Patents

Literature

46results about How to "Meet clean production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery method of glycolic acid in phenoxy carboxylic acid industrial wastewater

ActiveCN103193622AHigh puritySolve processing problemsCarboxylic compound separation/purificationPhenoxy acetic acidInorganic salts

The invention discloses a recovery method of glycolic acid in phenoxy carboxylic acid industrial wastewater. The recovery method comprises the following steps of: extracting the wastewater to remove most of the organic substances in the wastewater, and treating the extracted wastewater in the next step; evaporating and concentrating the wastewater to remove most of the inorganic salt in the wastewater; adjusting the pH value of the desalted wastewater to 1-4, carrying out reduced pressure distillation to remove most of the water in the wastewater, separating out salt from the wastewater in the distillation process, and filtering to remove the salt in the wastewater, thus obtaining more than 70% of henoxy carboxylic acid solution. The recovery method has the advantages of being simple in operation and low in cost, separating out the glycolic acid with high quality from the wastewater, solving the difficulty in treatment of phenoxy carboxylic acid industrial wastewater, being in line with national policy requirements, realizing resource utilization, obtaining good economic benefits, reducing product cost and achieving the clean production requirements.

Owner:SHANDONG WEIFANG RAINBOW CHEM

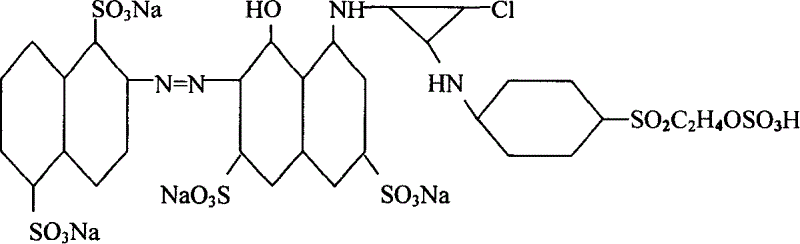

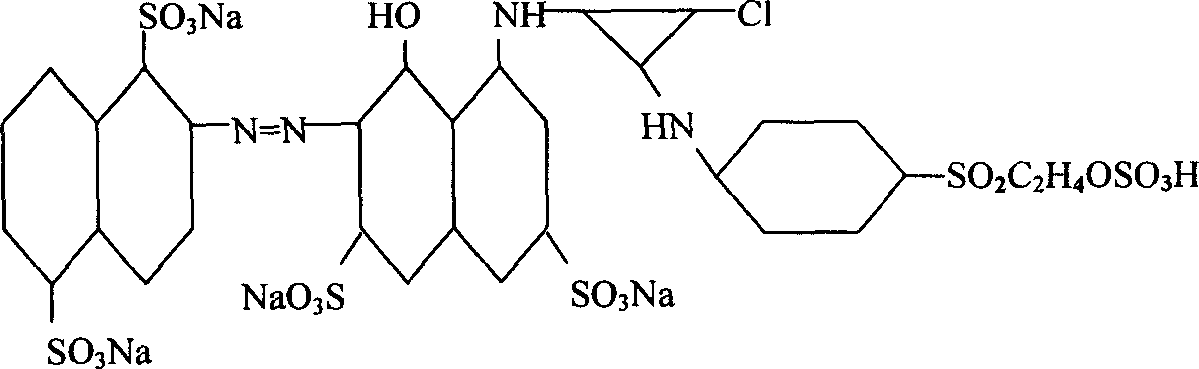

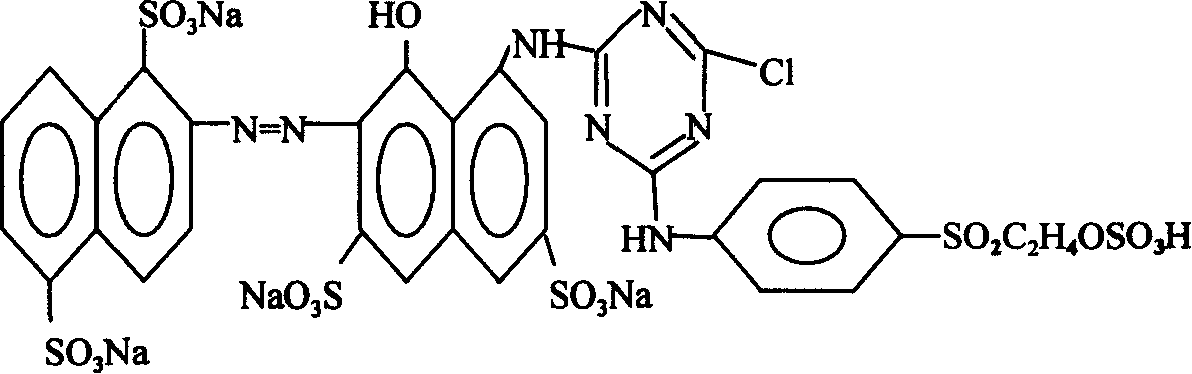

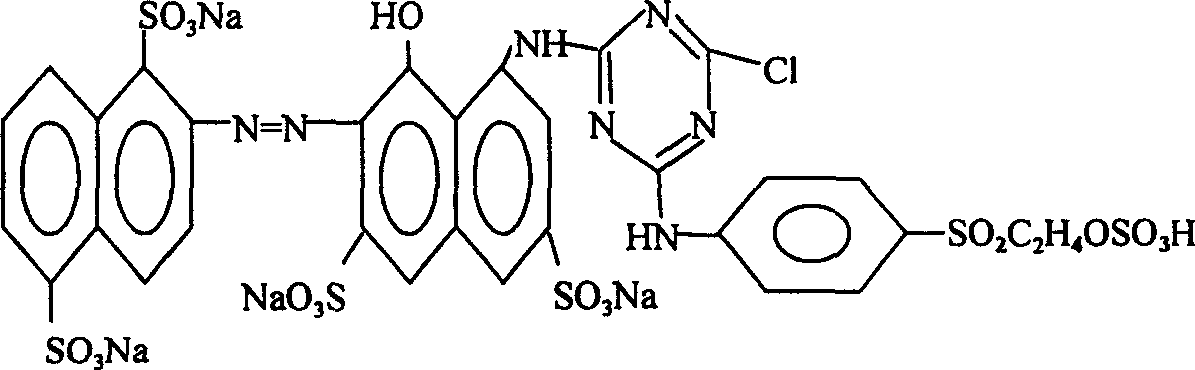

Active red SBE, synthetic method and its composite active red dye

Disclosed is a red SBE monomer which is prepared by beating the cyanuric chloride and dispersing agent into powder form at the presence of trash ice, charging dried p(beta-sulfate ethyl sulfone) phenylamine for primary condensation, controlling pH=2-4, the temperature 6-12 deg. C, charging dired H acid for second condensation, controlling the temperature between 25-35 deg. C, controlling pH=3-5, carrying out diazonium salt coupling with dried 1,5-disulfonic acid -2-naphthylamine, direct drying by spray.

