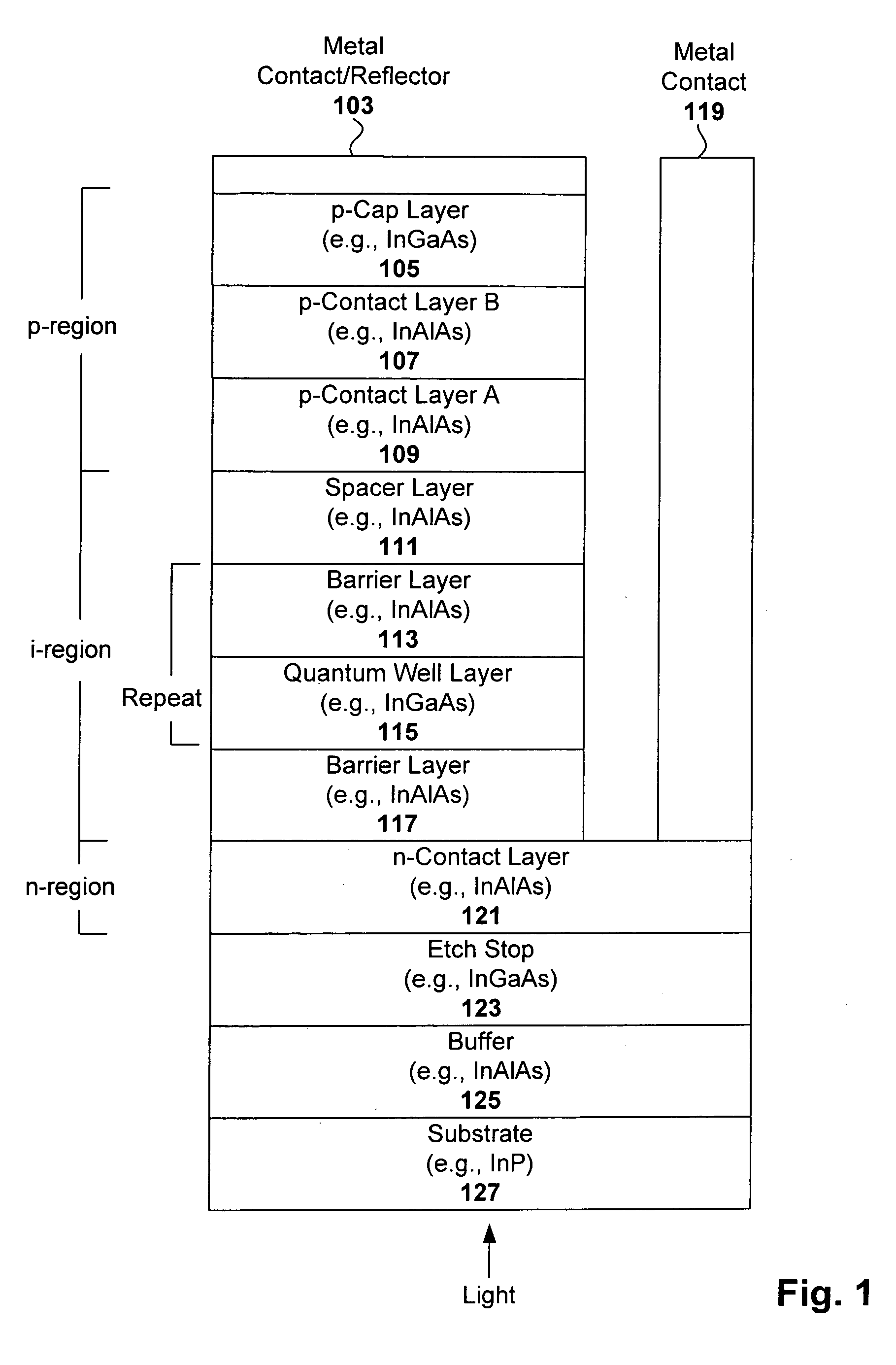

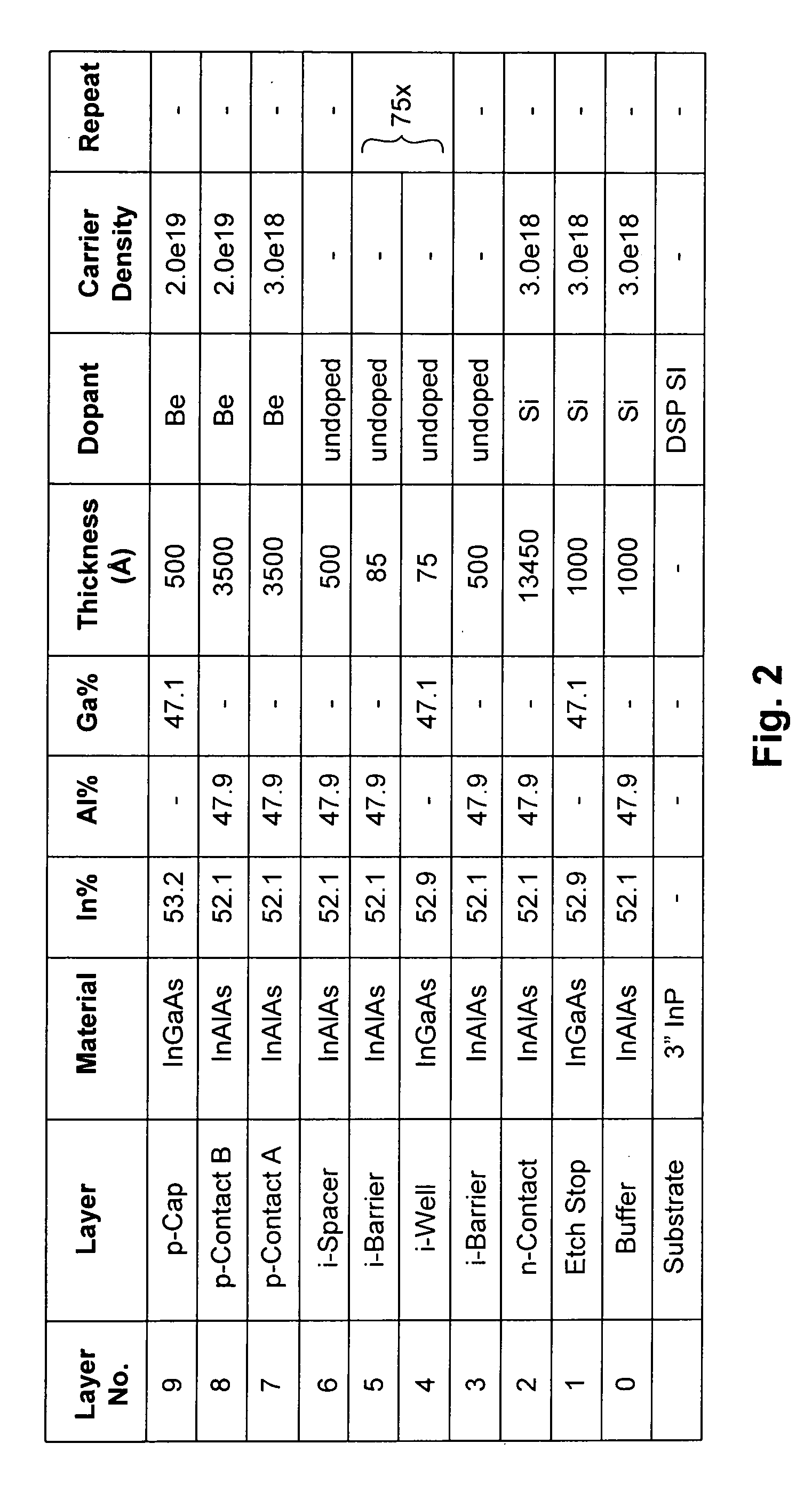

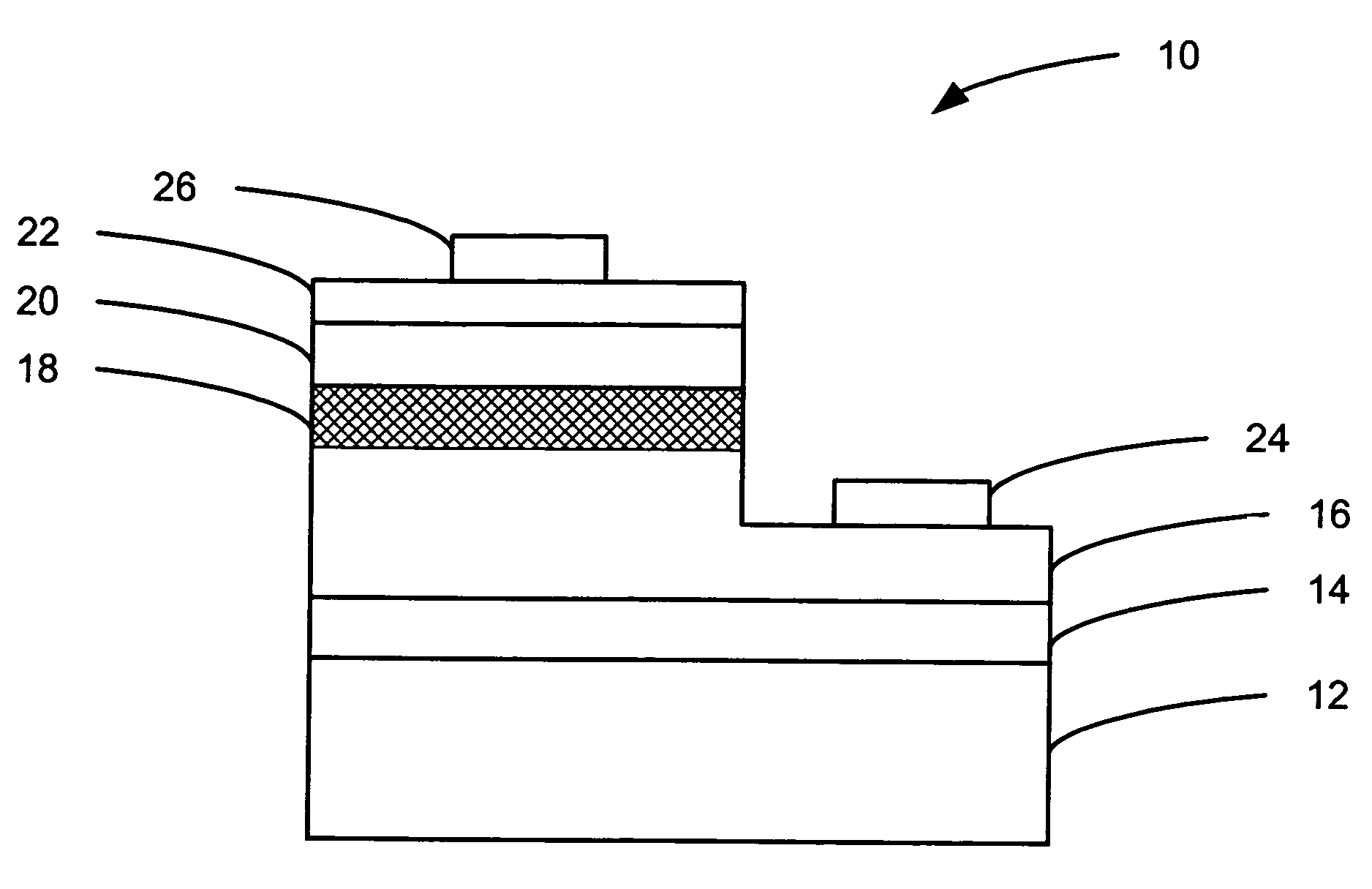

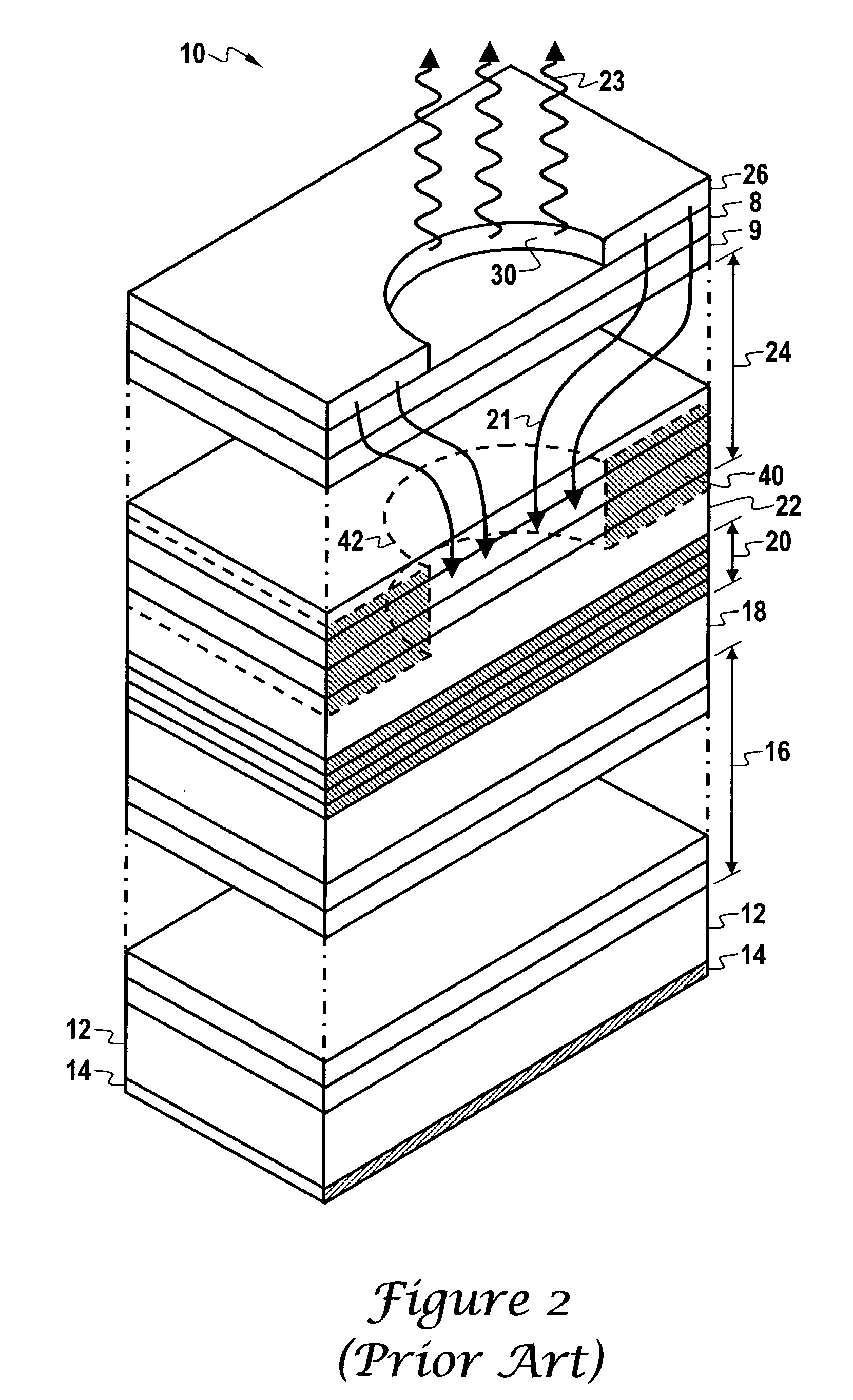

Resonant cavity enhanced multi-quantum well light modulator and detector

ActiveUS20060180830A1Increase contrastSemiconductor/solid-state device manufacturingNanoopticsTelecommunications linkSpatial light modulator

Multi-quantum well (MQW) spatial light modulator devices are disclosed that are capable of achieving reasonable quantum efficiencies and high contrast ratios in order to close an optical communication link by resolving the logical on or off state. The device both modulates and detects light through the use of the quantum well design and resonant cavity enhancement. Based on the materials (e.g., InGaAs / InAlAs) and their band structures, this device can be configured to communicate in the eye-safe wavelength range (e.g., 1550±20 nm). The device can be fabricated using standard photolithographic processes such as molecular beam epitaxy (MBE) and inductively coupled plasma (ICP) reactive ion etching (RIE).

