Preparation method used for sintering of building ceramsite from electroplating sludge

A technology of electroplating sludge and ceramsite, which is applied in the field of recycling of hazardous waste, can solve the problems of destroying the ecological environment and not conforming to the sustainable development strategy, and achieve the effect of reducing the concentration of leaching, reducing the risk of environmental pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

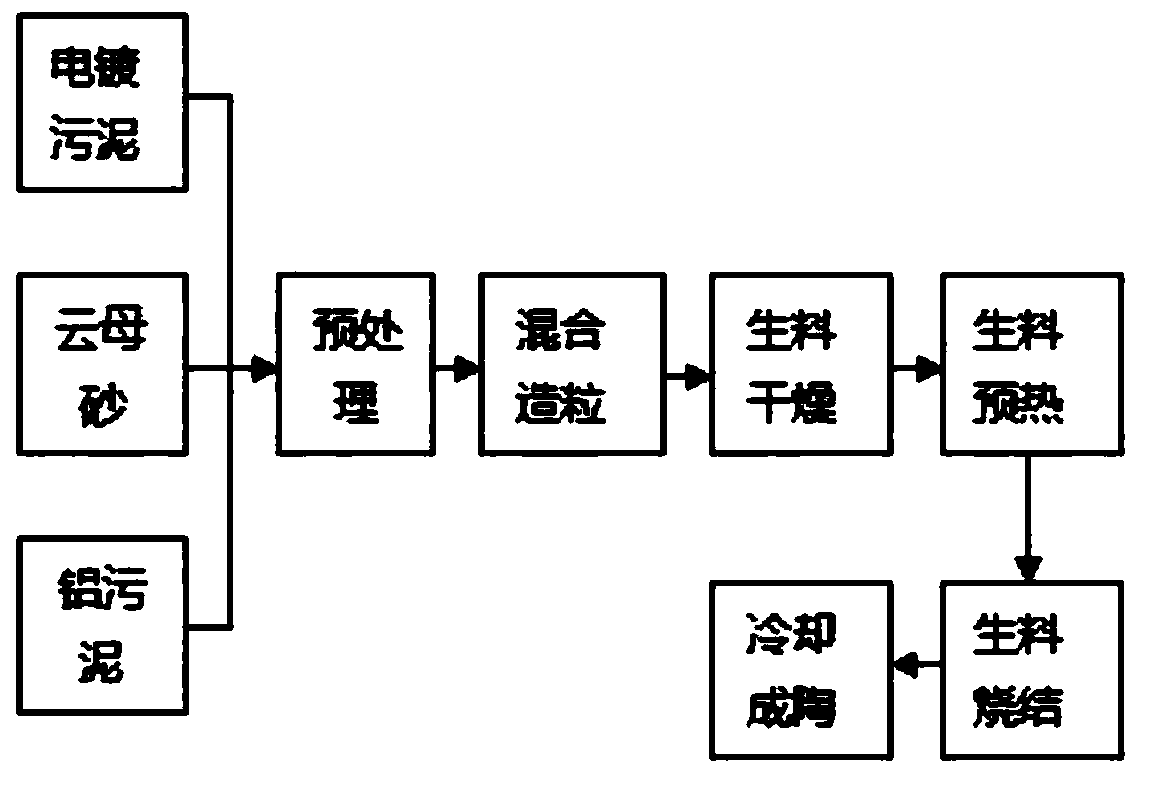

[0029] Such as figure 1 Shown, the preparation method of a kind of electroplating sludge sintered ceramsite of the present invention comprises the steps:

[0030] (1) Dry the electroplating sludge, mica sand, and aluminum sludge to constant weight respectively, grind them into powder and sieve through an 80-mesh sieve;

[0031] (2) mixing and stirring electroplating sludge, mica sand, and aluminum sludge evenly to obtain ceramsite raw materials;

[0032] (3) adding 3% to 5% sodium silicate solution as a ceramsite binder to the ceramsite raw material obtained in step (2), mixing and granulating to obtain raw ceramsite;

[0033] (4) Put the raw ceramsite obtained in step (3) into a muffle furnace at a heating rate of 10ºC / min, first raise the temperature to 105ºC for 1 hour, then raise the temperature to 500ºC for preheating for 15 minutes, and finally raise the temperature to 1200ºC Sintering for 25min;

[0034] (5) Let the sintered ceramsite slowly cool down to room tempera...

