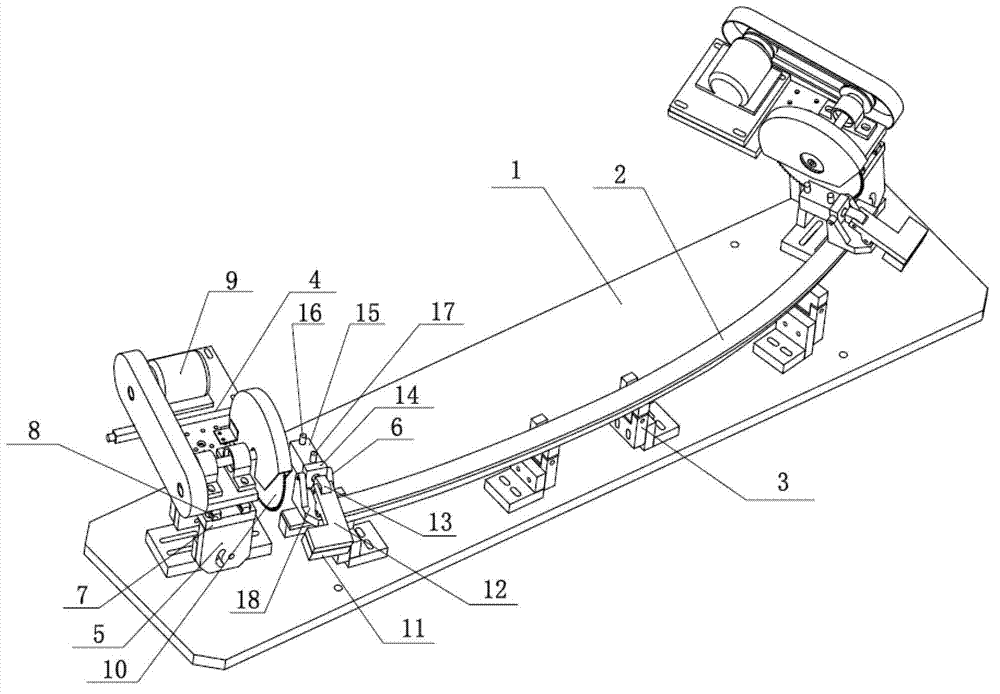

Automatic bending and saw cutting tool on bending machine

A bending machine and sawing device technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of easily damaged product surface, high labor input cost, the same product size, etc., to achieve simple structure, reduce production accidents, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