Owner:GULA CONSULTING LLC

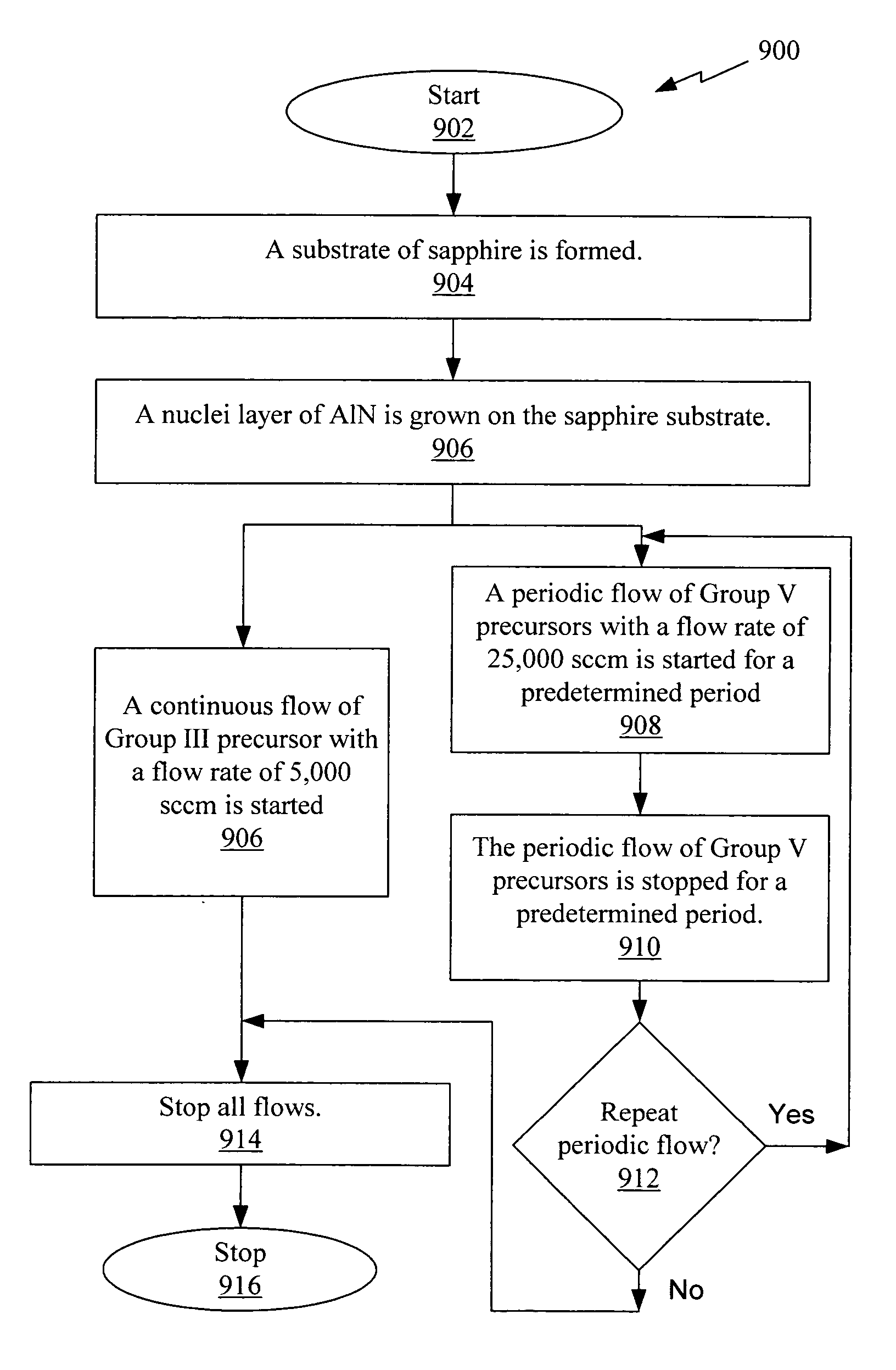

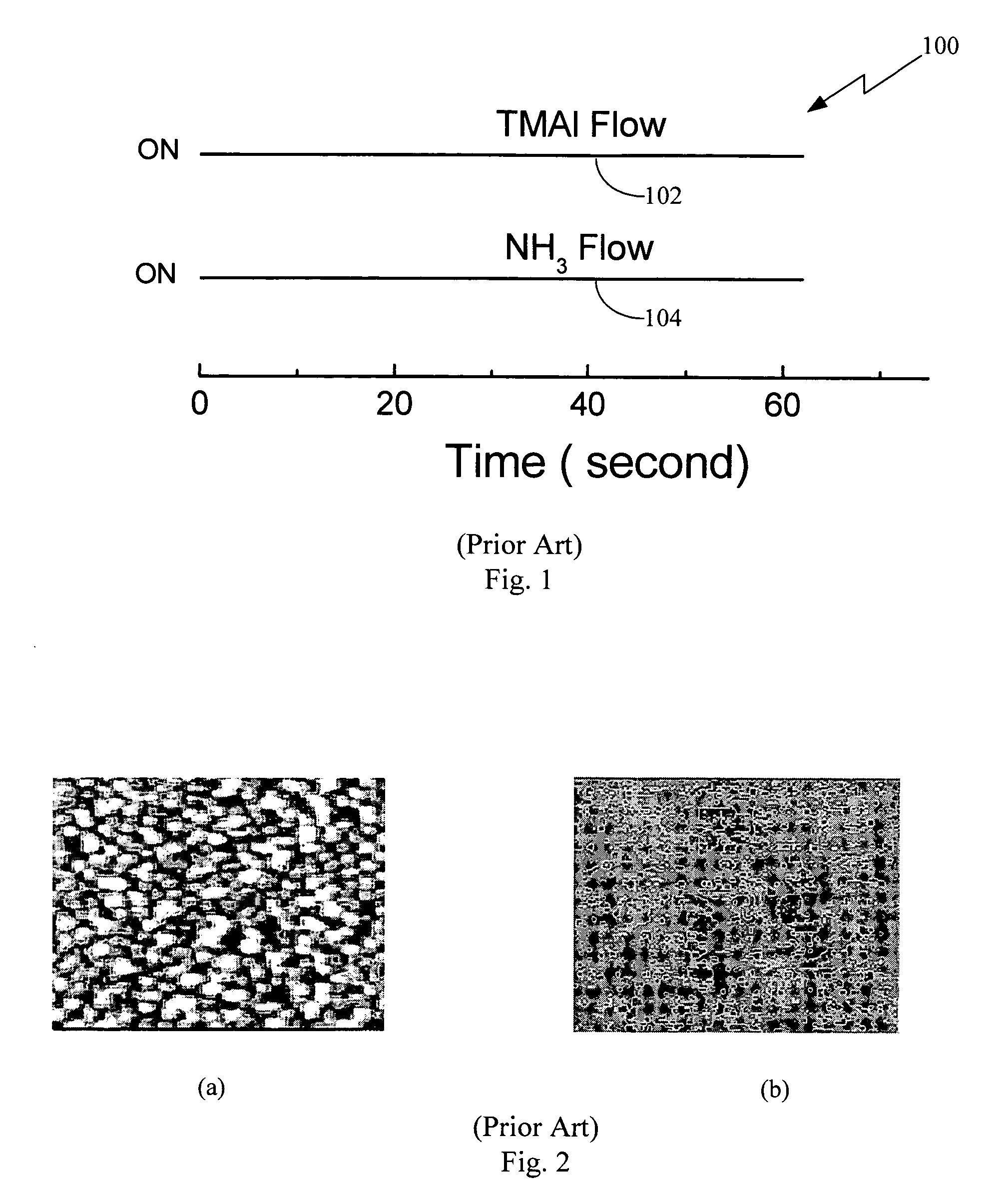

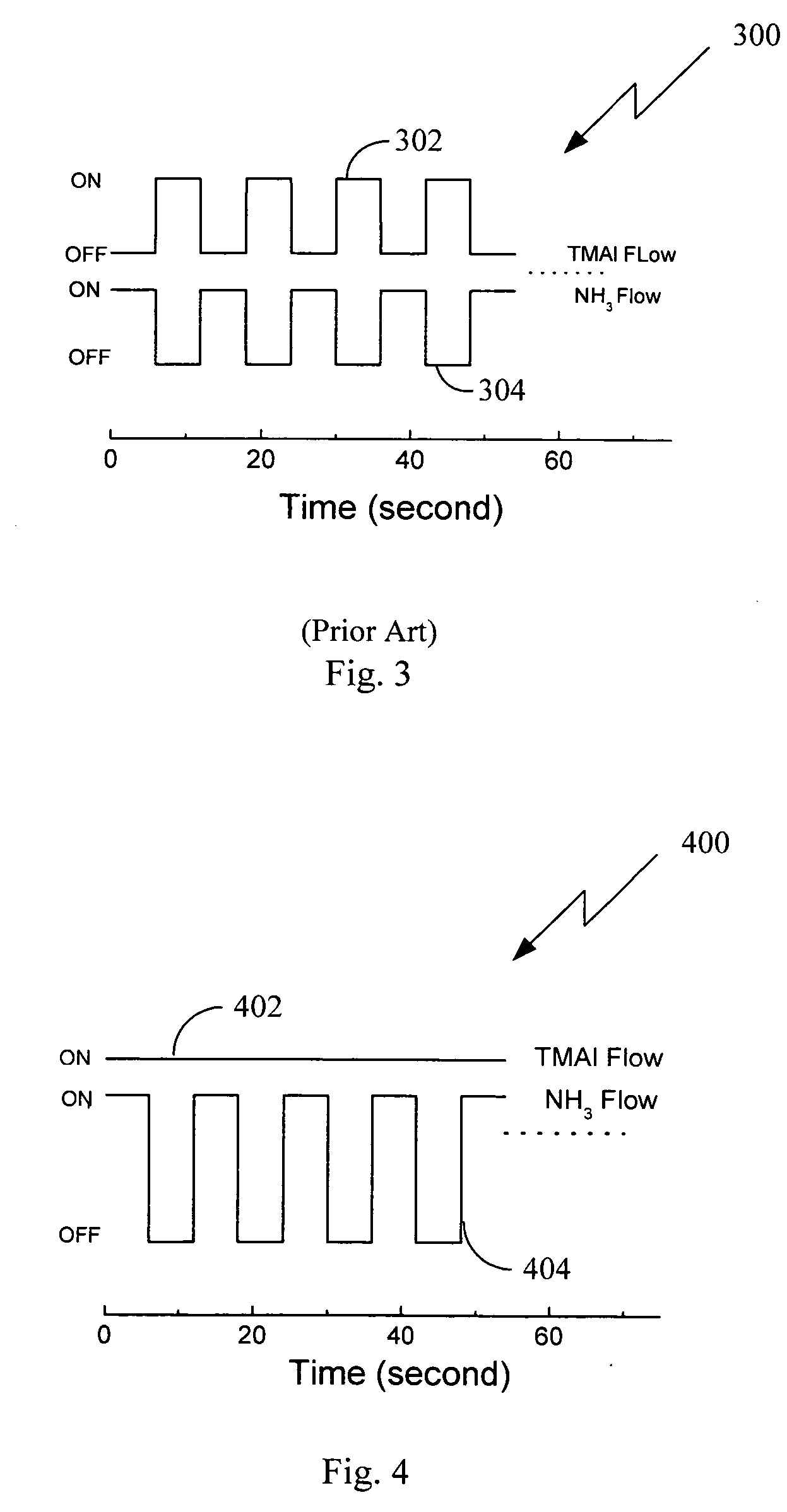

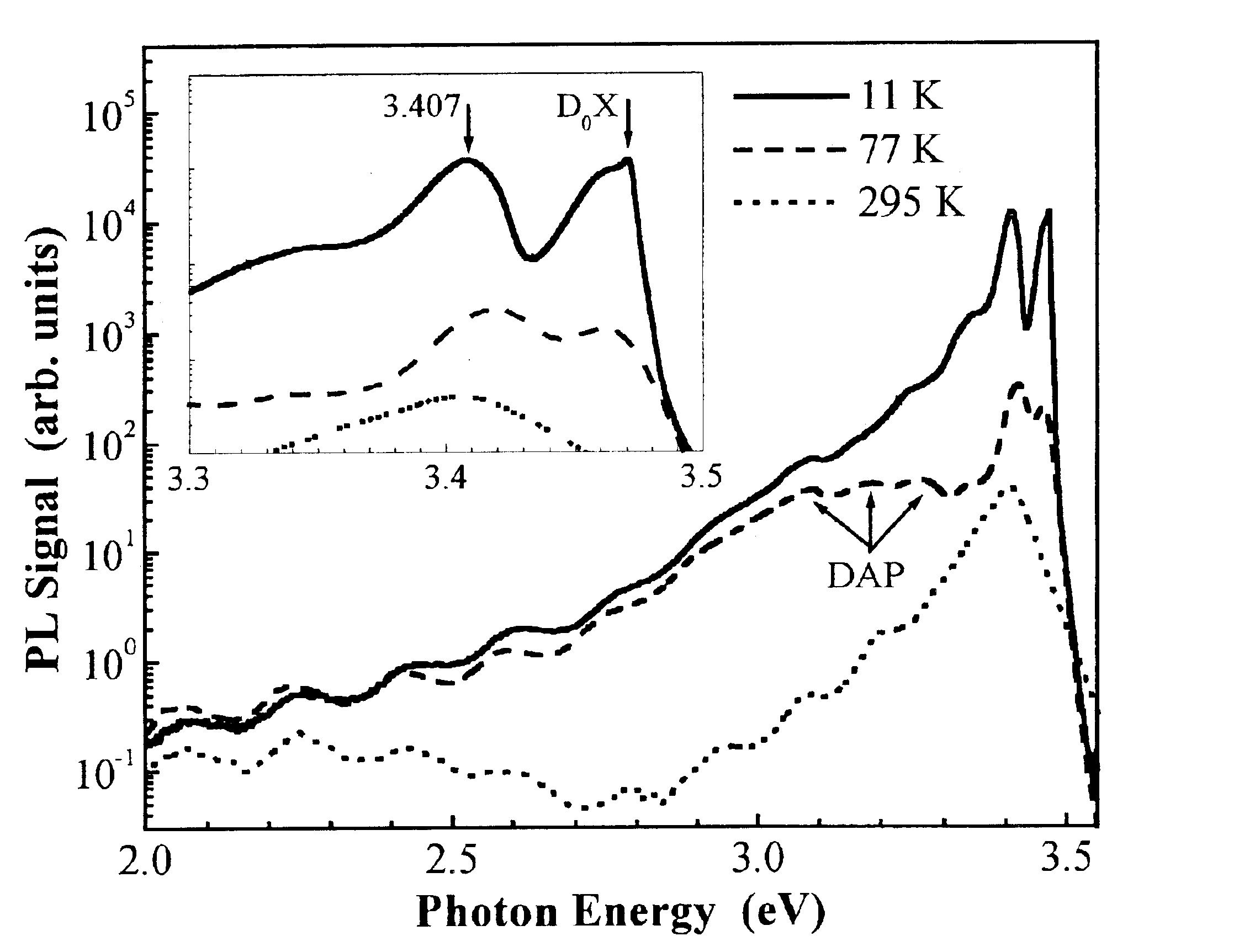

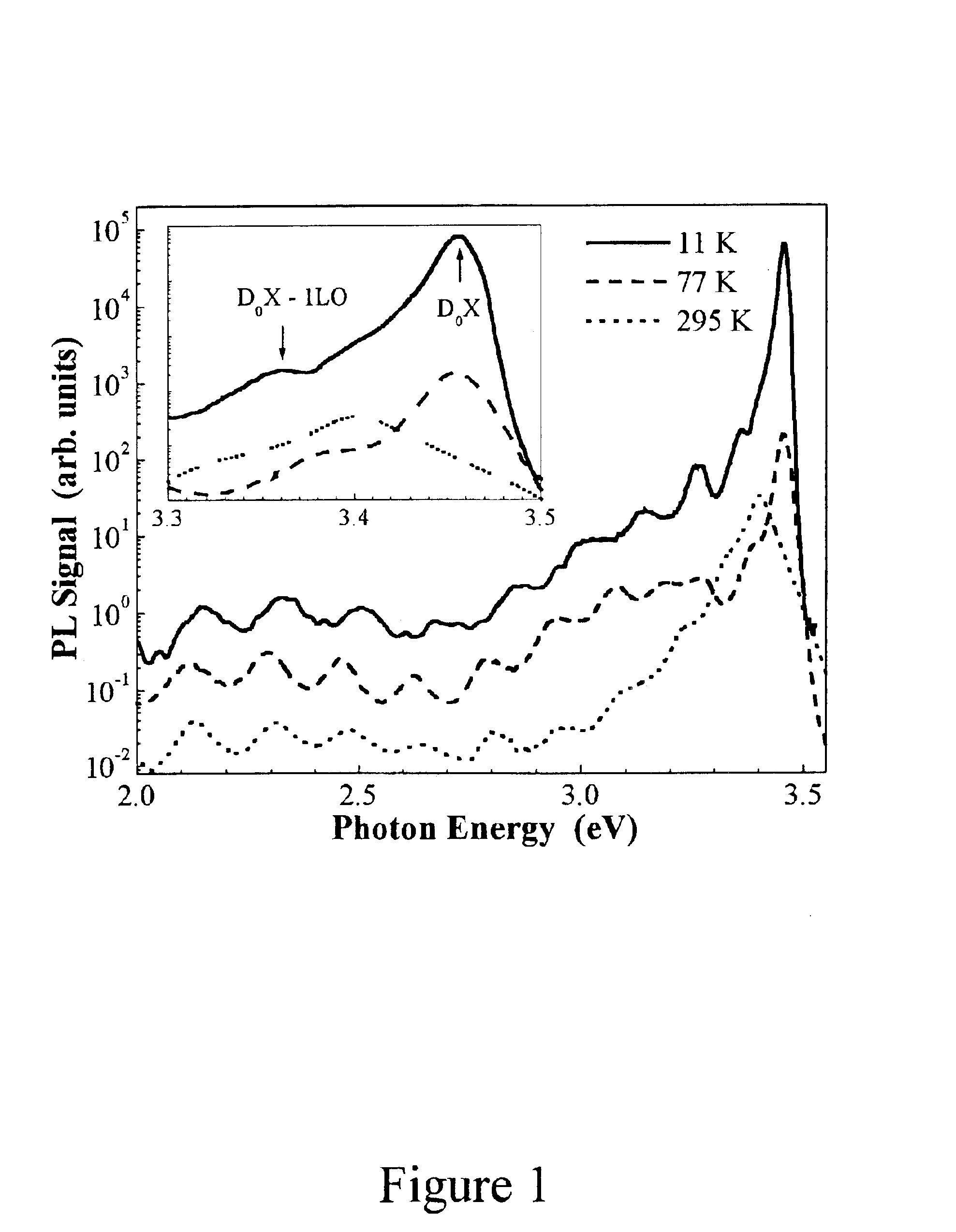

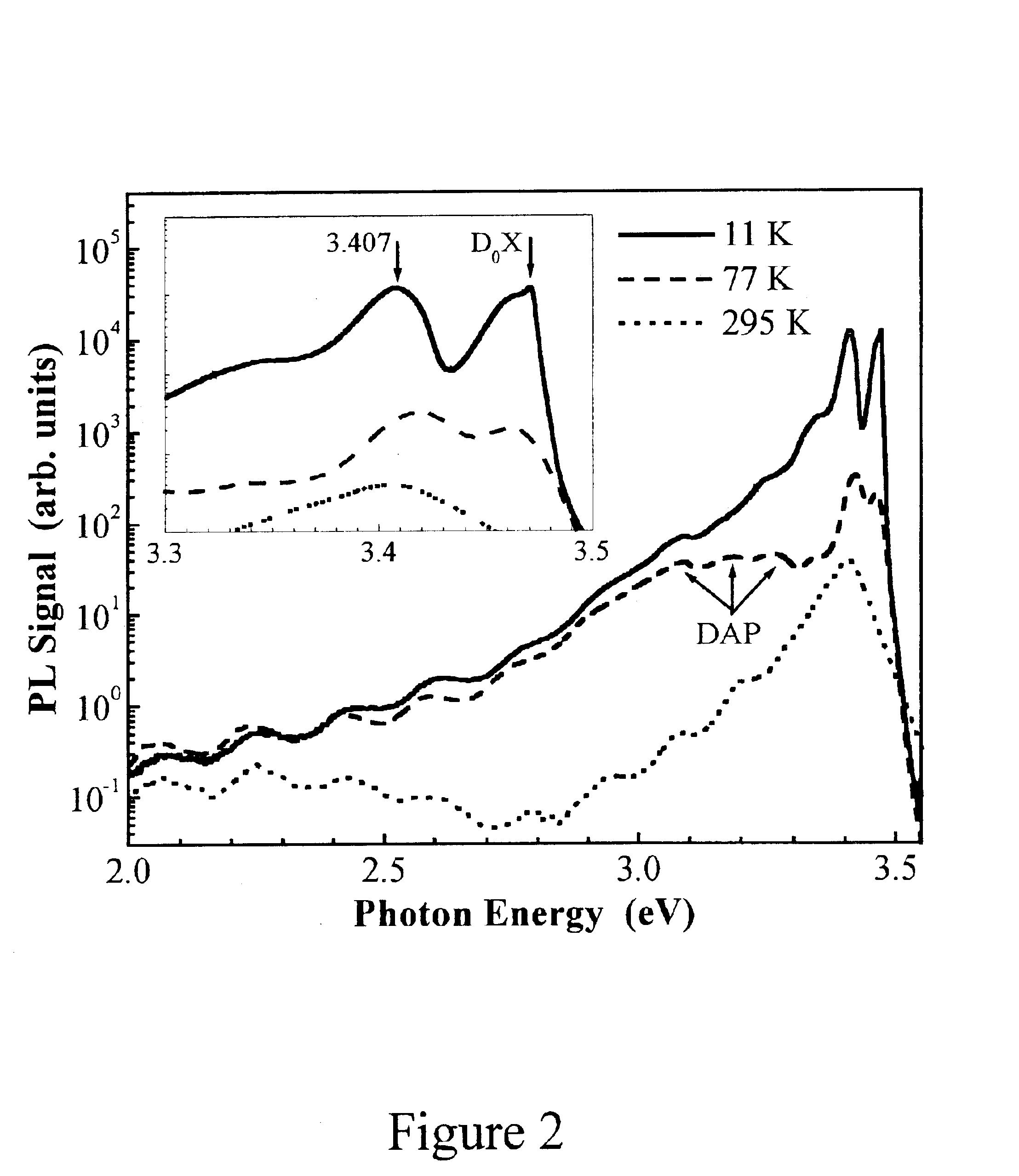

Innovative growth method to achieve high quality III-nitride layers for wide band gap optoelectronic and electronic devices

InactiveUS20060160345A1Improve machine lifeGood reproducibilitySemiconductor/solid-state device manufacturingSemiconductor devicesGas phaseBroadband

A method to achieve high quality III-nitride epitaxial layers including AlN, AlGaN, GaN, InGaN, and AlInGaN, by supplying group III precursors constantly and group V precursors periodically with the epitaxial growth systems including metal organic chemical vapor deposition (MOCVD), hydride vapor phase epitaxy (HVPE), and molecular beam epitaxy (MBE).

