A room temperature paraelectric-ferroelectric tunable ceramic material and its preparation method

A ceramic material and paraelectric technology, applied in the field of room temperature paraelectric-ferroelectric tunable ceramic materials and their preparation, can solve the problems of quantum fluctuation effect hindering the formation of ferroelectric order, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

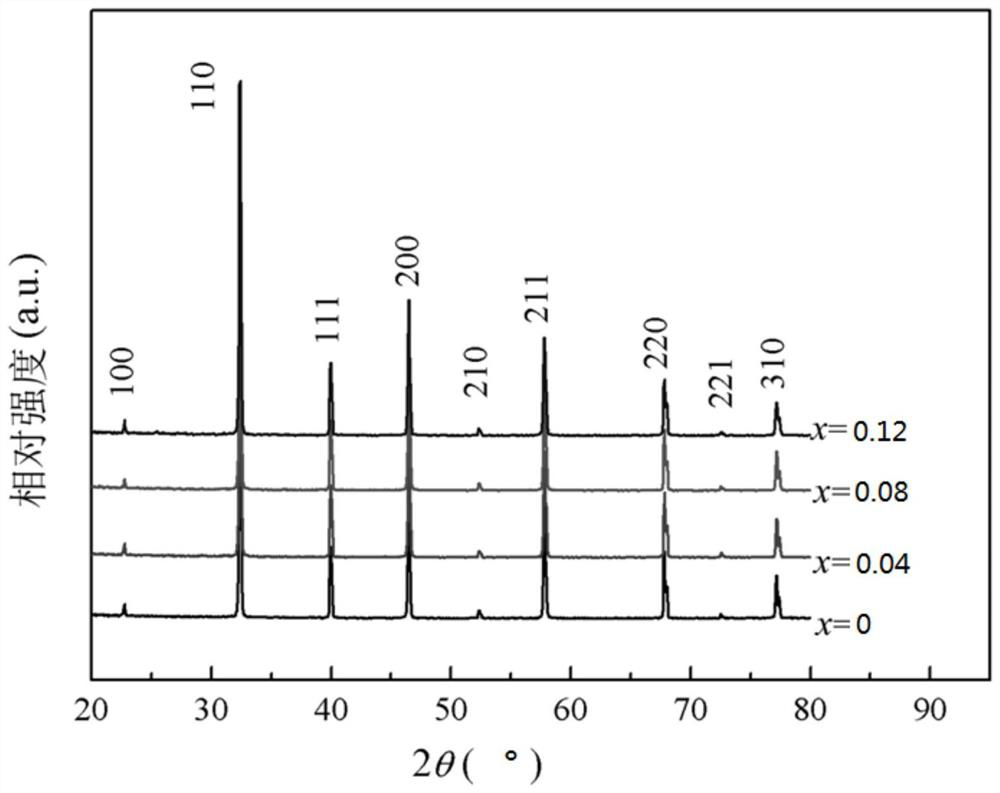

[0033] Specific Embodiment 1: In this embodiment, a room temperature paraelectric-ferroelectric adjustable ceramic material is strontium titanate ceramic material with a chemical formula of (1-x)SrTiO 3 -xLiAlSiO 4 , where 0﹤x≤0.15.

specific Embodiment approach 2

[0034] Specific embodiment two: In this embodiment, a method for preparing a room temperature paraelectric-ferroelectric adjustable ceramic material is carried out in the following steps:

[0035] One, according to the molar ratio of strontium titanate and eucryptite powder is (1-x): x, wherein 0﹤x≤0.15, weigh strontium titanate powder and eucryptite powder;

[0036] 2. Put the strontium titanate and eucryptite powder weighed in step 1 into a ball mill for mixing to obtain a slurry;

[0037] 3. Dry the slurry obtained in step 2 to obtain a mixed powder;

[0038] 4. Sieve the mixed powder obtained in step 3 to obtain a prefabricated powder;

[0039] 5. Add polyvinyl alcohol to the prefabricated powder prepared in step 4 to granulate to obtain mixed granules;

[0040] 6. Control the pressure of the mixture particles obtained in step 5 to 8-15 MPa, and press to obtain discs;

[0041] 7. Put the wafer obtained in step 6 into the sintering furnace, raise the temperature to 500-600...

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment two is: when mixing materials in step two, use absolute ethanol and zirconia grinding balls as the ball milling medium, control the mass ratio of the ball to material to be 5: 1, and the rotating speed is 300r / min, ball milling time is 8~12h. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com