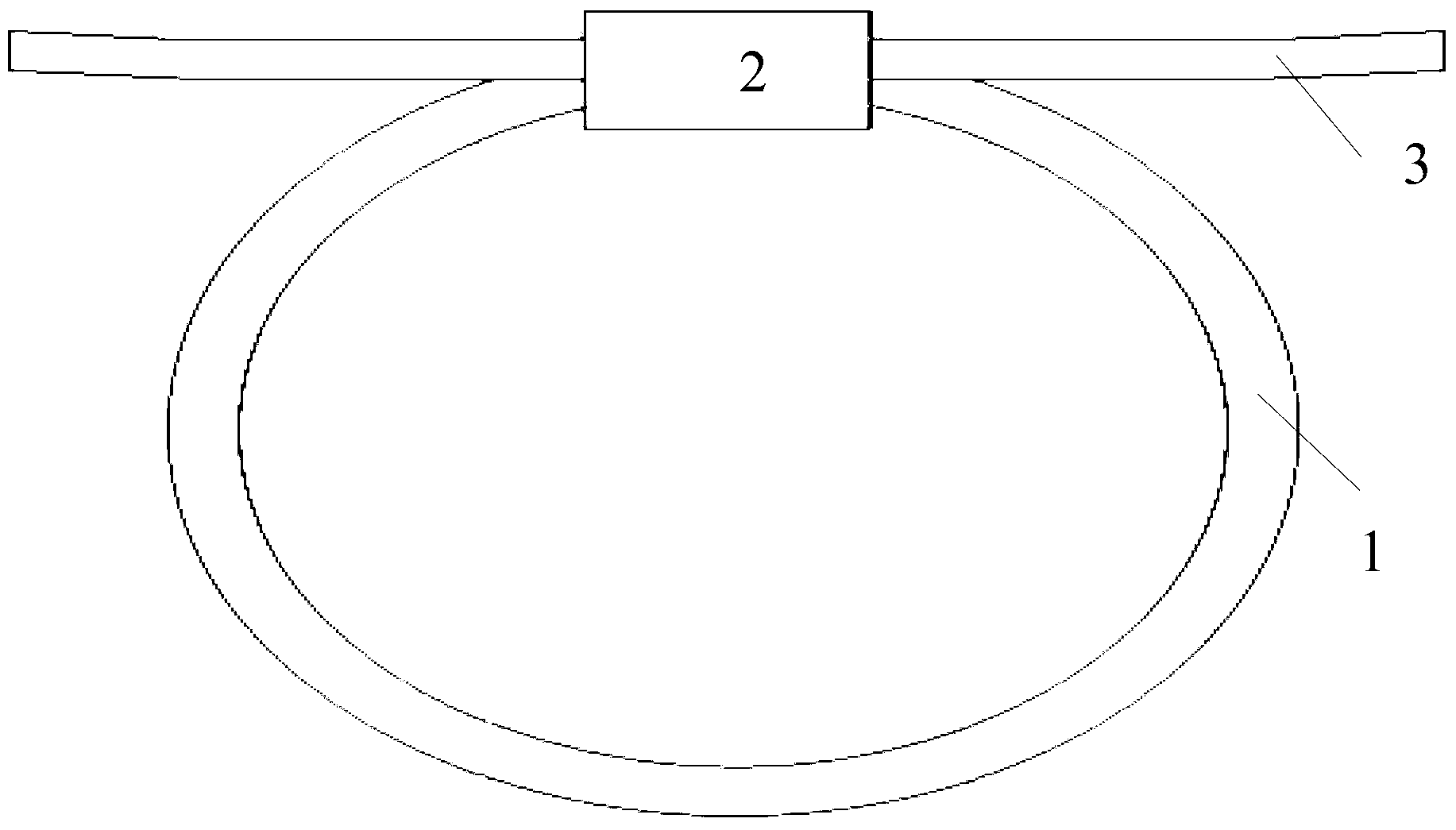

Annular semiconductor laser of vertical coupling structure and preparing method thereof

A ring laser and vertical coupling technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of increasing the difficulty and complexity of process preparation, poor reliability and stability of devices, etc., and achieve low loss, stable device performance, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