Owner:LIU XING QUAN +3

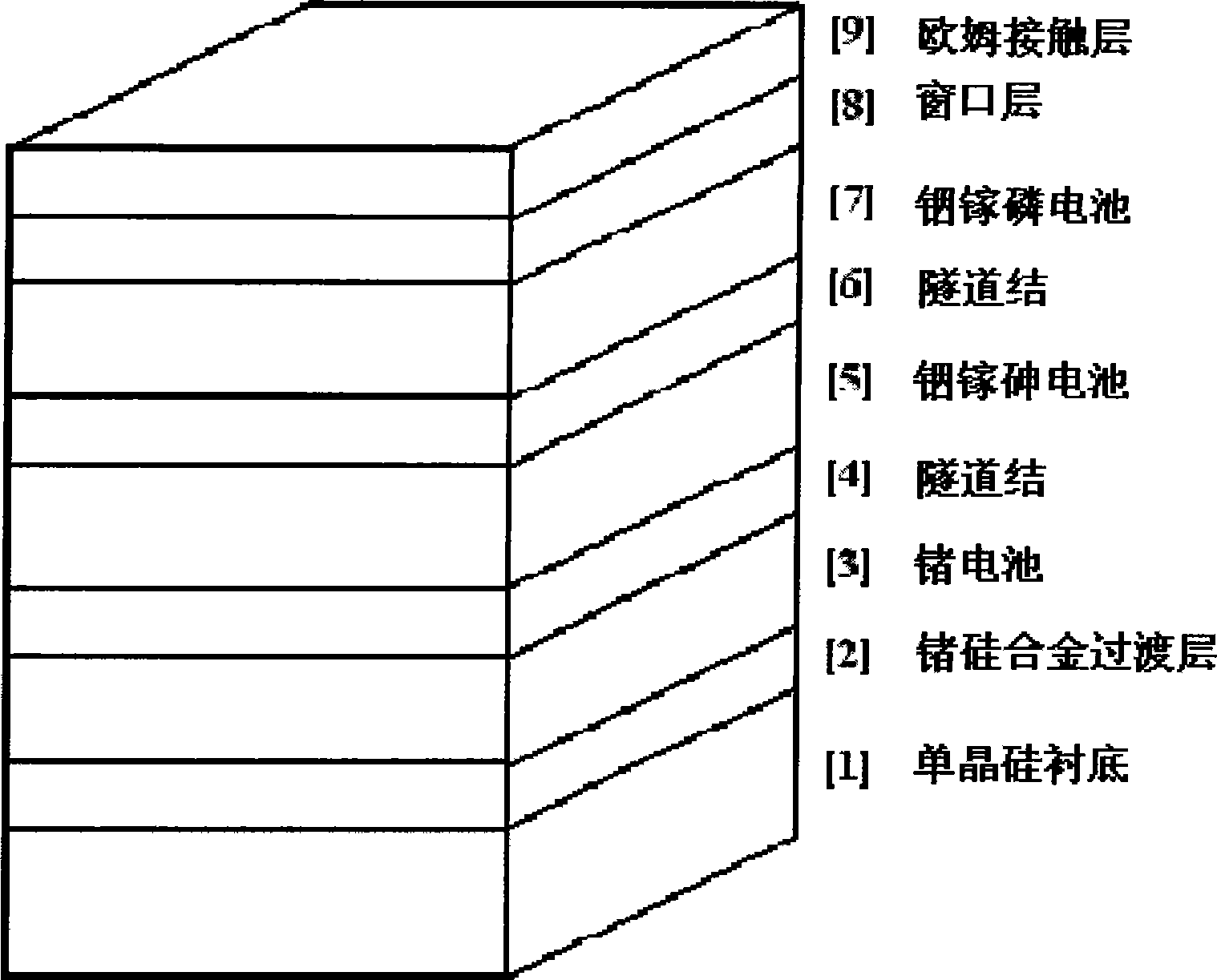

Multi-junction solar cell with monocrystalline silicon substrate

InactiveCN101483202ALow costImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesIndiumSilicon alloy

The invention discloses a multi-junction solar cell based on a monocrystalline silicon substrate for the solar energy power generation, especially suitable for a high efficiency concentrated solar energy power generation system characterized by growing the multi-junction solar cell materials by using a silicon single-crystal wafer as a substrate through a Metal Organic Chemical Vapor Deposition (MOCVD) method or a Molecular Beam Epitaxy (MBE) method. Firstly a germanium-silicon alloy transition layer is grown on the silicon single-crystal wafer, then a germanium cell structure, an indium-gallium-arsenic cell structure and an indium-gallium-phosphorus cell structure are grown in turn. The invention employs the silicon single-crystal sheet instead of the germanium single-crystal wafer and the gallium arsenide single-crystal wafer, greatly reduces the multi-junction solar cell cost, improves the conversion efficiency of the silicon based solar cell and expedites the application and development of the solar energy power generation.

Owner:北京索拉安吉清洁能源科技有限公司

Ultraviolet light emitting AlGaN composition, and ultraviolet light emitting device containing same

InactiveUS7812366B1Improve efficiencyOvercome difficultiesLaser optical resonator constructionSolid-state devicesCharge carrierUltraviolet lights

