Cesium tungsten bronze powder and preparation method thereof

A technology of cesium tungsten bronze and powder, which is applied in the field of pure cesium tungsten bronze powder and its preparation, can solve the problems of harmfulness to the human body and the environment, high cost of raw materials, and easy volatility, so as to achieve wide application prospects and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

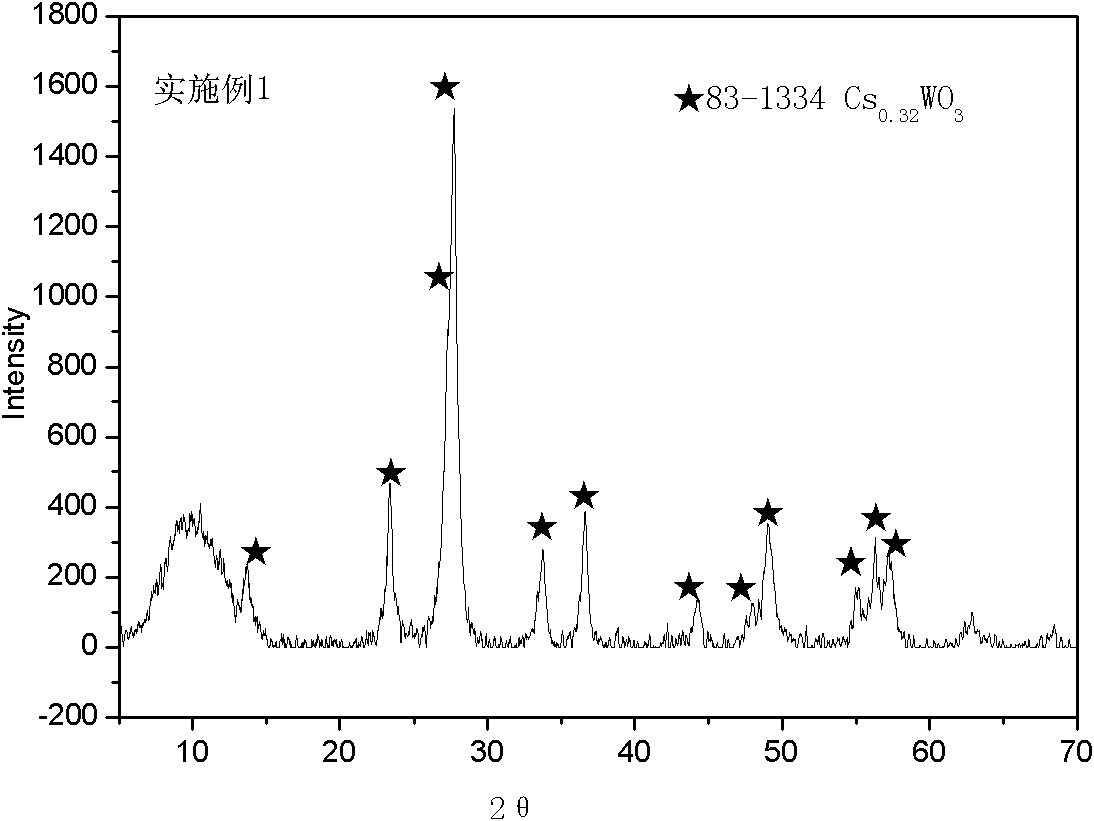

Embodiment 1

[0037] Prepare Cs with Cs / W (molar ratio)=0.3:1 0.3 WO 3 Powder.

[0038] ① Prepare 0.5mol / L tungstic acid solution:

[0039] Weigh a certain amount of sodium tungstate, dissolve it in deionized water, and prepare a 0.5mol / L sodium tungstate solution, and use styrene cation exchange resin to ion-exchange the sodium tungstate solution to obtain 0.5mol / L tungstic acid solution;

[0040] ② Prepare cesium carbonate solution and citric acid solution;

[0041] Weigh 0.488g of cesium carbonate, dissolve in deionized water, and make a 0.3mol / L cesium carbonate solution; weigh 6.3g of citric acid, dissolve in deionized water, and make a 1mol / L citric acid solution;

[0042] ③ Preparation of Cs 0.3 WO 3 The reaction precursor solution;

[0043] Take 20ml of the 0.5mol / L tungstic acid solution prepared above, put it into a beaker, add 30ml of 1mol / L citric acid solution once during stirring, slowly add 5ml of 0.3mol / L cesium carbonate solution dropwise, and continue stirring for 1...

