Single-fired glass ceramic composite brick and production method thereof

A technology of glass-ceramic ceramics and a production method, which is applied in the field of ceramic tile production, can solve the problem of strict requirements on the technical level of transparent micro-crystalline dry particles and production process management, the increase of related shrinkage pinhole defects, and the difficulty of reducing the glass-ceramic layer. Thinness and other problems, to improve thermal stability and acid and alkali resistance, reduce cold working cracking, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

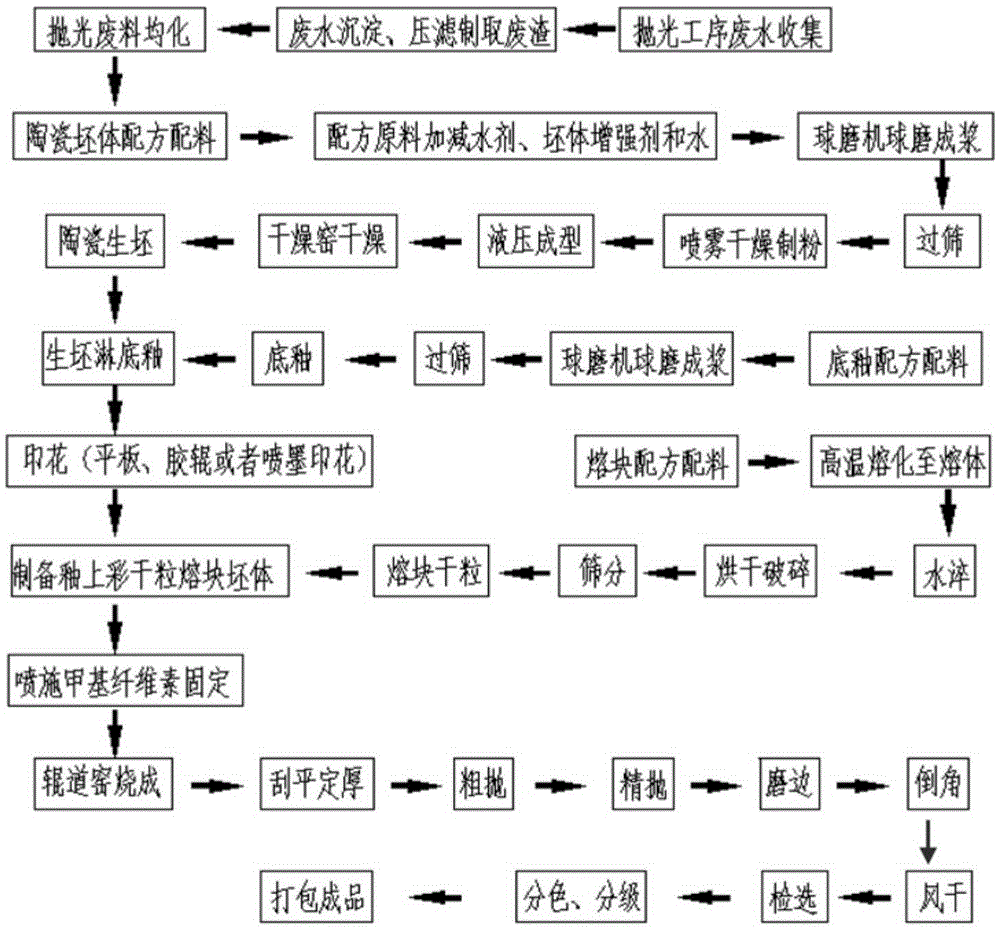

Method used

Image

Examples

Embodiment 1

[0043] The production method of the once-fired glass-ceramic composite brick has the following steps:

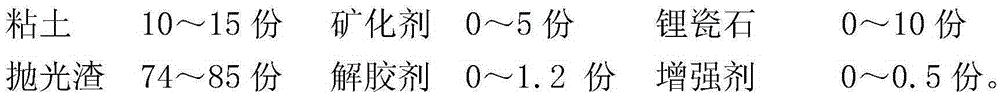

[0044] (1) preparing ceramic tile blanks, the ceramic tile blank formula is composed of the following components by weight:

[0045]

[0046] The ingredients are wet-milled and spray-dried, and then dry-pressed to obtain a ceramic green body, which is crushed to less than 5mm;

[0047] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0048] (3) Preparation of glass-ceramic composite tile glaze body, the composite tile glaze body is composed of the following components in parts by weight: 81 parts of HG-1 frit, 12 parts of kaolin, ...

Embodiment 2

[0058] The production method of the once-fired glass-ceramic composite brick has the following steps:

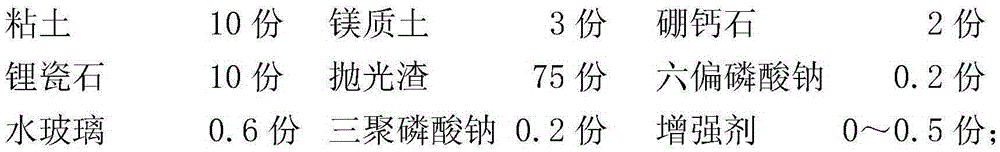

[0059] (1) preparing ceramic tile blanks, the ceramic tile blank formula is composed of the following components by weight:

[0060]

[0061] After batching, wet ball milling, spray drying, and dry pressing to obtain ceramic green bodies, which are crushed to less than 5mm;

[0062] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0063] (3) Prepare the glass-ceramic composite tile glaze base, and the composite tile glaze base is made up of the following components by weight:

[0064] HG-1 frit 90 parts kaolin 8 parts quartz 2 pa...

Embodiment 3

[0074] The production method of the once-fired glass-ceramic composite brick has the following steps:

[0075] (1) preparing ceramic tile blanks, the ceramic tile blank formula consists of the following components in parts by weight:

[0076]

[0077] After the formula is prepared, the ceramic green body is made by wet ball milling, spray drying, and then dry pressing, which is crushed to less than 5mm;

[0078] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0079] (3) Prepare the glass-ceramic composite tile glaze blank,

[0080] Preparation of glass-ceramic composite tile glaze body: the composite tile glaze body consists of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com