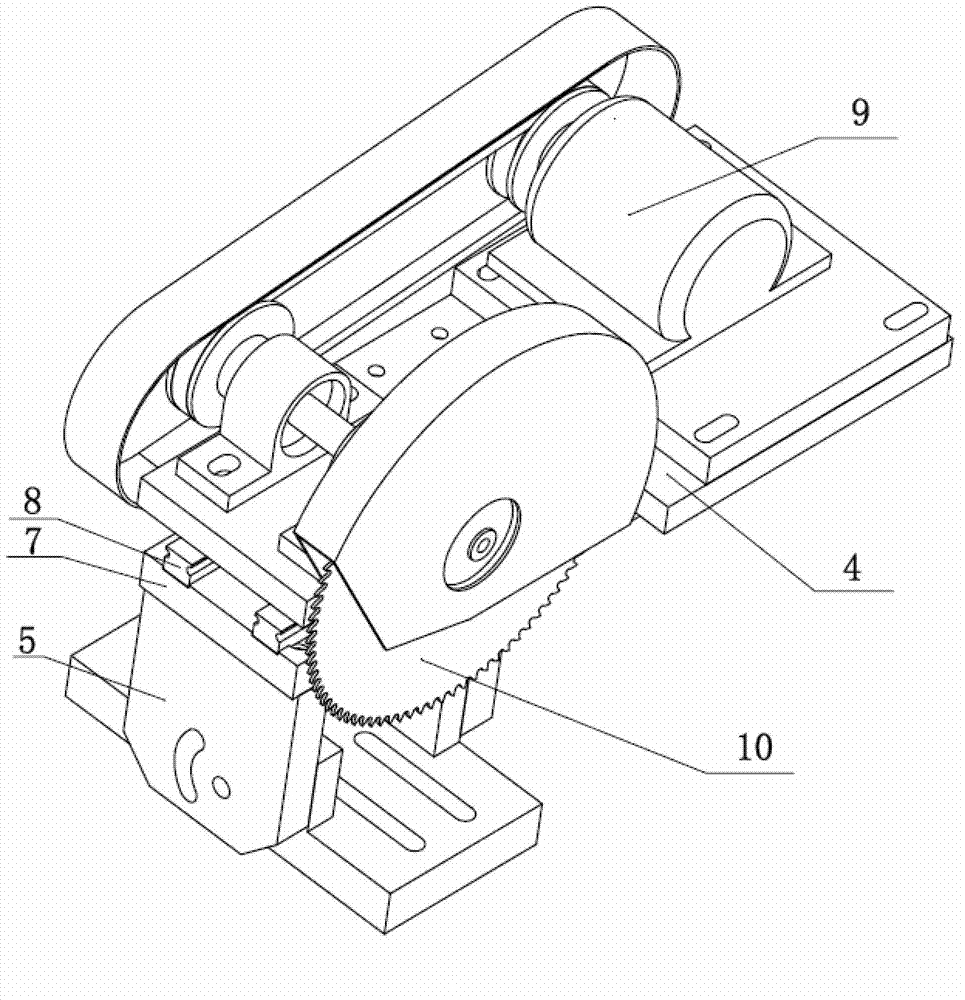

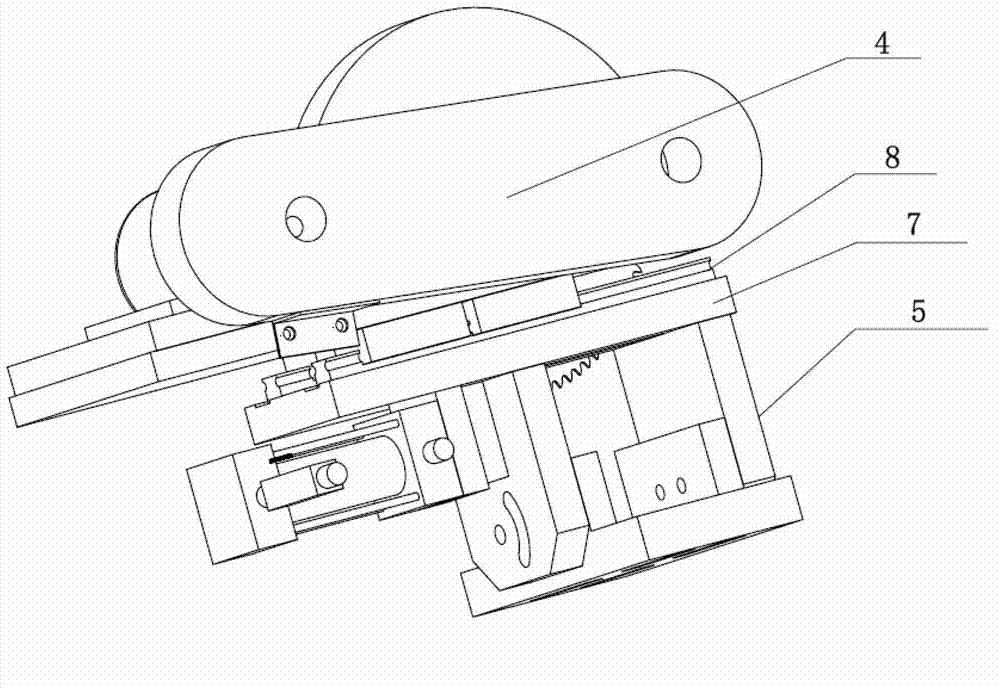

Embodiment 1

[0018] Clamp the elongated profile through the chuck of the bending machine, make the elongated profile cling to the outer surface of the bending die 2 through the movement of the bending machine, and complete the bending of the elongated profile, the bending range and bending The bending range of the mold 2 is the same. After the bending process is completed, the cylinder 15 of the pressing device 6 starts to move, and drives the pressing plate 12 connected with the cylinder connector 13 of the cylinder 15, so that the pressing plate 12 arranged at the lower part of the front end of the pressing plate 12 The material block 11 presses the bent profile. At this time, the motor 9 of the sawing device 4 starts to rotate, and the motor 9 drives the saw blade 10 to rotate together through the belt and pulley, and the pushing device 5 starts to push the sawing device 4 along the linear guide rail 8 Slide to make the rotating saw blade 10 gradually approach the curved profile, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com