Embodiment 1

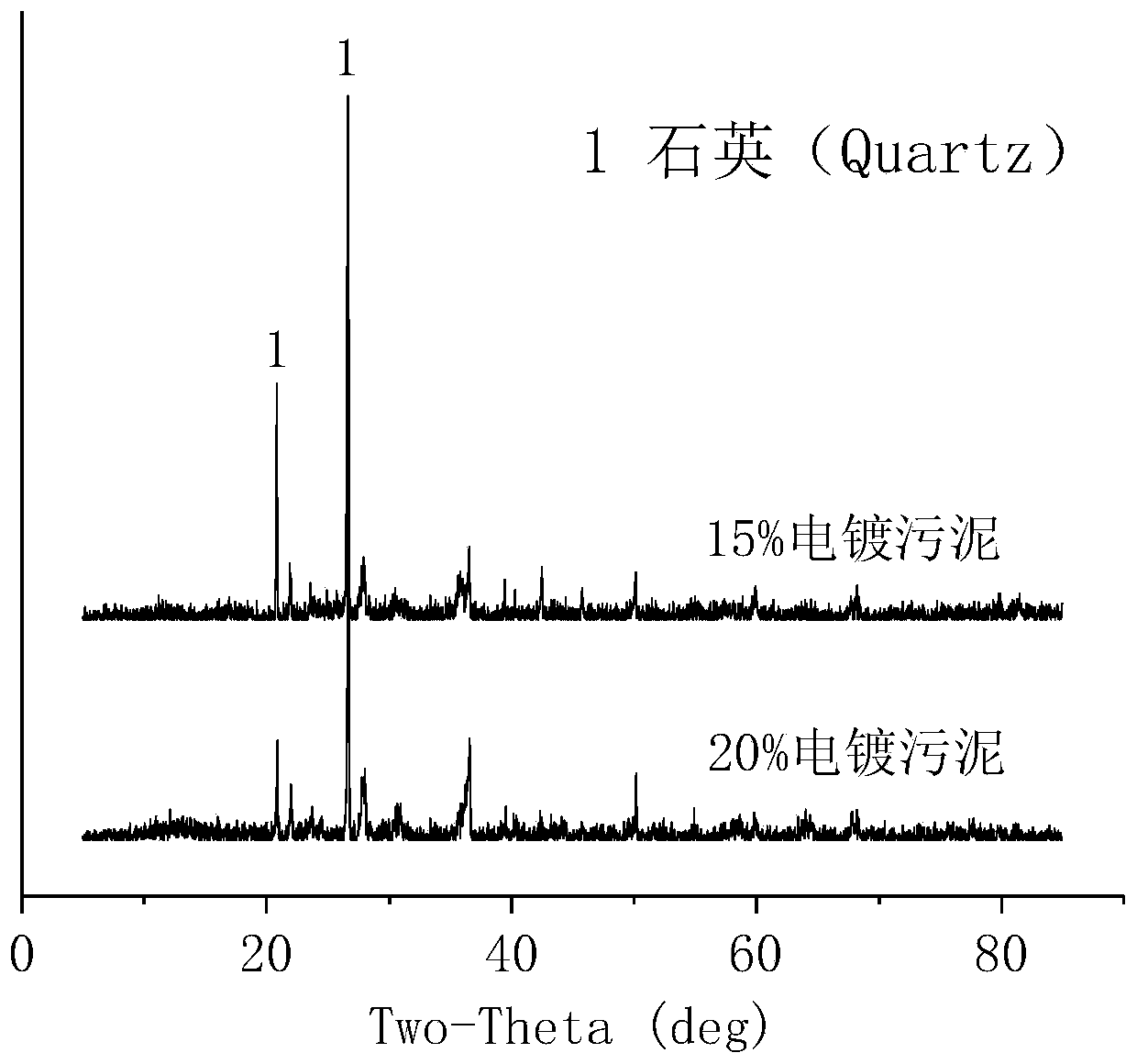

[0042] The invention discloses a preparation method of electroplating sludge sintered ceramsite. The raw material of the ceramsite is composed of 15% of electroplating sludge, 65% of mica sand and 20% of aluminum sludge.

