Biomass micro-positive-pressure pneumatic transmission system

A pneumatic conveying system and micro-positive pressure technology, applied in the field of machinery, can solve the problems of no improvement method, high energy consumption per unit conveying volume, low conveying concentration, etc., to achieve improved visibility, small space occupation, and on-site good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

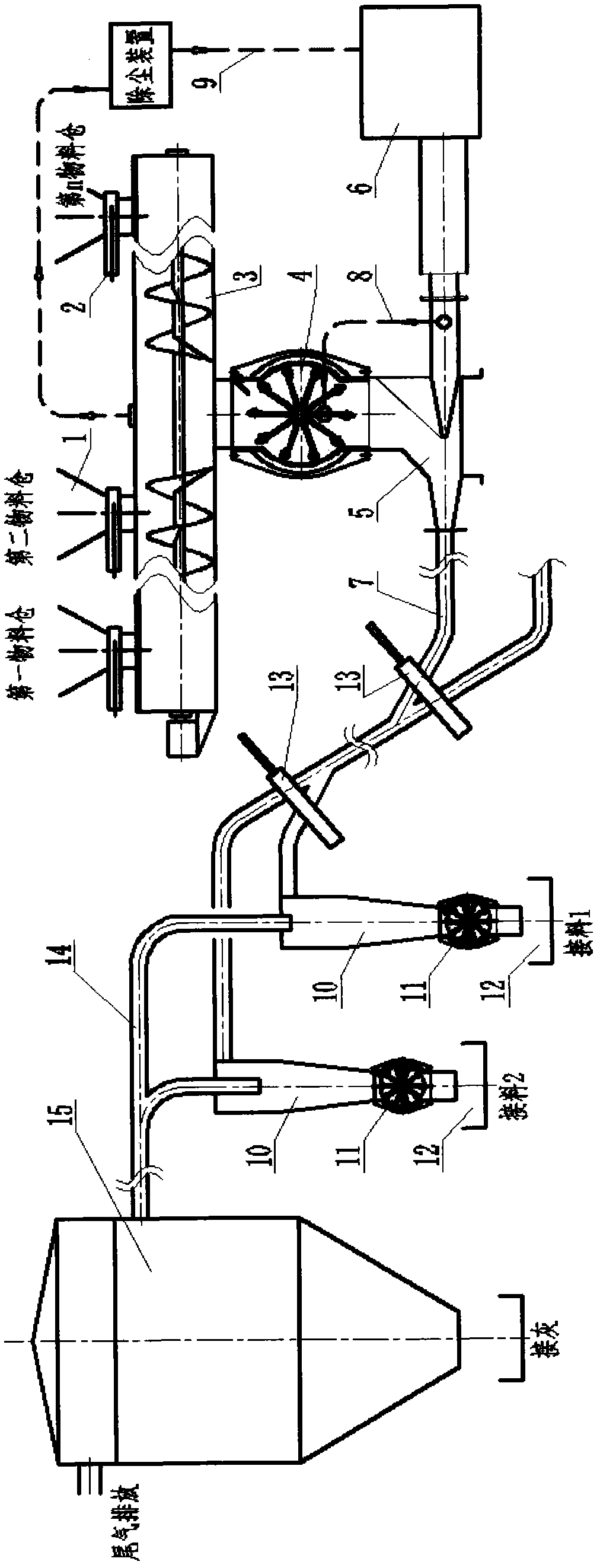

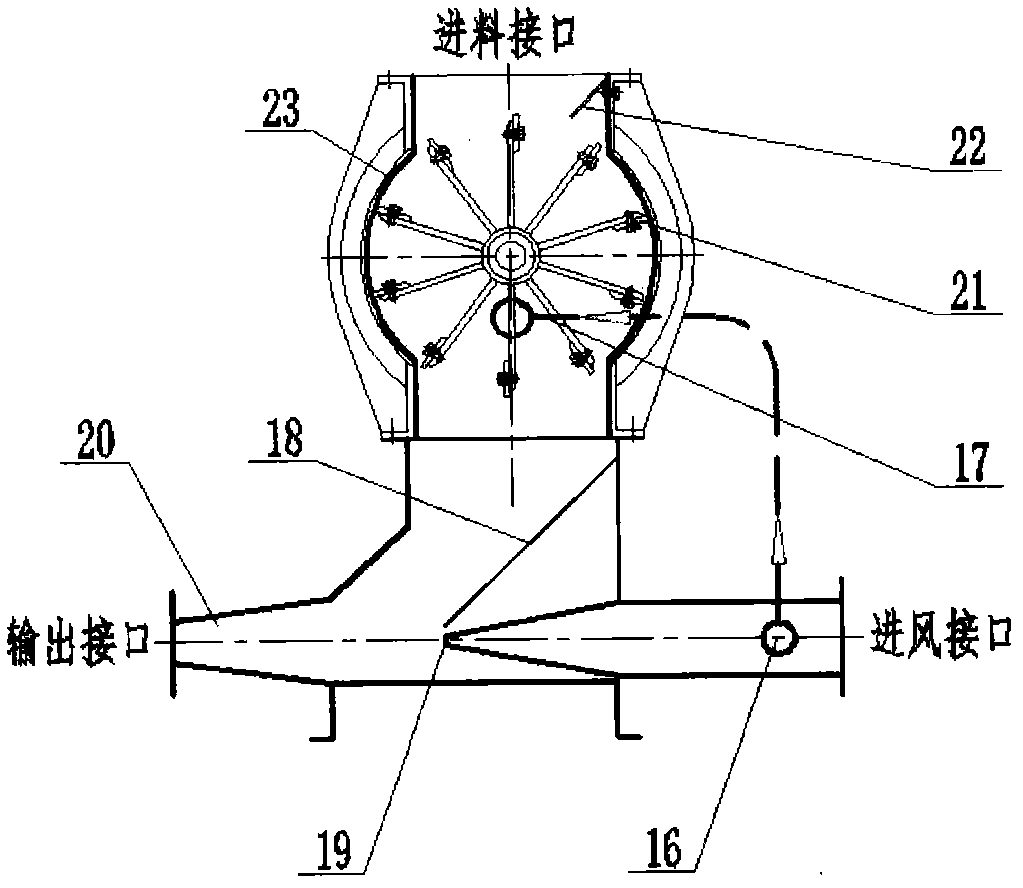

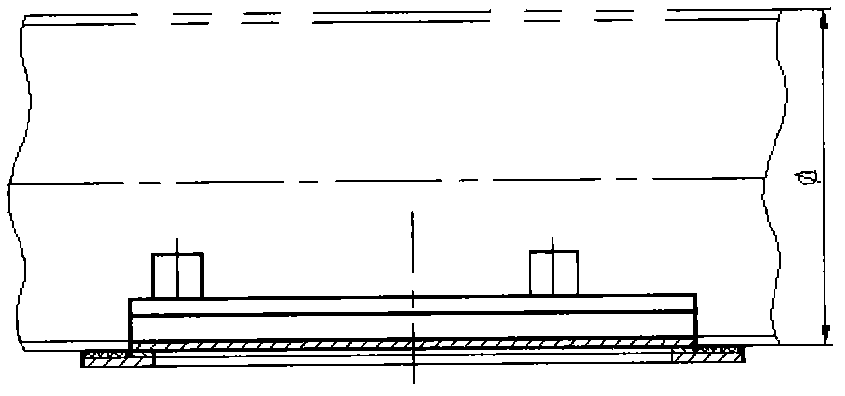

[0065] refer to Figure 1-6 As shown, the biomass micro-positive pressure conveying system is fed by the material bin 1, the material bin 1 is connected to the quantitative feeding device 2, and the quantitative feeding device 2 is connected to the collecting device 3. When multi-point feeding, the collecting device has corresponding multiple The feed port, the collecting device 3 are connected to the positive pressure air shutoff device 4, the lower outlet of the positive pressure air shutoff device 4 is connected to the upper opening of the accelerator 5, and the air outlet of the blower fan 6 is connected to the air inlet of the accelerator 5. The air pipe between the blower fan 6 and the accelerator is provided with an air inlet 16, and the end of the lower chamber of the positive pressure air shutoff device 4 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com