Gas lifting jack for excavator

A technology for excavators and lifters, which is applied in the directions of earth movers/shovels, lifting devices, construction, etc., can solve problems such as inconvenient installation of excavators, inability of excavators to press down working devices to support vehicles, and increased resistance, etc. Achieve the effect of reasonable and novel structure design, reduce work cost and increase lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

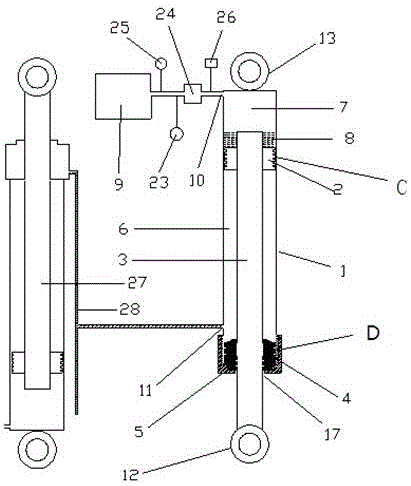

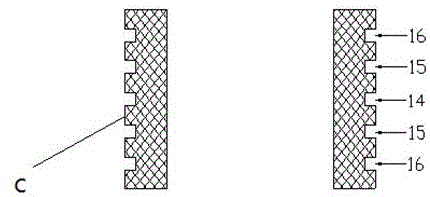

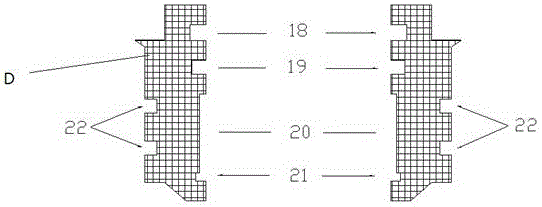

[0021] Such as figure 1As shown, this specific embodiment adopts the following technical solutions: it includes a lifter cylinder 1, a piston 2, a piston rod 3, a cylinder head 4, a cylinder cover 5, a rod chamber 6, a rodless chamber 7, and an oil storage chamber 8 , high-pressure gas cylinder 9, air inlet and outlet holes 10, oil inlet and outlet holes 11, first lifting ring 12, second lifting ring 13, first gray ring 14, YA-shaped sealing ring 15, guide belt 16, dust seal 17, second grid Lai ring 18, buffer seal 19, guide sleeve 20, guide sleeve circlip 21, O-ring 22, air pressure gauge 23, stop valve 24, inflation device 25, high-pressure gas safety valve 26, excavator boom cylinder 27 and excavator The oil pipe 28 with the rod chamber of the boom oil cylinder of the machine, the cylinder body 1 is designed as a barrel, and the piston rod 3 and the piston 2 are arranged in the cylinder body 1. One end of the piston rod 3 is connected with the piston 2, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com