Steelmaking whole process logistics informatization method based on Internet of things

A full-process, steel-making technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of unable to track and count the production status of the whole process in real time, and obtain production data in real time, so as to optimize the crane operation time, avoiding the mechanical loss of the crane, and reducing the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

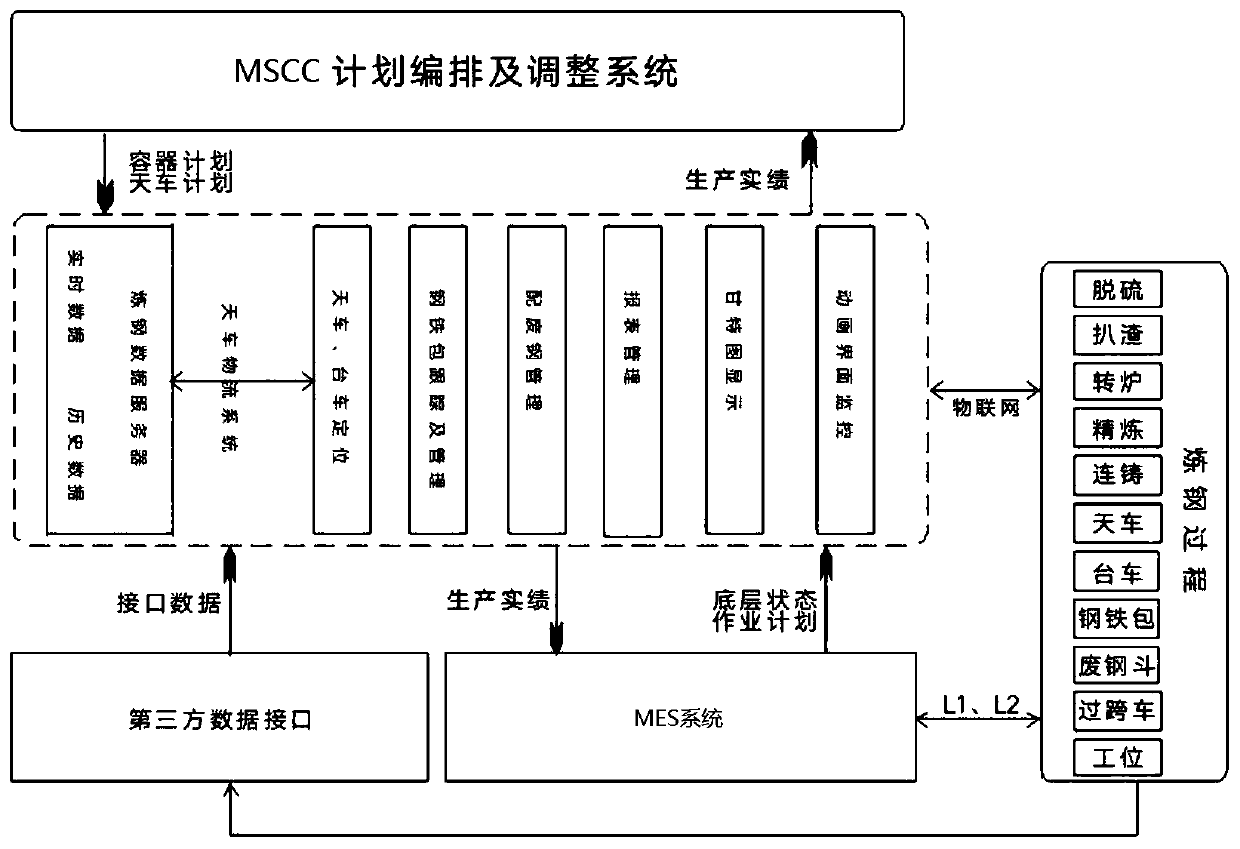

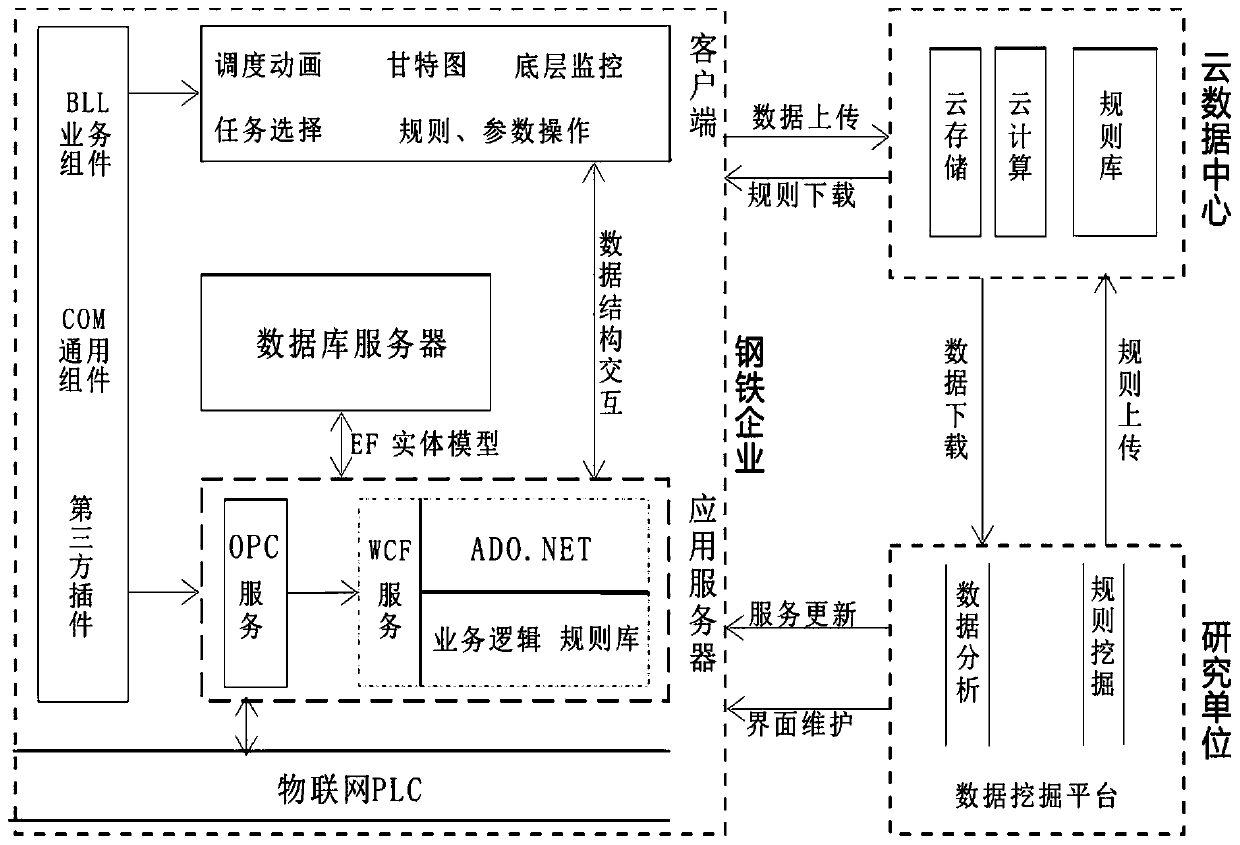

[0044] figure 2 It is a software architecture diagram of the steelmaking crane logistics system. In order to realize the intelligent scheduling of the steelmaking process, it is necessary to collect the underlying sensor signals of the steelmaking process and form a data center database. The steelmaking crane logistics system software is based on PLC to realize the steelmaking Internet of Things and build a big data The server collects all production data related to steelmaking. The system data center mainly realizes the centralized collection, storage, sharing and management of field data, including obtaining process parameters, control parameters, real-time equipment status and environmental data from various subsystems on site. Collect the installed sensor signals, obtain relevant signals of the MES system, collect production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com