Method for growing GeSn alloy on Si substrate by molecular beam epitaxy

A technology of molecular beam epitaxy and epitaxial growth, which is applied in the field of semiconductor thin film material preparation, can solve the problems of insufficient material quality, failure to reach device-level materials, and poor thermal stability of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

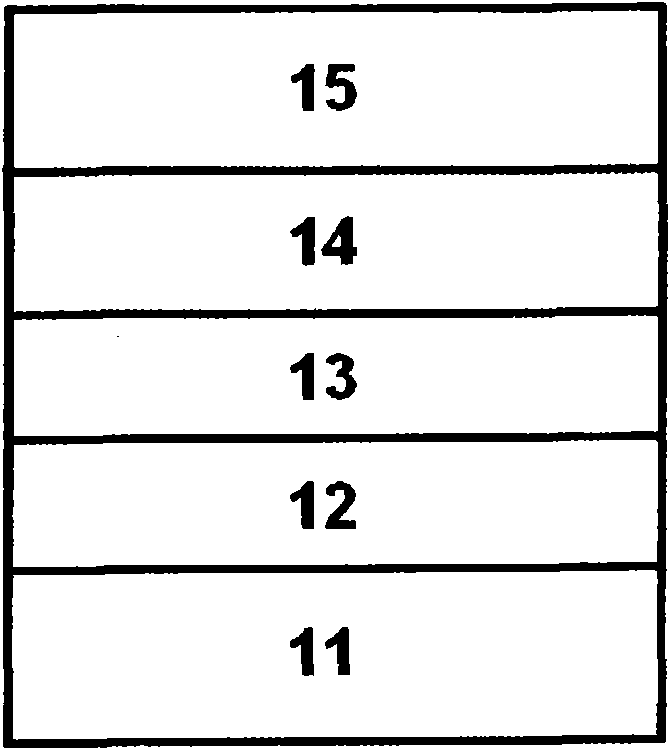

[0028] Please see attached figure 1 , which is the first embodiment of the present invention, which is a method for growing Si-based GeSn alloys by a low-temperature two-step method. It includes the following steps:

[0029] Step 1: growing a first Ge material layer 12 on the Si substrate 11, and the growth temperature of the first Ge material layer 12 is less than 400°C;

[0030] Step 2: growing a second Ge material layer 13 on the first Ge material layer 12, and the growth temperature of the second Ge material layer 13 is greater than 400°C;

[0031] The first and second Ge material layers are grown using solid Ge as the source material and grown by molecular beam epitaxy; the first and second Ge material layers are GeH 4 and Ge 2 H 6 The compound of Ge and H is used as the source material, which is grown by chemical vapor deposition method;

[0032] Step 3: growing a first GeSn alloy layer 14 on the second Ge material layer 13, the first GeSn alloy layer 14 is grown by...

no. 2 example

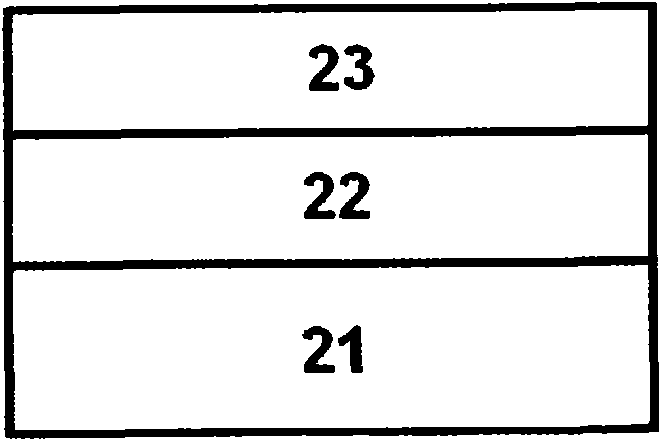

[0044] Attached below figure 2 Another implementation method of the present invention is illustrated.

[0045] see again figure 2 Shown, a kind of method of molecular beam epitaxial growth GeSn alloy of the present invention on Si substrate comprises the steps:

[0046] Step 1: On the Si substrate 21, using solid Ge material and solid Sn material as Ge source and Sn source respectively, using molecular beam epitaxy system to deposit a first GeSn alloy layer 22 with a thickness of 25nm, the growth temperature is 100°C ;

[0047] Step 2: on the first GeSn alloy layer 22, adopt solid Ge material and solid Sn material as Ge source and Sn source respectively, utilize the molecular beam epitaxy system to deposit the second GeSn alloy layer 23 with a thickness of 300nm, the growth temperature is 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com