Multifunctional pressure tester for blast furnace tap-hole clay

A pressure test and multi-functional technology, applied in the field of test instruments, can solve the problems of inability to test the comprehensive performance of blast furnace clay materials, achieve the effect of simple structure and reduce production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

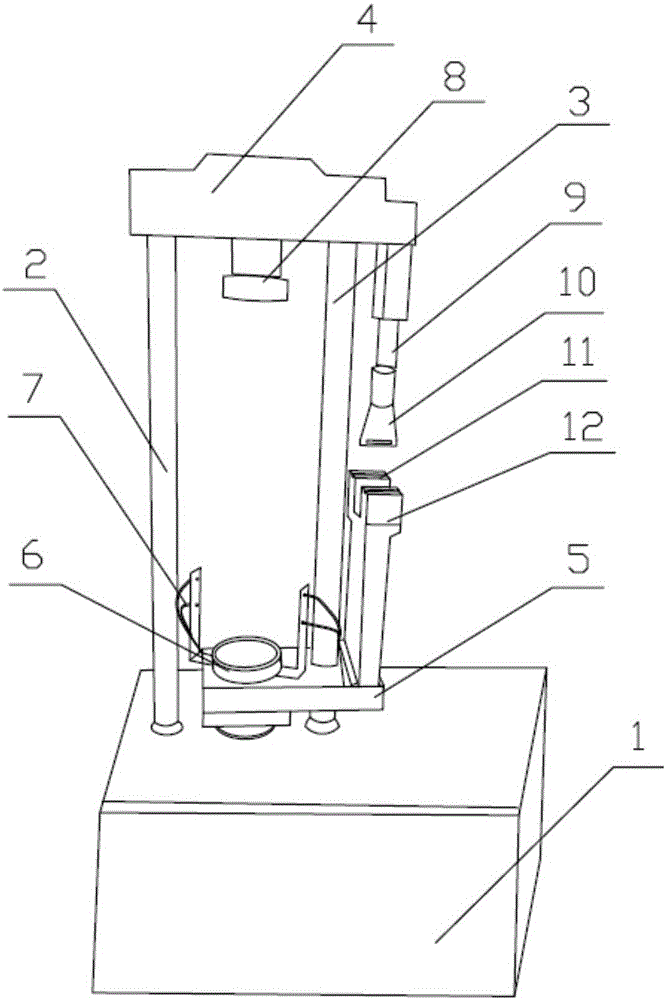

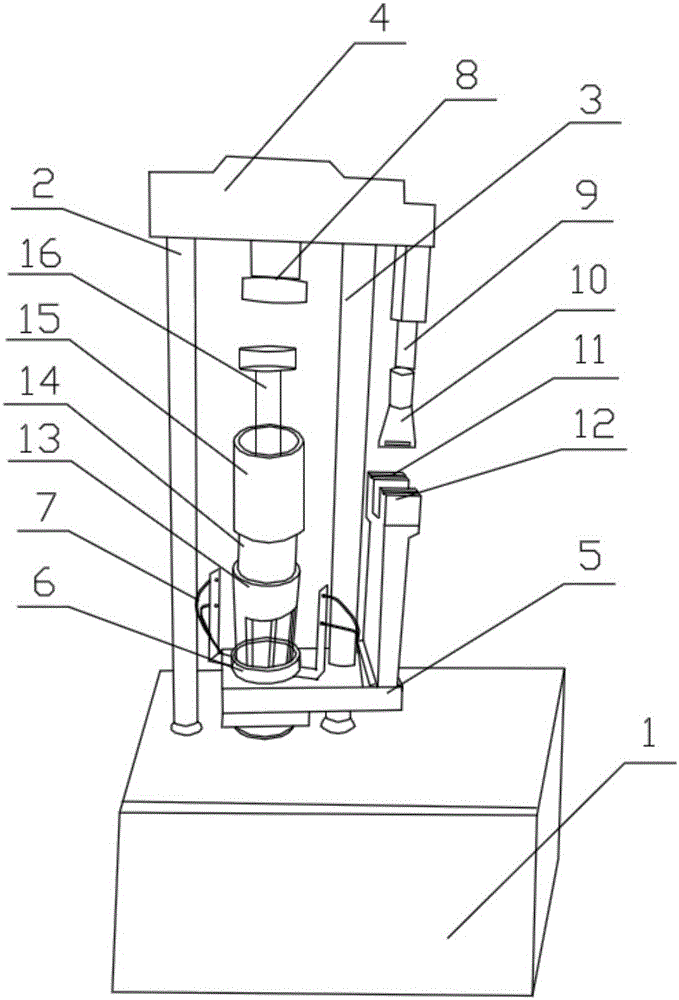

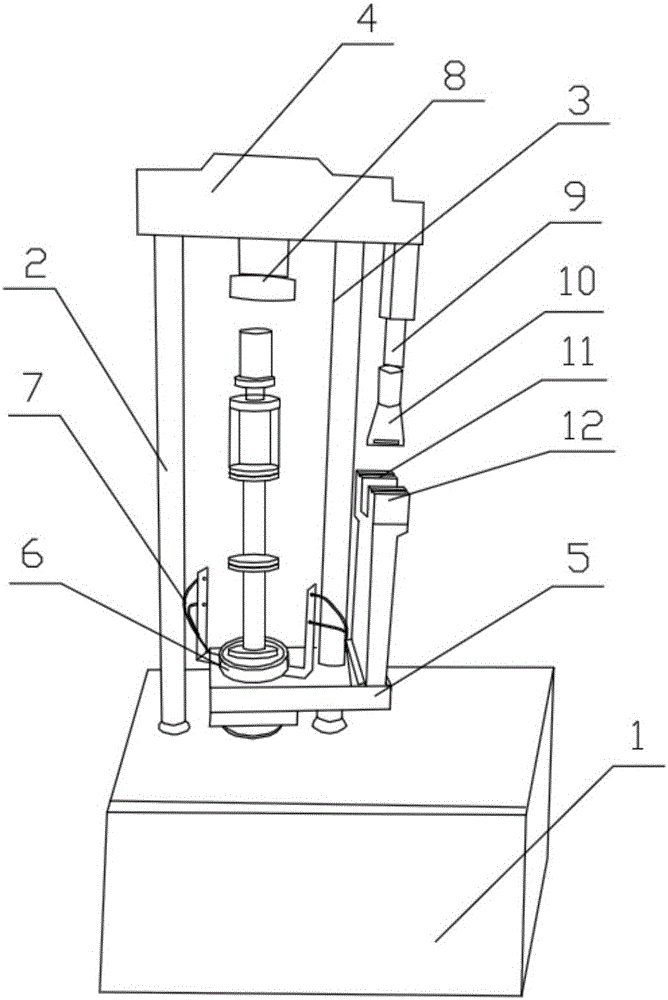

[0023] The structure of the present invention will be explained in detail below in conjunction with the drawings and embodiments.

[0024] like Figure 1-7 As shown, the multifunctional pressure tester for blast furnace clay of the present invention comprises a box body 1, a first column 2 and a second column 3 are vertically arranged on the box body 1, and the top of the first column 2 and the second column 3 passes through the beam 4 Fixed connection, the second column 3 is covered with a movable base 5, the base 5 is installed between the two columns with a support tray 6, the bottom end of the support tray 6 is connected to the infrared light-emitting diode 7 through an iron sheet, and the beam 4, a first pressure sensor 8 is installed hanging directly above the support tray 6; A second blade 11 and a third blade 12 are mounted on both sides corresponding to the bottom end of the first blade 10 .

[0025] Place the clay material on the support tray 6, and through the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com