Cable sleeve end plugging method

A cable sleeve and terminal technology, which is applied in the field of cable nozzle sealing, can solve the problems of imperfect port sealing process, easy cracking at the sealing place, and non-dense sealing, etc., and achieves strong durability, low cost, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for plugging the end of a cable bushing involved in this embodiment, the specific process steps are:

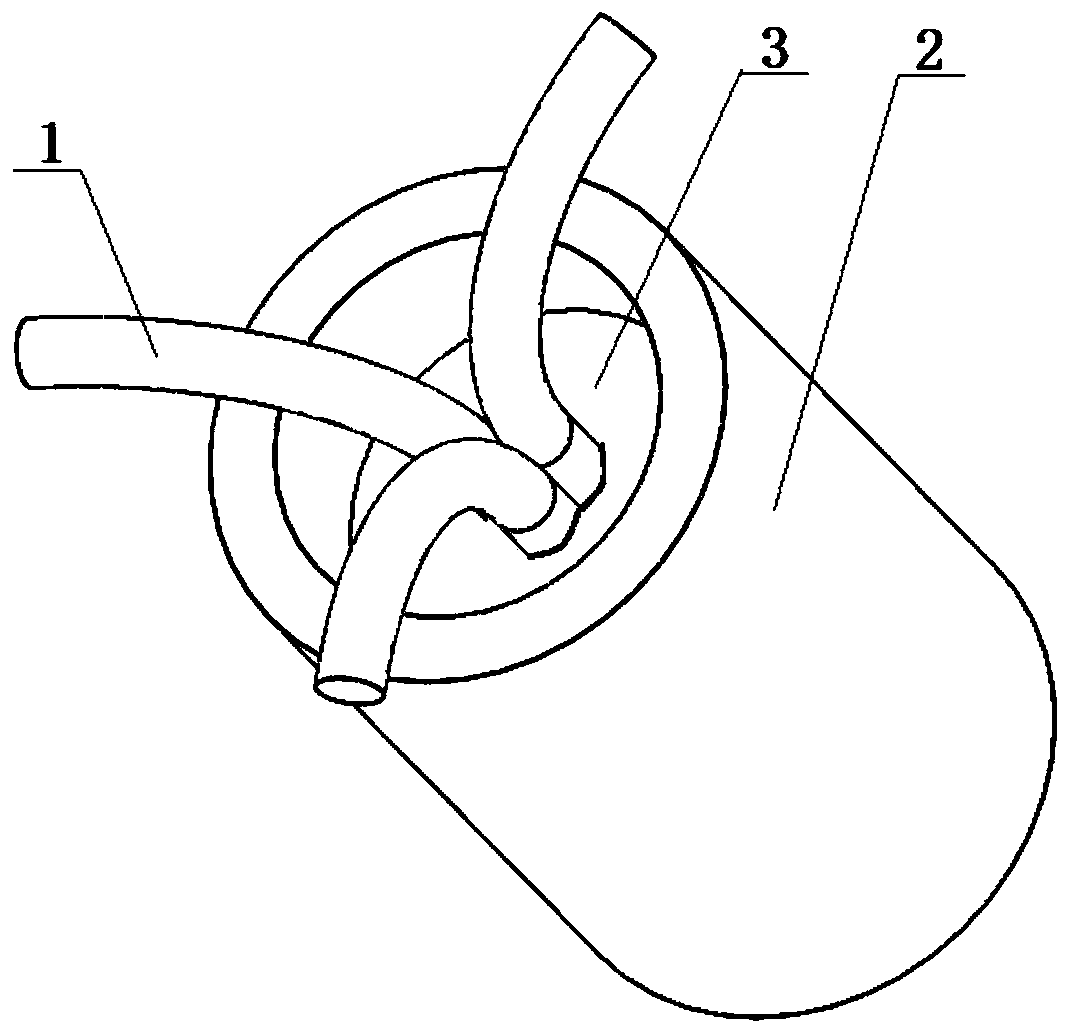

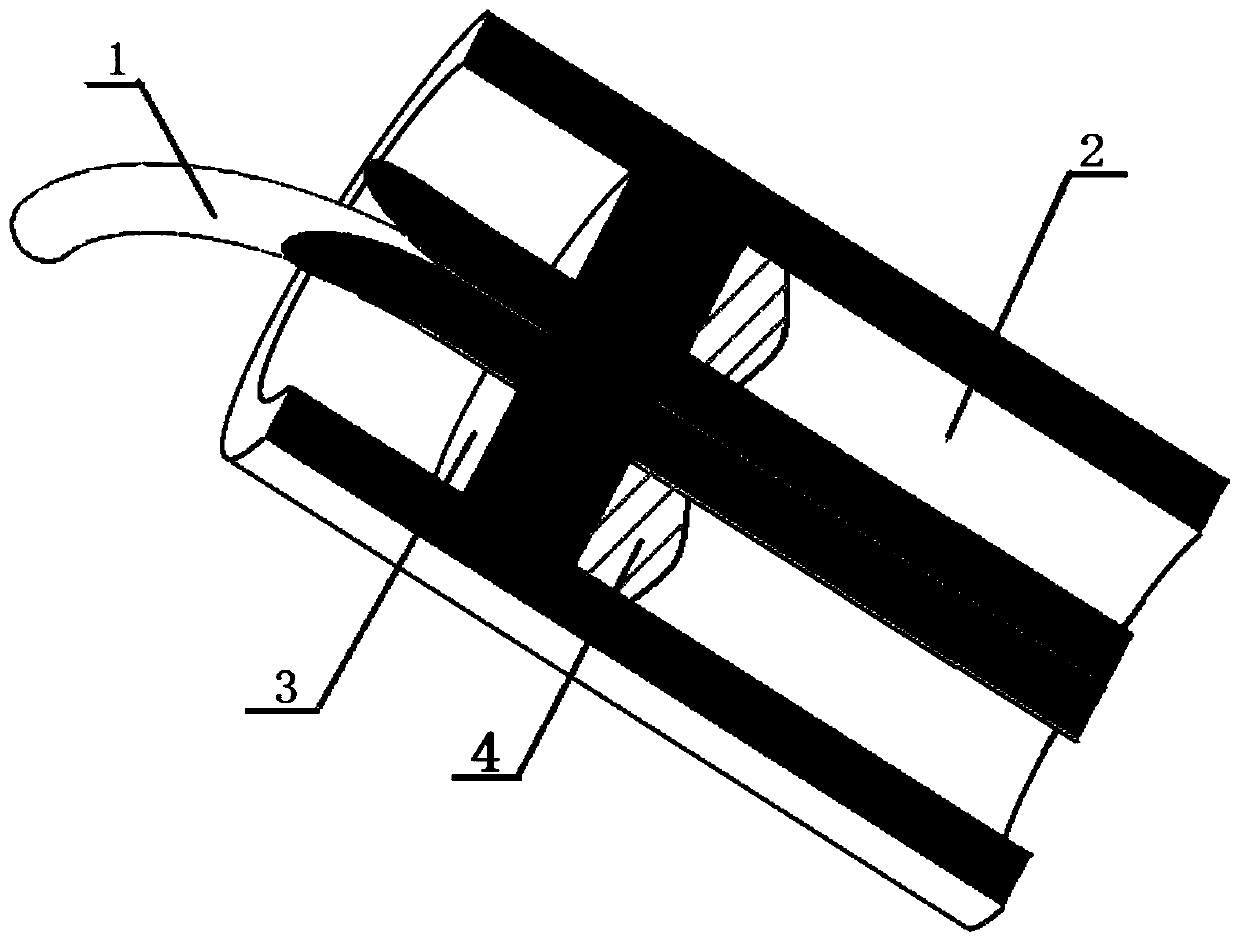

[0026] (1) At the outlet of the cable sleeve, use an air bag or a cloth bag 4 filled with cement to fix multiple cables 1 together and fix them in the middle of the inner cavity port of the cable sleeve 2, and then attach each cable 1 to the Together, the cable 1 cannot move freely;

[0027] (2) Take the polymer resin waterproof and anti-corrosion coating and mix it evenly, and apply the polymer resin waterproof and anti-corrosion coating to the surface layer between the multiple cables 1 that need to be fixed, and the cable 1 fixed position is far from the port of the cable sleeve 2 2-5 cm, so that the gap between the fixing points of multiple cables 1 is tightly sealed by polymer resin waterproof and anti-corrosion coating;

[0028] (3) The polymer resin waterproof and anti-corrosion coating is evenly added to the port 2 of the cable sleeve. Due to the exis...

Embodiment 2

[0040] This embodiment relates to a kind of cement mortar used for preparing the plugging layer 3. When the cement mortar is used for plugging the cable sleeve 2, cement, fine sand and fine hemp silk with a length of 2-3 cm are pressed by 1 : Mix at a weight ratio of 1:0.05, then add water in a conventional weight mixing ratio, and mix uniformly to obtain cement mortar, then carry out the plugging operation according to Example 1, and prepare the plugging layer 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com