Predication method for dynamic tail-escaping amount of strip steel

A strip and dynamic technology, applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of unsolved technical problems, more shearing, less shearing, etc., to achieve easy operation, reduce production accidents, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the shape meter of Meishan Iron & Steel Pickling Mill as an example.

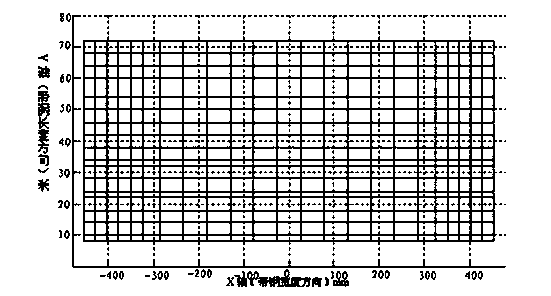

[0026] Step 1, collect the flatness data of the flatness data of the measurement points in the width direction of the strip and the distance data information corresponding to each set of data from the head of the strip, and form a data file in text format.

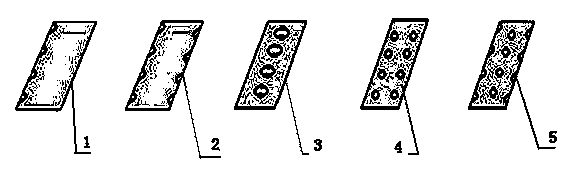

[0027] see Figure 4 , the shape meter is divided into the working side 6 and the driving side 7, the strip steel 9 passes through the center position 8 of the shape meter, and the shape meter periodically measures a width direction of the strip steel at the same time to form a strip section The flatness data set of . During the production process of a coil of strip steel, the system continuously collects such data groups for storage, and forms an independent text file at the end of the coil production.

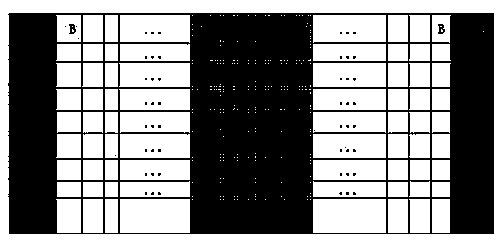

[0028] Step 2, see Figure 5 , extract effective data from each independent strip shape data file and carry out "grid" distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com