Method for purifying byproduct phosphogypsum of wet-process phosphoric acid

A wet-process phosphoric acid and purification method technology, applied in the field of phosphogypsum, can solve the problems of less than 20% effective utilization rate, immature industrialized devices, heavy burden on production enterprises, etc., and achieve continuous, stable and reliable production, low total energy consumption, and easy The effect of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

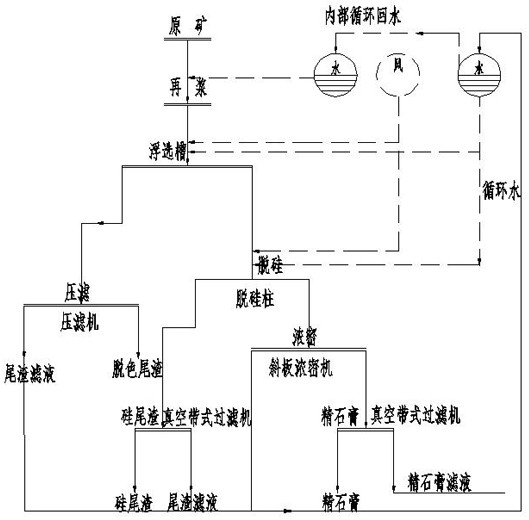

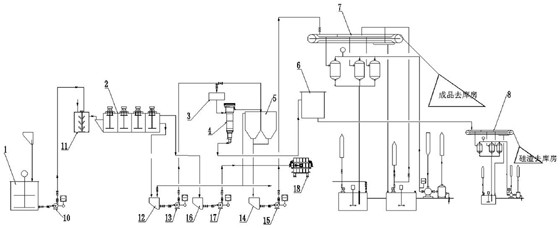

[0028] In the present embodiment, a kind of purification method of the by-product phosphogypsum of wet-process phosphoric acid comprises the following steps:

[0029] A. Decolorization of flotation tank: 420 tons of by-product phosphogypsum in the phosphoric acid process, add water to adjust to a slurry with a mass concentration of 38%, pump it into the dosing mixing tank, and add decolorization agent at a ratio of 0.15‰ at the same time, mix evenly, overflow into the float Choose a slot. Under the action of aeration and stirring, the pulp and the microbubbles collide and adsorb. Due to the difference in the physical and chemical properties of the surface of mineral particles, impurities such as carbon-containing particles and organic matter adhere to the foam, and are separated from the minerals by virtue of the buoyancy of the bubbles. 378 tons of useful minerals sink into concentrate and are discharged from the bottom into the next process; 42 tons of impurities such as car...

Embodiment 2

[0034] In the present embodiment, a kind of purification method of the by-product phosphogypsum of wet-process phosphoric acid comprises the following steps:

[0035] A. Decolorization of flotation tank: 420 tons of by-product phosphogypsum in the phosphoric acid process, add water to adjust to a slurry with a mass concentration of 28%, pump it into the dosing mixing tank, and add decolorization agent at a ratio of 0.18‰ at the same time, mix evenly, overflow into the float Choose a slot. Under the action of aeration and stirring, the pulp and the microbubbles collide and adsorb. Due to the difference in the physical and chemical properties of the surface of mineral particles, impurities such as carbon-containing particles and organic matter adhere to the foam, and are separated from the minerals by virtue of the buoyancy of the bubbles. 378 tons of useful minerals sink into concentrate and are discharged from the bottom into the next process; 42 tons of impurities such as car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com