In situ chain extension repairing-based regenerated ABS/HIPS alloy material and preparation method thereof

An alloy material and in-situ technology, applied in the field of preparation of the above-mentioned recycled alloys, can solve problems such as limited compatibility, reduced performance of recycled materials, deterioration of toughness, etc., to achieve growth and repair of broken chains, improve interface force weakening, increase The effect of chain extension potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

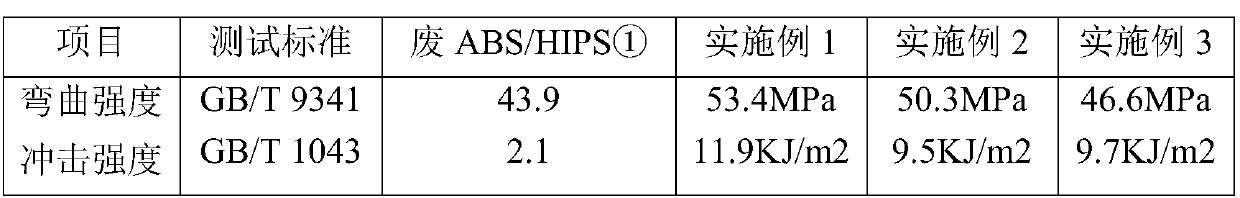

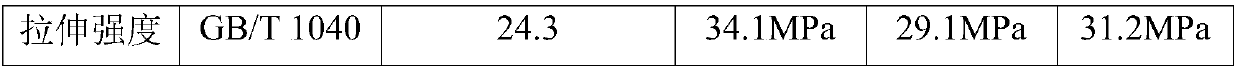

Examples

Embodiment 1

[0036] The recycled ABS / HIPS alloy material based on in-situ chain extension repair provided in this example is mainly composed of the following components by mass:

[0037] Mixture of waste ABS and waste HIPS: 100

[0038] ABS-based macromolecular chain extender: 5

[0039] HIPS-based macromolecular chain extender: 5.

[0040] Wherein the macromolecular chain extender is ABS grafted oxazoline, which is prepared by the following method: taking ABS high-glue powder, ethanolamine and zinc acetate as raw materials, 2,6-dichlorotoluene as solvent, and placing it in a reaction vessel to adjust The temperature is 170° C. after cold reflux reaction for 3 hours, and then the frozen precipitate is sucked and dried to obtain the macromolecular chain extender ABS grafted oxazoline.

[0041] The mass ratio of ABS high rubber powder, ethanolamine and zinc acetate is 100:50:3.

[0042] The consumption of 2,6-dichlorotoluene is 10 times of the total mass of raw material ABS high rubber po...

Embodiment 2

[0049] The regenerated ABS / HIPS alloy material based on in-situ chain extension repair provided in this example is composed of the following components by mass:

[0050] Mixture of waste ABS and waste HIPS: 100

[0051] ABS-based macromolecular chain extender: 3

[0052] HIPS-based macromolecular chain extender: 5.

[0053] Wherein the macromolecular chain extender is ABS grafted oxazoline, which is prepared by the following method: taking ABS high-glue powder, ethanolamine and zinc acetate as raw materials, 2,6-dichlorotoluene as solvent, and placing it in a reaction vessel to adjust The temperature is 180° C. after cold reflux reaction for 2 hours, and then the frozen precipitate is suction-filtered and dried to obtain the macromolecular chain extender ABS-grafted oxazoline.

[0054] The mass ratio of ABS high rubber powder, ethanolamine and zinc acetate is 100:30:2.

[0055] The consumption of 2,6-dichlorotoluene is 8 times of the total mass of raw material ABS high rubb...

Embodiment 3

[0062] The recycled ABS / HIPS alloy material based on in-situ chain extension repair provided in this example is mainly composed of the following components by mass:

[0063] Mixture of waste ABS and waste HIPS: 100

[0064] ABS-based macromolecular chain extender: 5

[0065] HIPS-based macromolecular chain extender: 3.

[0066] Wherein the ABS-based macromolecular chain extender is the same as in Example 1.

[0067] The HIPS-based macromolecular chain extender is the same as in Example 1.

[0068] The mixture of waste ABS and waste HIPS is the same as in Example 1.

[0069] The preparation method of the regenerated ABS / HIPS alloy material based on in-situ chain extension repair comprises the following steps: mixing waste ABS, waste HIPS mixture, and HIPS-based macromolecular chain extender according to the above-mentioned dosage relationship to obtain a mixed material, which is obtained from a twin-screw The main feeding device of the extruder adds the mixed material to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com