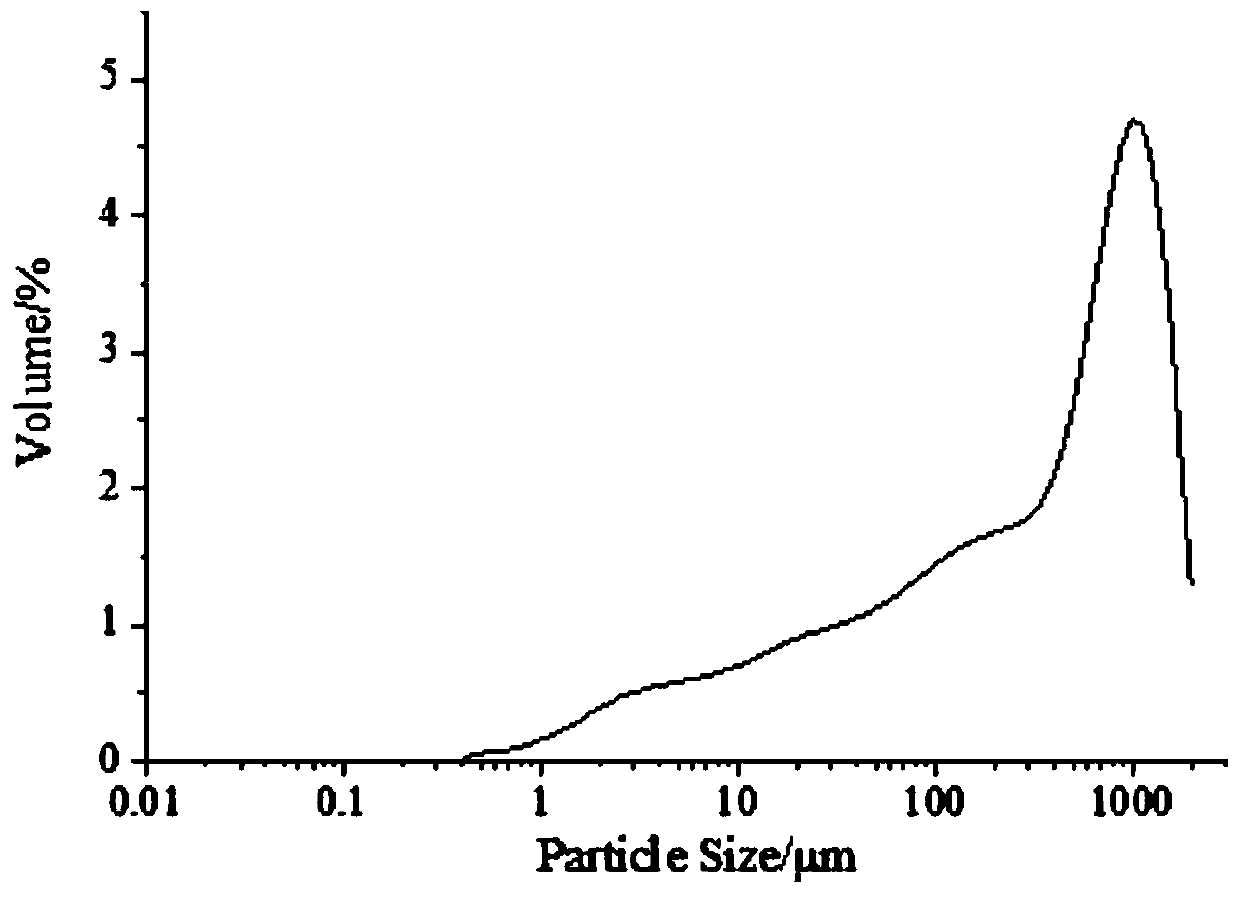

[0043] (1) Place the electroplating sludge, mica sand, and aluminum sludge in an oven at 105°C to dry to constant weight, grind them into powder and sieve through an 80-mesh sieve for use;

[0044] (2) mixing and stirring electroplating sludge, mica sand, and aluminum sludge in proportion to obtain ceramsite raw materials;

[0045] (3) adding 3% to 5% sodium silicate solution as a ceramsite binder to the ceramsite raw material obtained in step (2), mixing and granulating to obtain raw ceramsite;

[0046](4) Put the raw ceramsite obtained in step (3) into a muffle furnace at a heating rate of 10ºC / min, first raise the temperature to 105ºC for 1 hour, then raise the temperature to 500ºC for preheating for 15 minutes, and finally raise the temperature to 1200ºC...

Embodiment 2

[0053] The invention discloses a method for preparing electroplating sludge sintered ceramsite. The raw materials of the ceramsite are composed of 20% of electroplating sludge, 60% of mica sand and 20% of aluminum sludge.

[0054] (1) Place the electroplating sludge, mica sand, and aluminum sludge in an oven at 105°C to dry to constant weight, grind them into powder and sieve through an 80-mesh sieve for use;

[0055] (2) mixing and stirring electroplating sludge, mica sand, and aluminum sludge in proportion to obtain ceramsite raw materials;

[0056] (3) adding 3% to 5% sodium silicate solution as a ceramsite binder to the ceramsite raw material obtained in step (2), mixing and granulating to obtain raw ceramsite;

[0057] (4) Put the raw ceramsite obtained in step (3) into a muffle furnace at a heating rate of 10ºC / min, first raise the temperature to 105ºC for 1 hour, then raise the temperature to 500ºC for preheating for 15 minutes, and finally raise the temperature to 1200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com