Hydraulic lifting pipe conveyer for oil drilling platform

An oil drilling platform and hydraulic lifting technology, which is applied in the direction of drilling pipes, drilling equipment, drilling pipes, etc., can solve the problems of low production efficiency, unsafe production, high work intensity, etc., to achieve convenient and stable work and ensure a safe production environment , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

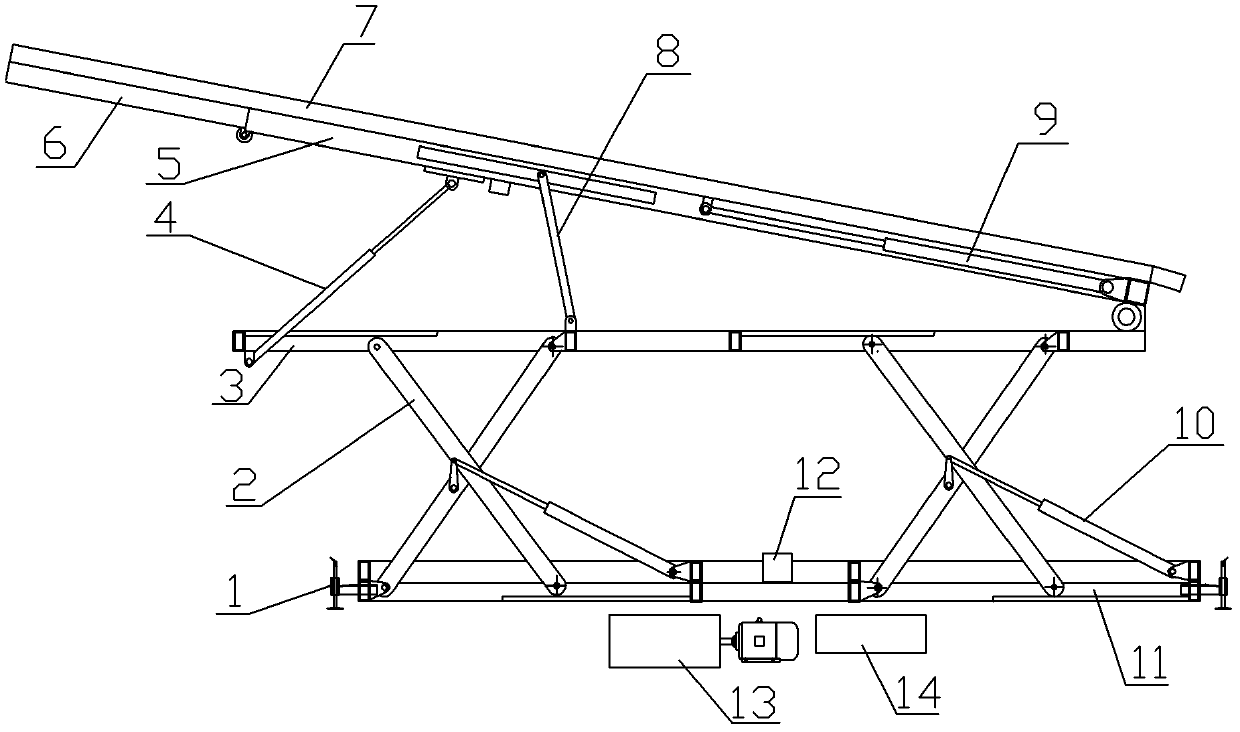

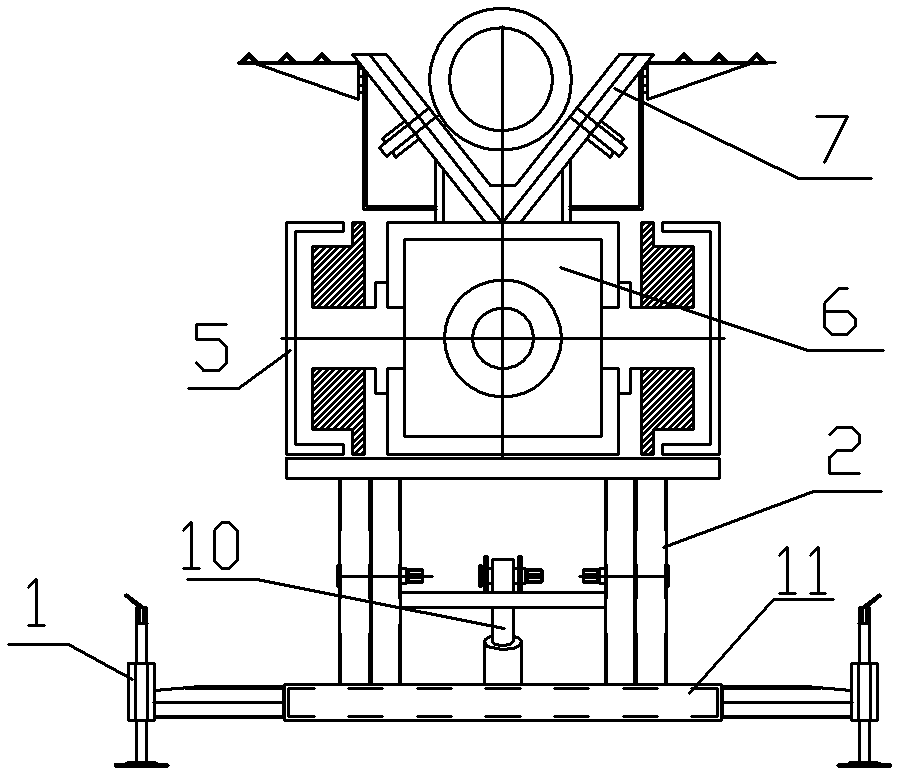

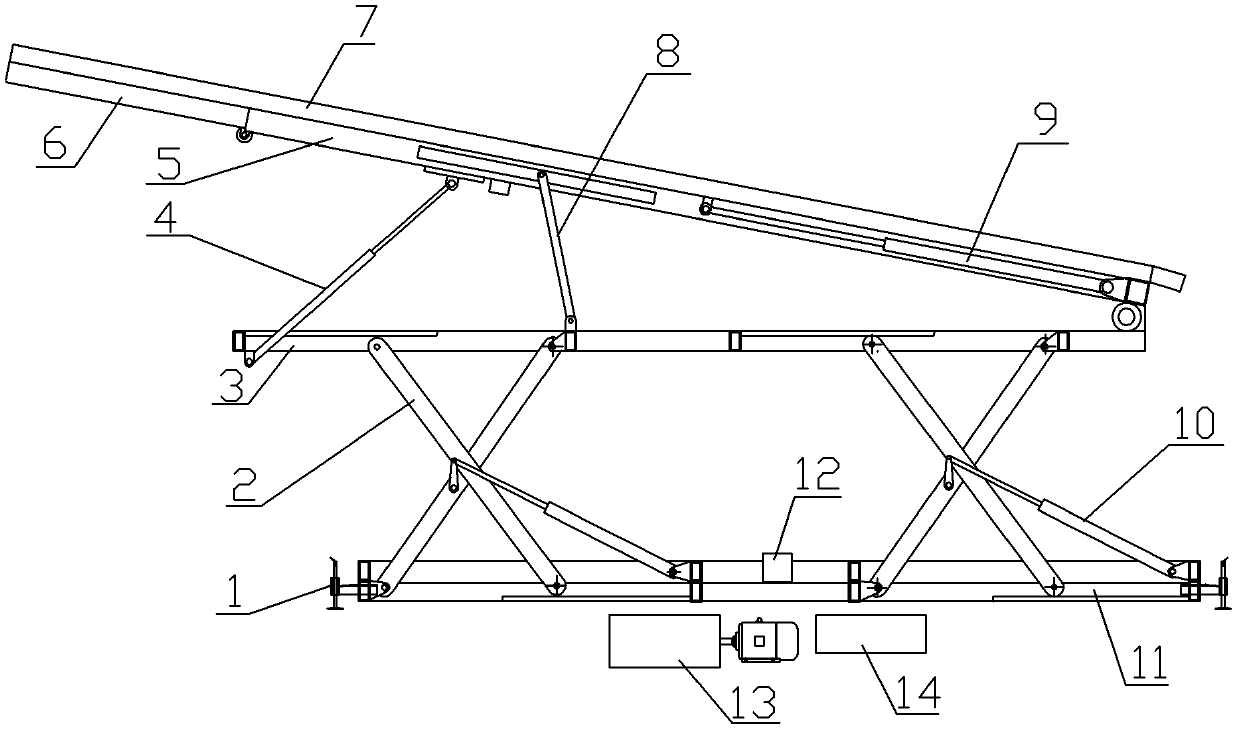

[0010] Refer to the attached figure 1 And attached figure 2 The oil drilling platform hydraulic lifting pipe delivery machine of the present invention will be described in detail below.

[0011] The structure of the oil drilling platform hydraulic lifting pipe delivery machine of the present invention includes a base frame 11, a support rod 2, an upper frame 3, an inclined table surface 5, an auxiliary support 8 for an inclined slideway and a telescopic table surface, and the support rod 2 is arranged on the base frame 11 and the upper frame 3, a lifting cylinder 10 is arranged between the underframe 11 and the pole 2, the inclined table 5 is arranged on the upper part of the upper frame 3 and is hinged with one end of the upper frame 3, and the inclined table 5 Between the upper frame 3 and the inclined lift cylinder 4 and the auxiliary support 8 of the inclined slideway, the telescopic table is arranged on the upper part of the inclined table 5, and the telescopic table in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com