High-energy-storage-performance ceramic/polymer dielectric composite material and preparation method thereof

A technology of composite materials and polymers, applied in the field of high energy storage performance ceramic/polymer dielectric composite materials and their preparation, can solve problems such as limiting energy storage density, reducing material breakdown field strength, increasing agglomeration and generating holes , to achieve the effects of improving breakdown strength, slowing down dielectric constant mismatch, improving energy storage density and energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

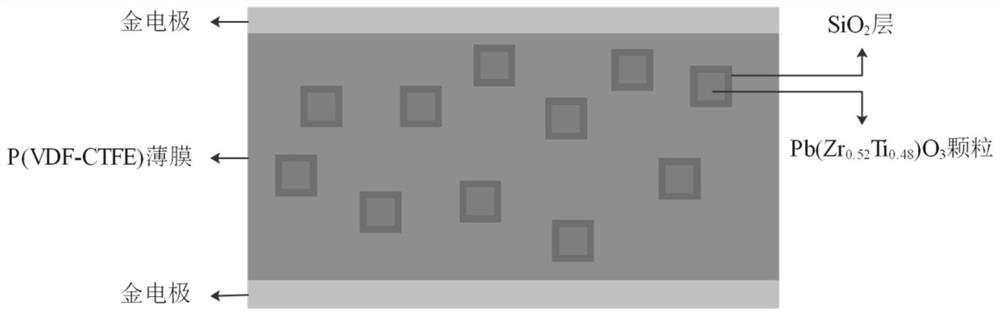

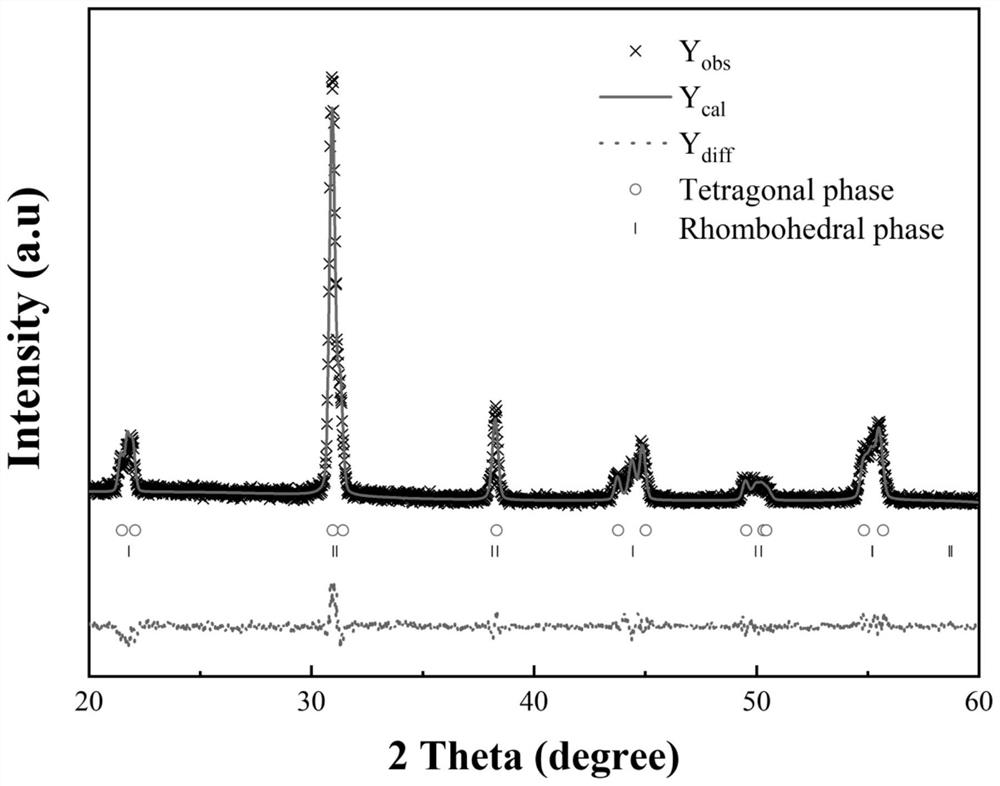

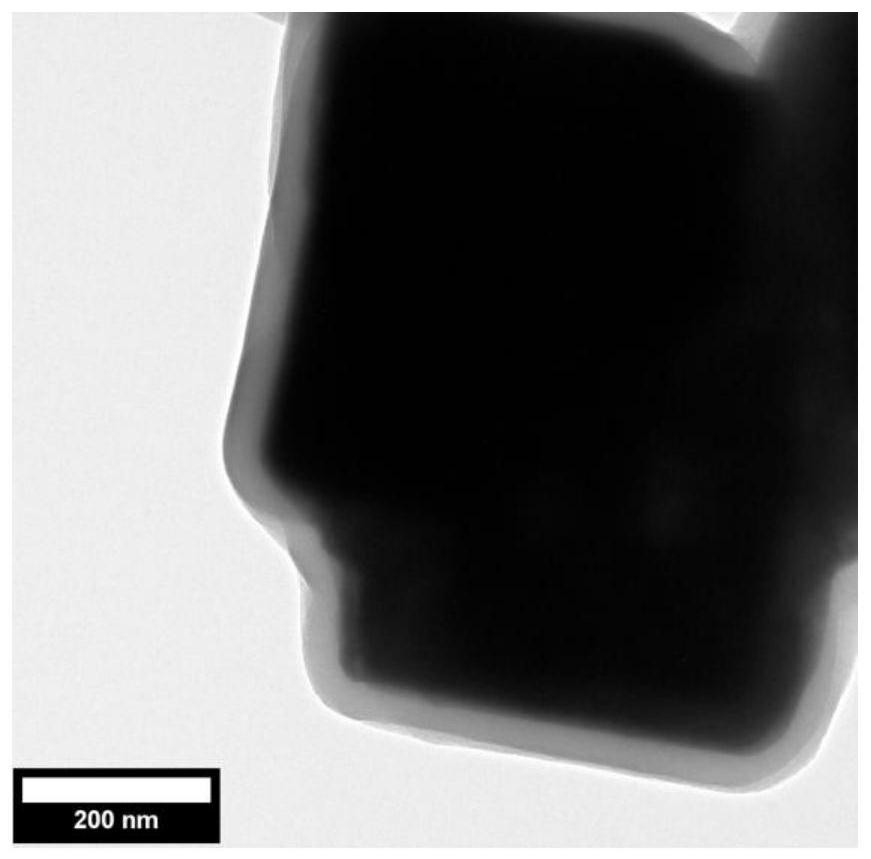

[0047] Preparation of Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 P(VDF-CTFE) / Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 Composite polymer film, the steps are as follows:

[0048](1) Dissolve 0.5g of P(VDF-CTFE) in 4g of N,N dimethylformamide and stir for 5 hours to make solution A for later use.

[0049] (2) Prepare 180mL of 0.08mol / l Ti(C 4 h 9 O) 4 Ethanol solution, ultrasonic dispersion for 10 minutes; prepare 156mL of 0.1mol / l ZrOCl 2 ·8H 2 O solution, magnetic stirring for 5 minutes, ultrasonic dispersion for 5 minutes. ZrOCl will be formulated 2 ·8H 2 O solution was slowly added to Ti(C 4 h 9 O) 4 Ethanol solution, mixed, magnetically stirred for 10 minutes, ultrasonically dispersed for 10 minutes, and ammonia water was added to adjust the pH of the solution to pH=9, magnetically stirred for 30 minutes, ultrasonically dispersed for 10 minutes, until no white precipitate was produced. Transfer the precipitate after centrifugation to a reaction kettle, add 200mL of deionized wat...

Embodiment 2

[0055] Preparation of Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 P(VDF-CTFE) / Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 Composite polymer film, the steps are as follows:

[0056] (1) Dissolve 0.5g of P(VDF-CTFE) in 4g of N,N dimethylformamide and stir for 5 hours to make solution A for later use.

[0057] (2) Prepare 180mL of 0.08mol / l Ti(C 4 h 9 O) 4 Ethanol solution, ultrasonic dispersion for 10 minutes; prepare 156mL of 0.1mol / l ZrOCl 2 ·8H 2 O solution, magnetic stirring for 5 minutes, ultrasonic dispersion for 5 minutes. ZrOCl will be formulated 2 ·8H 2 O solution was slowly added to Ti(C 4 h 9 O) 4 Ethanol solution, mixed, magnetically stirred for 10 minutes, ultrasonically dispersed for 10 minutes, and ammonia water was added to adjust the pH of the solution to pH=9, magnetically stirred for 30 minutes, ultrasonically dispersed for 10 minutes, until no white precipitate was produced. Transfer the precipitate after centrifugation to a reaction kettle, add 200mL of deionized wa...

Embodiment 3

[0063] Preparation of Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 P(VDF-CTFE) / Pb(Zr 0.52 Ti 0.48 )O 3 @SiO 2 Composite polymer film, the steps are as follows:

[0064] (1) Dissolve 0.5g of P(VDF-CTFE) in 4g of N,N dimethylformamide and stir for 5 hours to make solution A for later use.

[0065] (2) Prepare 180mL of 0.08mol / l Ti(C 4 h 9 O) 4 Ethanol solution, ultrasonic dispersion for 10 minutes; prepare 156mL of 0.1mol / l ZrOCl 2 ·8H 2 O solution, magnetic stirring for 5 minutes, ultrasonic dispersion for 5 minutes. ZrOCl will be formulated 2 ·8H 2 O solution was slowly added to Ti(C 4 h 9 O) 4 Ethanol solution, mixed, magnetically stirred for 10 minutes, ultrasonically dispersed for 10 minutes, and ammonia water was added to adjust the pH of the solution to pH=9, magnetically stirred for 30 minutes, ultrasonically dispersed for 10 minutes, until no white precipitate was produced. Transfer the precipitate after centrifugation to a reaction kettle, add 200mL of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com