Owner:无锡润新染料有限公司

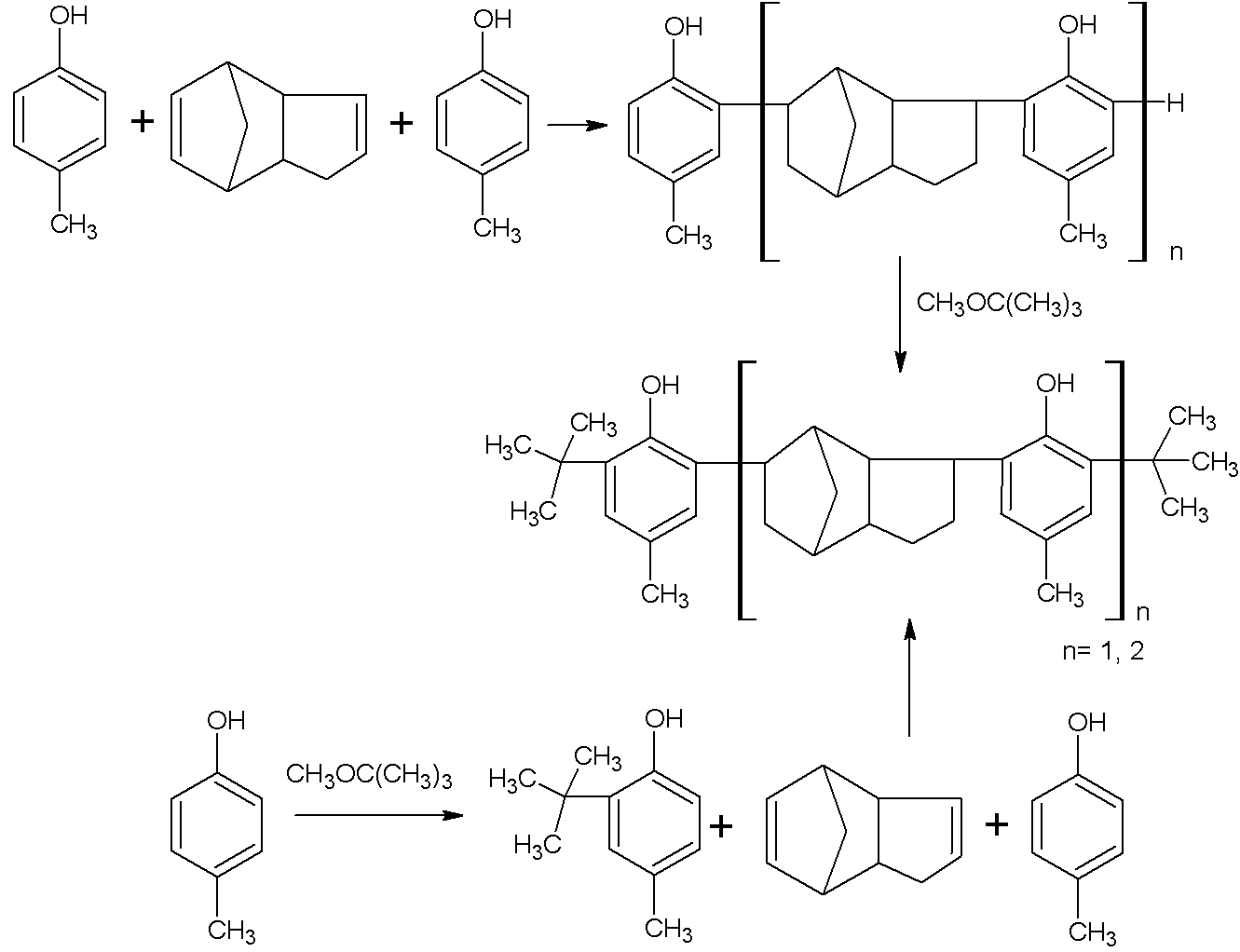

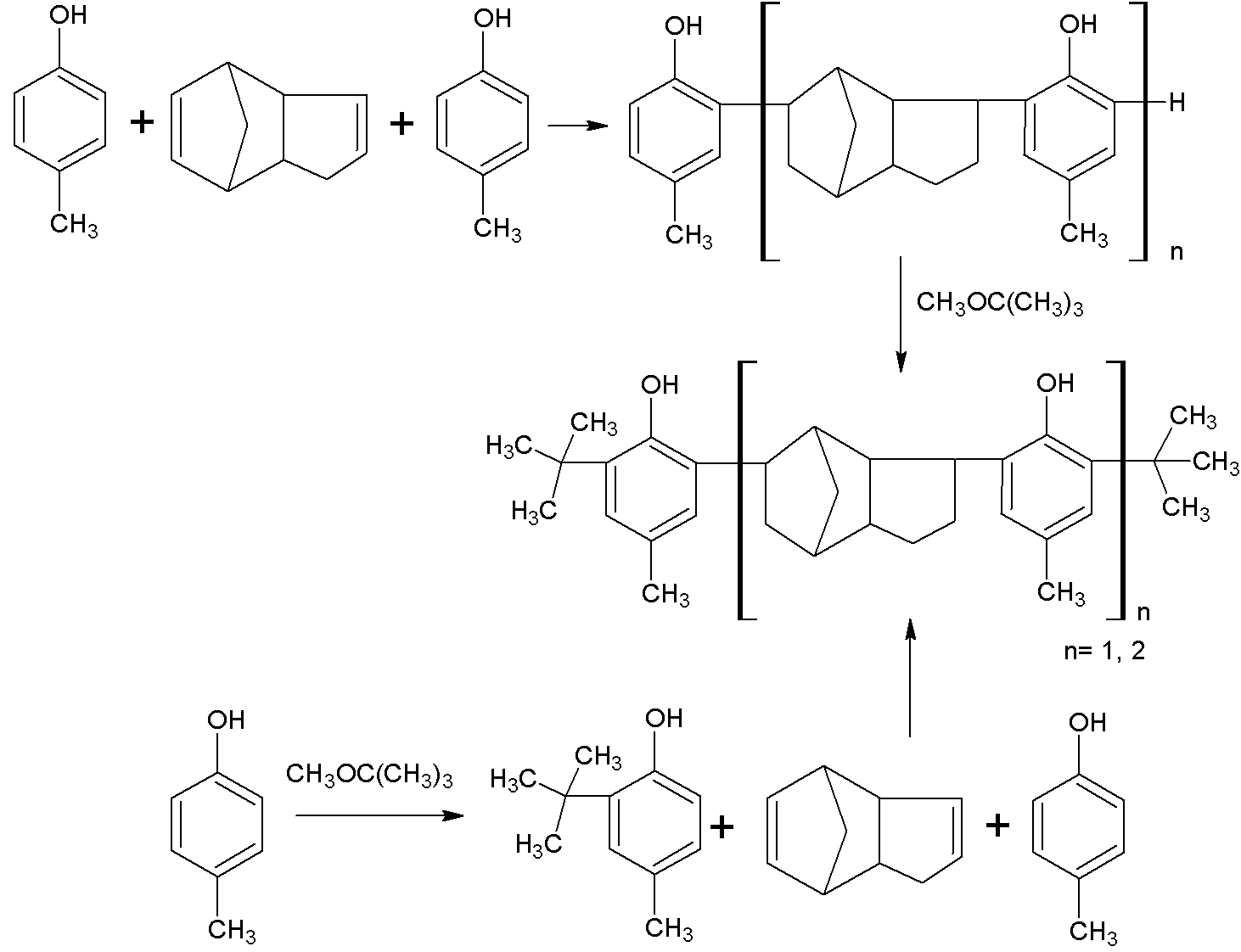

Method for producing aggregate-type hindered phenol antioxidant

InactiveCN103319315AReduce usageImprove efficiencyOrganic chemistryOrganic compound preparationSolubilityWater vapor

The invention provides a method for producing aggregate-type hindered phenol antioxidant. The method comprises the following steps of: firstly reacting p-cresol with dicyclopentadiene and a non-water-solubility solvent through an organic composite sulfonic acid catalyst under the anhydrous condition to obtain p-cresol-dicyclopentadiene resin; then adding tert-Butyl methyl ether so as to produce a p-cresol-dicyclopentadiene-isobutylated resin crude product, or firstly reacting the p-cresol with the tert-Butyl methyl ether and the non-water-solubility solvent through the organic composite sulfonic acid catalyst under the anhydrous condition to obtain an o-tert-butyl p-cresol; then adding the dicyclopentadiene so as to produce the p-cresol-dicyclopentadiene-isobutylated resin crude product; washing the crude product by water, and carrying out steam distillation on the crude product to obtain the aggregate-type hindered phenol antioxidant, wherein the final yield reaches more than 95%. The method has the advantages that the adopted organic composite sulfonic acid catalyst is low in cost, common and easy to wash by water and separate, water can be recycled, the product has good color and luster, low ash content and high purity, the treatment process is simple, equipment is free of being corroded, the technology is clean and environmentally-friendly, and the product yield reaches more than 95%.

