Flat-head tower crane

A tower crane and flat head technology, applied in cranes and other directions, can solve the problems of large design cost, large calculation result error, large calculation amount, etc., and achieve low requirements for installation equipment, less overall installation time, and high space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

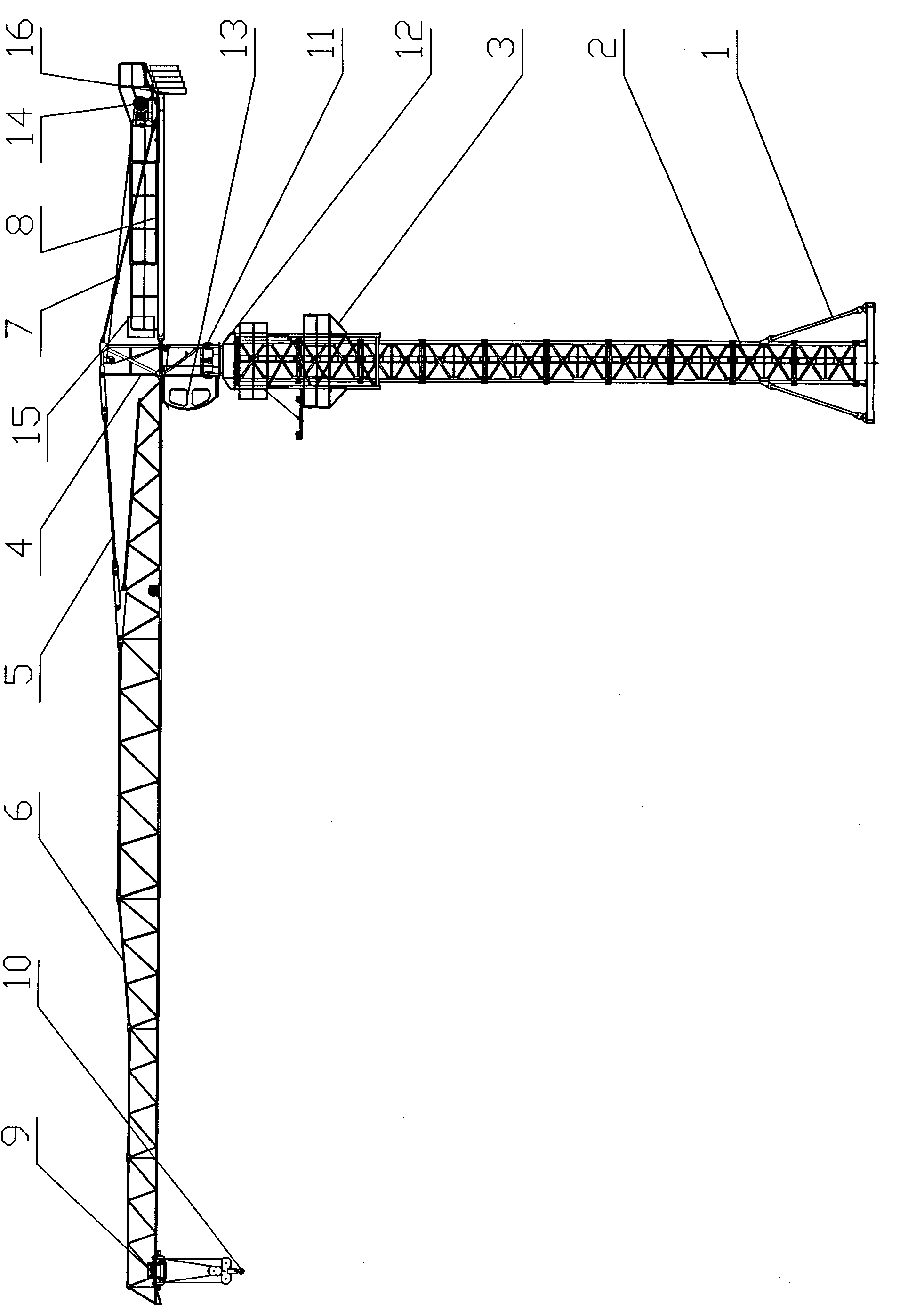

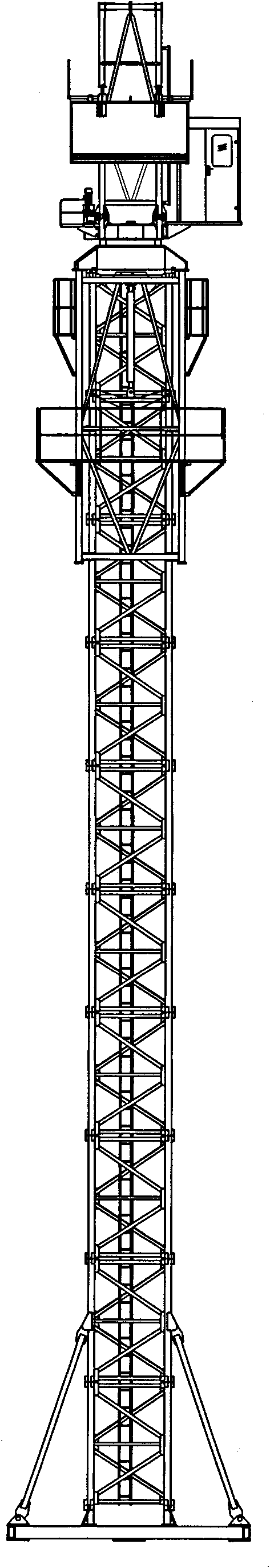

[0020] Flat head tower crane, its composition includes: base frame 1 is used to determine the position of the tower crane and support the whole machine, and a set of standard sections 2 are connected to the base frame in sequence, and the increase and decrease of standard sections can change the structure of the tower crane. The working height of the above-mentioned standard section at the upper end is connected to the slewing assembly, and the slewing assembly is used to complete the slewing operation during the working process of the tower crane, so that the tower crane can complete the rotation of ±540° centering on the tower body. The lower part of the slewing bearing is connected to the sleeve frame 3 located outside the standard section. During the operation, the standard section is separated from the lower support of the slewing bearing. The role of the section. The slewing assembly is connected to the slewing tower body 4 above, and one side of the slewing tower body i...

Embodiment 2

[0022] In the flat-top tower crane, the slewing assembly includes an upper support 11 and a lower support 12, and the upper support is connected to a driver's cab 13.

Embodiment 3

[0024] In the flat-top tower crane, the balance arm has a lifting mechanism 14 and a lifting mechanism electric control box 15, and the rear end of the balance arm has a group of counterweights 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com