Method for obtaining CsPbBr3 ferroelectric single crystal film through tensile strain induction

A single crystal thin film, tensile strain technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of complex stress application methods, cumbersome preparation process, and inability to meet the use requirements, and achieve cost Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

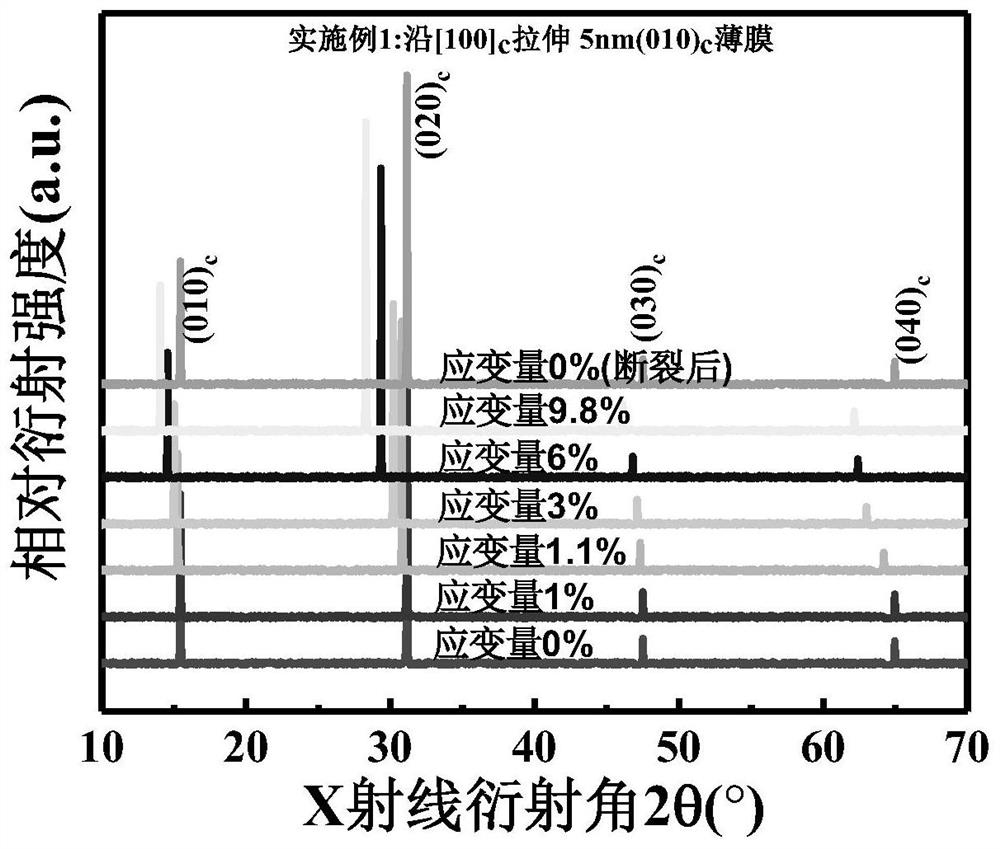

Embodiment 1

[0042] A CsPbBr induced by tensile strain 3 The method for ferroelectric single crystal thin film, the operation link of described method is as follows:

[0043] Link 1, CsPbBr 3 Single crystal preparation

[0044] (1) CsBr and PbBr with a molar ratio of 1:1 2 The mixture was dissolved in dimethylformamide (DMF) to form a supersaturated solution with a concentration of 1.5 mol / L, which was fully stirred at 70°C.

[0045] (2) Heat the supersaturated solution to 150° C., filter out the suspended insoluble matter, and then gradually cool the solution to 70° C. and keep it for 10 hours to grow seed crystals.

[0046] (3) Prepare a new supersaturated solution according to step (1), put the seed crystal obtained in step (2) into it to obtain a larger seed crystal, repeat three times and then put the seed crystal into anti-solvent toluene to keep room temperature High quality CsPbBr of desired size can be obtained in 7 days 3 For a single crystal, the side length of the single c...

