Double-verification type batching and feeding production method

A production method and verification technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as single process and inability to guarantee the accuracy of raw materials selected, and achieve the effect of reasonable and complete process, reliable principle, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

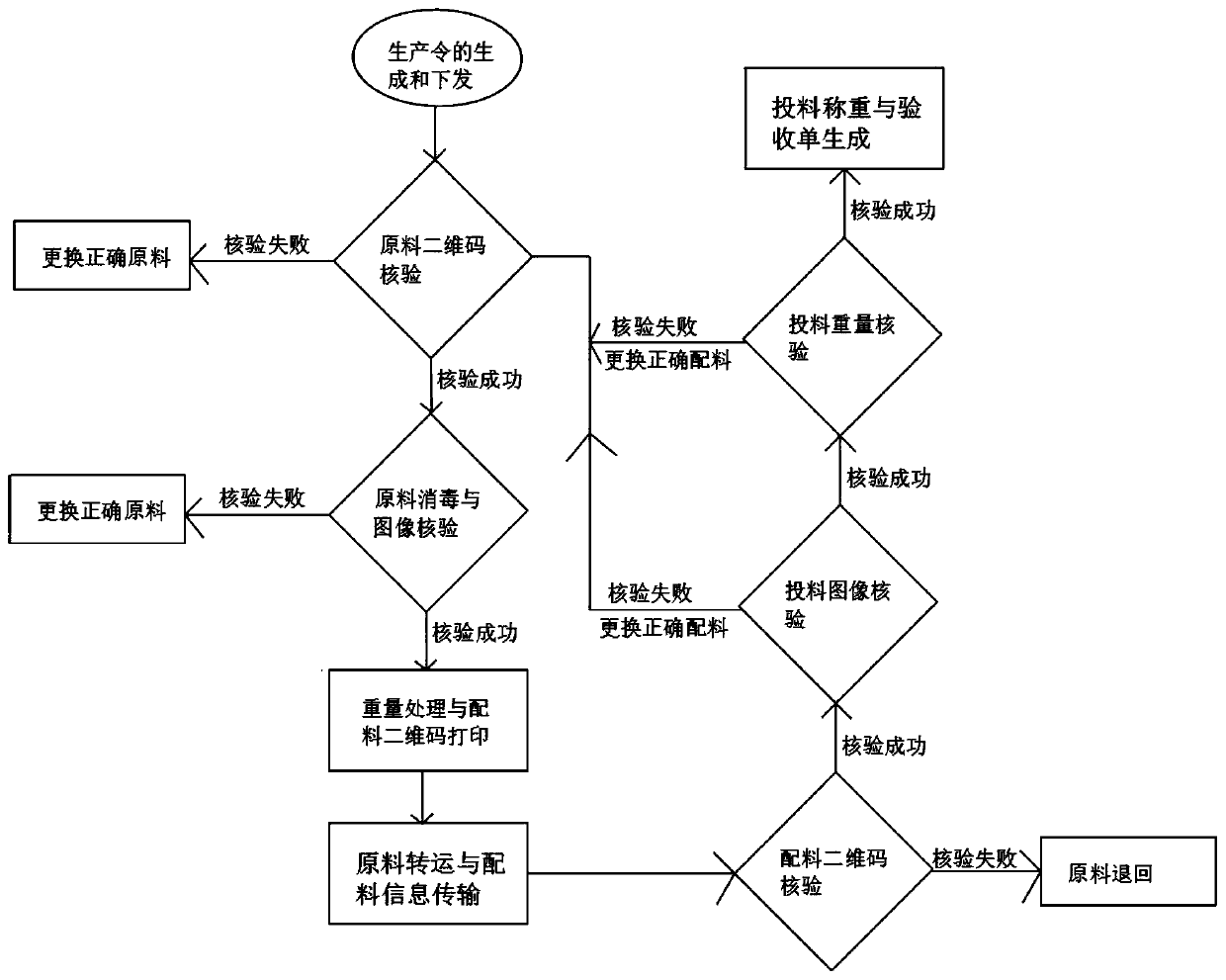

[0035] Such as figure 1 As shown, the double-verification batching and feeding production method involved in this embodiment includes: generation and distribution of production orders, raw material QR code verification, raw material disinfection and image verification, weight processing and batching QR code printing, raw material transfer and batching Information transmission, batching two-dimensional code verification, feeding image verification, feeding weight verification, feeding weighing and acceptance form generation; the specific process steps of the double verification type batching and feeding production method used in conjunction with the batching and feeding weighing system are as follows:

[0036] (1) Generation and distribution of production order: the control center 1 inputs production information through the instruction generation unit 4 to generate a production order, which includes a raw material list, and the detailed record of the raw material list shows the ...

