Novel prefabricated concrete member hoisting point embedded part system

A technology of prefabricated concrete and embedded parts, which is applied in building construction, processing of building materials, construction, etc., can solve problems such as the complex stress state of embedded parts at lifting points, and improve the axial pull-out bearing capacity and increase Performance, the effect of preventing local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

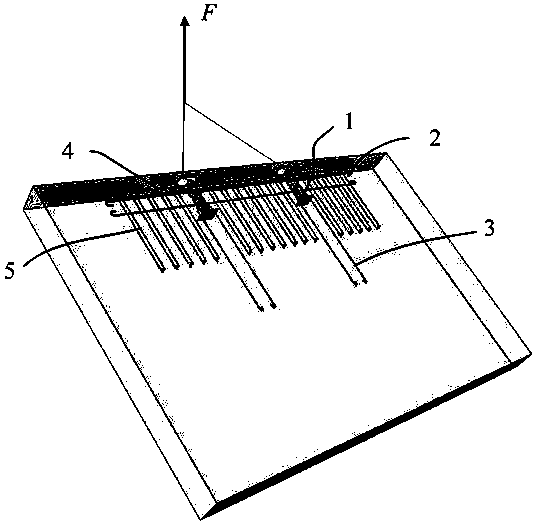

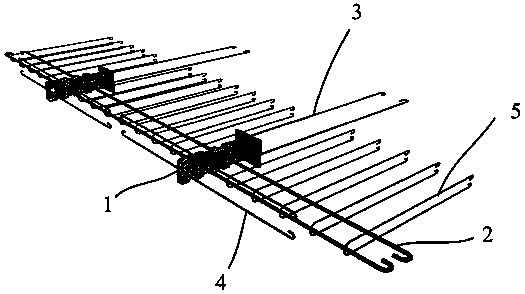

[0029] Such as figure 1 As shown, a new type of precast concrete component lifting point embedded parts system, the system includes embedded parts (1), anti-split steel bars (2), pull-out steel bars (3), horizontal U-shaped steel bars (4) , distributed steel bars (5), and end plates (6). This system can be used in prefabricated concrete components of prefabricated structures, and can be poured and formed together with prefabricated concrete components. It can be used alone or together as a group of lifting points.

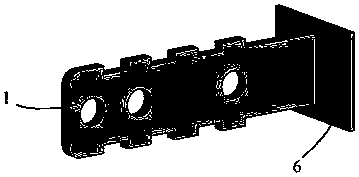

[0030] Such as figure 2 As shown, the embedded part (1) is made of high-strength steel, grooves are set on the upper and lower sides of the embedded part, and the end plate (6) is welded to the end of the embedded part to increase the adhesion between the embedded part (1) and the concrete. knot performance.

[0031] Such as image 3 As shown, the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com