Owner:US SEC THE ARMY THE

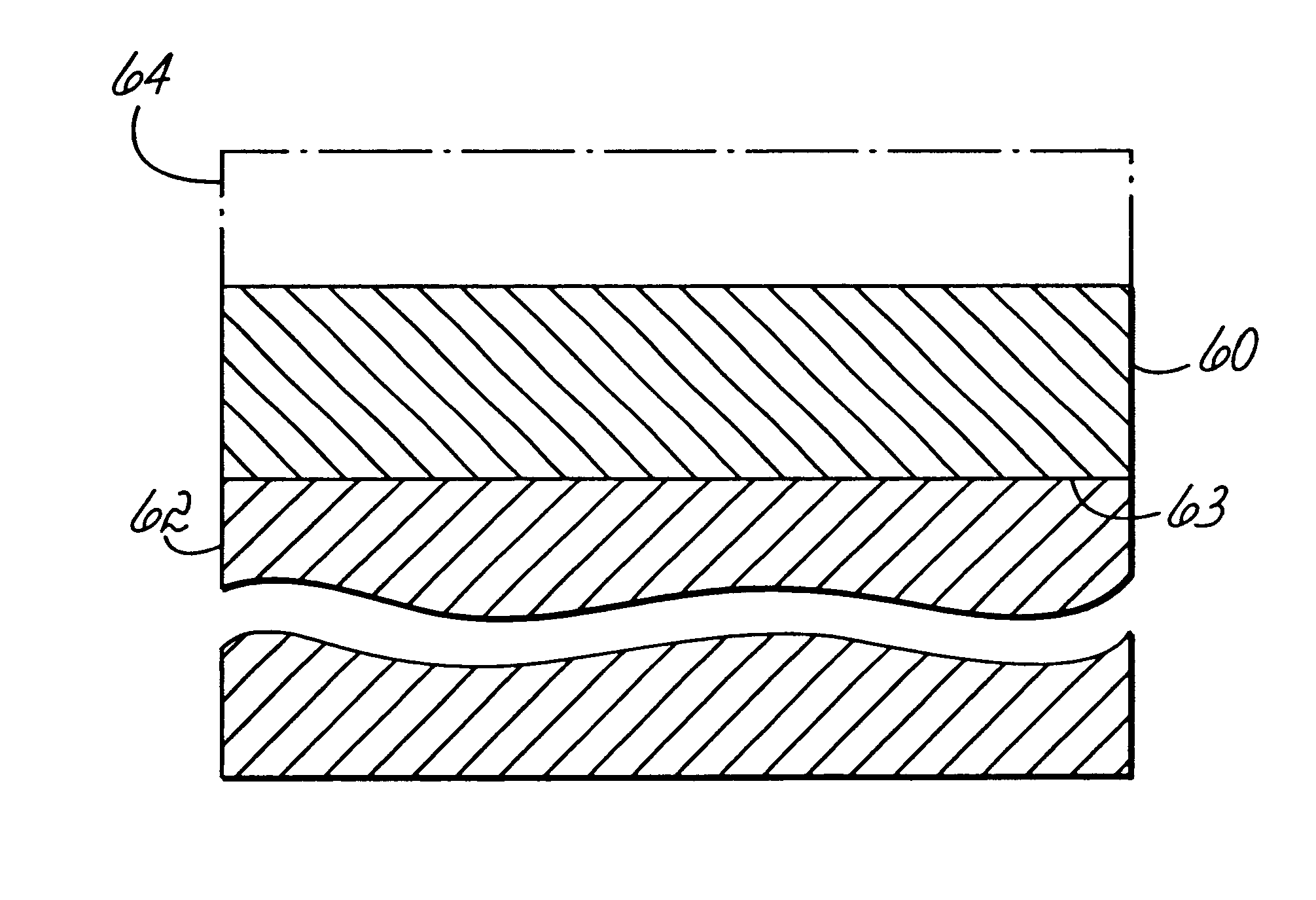

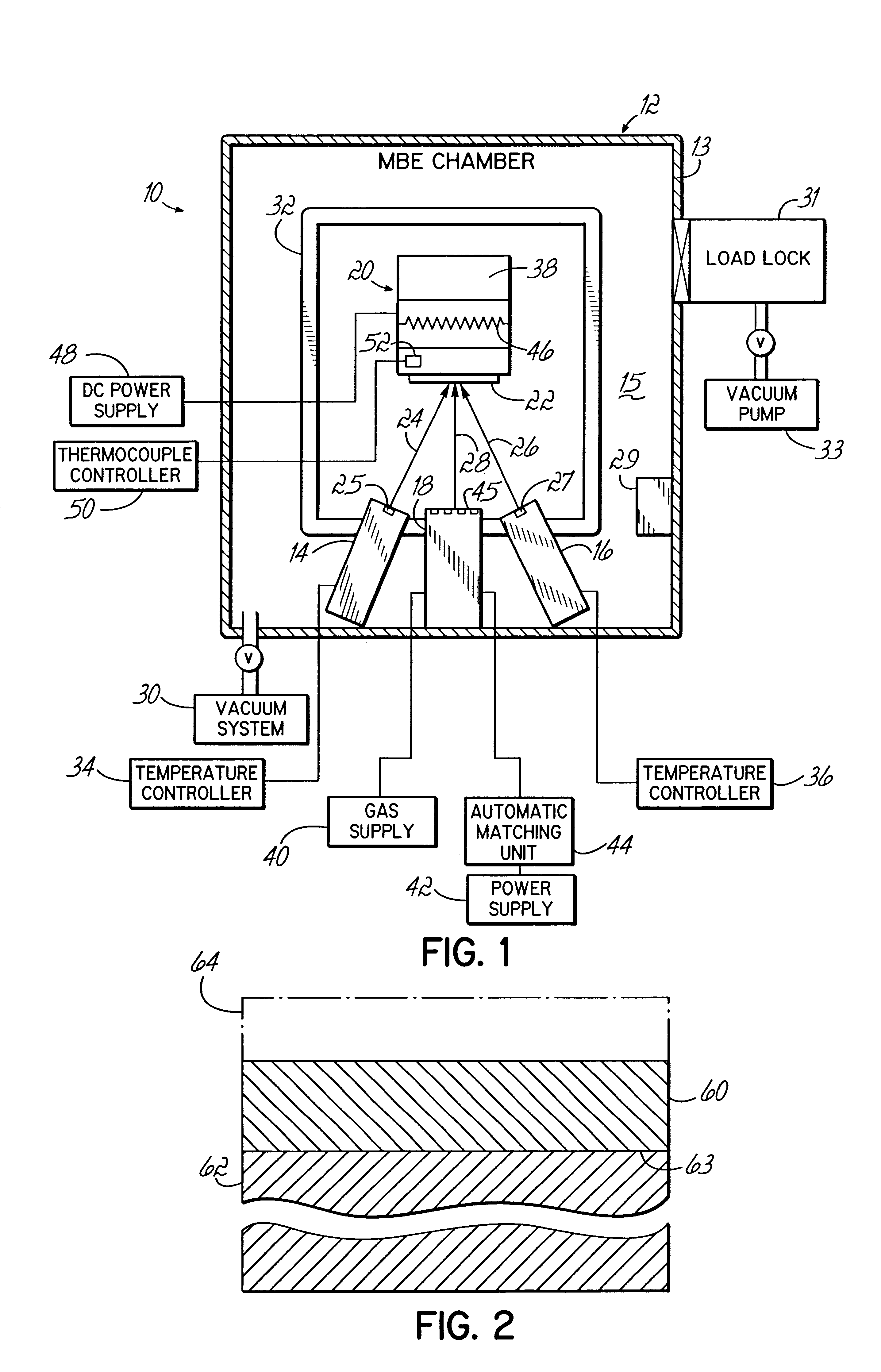

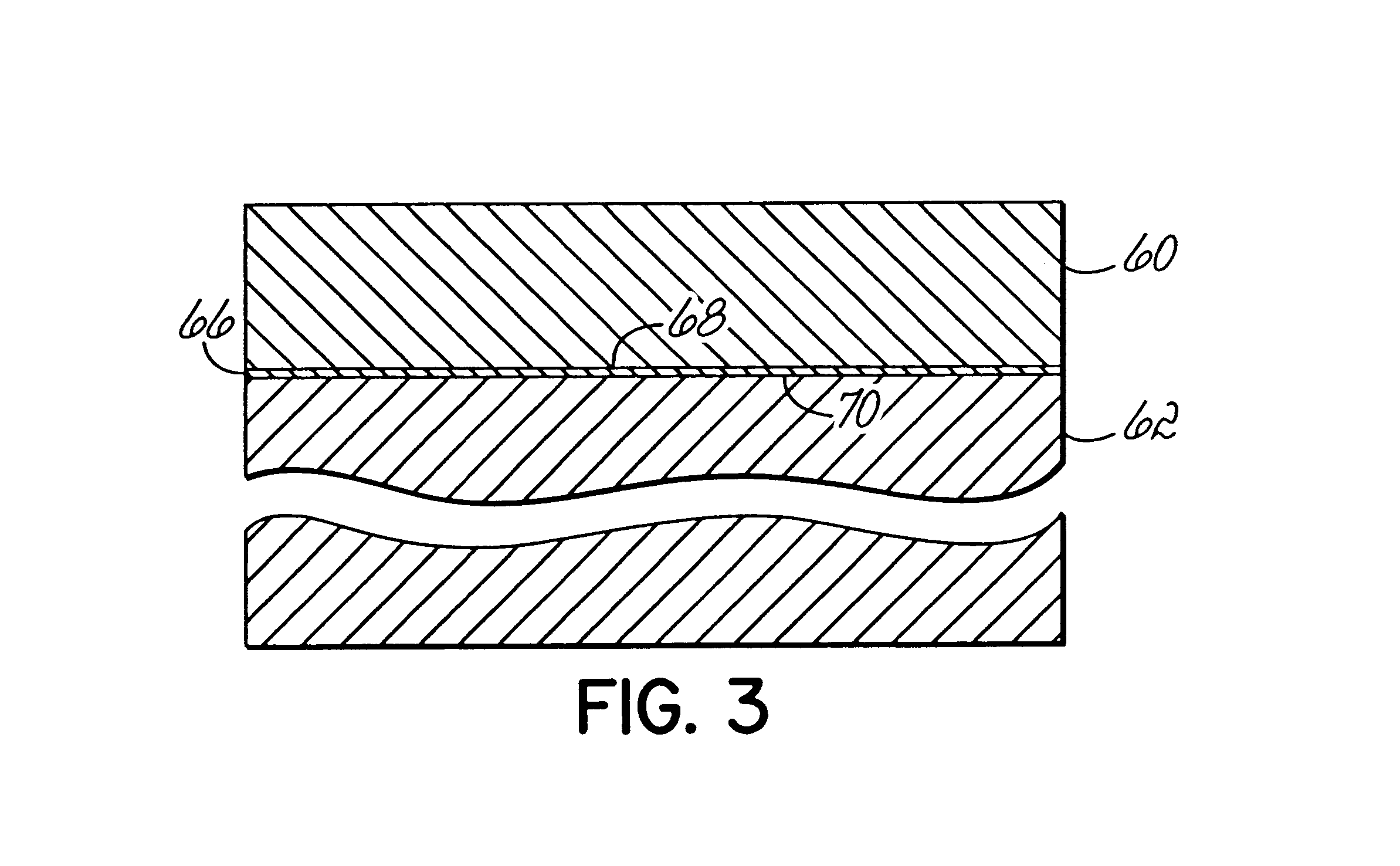

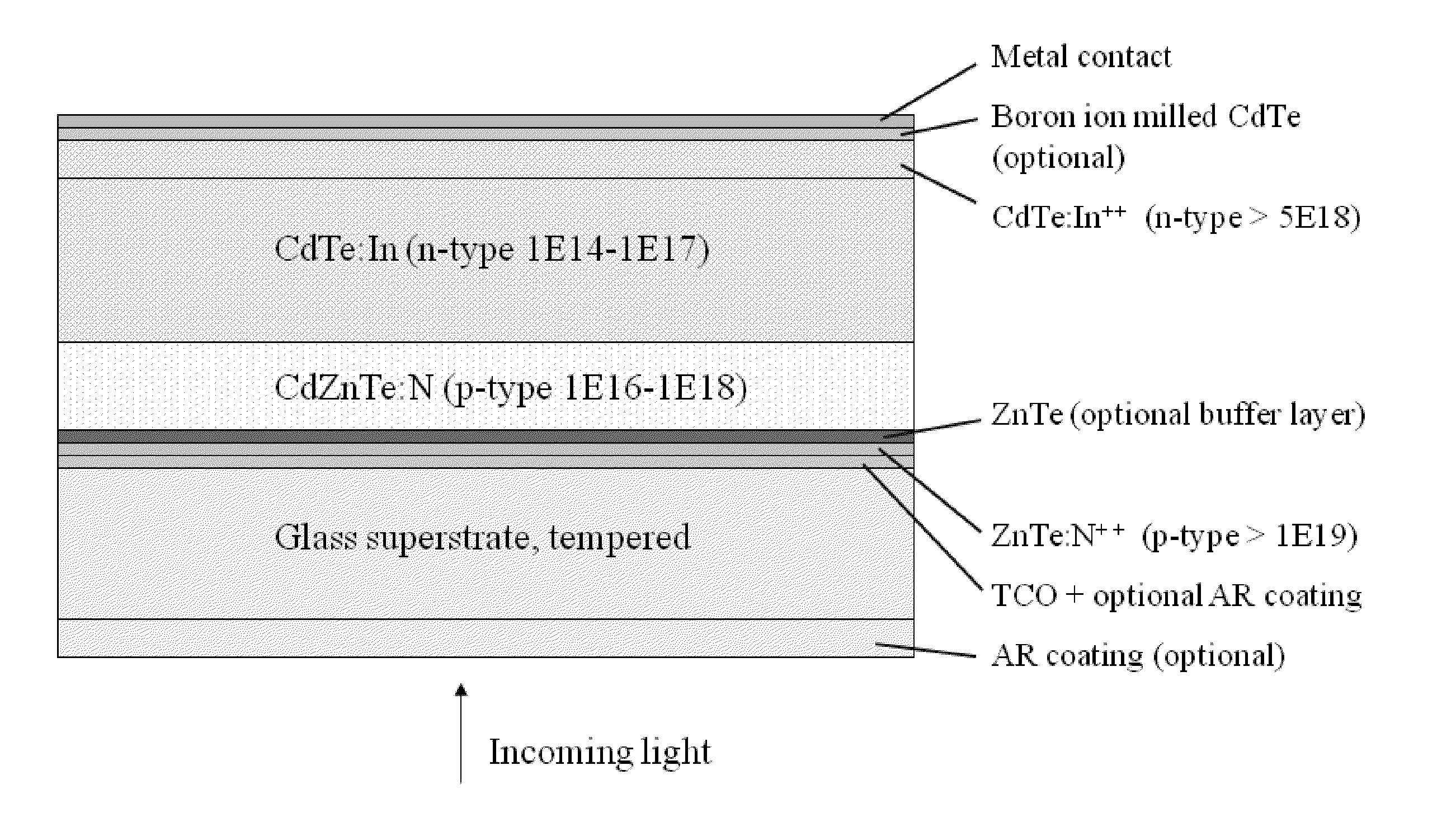

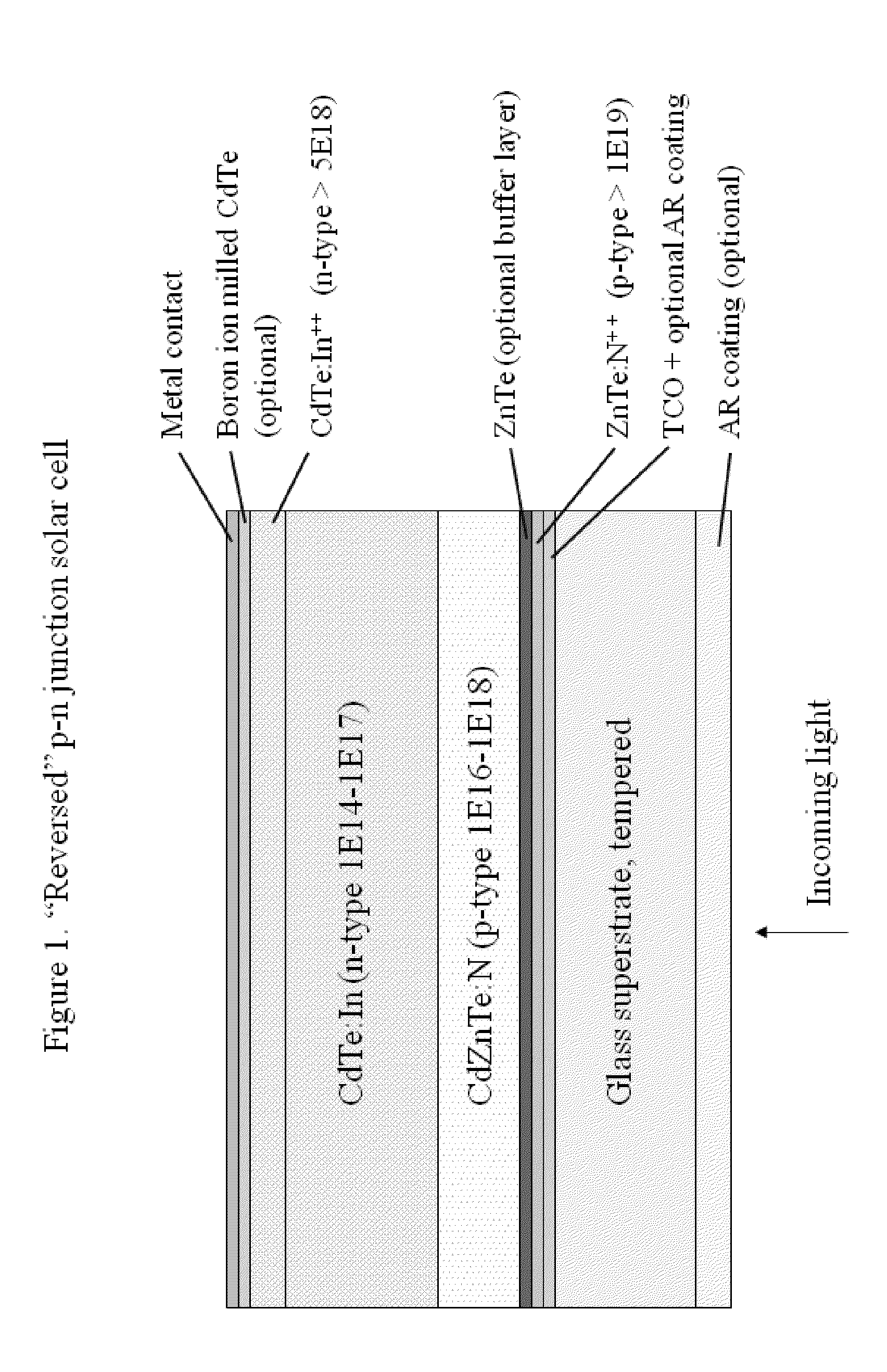

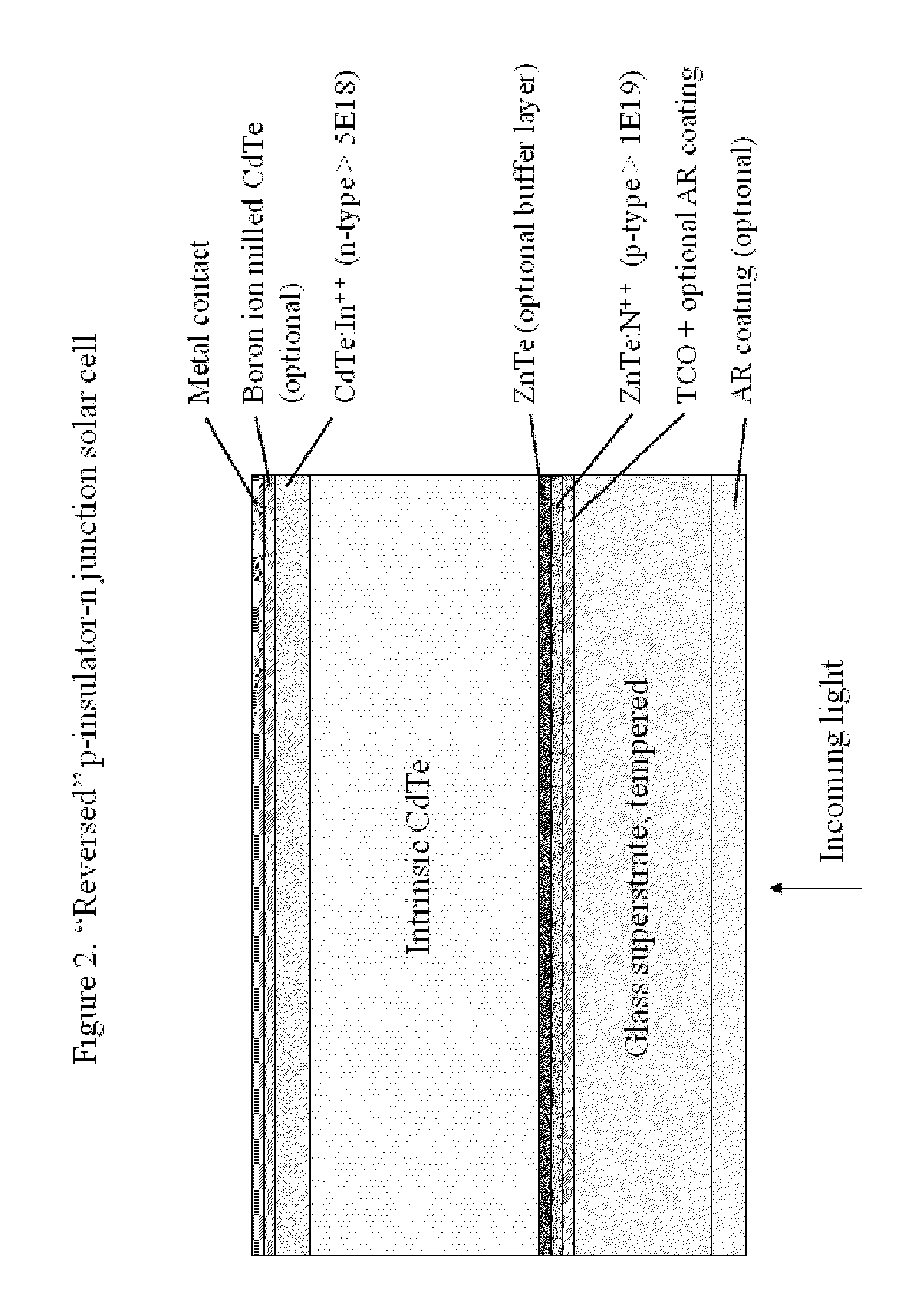

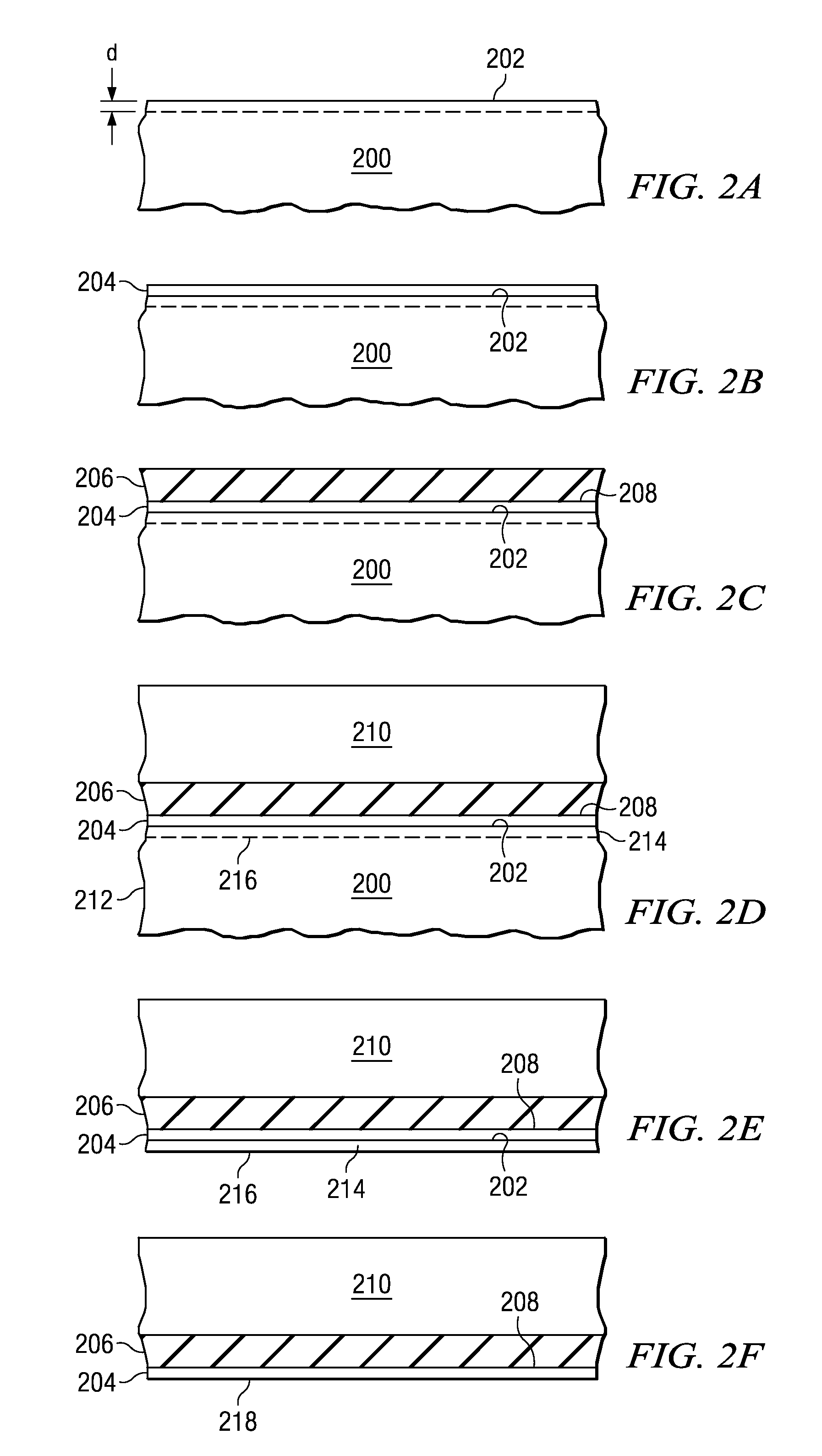

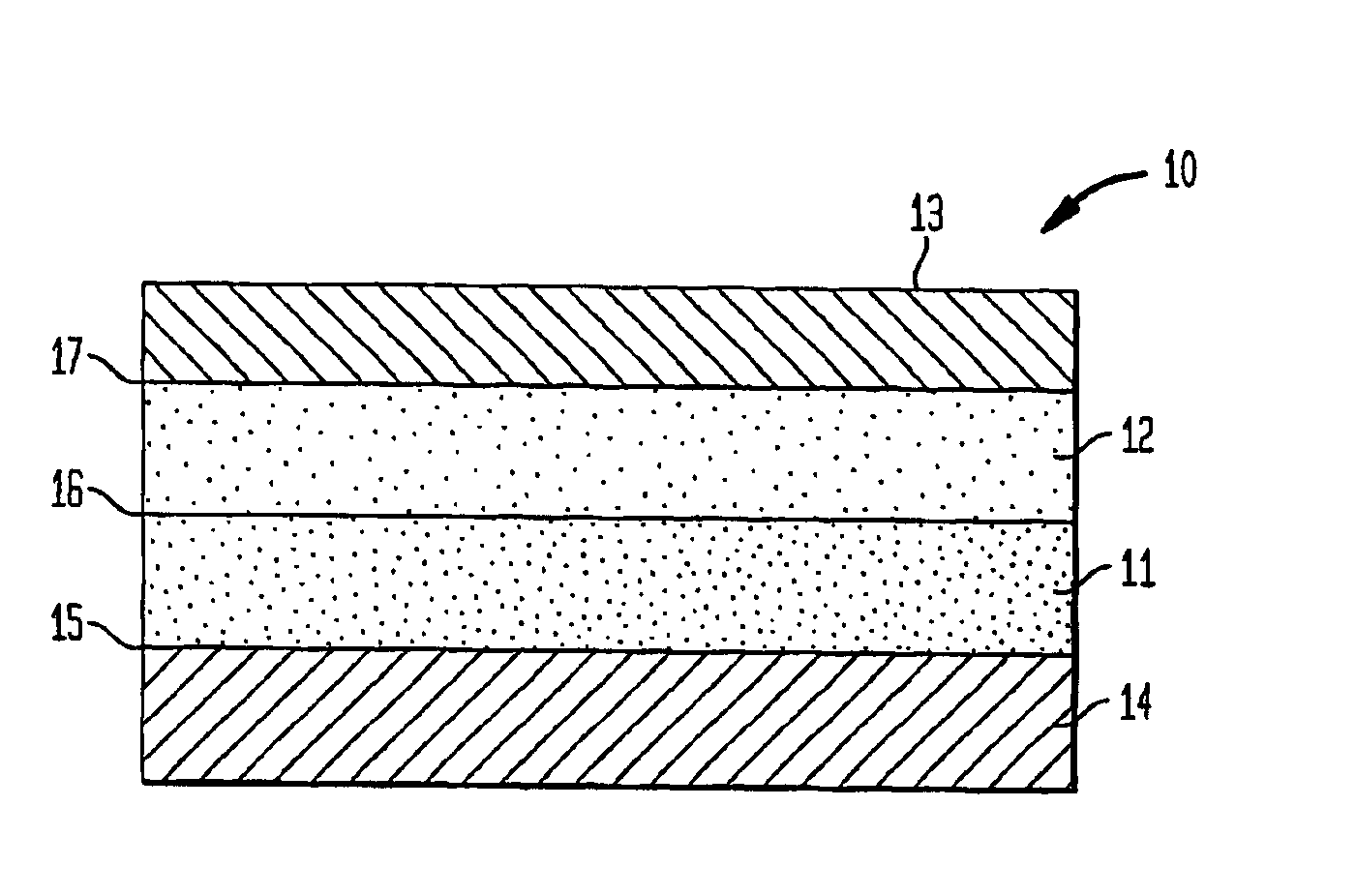

High Power Efficiency Polycrystalline CdTe Thin Film Semiconductor Photovoltaic Cell Structures for Use in Solar Electricity Generation

InactiveUS20110139249A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationIntrinsicsEngineering

Solar cell structures formed using molecular beam epitaxy (MBE) that can achieve improved power efficiencies in relation to prior art thin film solar cell structures are provided. A reverse p-n junction solar cell device and methods for forming the reverse p-n junction solar cell device using MBE are described. A variety of n-p junction and reverse p-n junction solar cell devices and related methods of manufacturing are provided. N-intrinsic-p junction and reverse p-intrinsic-n junction solar cell devices are also described.

Owner:URIEL SOLAR

Method for growing GeSn alloy on Si substrate by molecular beam epitaxy

InactiveCN101962802ASemiconductor/solid-state device manufacturingFrom chemically reactive gasesAlloySilicon

The invention provides a method for growing GeSn alloy on a silicon (Si) substrate by molecular beam epitaxy. The method comprises the following steps of: 1, growing a first Ge material layer on the Si substrate; 2, growing a second Ge material layer on the first Ge material layer; 3, growing a first GeSn alloy layer on the second Ge material layer; and 4, growing a second GeSn alloy layer on the first GeSn alloy layer to finish the growth of the material.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

