Sandwich layer used for making light partition wall batten

A technology of lightweight partition wall slats and sandwich layers, which is applied in the field of building materials, can solve the problems of low production efficiency, high thermal conductivity, and low porosity, and achieve high production efficiency, low thermal conductivity, and high added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

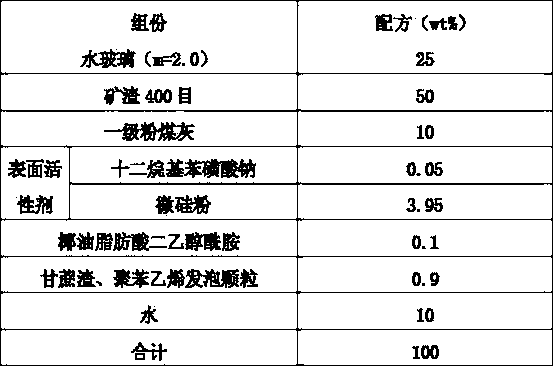

[0024] Formula one of the present invention:

[0025]

[0026] Preparation:

[0027] (1) Prepare the raw materials for preparing the sandwich layer according to the proportion, mix the raw materials except boiling water glass, light filler and water evenly to obtain powder materials, and set aside;

[0028] (2) Now add the light filler into the mixer, and then add the water glass into the rotating mixer, stir for 2-5 minutes, then add the powder material and water, and continue to stir until the slurry is uniform and paste , the order of the feeding process cannot be disturbed, otherwise the prepared core material slurry will not be full and the viscosity will be poor;

[0029] (3) Place the calcium silicate board on both sides of the mold, with the grouting space in the middle, and the mold has a concave-convex shape, so that the board after demoulding can have a concave-convex interface;

[0030] (4) Pour the stirred slurry into the mold by pumping, and vibrate the mold...

Embodiment 2

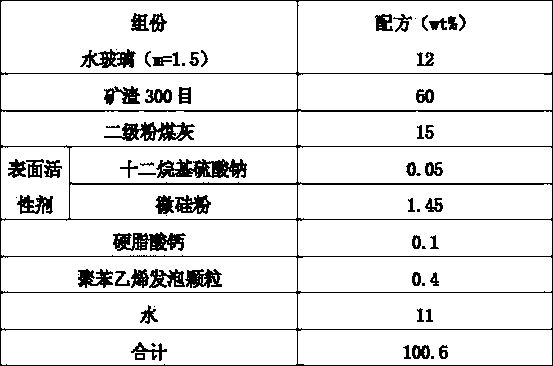

[0035] Formula two of the present invention:

[0036]

[0037] Preparation:

[0038] (1) Prepare the raw materials for preparing the sandwich layer according to the proportion, mix the raw materials except boiling water glass, light filler and water evenly to obtain powder materials, and set aside;

[0039] (2) Now add the light filler into the mixer, and then add the water glass into the rotating mixer, stir for 2-5 minutes, then add the powder material and water, and continue to stir until the slurry is uniform and paste , the order of the feeding process cannot be disturbed, otherwise the prepared core material slurry will not be full and the viscosity will be poor;

[0040] (3) Place the calcium silicate board on both sides of the mold, with the grouting space in the middle, and the mold has a concave-convex shape, so that the board after demoulding can have a concave-convex interface;

[0041] (4) Pour the stirred slurry into the mold by pumping, and vibrate the mold...

Embodiment 3

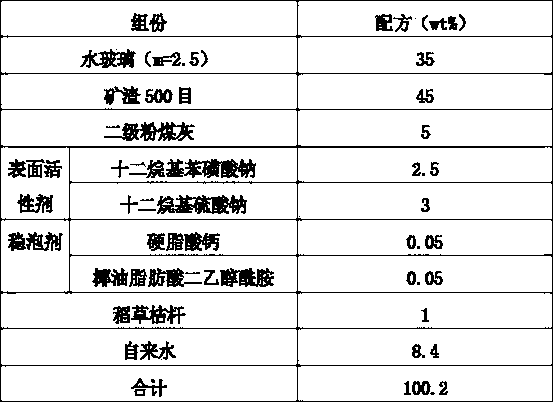

[0046] Formula three of the present invention:

[0047]

[0048] Preparation:

[0049] (1) Prepare the raw materials for preparing the sandwich layer according to the proportion, mix the raw materials except boiling water glass, light filler and water evenly to obtain powder materials, and set aside;

[0050] (2) Now add the light filler into the mixer, and then add the water glass into the rotating mixer, stir for 2-5 minutes, then add the powder material and water, and continue to stir until the slurry is uniform and paste , the order of the feeding process cannot be disturbed, otherwise the prepared core material slurry will not be full and the viscosity will be poor;

[0051] (3) Place the calcium silicate board on both sides of the mold, with the grouting space in the middle, and the mold has a concave-convex shape, so that the board after demoulding can have a concave-convex interface;

[0052] (4) Pour the stirred slurry into the mold by pumping, and vibrate the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com