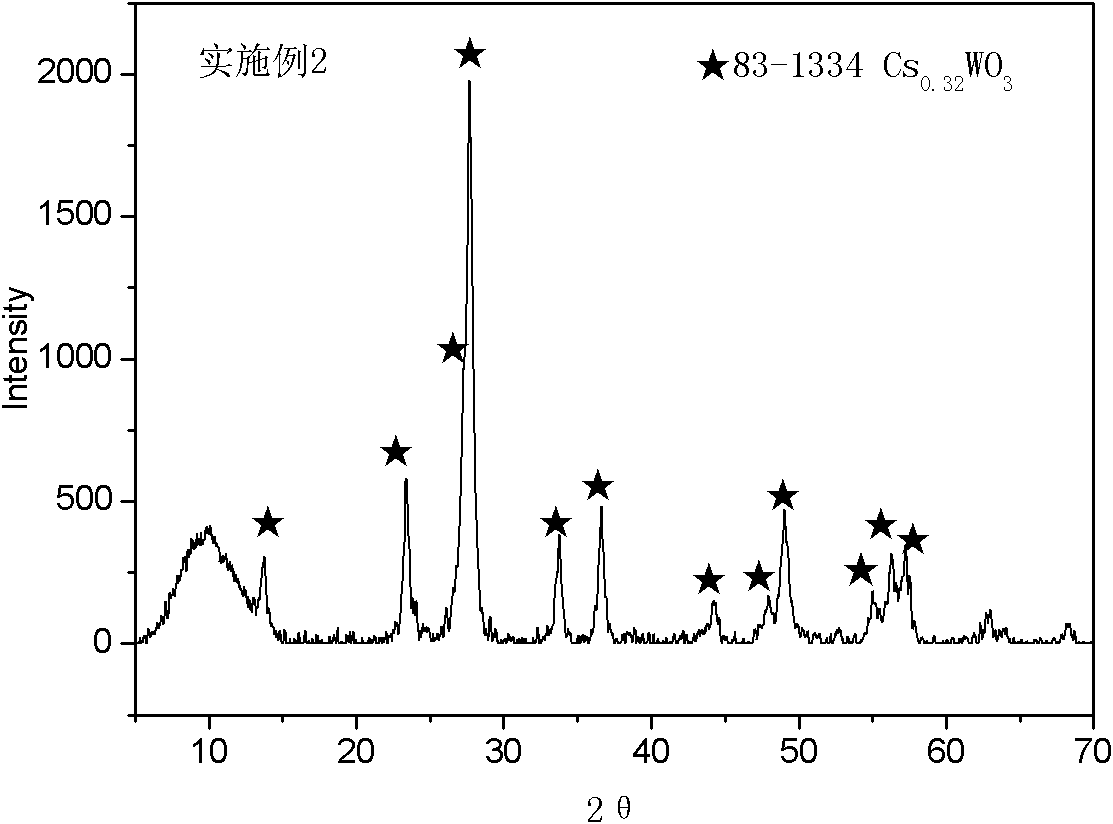

Embodiment 2

[0048] Prepare Cs with Cs / W (molar ratio)=0.3:1 0.3 WO 3 Powder.

[0049] ① Prepare 0.5mol / L tungstic acid solution: same as step ① in Example 1;

[0050] ② Prepare cesium carbonate solution and citric acid solution;

[0051] Weigh 0.488g of cesium carbonate, dissolve in deionized water, and make a 0.3mol / L cesium carbonate solution; weigh 12.6g of citric acid, dissolve in deionized water, and make a 2mol / L citric acid solution;

[0052] ③ Preparation of Cs 0.3 WO 3 The reaction precursor solution;

[0053] Take 20ml of the 0.5mol / L tungstic acid solution prepared above, put it into a beaker, add 30ml of 2mol / L citric acid solution once during stirring, slowly add 5ml of 0.3mol / L cesium carbonate solution dropwise, and continue stirring for 1h to obtain Preparation of Cs 0.3 WO 3 Powder reaction precursor solution, the concentration of tungstic acid in the precursor is 0.18mo / L, and the concentration of citric acid is 1.10mol / L;

[0054] ④Transfer the reaction precurs...

