A kind of environment-friendly rubber release agent

An environmentally friendly rubber and release agent technology, applied in the field of release agents, can solve the problems of mass death of fish and other organisms, difficulties in processing, transportation and storage, and decrease in dissolved oxygen in water bodies. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

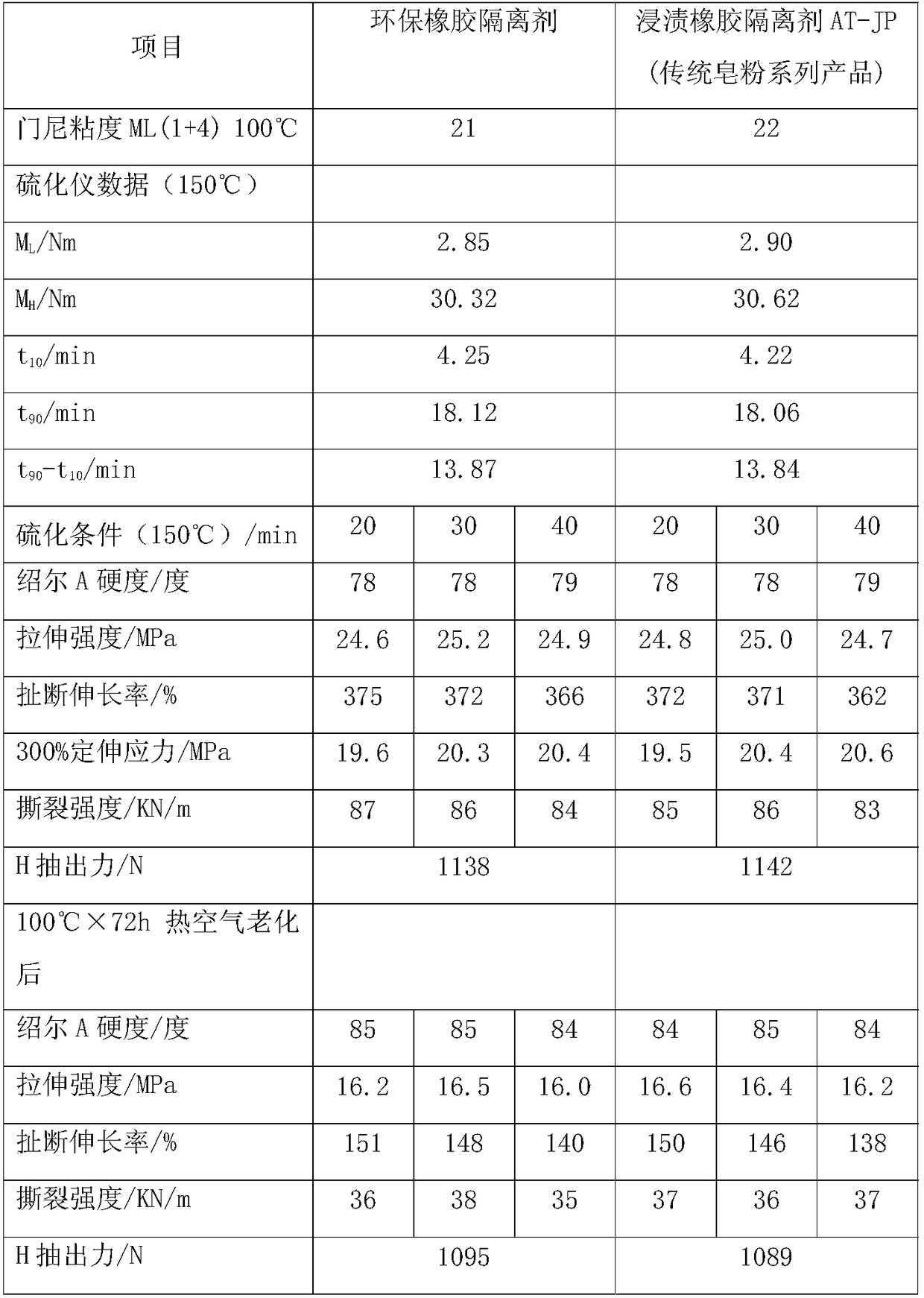

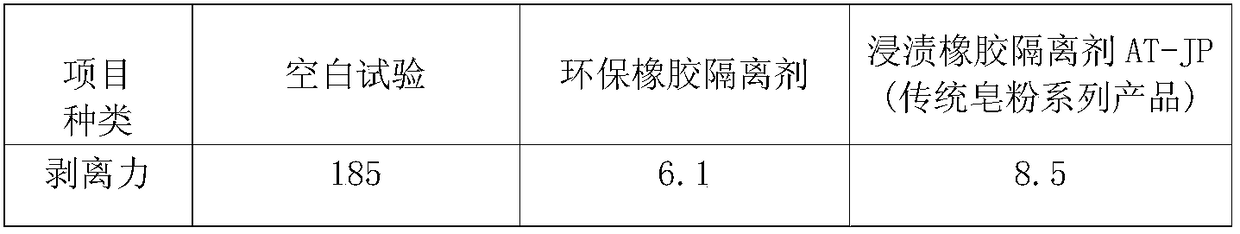

Examples

Embodiment 1

[0043] This embodiment provides an environmentally friendly rubber release agent. The release agent includes the following components in parts by weight: polyoxyethylene sorbitan monooleate: 24 parts, water-based polyamide wax: 2 parts, calcium stearate :30 parts, hydrated silicon dioxide: 18 parts, potassium stearate: 8 parts, silicone oil defoamer: 2 parts, sodium carboxymethyl cellulose: 2 parts.

[0044] The preparation process of the release agent is as follows:

[0045] Step (1): Put polyoxyethylene sorbitan monooleate into a high-speed mixer;

[0046] Step (2): Put the water-based polyamide wax and potassium stearate into the high-speed mixer, set the speed of the high-speed mixer to 600r / min, and stir for 2 minutes;

[0047] Step (3): Then put in hydrated silica, and continue to stir for 1 min while maintaining the rotation speed at 600r / min;

[0048] Step (4): Add calcium stearate into the high-speed mixer, and stir for 2 minutes at a rotation speed of 600r / min to obtain a sol...

Embodiment 2

[0052] This embodiment provides an environmentally friendly rubber release agent, which includes the following components in parts by weight: polyoxyethylene sorbitan monooleate: 36 parts, water-based polyamide wax: 4 parts, calcium stearate : 38 parts, hydrated silicon dioxide: 30 parts, potassium stearate: 14 parts, silicone oil defoamer: 5 parts, sodium carboxymethyl cellulose: 6 parts.

