Furfural production process system for conveying raw materials in closed mode

A production process and raw material technology, applied in the field of furfural production system, can solve the problems of large space occupation, high maintenance rate, dust pollution, etc., and achieve the effect of compact appearance, high conveying efficiency, and no dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

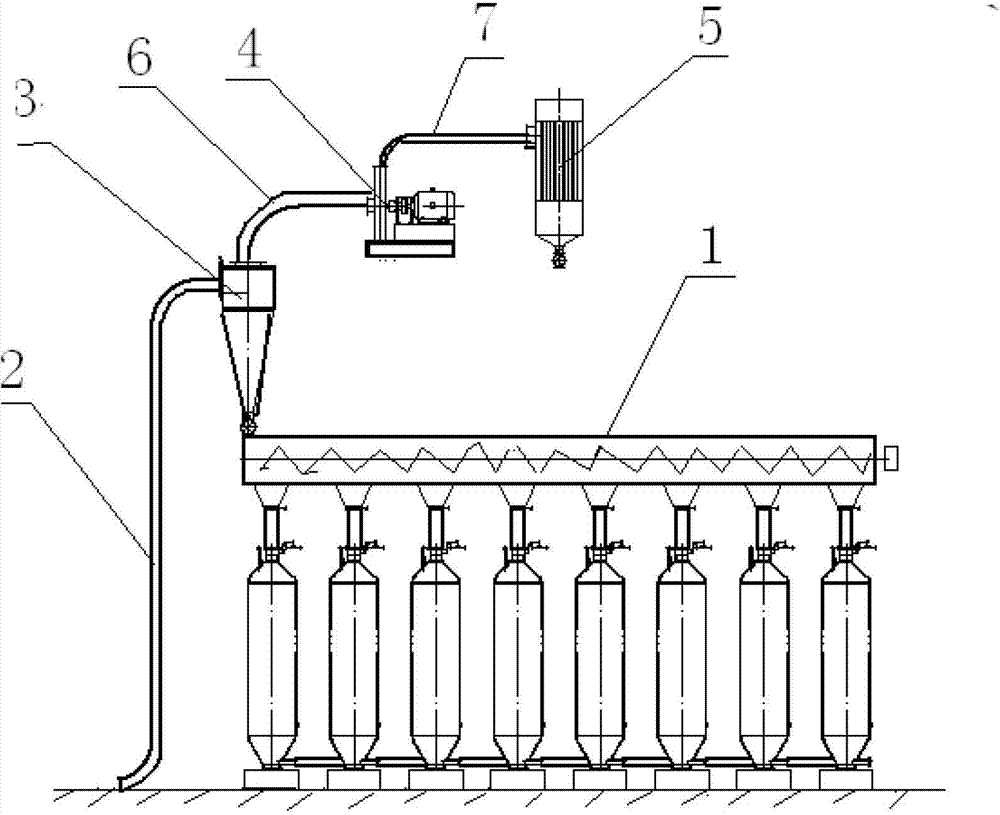

[0008] Such as figure 1 The furfural production process system shown in the closed delivery of raw materials is composed of several hydrolysis kettles and a feeding system. A hydrolysis kettle silo 1 is arranged on the hydrolysis kettle, and a screw conveyor is arranged in the hydrolysis kettle silo 1; wherein, the feeding system adopts Negative pressure conveying equipment, the negative pressure conveying equipment includes a cyclone separator 3 installed on the inlet of the hydrolysis tank silo 1, the top air outlet of the cyclone separator 3 is connected to the exhaust pipe 6, and the side feed port is connected to the feed pipe 2 , the exhaust pipe 6 is connected to the air inlet of the exhaust fan 4, and the feed pipe 2 hangs down into the raw material pile; in order to remove the dust drawn out by the exhaust fan 4, the pulse bag is connected to the air outlet of the exhaust fan 4 through the dust removal pipe 7 Dust collector 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com