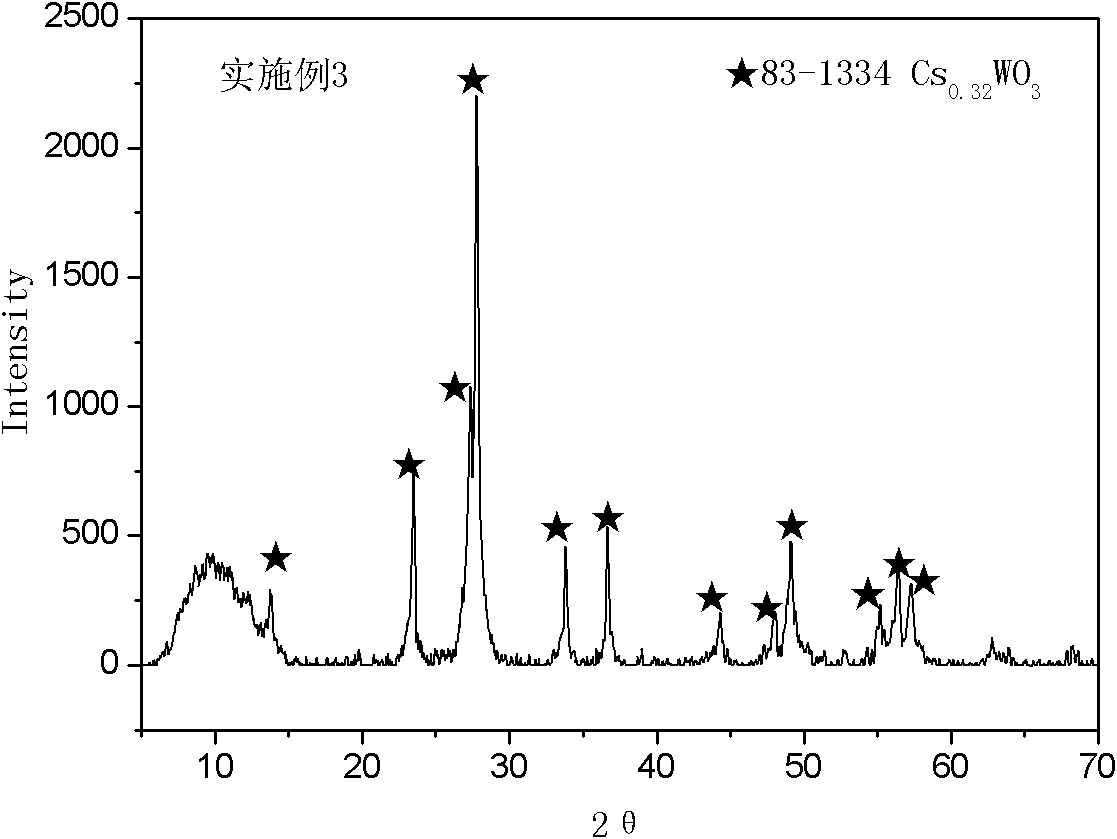

Embodiment 3

[0058] Prepare Cs with Cs / W (molar ratio)=0.3:1 0.3 WO 3 Powder.

[0059] ① Prepare 0.5mol / L tungstic acid solution: same as step ① in Example 1;

[0060] ② Preparation of cesium carbonate solution:

[0061] Weigh 0.488g of cesium carbonate, dissolve in deionized water, and make 0.3mol / L cesium carbonate solution;

[0062] ③ Preparation of Cs 0.3 WO 3 The reaction precursor solution;

[0063] Take 20ml of the above-prepared 0.5mol / L tungstic acid solution, put it into a beaker, add 12.6g of citric acid once during stirring, after stirring evenly, slowly add 5ml of 0.3mol / L cesium carbonate solution dropwise, and then add 30ml Absolute ethanol, continue to stir for 1h, obtain preparation Cs 0.3 WO 3 The reaction precursor solution of the powder, the concentration of tungstic acid in the precursor is 0.18mol / L, the concentration of citric acid is 1.10mol / L, and the volume ratio of alcohol to water is 3:2;

[0064] ④ Transfer the reaction precursor solution prepared abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com