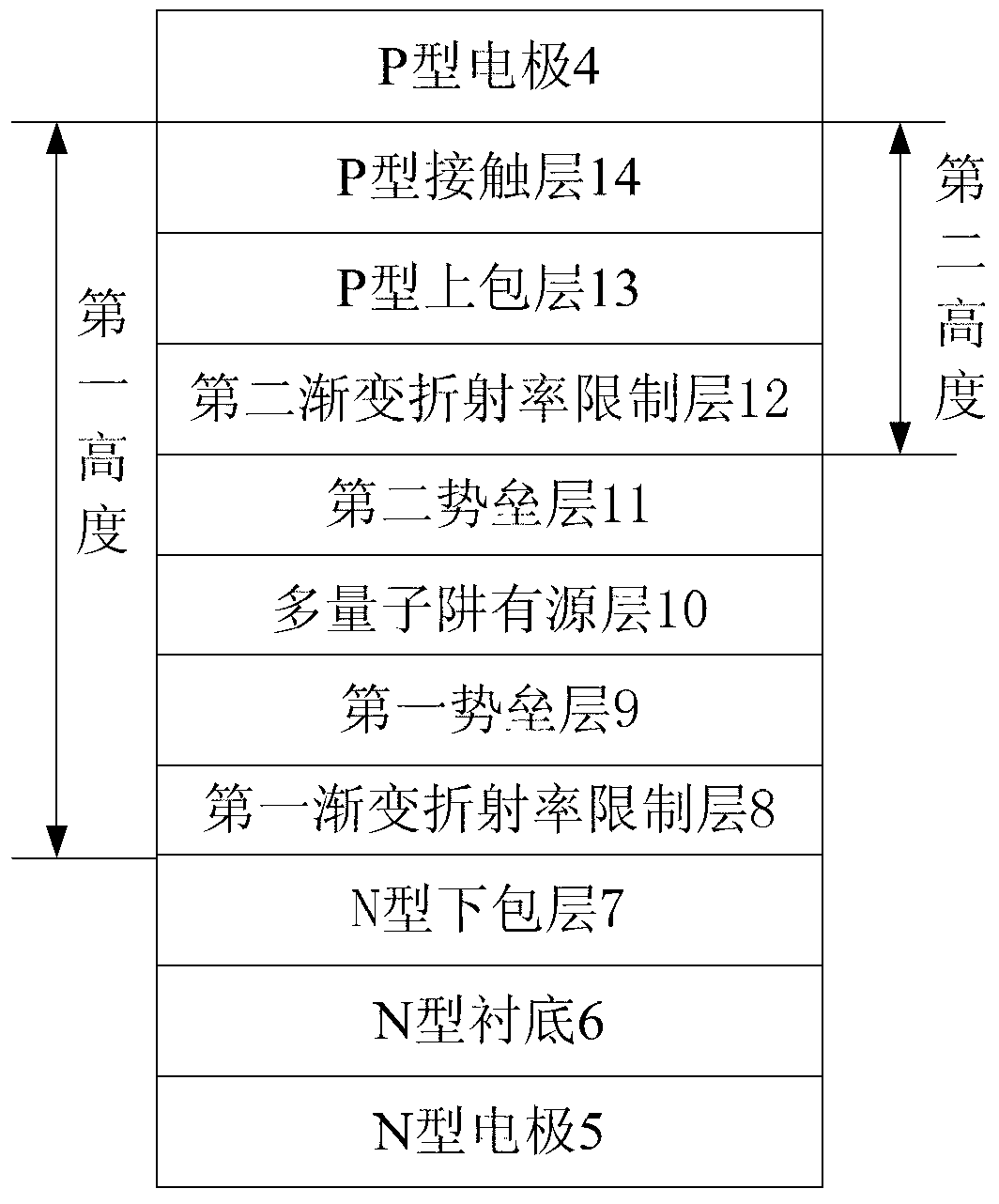

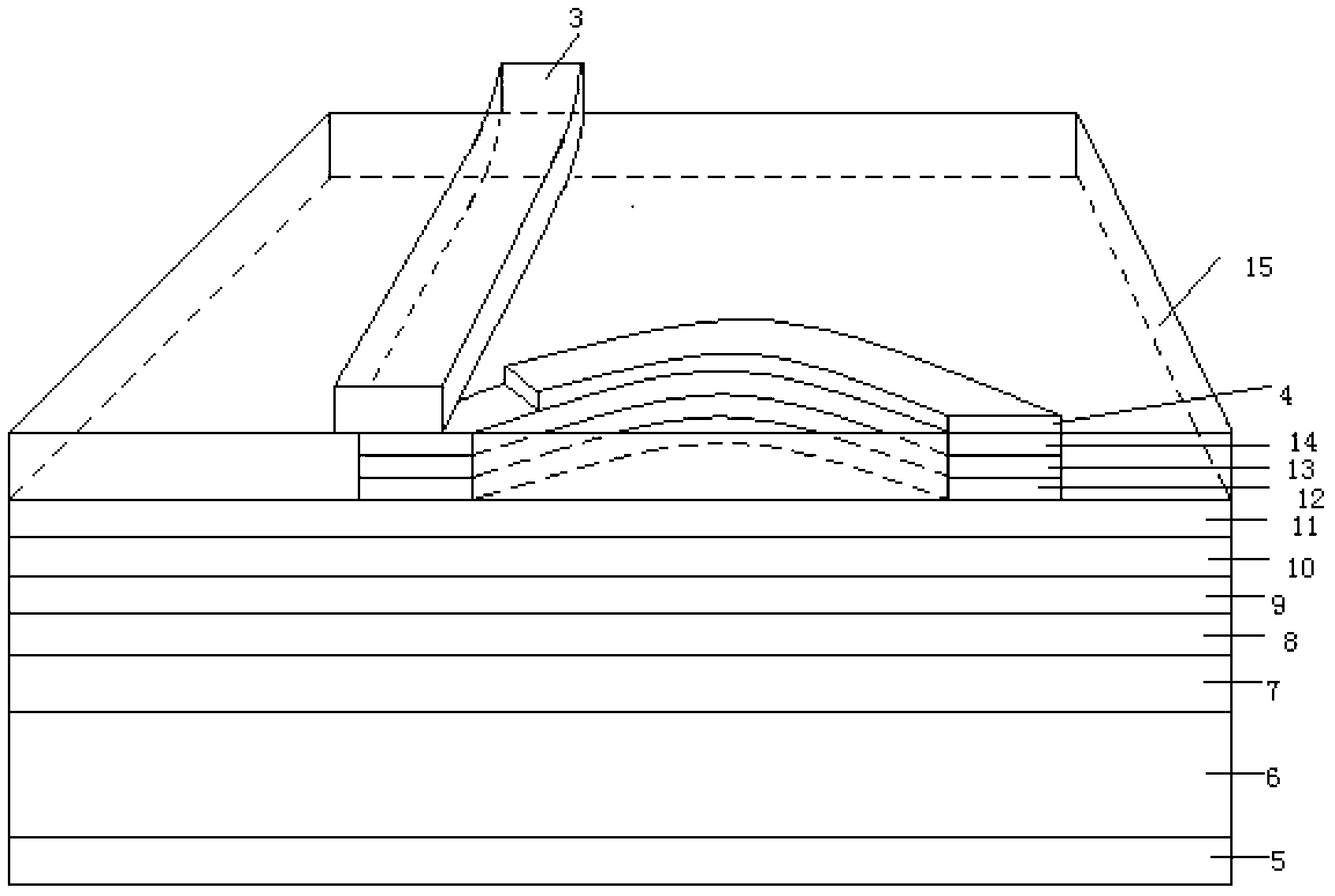

Annular semiconductor laser of vertical coupling structure and preparing method thereof

InactiveCN103259190AVersatileSimple structureOptical wave guidanceLaser detailsGas phaseRefractive index

The invention discloses an annular semiconductor laser of a vertical coupling structure and a preparing method thereof. An annular active resonator cavity is any one closed loop composed of ridge type waveguide and strip type waveguide, a P type electrode and an N type electrode are arranged on the annular active resonator cavity, laser light in the annular active resonator cavity is coupled to strip type straight waveguide through a vertical coupler, and the strip type straight waveguide outputs the laser light. An N type lower wrapping layer, a first gradual-change refractive index limiting layer, a first barrier layer, a multiple quantum well active layer, a second barrier layer, a second gradual-change refractive index limiting layer, a P type upper wrapping layer and a P type contacting layer which have preset thicknesses and concentration are successively formed by means of a metal organism chemical vapor deposition or molecular beam epitaxy method. A plurality of epitaxial layers are etched by using a SiO2 image as a mask, the etching depth is less than or equal to a first height and greater than or equal to a second height, and the annular active resonator cavity is transferred to a chip. The obtained annular semiconductor laser has the advantages of being simple in process, low in cost, stable in performance of parts, high in reliability and the like.

Owner:TIANJIN UNIV

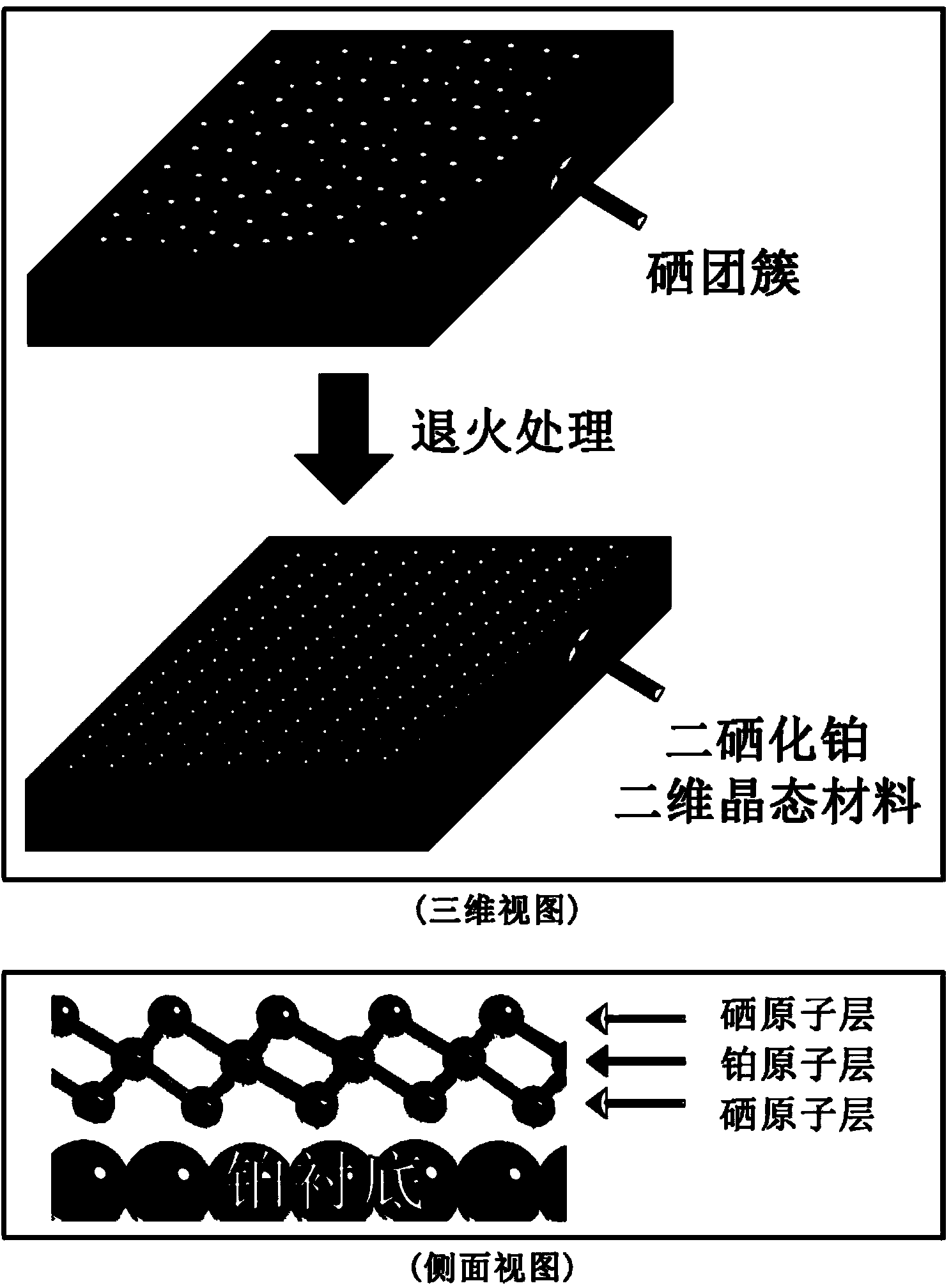

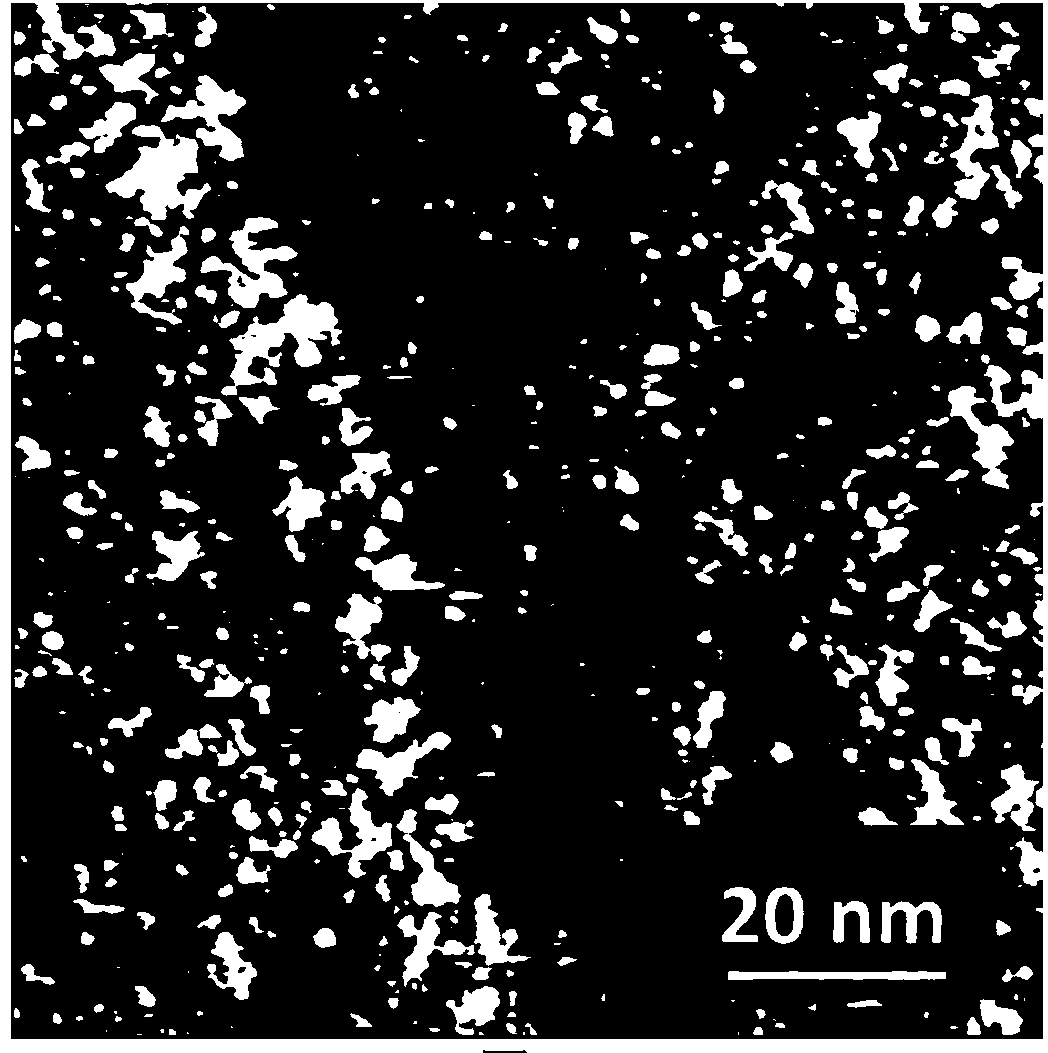

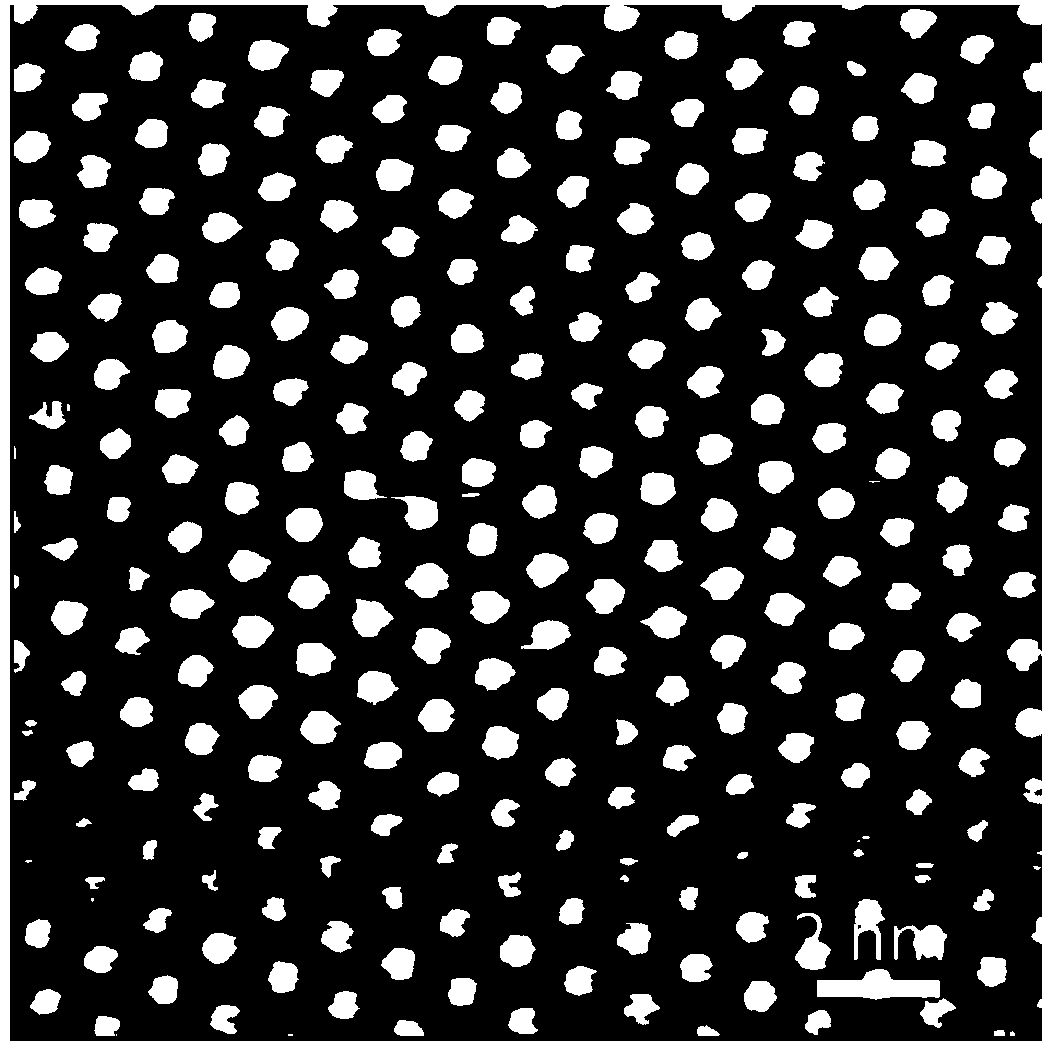

Platinum diselenide crystal material and preparation method thereof

ActiveCN104233214ABroaden the field of studyImprove electronic propertiesVacuum evaporation coatingSputtering coatingTitanium diselenideSe element

The invention discloses a platinum diselenide crystal material and a preparation method thereof. The preparation method comprises the following steps: 1) under a vacuum environment, evaporating and depositing a proper amount of high purity selenium on a metal platinum substrate; and 2) carrying out an annealing treatment, so that selenium atoms covering the surface of the substrate and platinum atoms on the substrate interact to form a two-dimensional ordered crystalline state membrane structure in a sandwich arrangement of selenium-platinum-selenium so as to obtain the platinum diselenide crystal material. The inorganic two-dimensional crystalline state material is a new member of a transitional metal disulfide compound family, expands the field of research on non-carbon based two-dimensional crystal materials, and has a wide application potential in future information electronics and apparatus development and research. According to the method disclosed by the invention, the platinum diselenide two-dimensional crystalline state material with a big area and a high quality is grown on a molecular beam epitaxial method, so that the electronic properties of the platinum diselenide crystalline state material and related applications and development are favorably researched.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

