Reinforcement chip mounter

A technology for reinforcing patches and reinforcing plates, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of inability to effectively tighten the reinforcing plates, increasing costs, and damage to the reinforcing plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Such as Figure 3-7 shown.

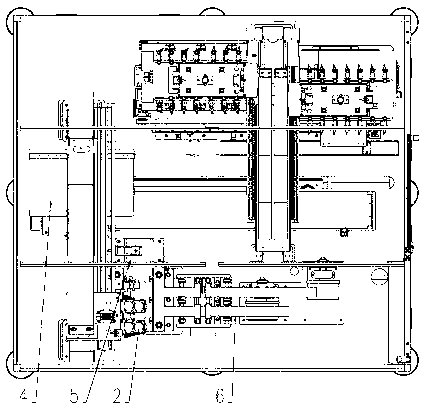

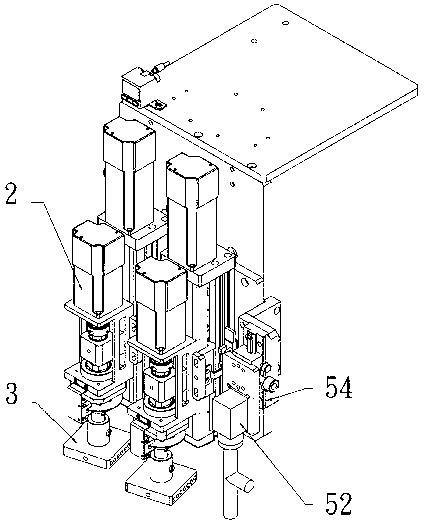

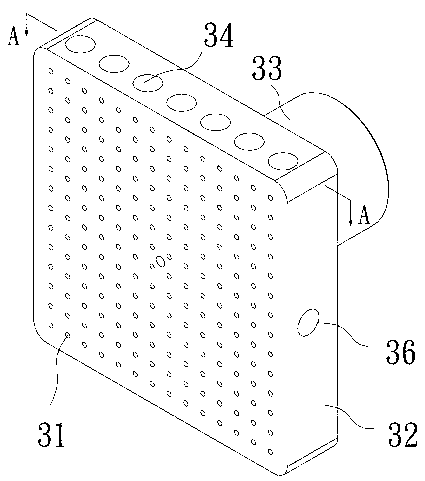

[0020] The reinforced chip placement machine of the present invention comprises a frame 1, on which two rotating suction cup assemblies 2 are arranged, on which the rotating suction cup assembly 2 is provided with a suction cup 3 for absorbing a reinforcing plate, and the suction cup 3 includes a bottom opening The suction cup seat 32 of a plurality of suction holes 31, the top center of the suction cup seat 32 has a central hole 37; the connection pipe 33 connecting the rotary suction cup assembly 2 and the suction cup seat 32, the connection pipe 33 is connected to the top of the suction cup seat 32, and connects with the center The holes 37 are connected; the opposite sides of the suction cup seat 32 are provided with a plurality of regulating air holes 34 communicated with the suction holes 31, and the suction holes 31 are evenly distributed on the regulating air holes 34; Each has a horizontal adjustment hole 36, the horizontal adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com