One-phase ferroelectric film and preparing method thereof as well as effective resistance regulation mode

A ferroelectric thin film, effective resistance technology, applied in the field of microelectronic materials, can solve the problems of not considering effective resistance modulation, and introduce ferroelectric properties and semiconductor properties at the same time, achieve short polarization time, improve anti-fatigue performance, extremely Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

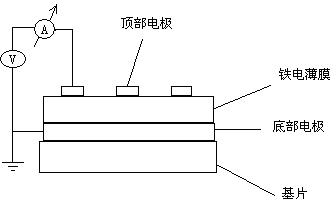

[0031] On Pt / TiO 2 / Ti / SiO 2 / Si substrates grow BiFeO 3 (200 nm) and Bi 0.85 Nd 0.15 FeO 3 (200 nm) thin film, as attached figure 1 shown.

[0032] (1) The epitaxial ferroelectric film was grown by magnetron sputtering method, and Pt was used as the top and bottom electrodes, and the Pt / TiO 2 / Ti / SiO 2 / Si substrates grow BiFeO 3 (200 nm) and Bi 0.85 Nd 0.15 FeO 3 (200 nm) films, followed by BiFeO 3 and Bi 0.85 Nd 0.15 FeO 3 The Pt top electrode is grown on the thin film.

[0033] (2) The specific growth conditions are: control Pt / TiO 2 / Ti / SiO 2 / Si substrate temperature is 400°C, in O 2 The pressure in the atmosphere is 1Pa, the sputtering power is 500W, and annealing is performed at 400°C for 30 minutes after the deposition is completed.

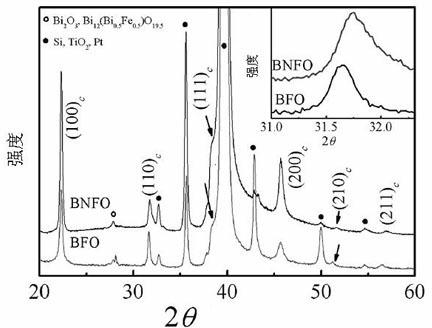

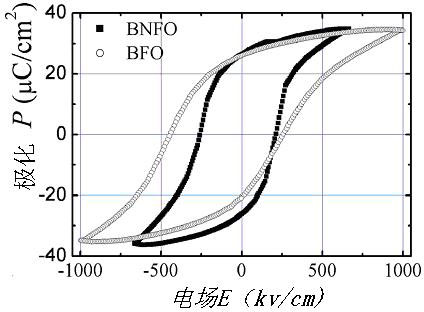

[0034] (3) Using XRD diffraction and ferroelectric tester to test the prepared BiFeO 3 (200nm) / Pt / TiO 2 / Ti / SiO 2 / Si film and Bi 0.85 Nd 0.15 FeO 3 (200nm) / Pt / TiO 2 / Ti / SiO 2 / Si thin film was analyzed, and th...

Embodiment 2

[0039] By Bi 0.8 Ca 0.1 FeO 3-d (100 nm) / SrRuO 3 (50 nm) / (001) c SrTiO 3 Thin film as an example:

[0040] (1) Preparation of Bi 0.8 Ca 0.1 FeO 3-d and SrRuO 3 target, where SrRuO 3 (50 nm) as top and bottom electrodes (100) c SrTiO 3 as a substrate.

[0041] (2) The film was prepared by pulsed laser deposition method, using (001) c SrTiO 3 As a substrate, SrRuO 3 (50 nm) as the top and bottom electrodes, grow epitaxial ferroelectric films, first at (100) c SrTiO 3 SrRuO grown on substrate 3 (50 nm) bottom electrode thickness, followed by SrRuO 3 (50 nm) / (100) c SrTiO 3 Growth Bi 0.8 Ca 0.1 FeO 3-d The film thickness is 100 nm, and finally again in Bi 0.8 Ca 0.1 FeO 3-d Growth of SrRuO on Thin Films 3(50 nm) as the top electrode.

[0042] (3) Specific growth method: install the substrate and the target in the growth chamber, and then use a mechanical pump and a molecular pump to evacuate it. Before deposition, the substrate temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com