Wedge-shaped block type clamp pushing and pulling mechanism

A technology of wedge block and limit block, applied in workpiece clamping devices, manufacturing tools and other directions, can solve the problems of reducing the work efficiency of mobile phone assembly equipment, improving the labor intensity of operators, and taking a long time, so as to reduce the occurrence of production accidents. chance, save time and energy, avoid the effect of movement confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

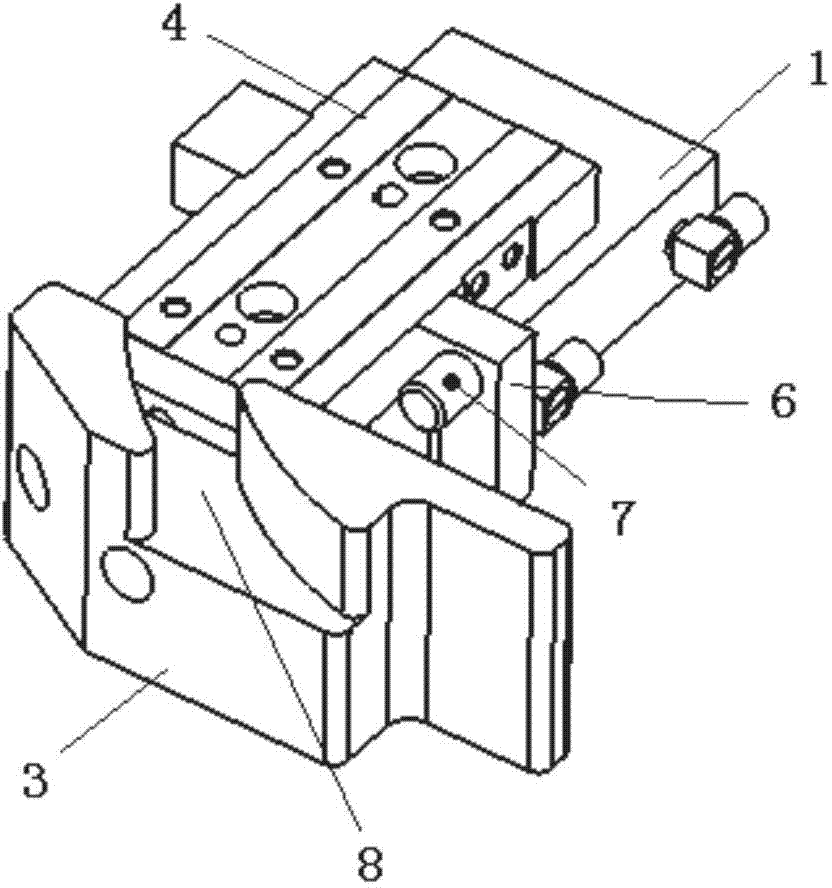

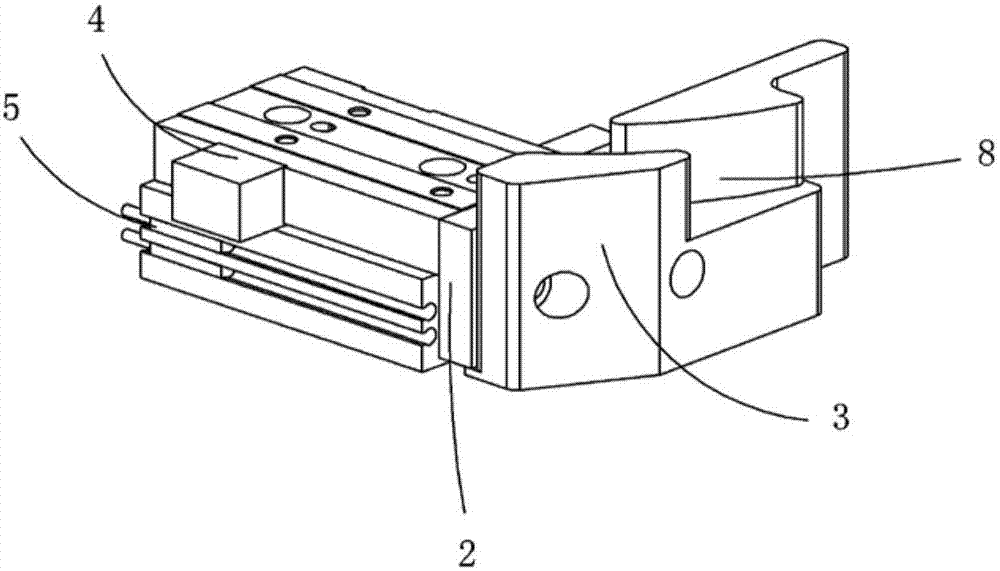

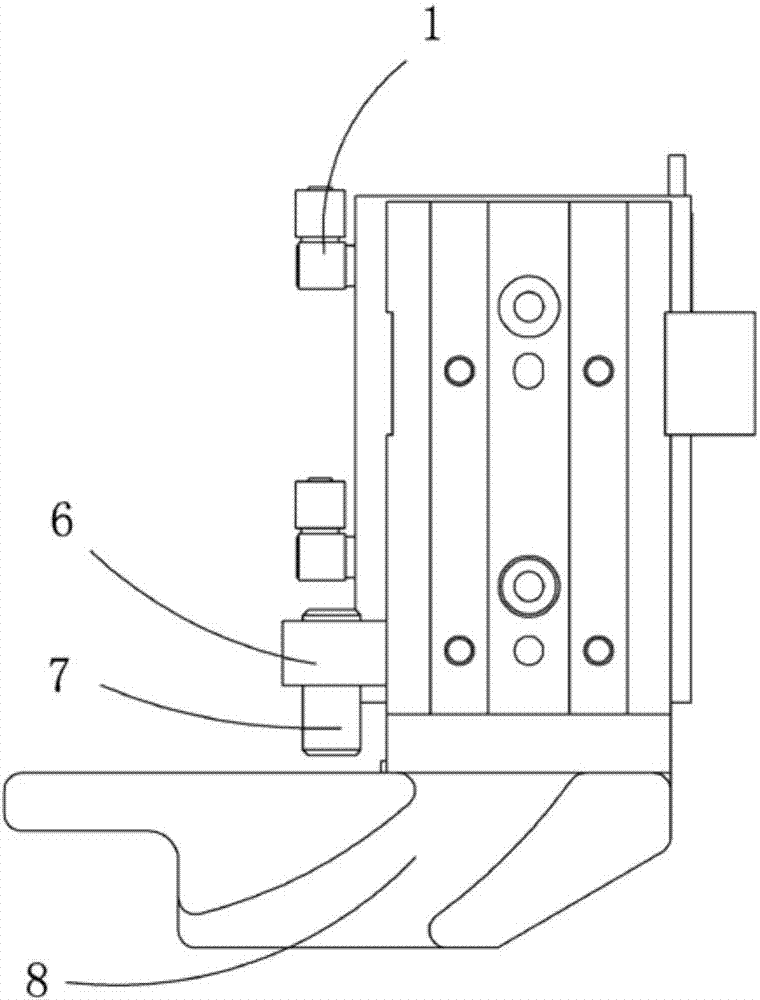

[0017] Examples, see attached Figure 1~3 , a wedge block push-pull clip mechanism, which includes a cylinder 1, a push block 2, a wedge block 3, a solenoid valve 4, a magnetic switch 5, a limit block 6 and a limit nut 7, the front end of the piston rod of the cylinder is connected to the push The front end of the push block is connected with a wedge-shaped block; two magnetic switches are installed on the left side of the cylinder, and a limit block is installed on the right side of the cylinder, and a limit nut is installed on the limit block, and the limit nut can control the movement of the cylinder. The movement is formed to indirectly control the opening degree of the clamp; the rear end of the push block is connected to a solenoid valve, and the solenoid valve is located above the cylinder, and the cylinder realizes reciprocating movement under the control of the solenoid valve, and the cam groove on the wedge block pushes the clamp The upper connecting rod drives the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com