Embodiment 2

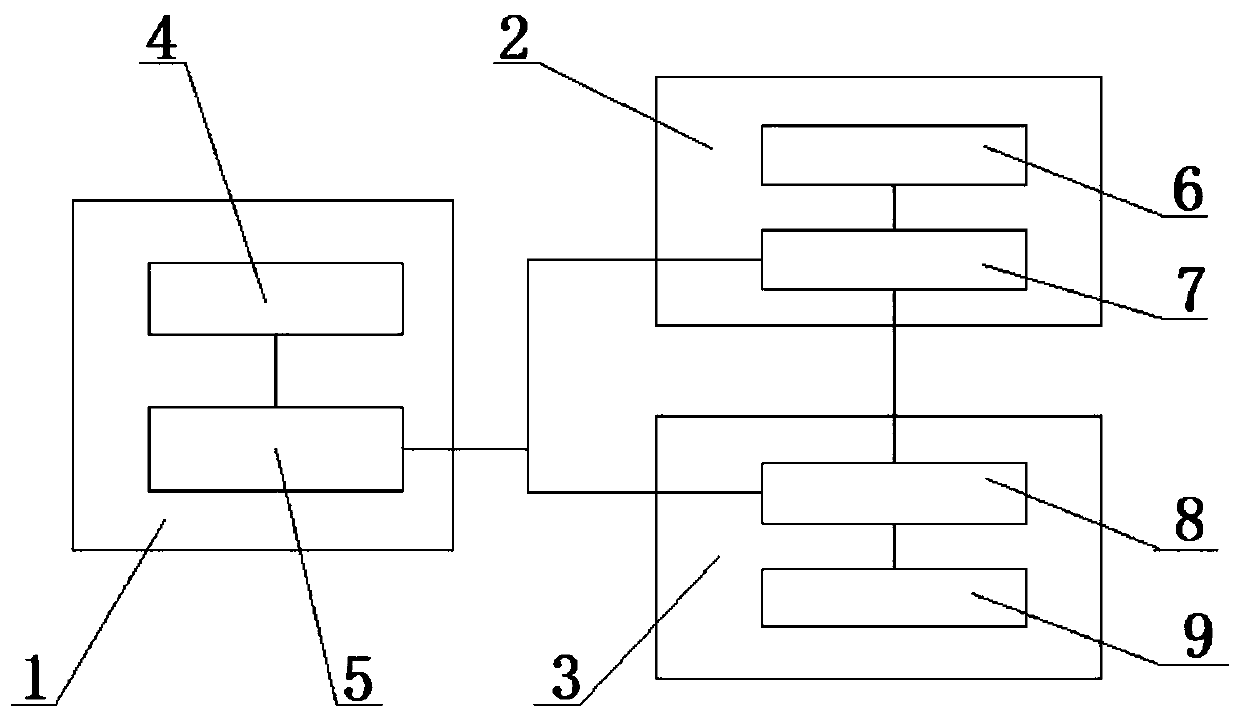

[0046] The batching weighing system that embodiment 1 relates to, as figure 2 As shown, its main structure includes a control center 1, a warehouse batching module 2 and a production feeding module 3; wherein the control center 1 is provided with an instruction generation unit 4 and an information transmission unit 5, and the instruction generation unit 4 is used to input production information and generate production orders , the output terminal of the instruction generation unit 4 is connected with the receiving terminal of the information transmission unit 5; the production order includes a raw material list, and the detailed record of the raw material list shows the products and product quantities that need to be produced, and the warehouse batching module 2 is used for the production of products. The types of ingredients to be prepared, the image of each ingredient prepared by the warehouse ingredient module 2 for the production of products and the weight list of each ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com