Power slip

A technology of power slips and slips, which is applied to drilling equipment, earthwork drilling, drill pipes, etc., can solve the problems of large replacement parts, small replacement parts, low work efficiency, etc. The effect of small amount and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

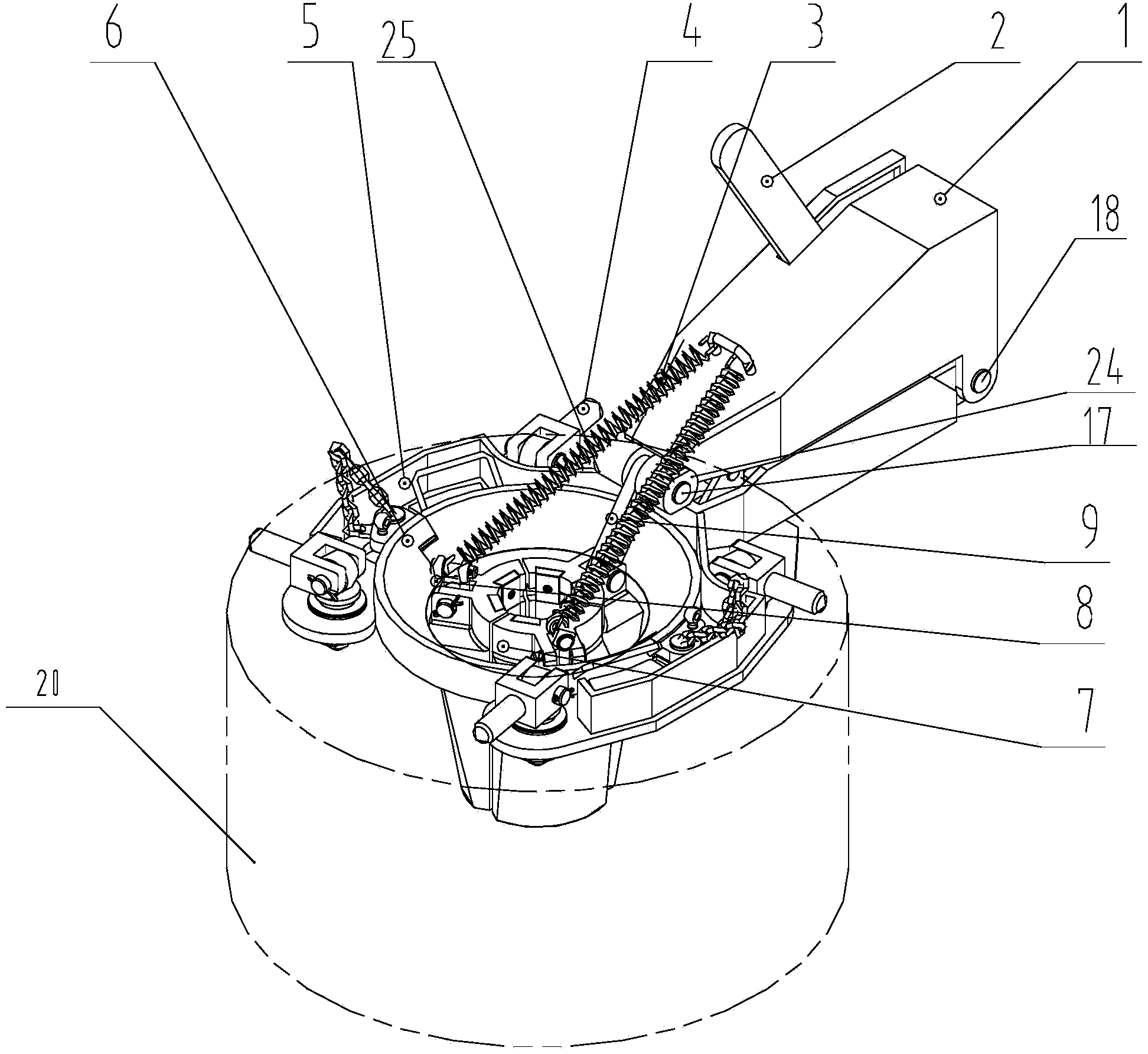

[0056] Such as figure 1 As shown, a power slip includes a base 5 connected to a turntable 20 through a quick connection device 4 .

[0057] The schematic diagram of the three-dimensional structure of the base 5 is as Figure 5 shown. The base 5 is provided with four turntable connection holes 52, and the quick connection device 4 passes through the turntable connection holes 52 to fix the base 5 in the corresponding pin hole on the turntable 20. The pin holes of the turntable 20 are self-contained pin holes, and no additional processing is required. ; The base 5 is also provided with a chute 51 , the chute 51 is used to position the slip body guide 6 installed on the base 5 .