[0053] The preparation process of the release agent is as follows:

[0054] Step (1): Put polyoxyethylene sorbitan monooleate into a high-speed mixer;

[0055] Step (2): Put the water-based polyamide wax and potassium stearate into the high-speed mixer, set the speed of the high-speed mixer to 700r / min, and stir for 3 minutes;

[0056] Step (3): Then put in the hydrated silica, and continue to stir for 2 minutes while maintaining the rotation speed at 700r / min;

[0057] Step (4): Put calcium stearate into the high-speed mixer, and stir for 4 minutes at a speed of 700r / min to obtain a solubilized mo...

Embodiment 3

[0061] This embodiment provides an environmentally friendly rubber release agent, which includes the following components in parts by weight: polyoxyethylene sorbitan monooleate: 30 parts, water-based polyamide wax: 3 parts, calcium stearate : 35 parts, hydrated silica: 24 parts, potassium stearate: 12 parts, silicone oil defoamer: 3 parts, sodium carboxymethyl cellulose: 4 parts.

[0062] The preparation process of the release agent is as follows:

[0063] Step (1): Put polyoxyethylene sorbitan monooleate into a high-speed mixer;

[0064] Step (2): Put the water-based polyamide wax and potassium stearate into the high-speed mixer, set the speed of the high-speed mixer to 650r / min, and stir for 2 minutes;

[0065] Step (3): Then put in the hydrated silica, and keep stirring at 650r / min for 1 min;

[0066] Step (4): Add calcium stearate to the high-speed mixer, and stir for 3 minutes at a speed of 650r / min to obtain a solubilized modified intermediate;

[0067] Step (5): Put silicone oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com