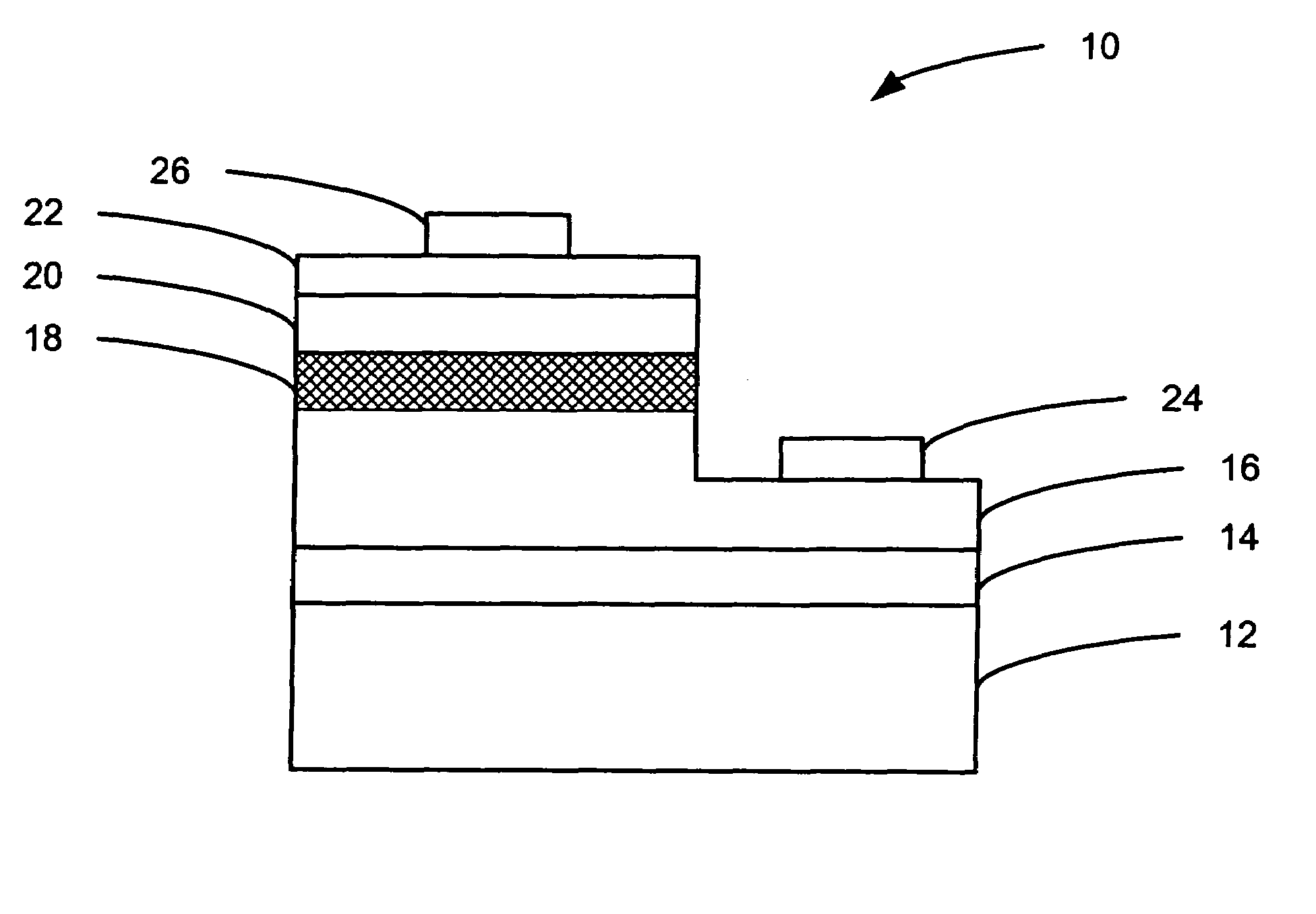

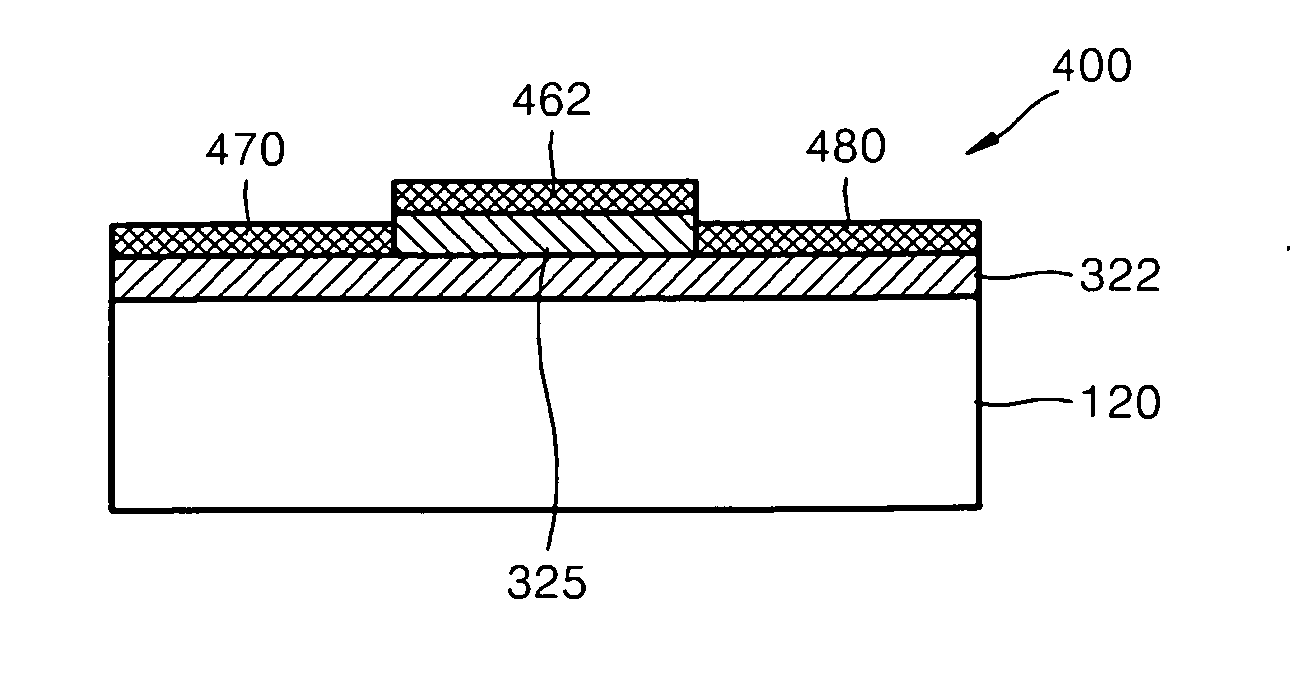

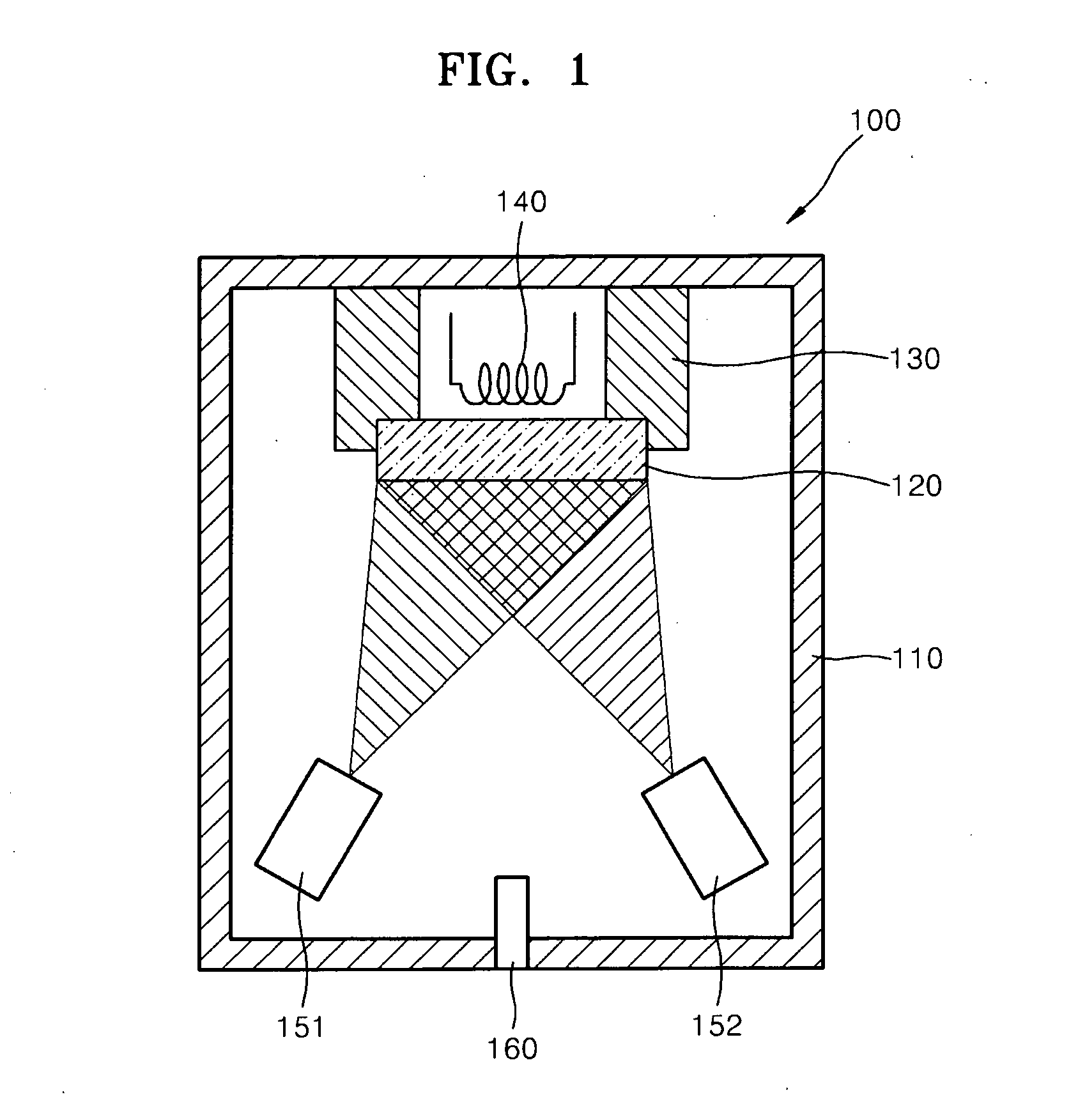

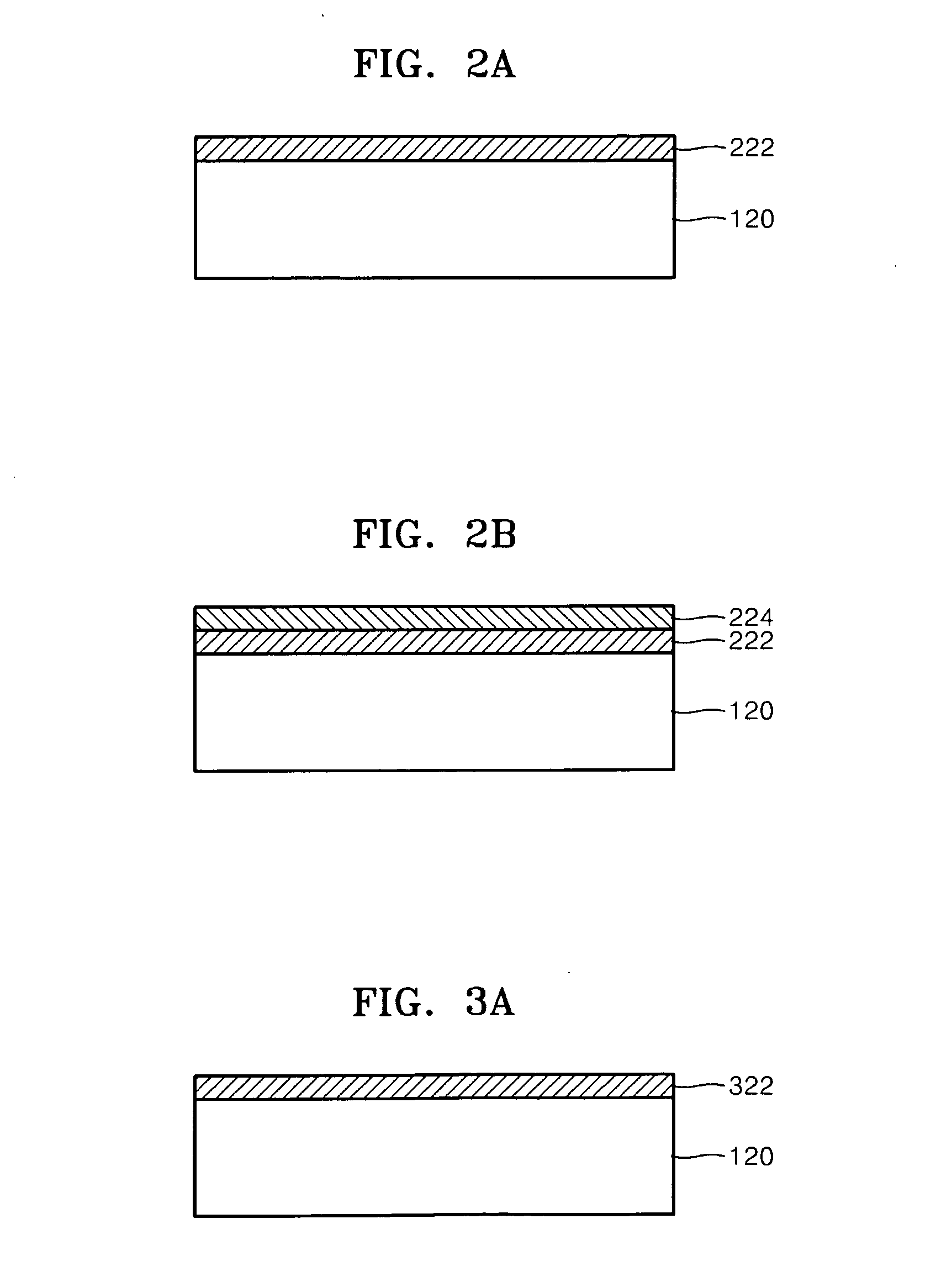

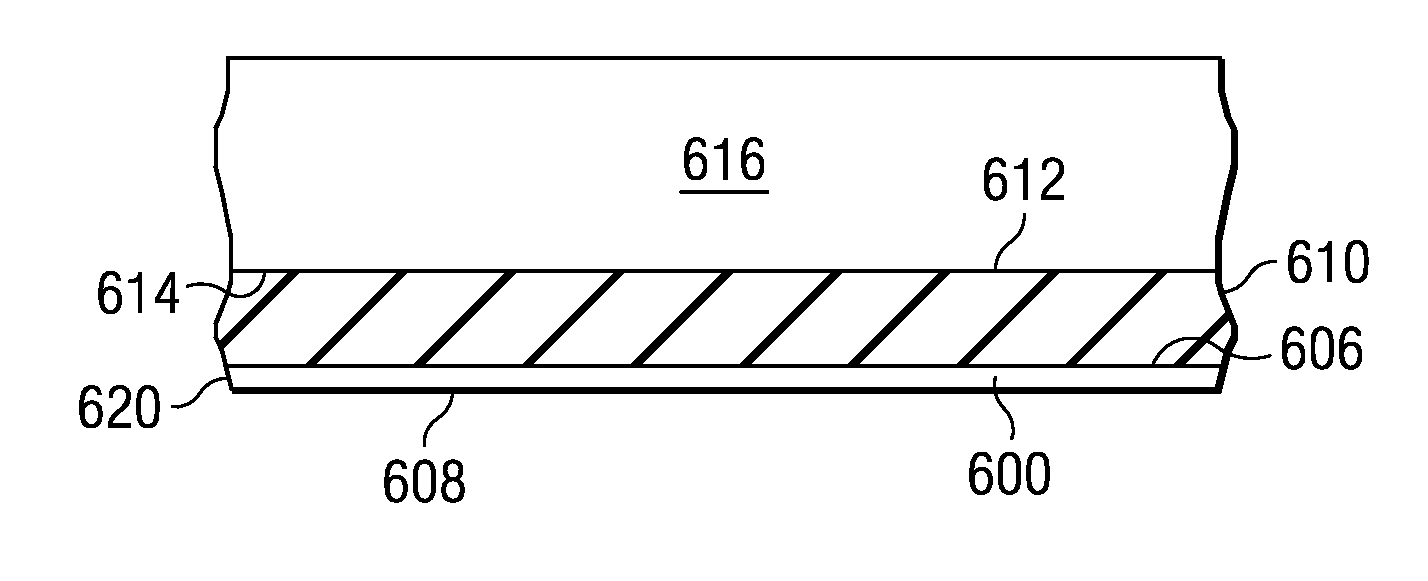

Field effect transistors, methods of fabricating a carbon-insulating layer using molecular beam epitaxy and methods of fabricating a field effect transistor

ActiveUS20110121409A1Semiconductor/solid-state device manufacturingSemiconductor devicesDiamond-like carbonField-effect transistor

Field effect transistors, methods of fabricating a carbon insulating layer using molecular beam epitaxy and methods of fabricating a field effect transistor using the same are provided, the methods of fabricating the carbon insulating layer include maintaining a substrate disposed in a molecular beam epitaxy chamber at a temperature in a range of about 300° C. to about 500° C. and maintaining the chamber in vacuum of 10−11 Torr or less prior to performing an epitaxy process, and supplying a carbon source to the chamber to form a carbon insulating layer on the substrate. The carbon insulating layer is formed of diamond-like carbon and tetrahedral amorphous carbon.

Owner:SAMSUNG ELECTRONICS CO LTD +1

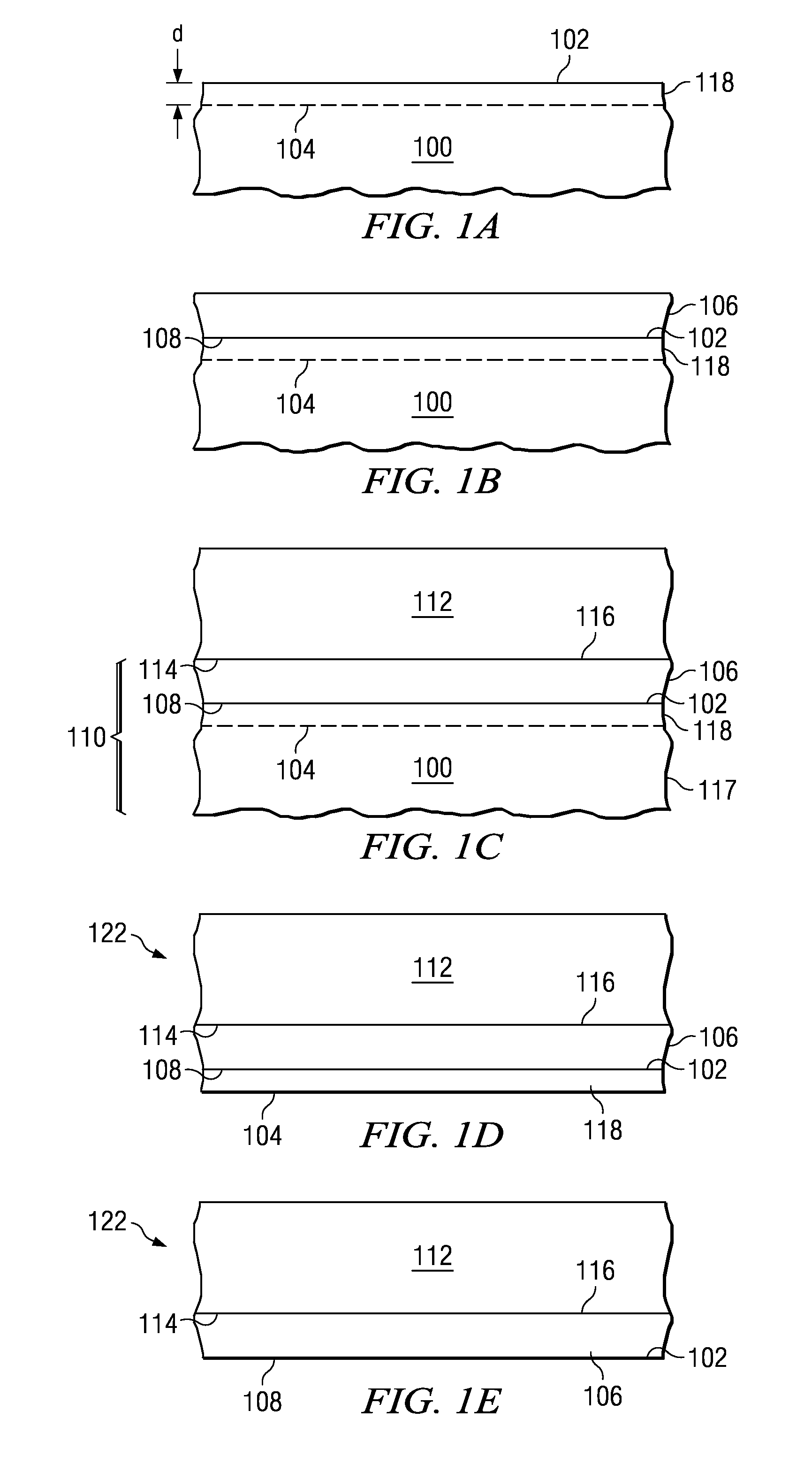

Creation of thin group ii-vi monocrystalline layers by ion cutting techniques

InactiveUS20110024876A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationHydrogenSemiconductor structure

Expungement ions, preferably including hydrogen ions, are implanted into a face of a first, preferably silicon, substrate such that there will be a maximum concentration of the expungement ions at a predetermined depth from the face. Subsequently a monocrystalline Group II-VI semiconductor layer, or two or more such layers, is / are grown on the face, as by means of molecular beam epitaxy. After this a second, preselected substrate is attached to an upper face of the Group II-VI layer(s). Next, the implanted expungement ions are used to expunge most of the first substrate from a remnant thereof, from the grown II-VI layer, and from the second substrate. In another embodiment, a group II-VI layer is grown on a first substrate silicon and an ionic implantation is conducted such that a maximum concentration of expungement ions occurs either in the silicon substrate at a predetermined depth from its interface with the II-VI layer or in the first Group II-VI semiconductor layer at a predetermined depth from the top face of the Group II-VI semiconductor layer. Thereafter all of the first substrate is expunged from the rest of the workpiece. Thin monocrystalline Group II-VI semiconductor structures may thus be mounted to substrates of the fabricator's choice; these substrates may be semiconductors, integrated circuits, MEMS structures, polymeric, metal or glass, may be flexible and may be curved.