Owner:HUBEI UNIV OF TECH

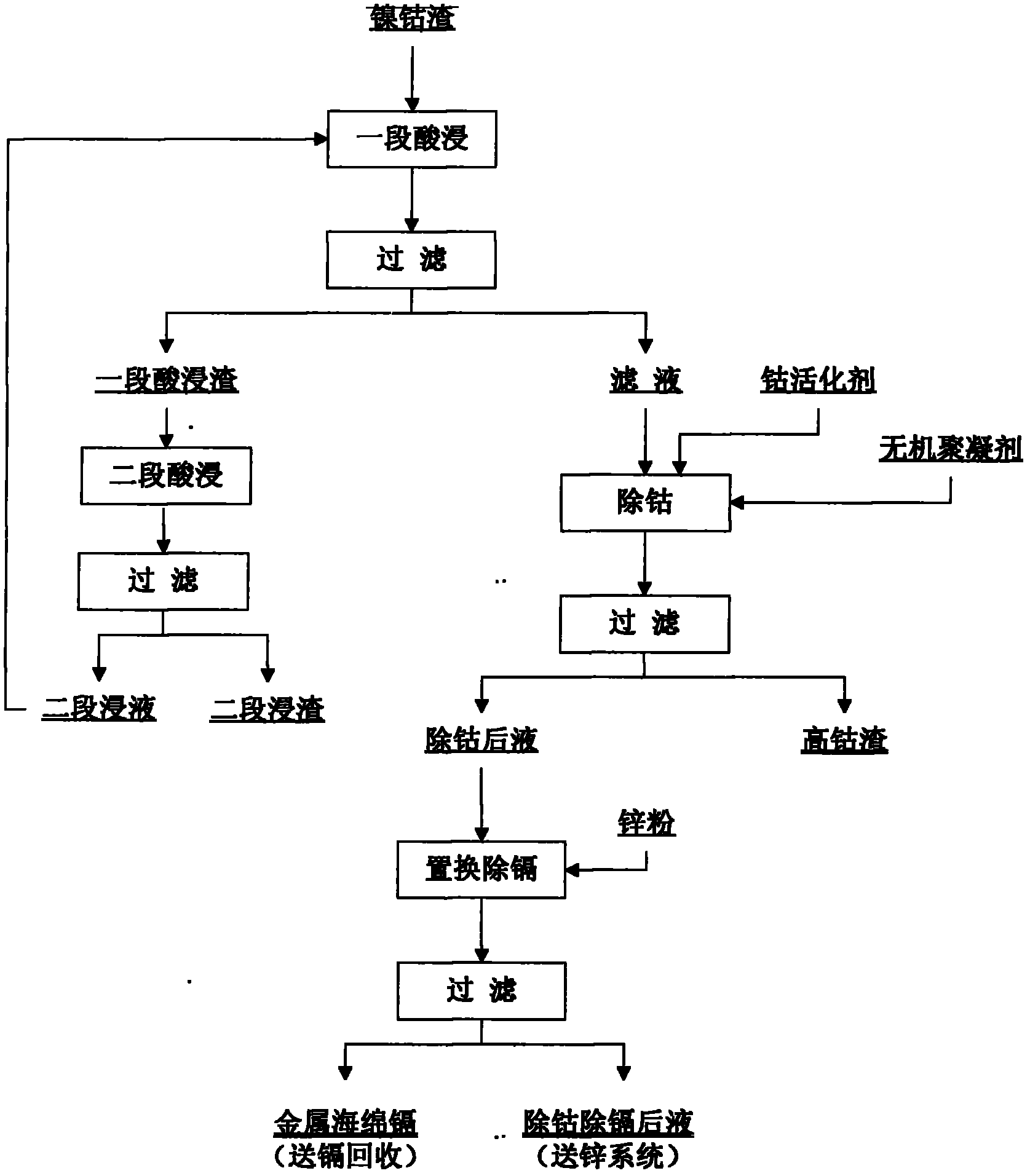

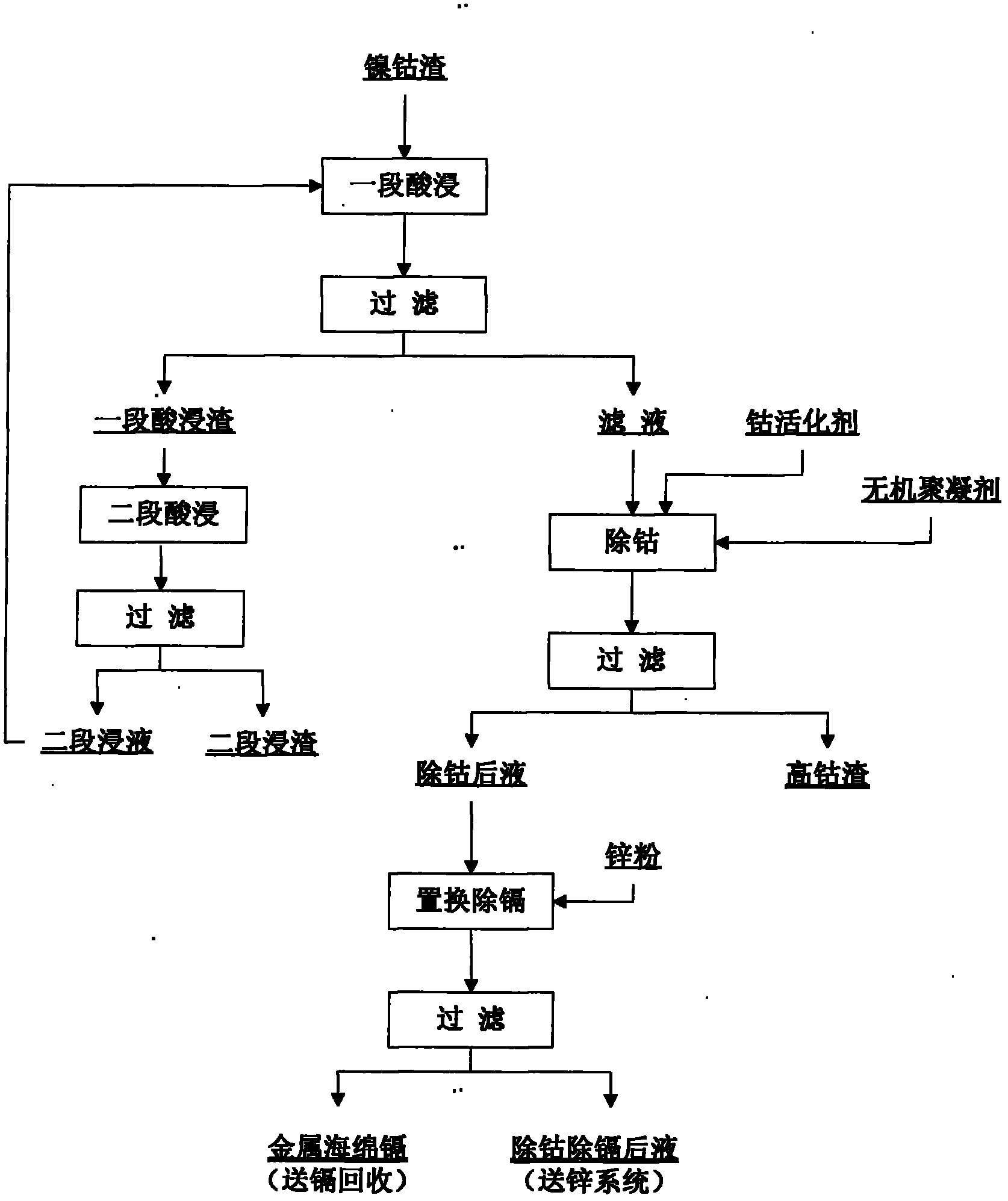

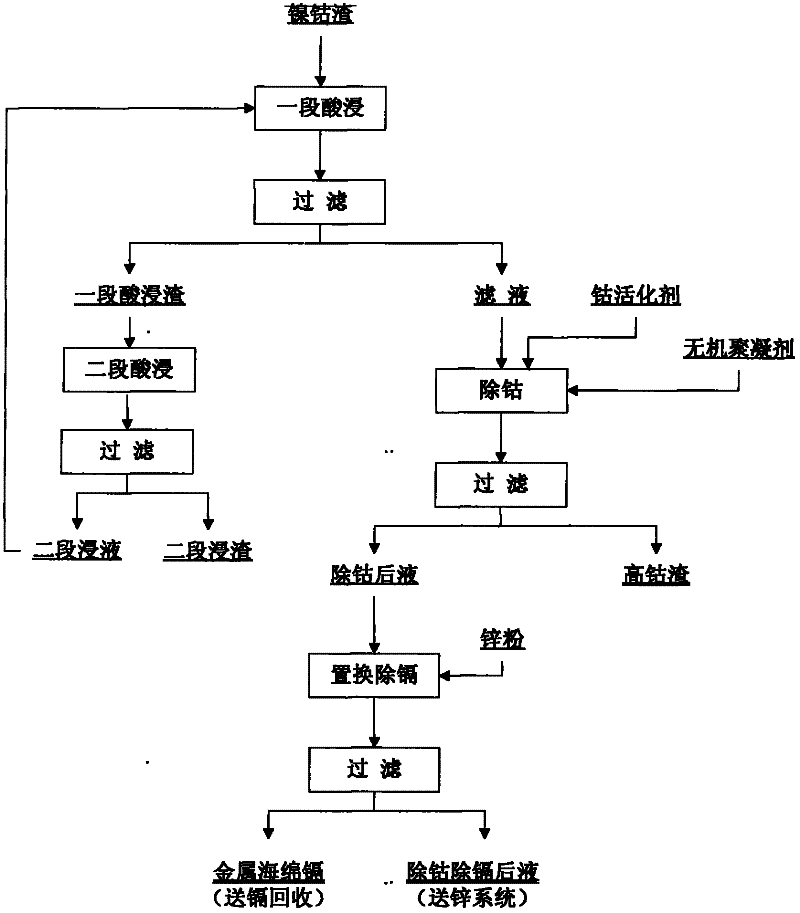

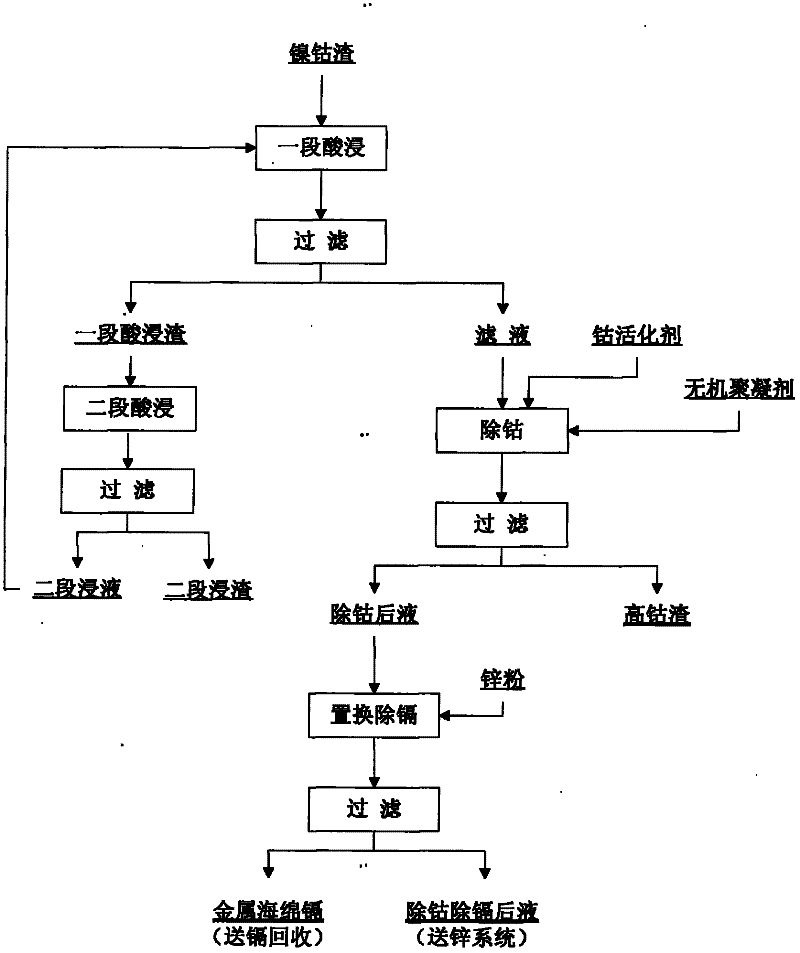

Novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification

ActiveCN101994008AEliminate the effects of pollutionRealize closed-loop operationProcess efficiency improvementBiological activationCobalt

The invention relates to a novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification, which comprises: separating cobalt from lixivium of nickel and cobalt slag by using a cobalt activation inorganic flocculation method, enriching the cobalt, recovering cobalt, removing cadmium from the cobalt-free lixivium by using the conventional zinc replacement method, obtaining sponge metal cadmium, delivering the sponge metal cadmium to a zinc smelting copper and cadmium processing step to recover metal cadmium. After cobalt and cadmium are removed, the lixivium is returned to a leaching step in a main zinc smelting system for recovering zinc. Thus, metals such as zinc, cobalt, cadmium and the like are recovered from the nickel and cobalt slag; meanwhile, the environmental pollution influence of the long-term piled up slag and the risk of irregular transfer of heavy metal pollutants such as cadmium in the zinc industry are eliminated, the closed-circuit operation of the recycling of the slag is realized, discharge of waste water and gas is avoided, valuable metals are comprehensively recovered, the requirement on pollution-free production is met and the problem of the industry is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