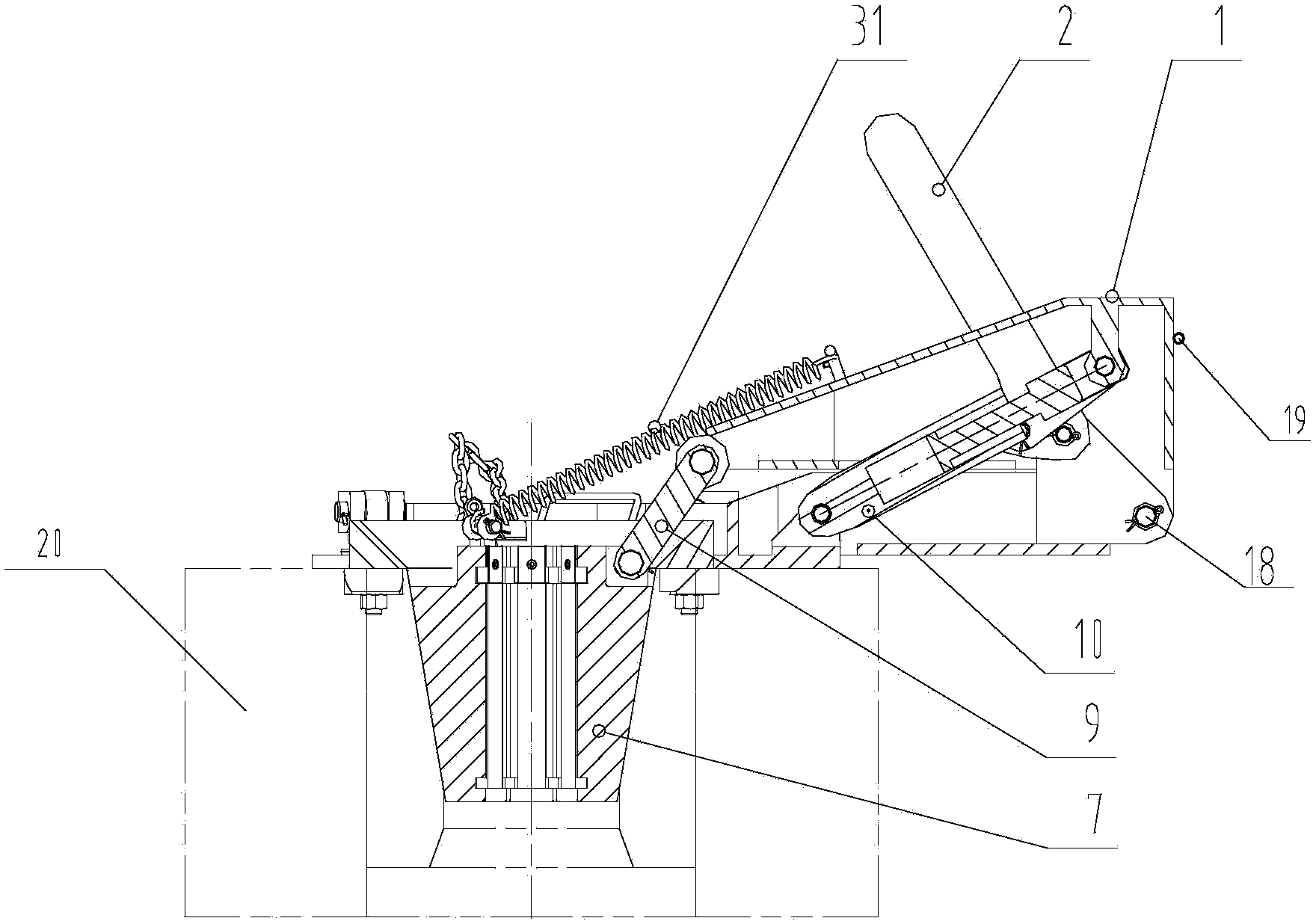

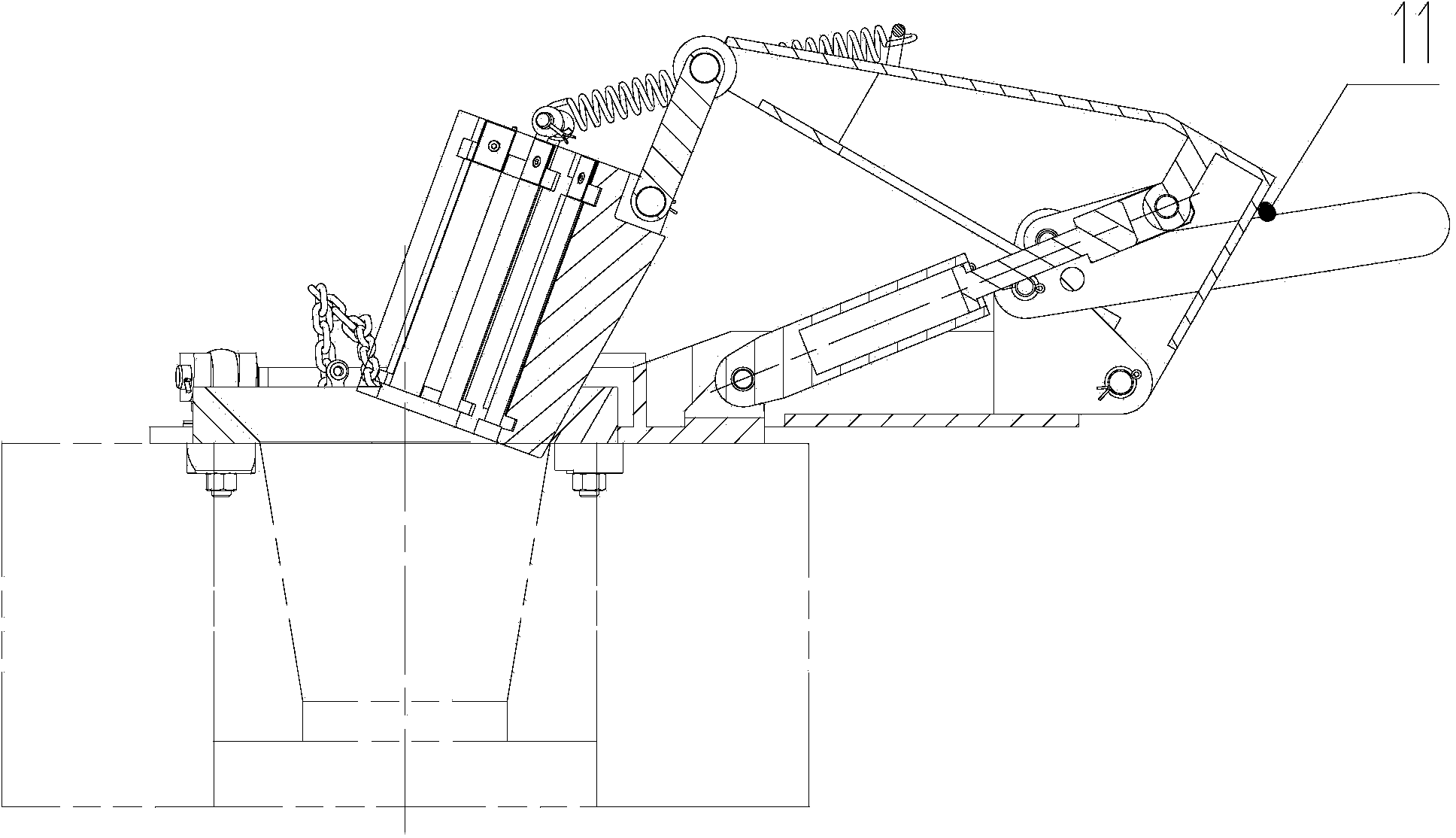

[0058] Figure 6 , Figure 7 It is a schematic structural view of the quick connection device 4 used to fix the base 5, Figure 6 It is a structural schematic diagram of the quick connection device 4 in a loosened state, Figure 7 It is a structural schematic diagram of the quick connection device...

Embodiment 2

[0067] The power slips in this embodiment are multi-piece casing slips. The difference between the multi-piece sleeve slips of this embodiment and the three-piece power slips disclosed in Embodiment 1 is that:

[0068] Replace the three-piece slips 7 and the lifting rod 9 of the power slips in Example 1, and assemble them as follows: Figure 16 The U-shaped lifting ring 12 and the multi-piece casing slip 14 are shown.

[0069] Figure 16 The U-shaped lifting ring 12 shown includes a U-shaped piece 1201 and a U-shaped positioning connecting piece.

[0070] The U-shaped piece 1201 is provided with 3 small holes, and the 3 small holes are located at the bottom of the U-shaped piece and the two ends of the open end of the U-shaped piece respectively. One ends of the three small chains 13 pass through the small holes and are respectively fixed on the U-shaped pieces, and the other ends of the small chains 13 are respectively connected to the multi-piece casing slips 14 through s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com