Owner:EPIR TECH INC

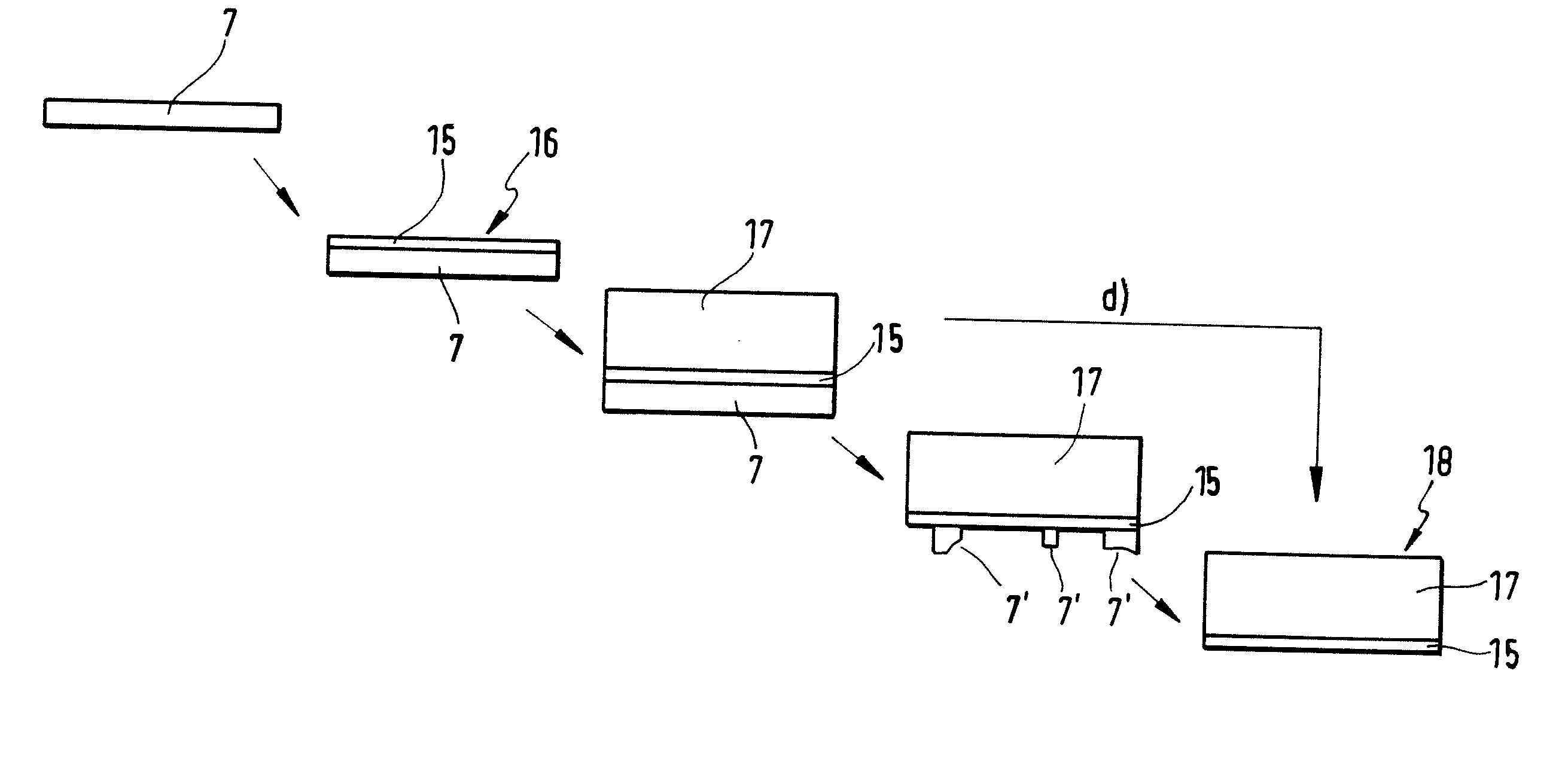

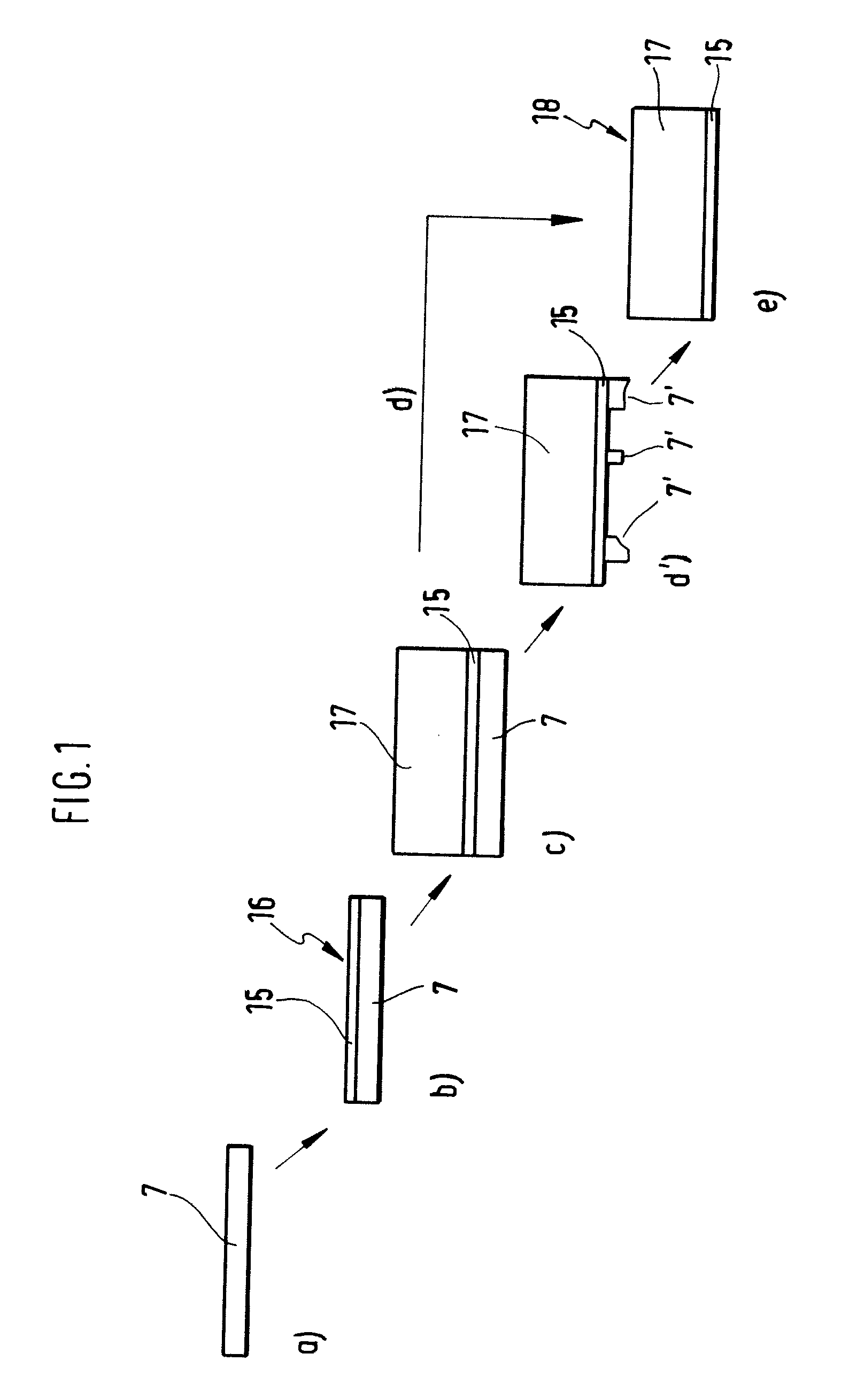

Process for producing a free-standing iii-n layer, and free-standing iii-n substrate

InactiveUS20070141814A1Polycrystalline material growthSemiconductor/solid-state device manufacturingVapor phaseAqua regia

A process for producing a free-standing III-N layer, where III denotes at least one element from group III of the periodic system, selected from Al, Ga and In, comprises depositing on a Li(Al,Ga)Ox substrate, where x is in a range between 1 and 3 inclusive, at least one first III-N layer by means of molecular beam epitaxy. A thick second III-N layer is deposited on the first III-N layer by means of a hydride vapor phase epitaxy. During cooling of the structure produced in this way, the Li(Al,Ga)Ox substrate completely or largely flakes off the III-N layers, or residues can be removed if necessary, by using etching liquid, such as aqua regia. A free-standing III-N substrate being substantially free of uncontrolled impurities and having advantageous properties is provided.

Owner:FREIBERGER COMPOUND MATERIALS

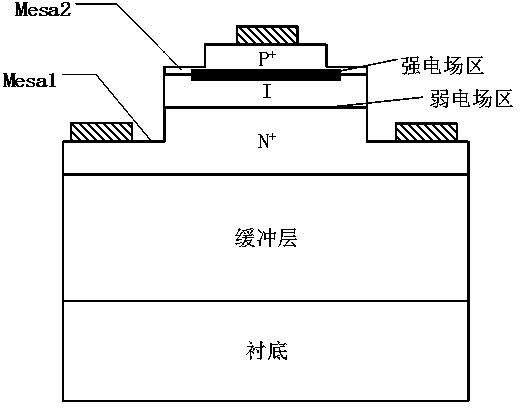

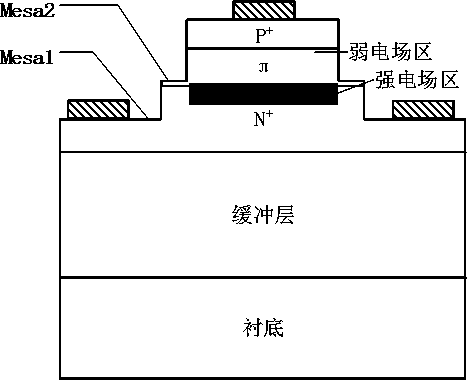

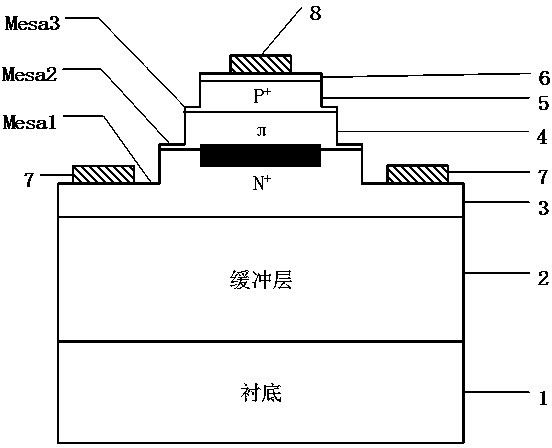

Three-mesa p-Pi-n structured III-nitride semiconductor avalanche photodetector and preparation method thereof

InactiveCN104282793AAvoid premature breakdownSolve the problem of reverse premature breakdownFinal product manufactureSemiconductor devicesPhotodetectorElectrode Contact

The invention relates to the technical field of detectors, in particular to a three-mesa p-Pi-n structured III-nitride semiconductor avalanche photodetector and a preparation method of the three-mesa p-Pi-n structured III-nitride semiconductor avalanche photodetector. The three-mesa p-Pi-n structured III-nitride semiconductor avalanche photodetector comprises a substrate, a buffer layer, an n-type doping nitride ohmic electrode contact layer, a Pi-type nitride active layer, a p-type doping nitride layer, a p-type heavy-doping nitride ohmic contact layer, n-type ohmic contact electrodes and a p-type ohmic contact electrode, wherein the buffer layer, the n-type doping nitride ohmic electrode contact layer, the Pi-type nitride active layer, the p-type doping nitride layer and the p-type heavy-doping nitride ohmic contact layer are sequentially grown on the substrate through epitaxial growth methods such as a molecular beam epitaxial method or an organometallic chemical vapor deposition epitaxial method; the n-type ohmic contact electrodes are manufactured on the n-type layer, and the p-type ohmic contact electrode is manufactured on the p-type layer. The three-mesa p-Pi-n structured III-nitride semiconductor avalanche photodetector can solve the problems that a traditional p-i-n structured device leaks a large number of currents and the edge of the traditional p-i-n structured device can be broken through easily in advance; moreover, a three-mesa structure conducts double-suppression protection on edge electric fields of a strong electric field region and a weak electric field region of a p-Pi-n structured device, so that the edge electric field is effectively prevented from being broken through in advance.

Owner:SUN YAT SEN UNIV

Hafnium nitride buffer layers for growth of GaN on silicon

InactiveUS6929867B2Improve the immunityCloser conductivityPolycrystalline material growthSemiconductor/solid-state device manufacturingCrack freeHafnium

Gallium nitride is grown by plasma-assisted molecular-beam epitaxy on (111) and (001) silicon substrates using hafnium nitride buffer layers. Wurtzite GaN epitaxial layers are obtained on both the (111) and (001) HfN / Si surfaces, with crack-free thickness up to 1.2 m. However, growth on the (001) surface results in nearly stress-free films, suggesting that much thicker crack-free layers could be obtained.

Owner:RGT UNIV OF CALIFORNIA

Nitrogen sources for molecular beam epitaxy

InactiveUS7255746B2Polycrystalline material growthSemiconductor/solid-state device manufacturingDimethylhydrazineNitrogen source

MBE nitrogen sources of dimethylhydrazine, tertiarybutlyhydrazine, nitrogentrifloride, and NHx radicals. Those nitrogen sources are beneficial in forming nitrogen-containing materials on crystalline subtrates using MBE. Semiconductor lasers in general, and VCSEL in particular, that have nitrogen-containing layers can be formed using such nitrogen sources.