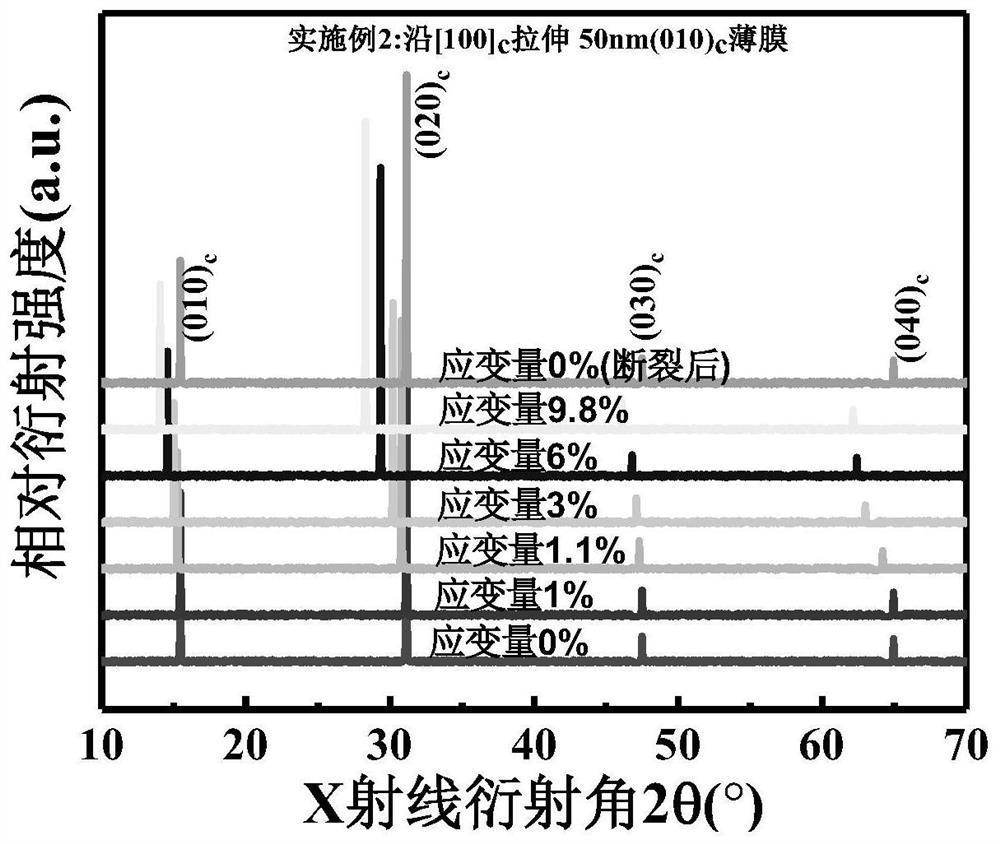

Embodiment 2

[0066] This embodiment prepares CsPbBr in the same manner as in Example 1 3 Single crystal thin film is also stretched and tested in the same manner as in Example 1, the difference being that:

[0067] In link 2 step (5), preferably, after the second thinning treatment, CsPbBr 3 The thickness of the single crystal thin film was 50 nm.

[0068] In link 4 step (1), when the strain amount is 1.1%, its saturated ferroelectric polarization is 0.10μC / cm 2 ; When the strain amount is 3%, its saturated ferroelectric polarization is 0.18μC / cm 2 ; When the strain is 6%, its saturated ferroelectric polarization is 0.27μC / cm 2 ; When the strain amount is 9.8%, its saturated ferroelectric polarization is 0.42μC / cm 2 . Test obtains this embodiment CsPbBr 3 The XRD patterns of the single crystal film before and after stretching and during stretching are as follows: image 3 As shown, the data of the lattice constant and its crystal system, point group, saturated ferroelectric polariza...

Embodiment 3

[0070] A CsPbBr induced by tensile strain 3 The method for ferroelectric single crystal thin film, the operation link of described method is as follows:

[0071] Link 1, CsPbBr 3 Single crystal preparation

[0072] (1) CsBr and PbBr with a molar ratio of 1:1 2 The mixture was dissolved in dimethylformamide (DMF) to form a supersaturated solution with a concentration of 1.5 mol / L, which was fully stirred at 70°C.

[0073] (2) Heat the supersaturated solution to 150° C., filter out the suspended insoluble matter, and then gradually cool the solution to 70° C. and keep it for 10 hours to grow seed crystals.

[0074] (3) Prepare a new supersaturated solution according to step (1), put the seed crystal obtained in step (2) into it to obtain a larger seed crystal, repeat three times and then put the seed crystal into anti-solvent toluene to keep room temperature High quality CsPbBr of desired size can be obtained in 7 days 3 For a single crystal, the side length of the single c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com