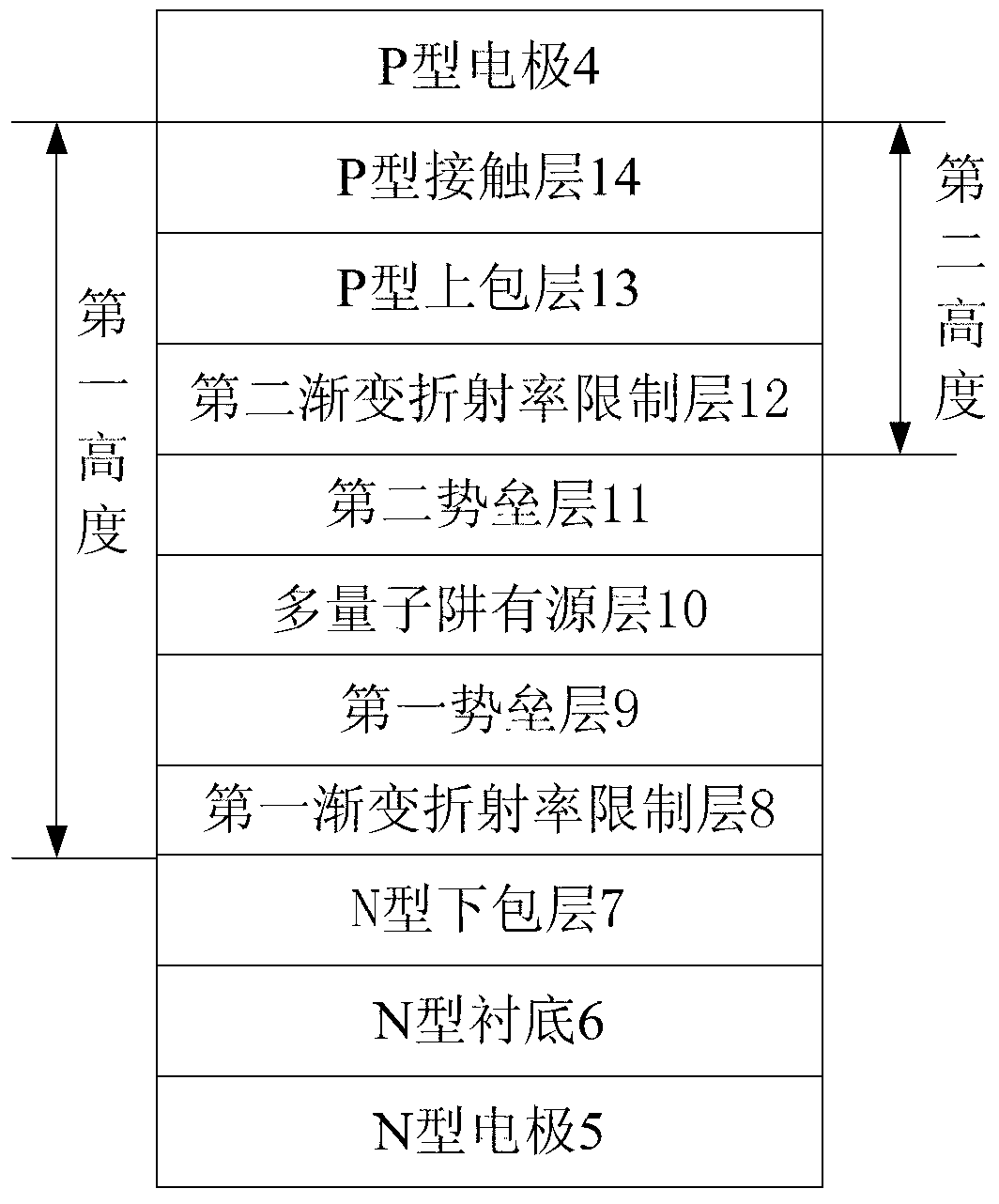

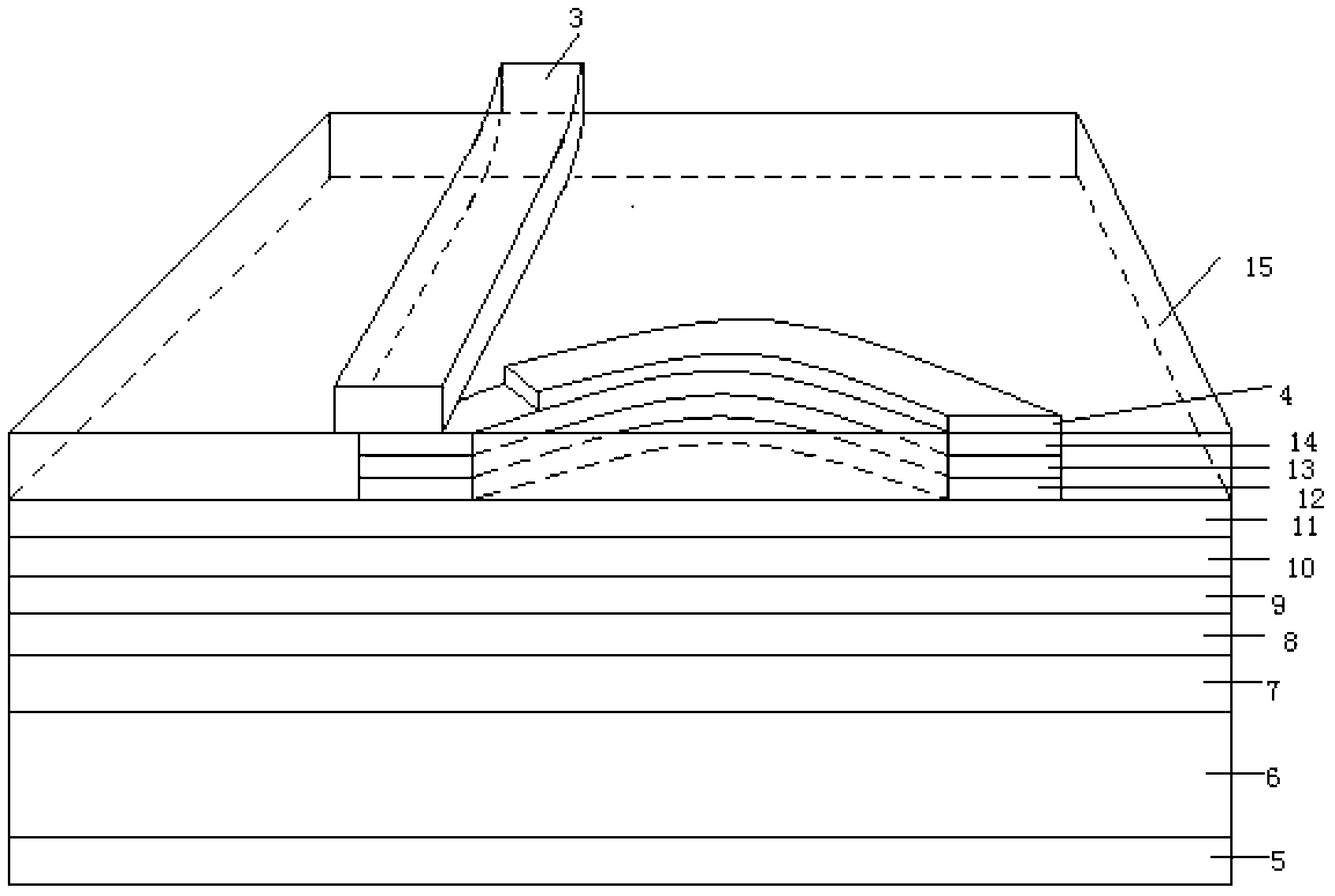

[0050] see figure 2 and image 3 , the preparation process of InP-based semiconductor ring laser is as follows:

[0051] 1. On the N-type InP substrate 6 with (100) crystal orientation, use metal-organic chemical vapor deposition or molecular beam epitaxy to grow a thickness of 1000-2000nm and a doping concentration of 1×10 18 cm -3The N-type InP lower cladding layer 7; the InP lower cladding layer 7 also serves as a buffer layer for epitaxial growth, so as to reduce the defect density of the epitaxial growth thin layer thereon.

[0052] 2. Sequentially grow the first graded-index confinement layer 8, the first barrier layer 9, the AlGaInAs multi-quantum well active layer 10, the second barrier layer 11, and the second graded-refraction confinement layer 12 of AlGaInAs quaternary system material ;

[0053] Wherein, the thickness of the first graded index confining layer 8 is 50 nm, and the doping concentration is 1×10 18 cm -3 The thickness of the first barrier layer 9 ...

Embodiment 2

[0070] see figure 2 and image 3 , the fabrication process of GaAs-based semiconductor ring laser is as follows:

[0071] 1. On an N-type GaAs substrate 6 with a (100) crystal orientation, grow it with a thickness of 1000-2000 nm and a doping concentration of 1×10 by metal-organic chemical vapor deposition or molecular beam epitaxy. 18 cm -3 The N-type AlGaAs lower cladding layer 7; the AlGaAs lower cladding layer 7 also serves as a buffer layer for epitaxial growth, so as to reduce the defect density of the epitaxial growth thin layer thereon.

[0072] 2. Sequentially grow the first graded index confinement layer 8, the first barrier layer 9, the AlGaAs multi-quantum well active layer 10, the second barrier layer 11 and the second graded index confinement layer 12 of AlGaAs ternary system material ;

[0073] Wherein, the thickness of the first graded index confining layer 8 is 50 nm, and the doping concentration is 1×10 18 cm -3 The thickness of the first barrier layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com