Owner:II VI DELAWARE INC

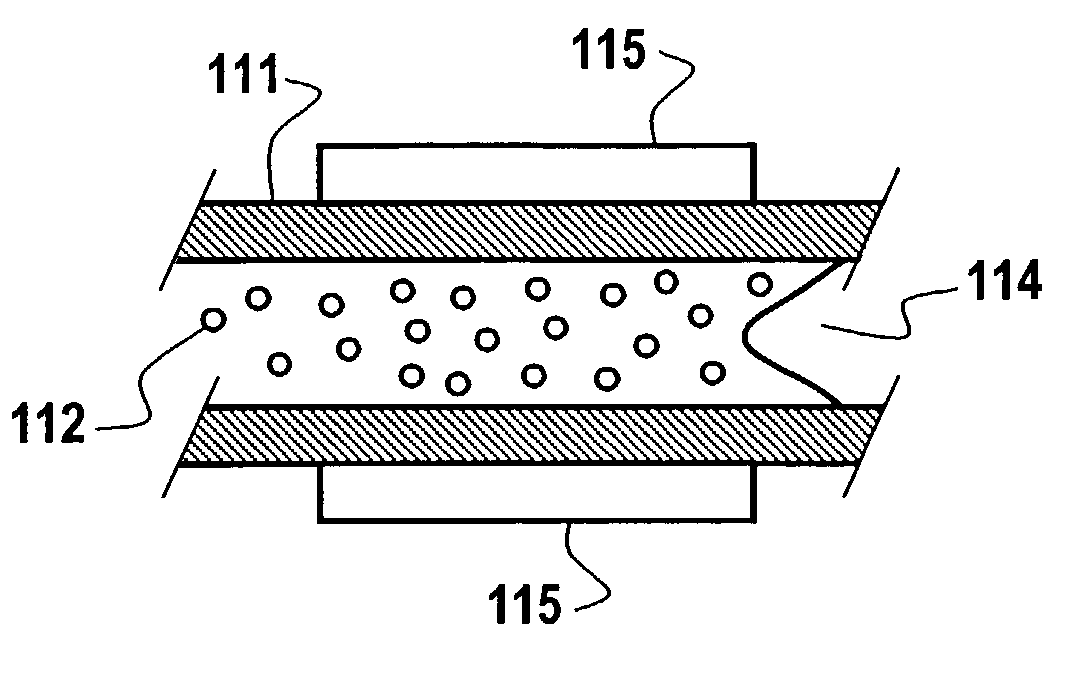

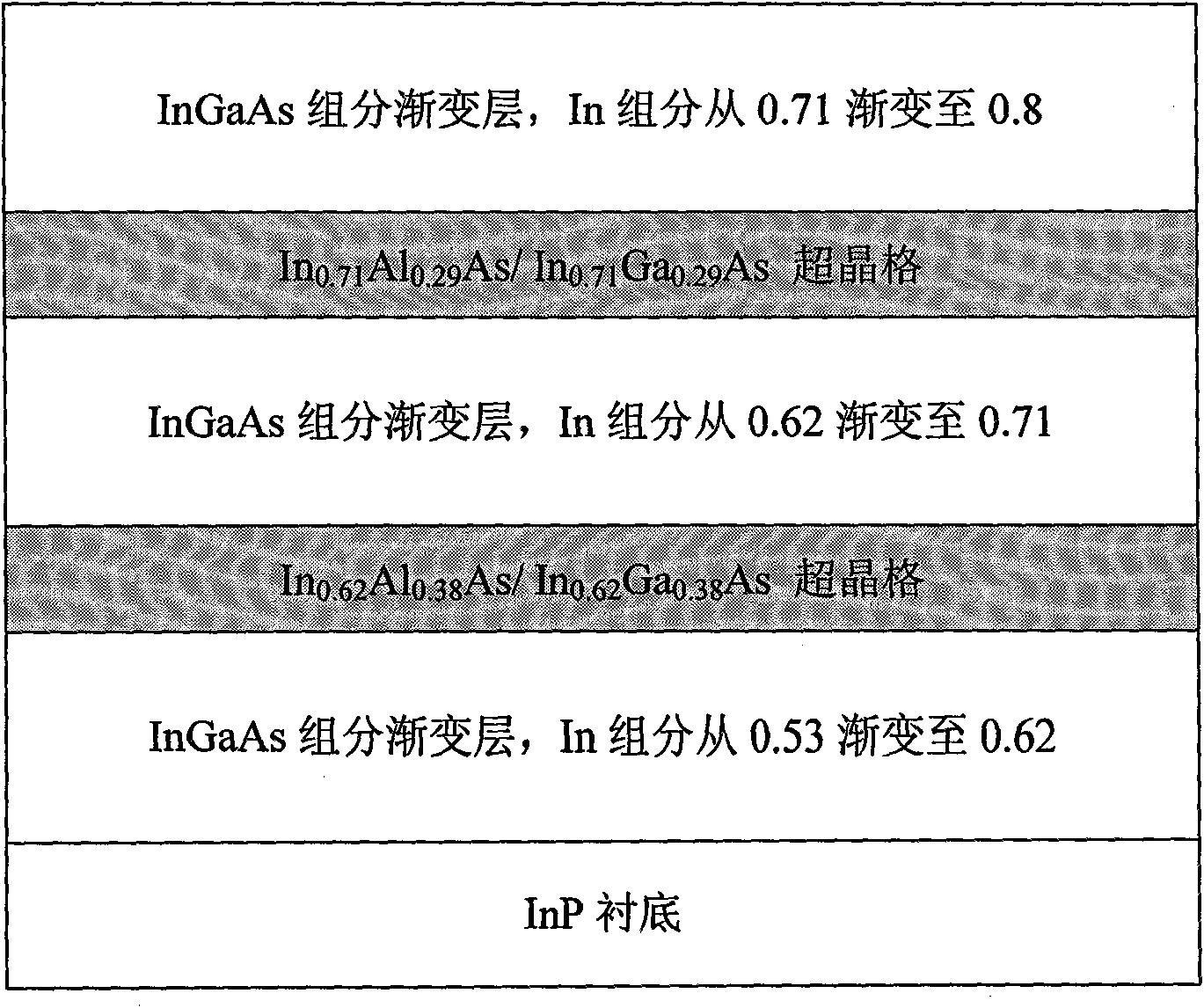

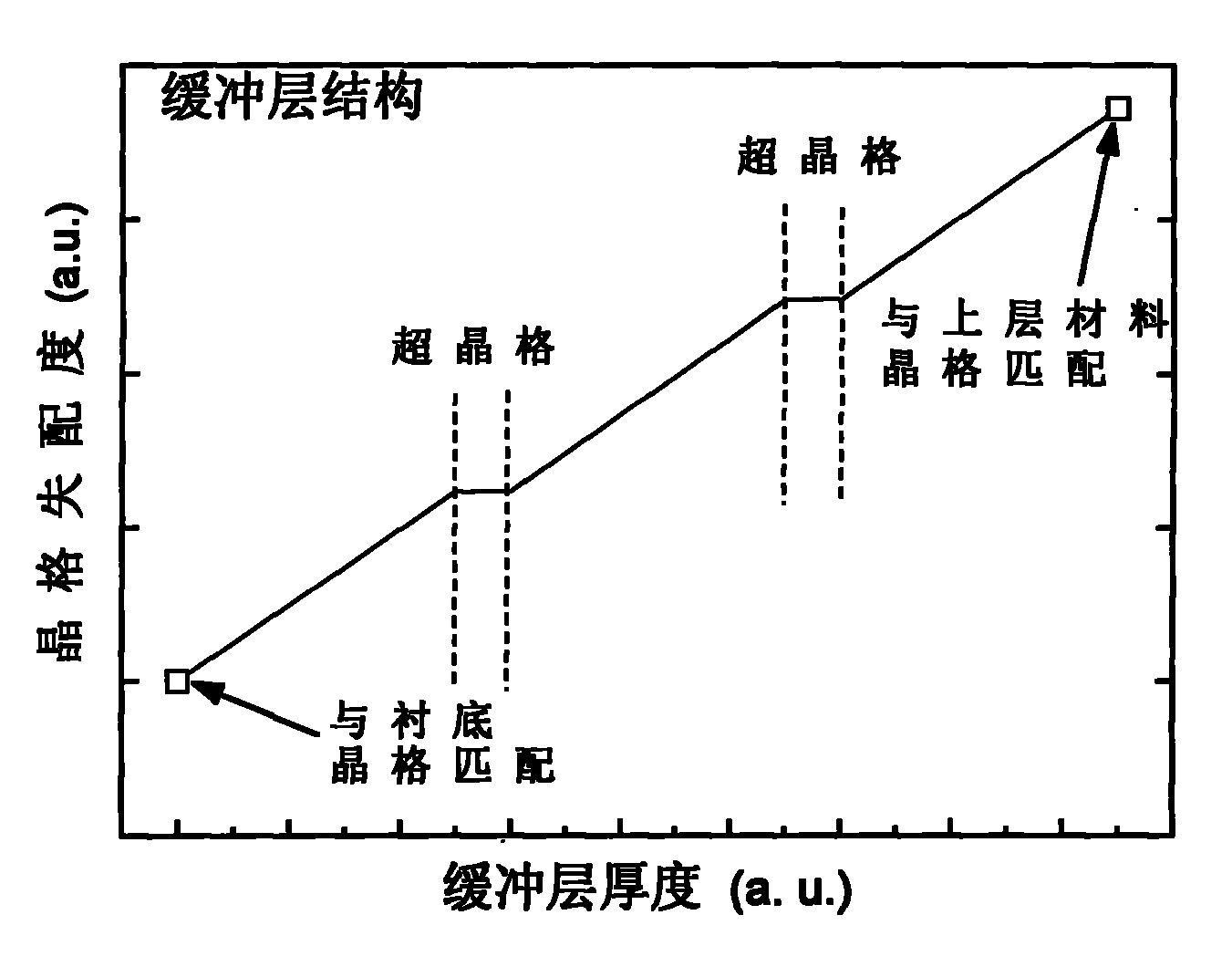

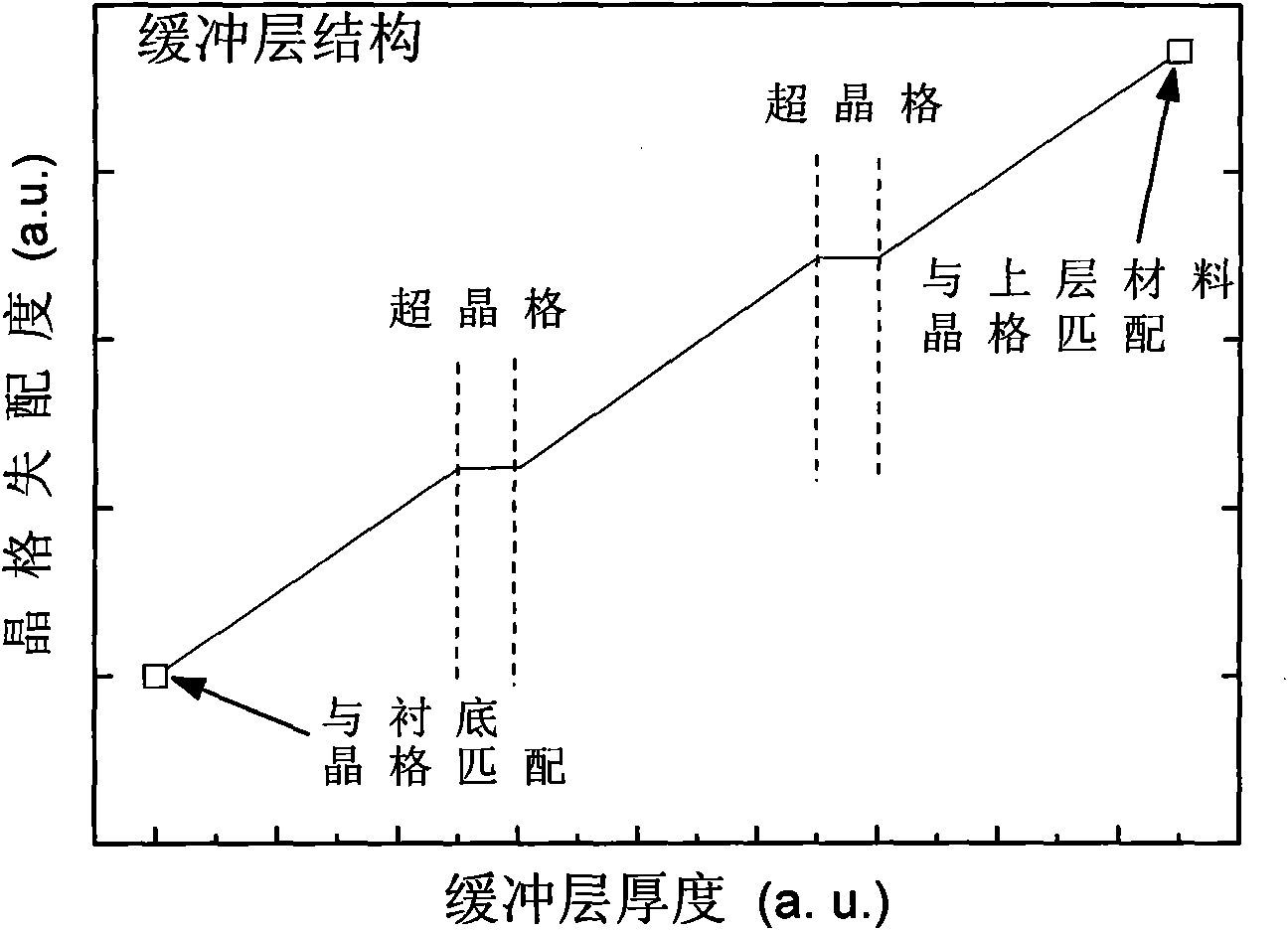

Macrolattice mismatch epitaxial material buffer layer structure containing superlattice isolated layer and preparation thereof

ActiveCN101814429AReduce thicknessIncrease rate of component changeSemiconductor/solid-state device manufacturingFurnace temperatureBeam source

The invention relates to a macrolattice mismatch epitaxial material buffer layer structure containing a superlattice isolated layer and preparation thereof. N layers of strain-free superlattice isolated layer materials are inserted in a component gradual change buffer layer, wherein n is a natural number and is not smaller than 1 and not larger than 5. The preparation process comprises the following steps of: firstly, determining the parameters of growth temperature, beam source furnace temperature and other parameters; and then sequentially and alternately growing buffer layers with gradually increased strain capacities and strain-free superlattice isolated layer materials on a substrate by adopting a molecular beam epitaxy method until finishing the growth of a buffer layer reaching an expected strain capacity. The material contains the superlattice isolated layer and can ensure that relaxation can quickly and effectively occur to a macrolattice mismatch epitaxial material to release stress in the buffer layer so as to reduce the dislocation density of the epitaxial material on the buffer layer. Moreover, the uninterrupted growth of the material is carried out by adopting a conventional molecular beam epitaxy method, thus the invention has the advantages of easy control of operations, low cost, environmental protection, and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

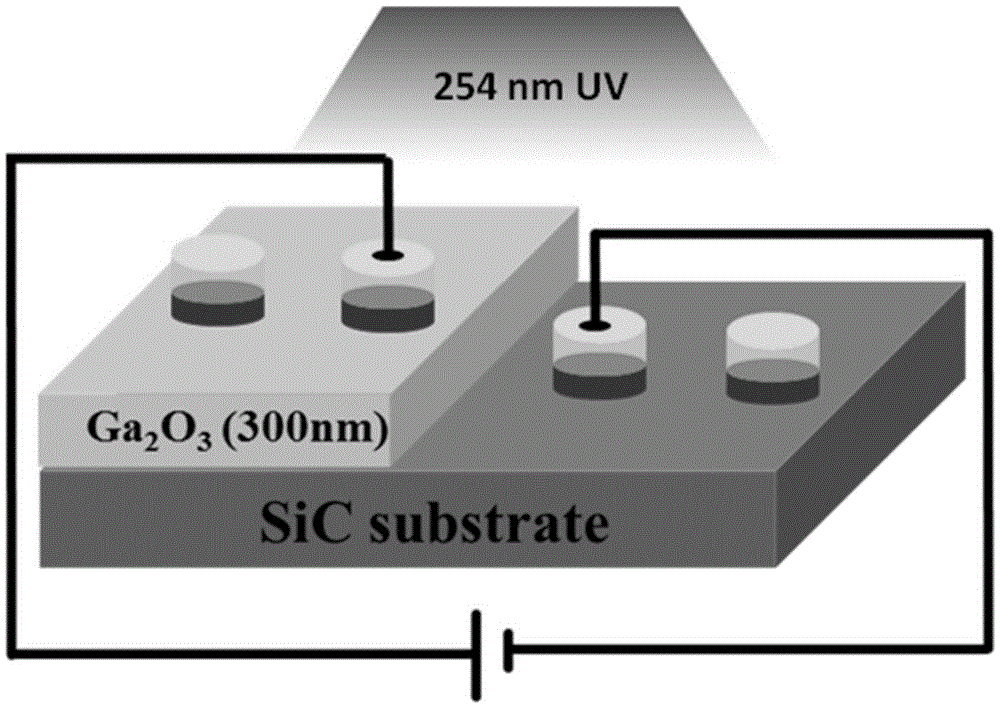

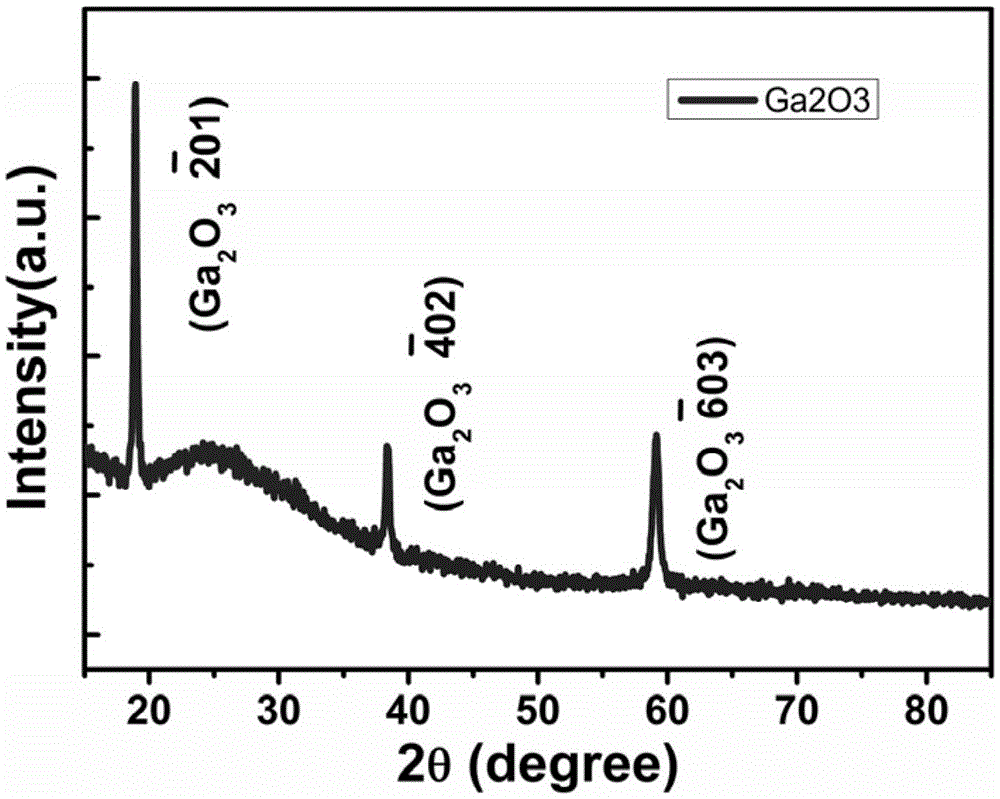

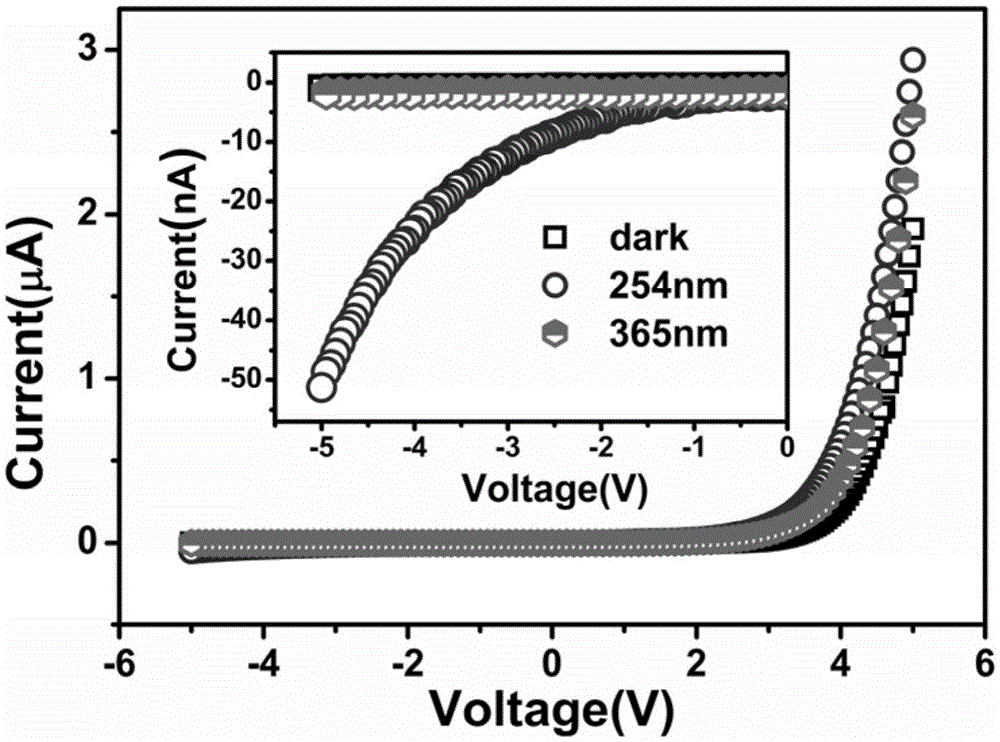

Ultraviolet detector with high spectral selectivity and high sensitivity and preparation method of ultraviolet detector

ActiveCN105679874AHighly selectiveHigh sensitivityFinal product manufactureSemiconductor devicesRadio frequency magnetron sputteringHigh pressure

The invention relates to an ultraviolet detector, in particular to an ultraviolet detector with high spectral selectivity and high sensitivity and a preparation method of the ultraviolet detector. A beta-Ga<2>O<3> film is deposited on an n-type 4H-SiC substrate through a laser molecular beam epitaxy technique; and a Ti / Au film is deposited on the n-type 4H-SiC substrate and the beta-Ga<2>O<3> film for use as an electrode by a mask through a radio-frequency magnetron sputtering technique. The ultraviolet detector has the advantages that the prepared ultraviolet detector has stable performance, has high selectivity and high sensitivity on an ultraviolet spectrum with a specific wavelength, is low in dark current, and can be applied to fire alarm, high-voltage line corona and detection of the spectrum with the specific wavelength; furthermore, the preparation method has the characteristics of being high in process controllability, simple in operation, good in universality and the like and has a great application prospect; and a repeated test has recoverability.

Owner:东港智科产业园有限公司

MIS hydrogen sensors

InactiveUS6935158B2Analysing fluids using sonic/ultrasonic/infrasonic wavesSemiconductor/solid-state device manufacturingThin metalRectifier diodes

Hydrogen gas sensors employ an epitaxial layer of the thermodynamically stable form of aluminum nitride (AlN) as the “insulator” in an MIS structure having a thin metal gate electrode suitable for catalytic dissociate of hydrogen, such as palladium, on a semiconductor substrate. The AlN is deposited by a low temperature technique known as Plasma Source Molecular Beam Epitaxy (PSMBE). When silicon (Si) is used the semiconducting substrate, the electrical behavior of the device is that of a normal nonlinear MIS capacitor. When a silicon carbide (SiC) is used, the electrical behavior of the device is that of a rectifying diode. Preferred structures are Pd / AlN / Si and Pd / AlN / SiC wherein the SiC is preferably 6H—SiC.

Owner:WAYNE STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com