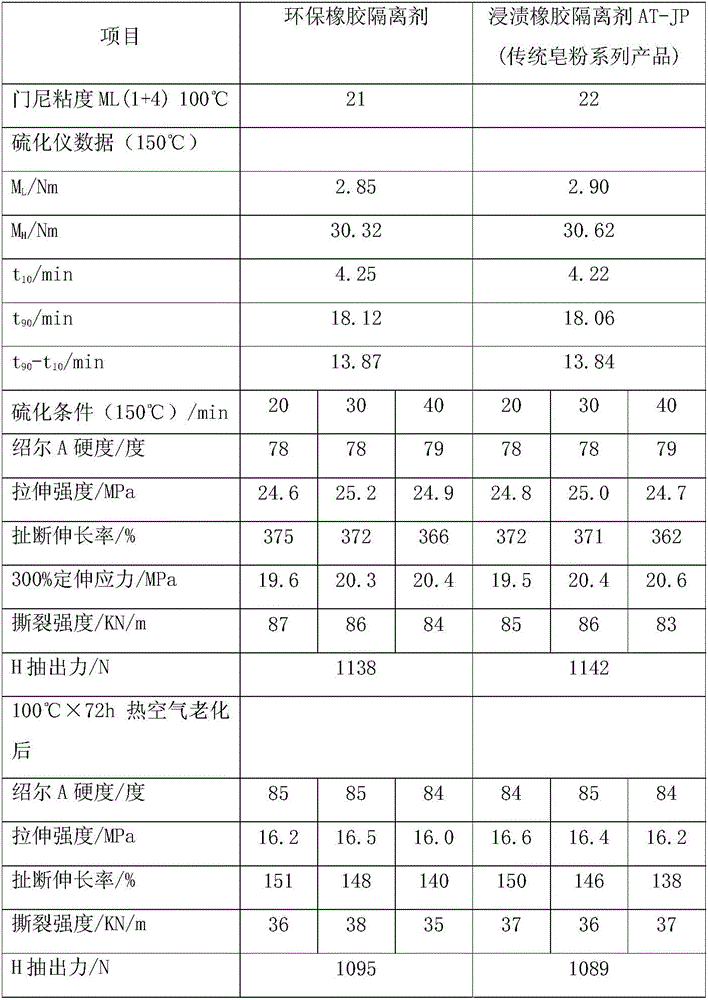

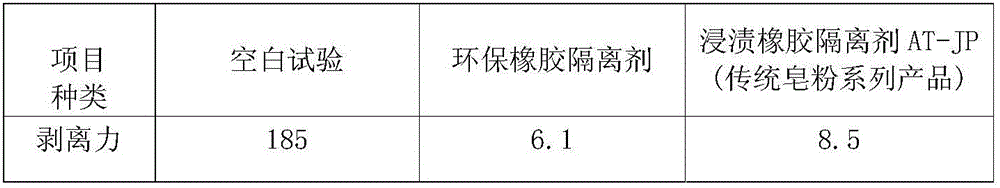

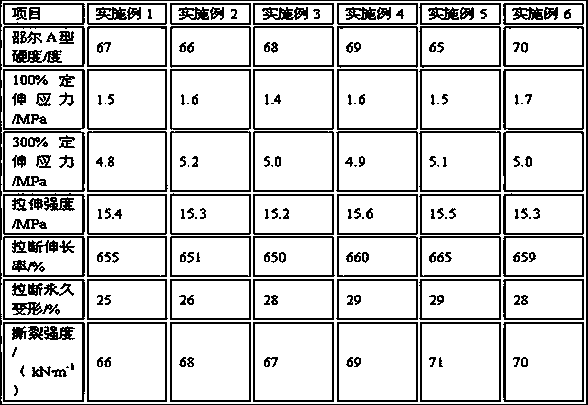

Environment-friendly rubber isolation agent

The invention discloses an environment-friendly rubber isolation agent. The isolation agent comprises the following components in parts by weight: 24-36 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of waterborne polyamide wax, 30-38 parts of calcium stearate, 18-30 parts of hydrated silicon dioxide, 8-14 parts of potassium stearate, 2-5 parts of silicone oil defoaming agents and 2-6 parts of sodium carboxymethylcellulose. The isolation agent is excellent in compatibility, long in actual effect and low in addition amount, and is green and environmentally friendly; the preparation process of the environment-friendly rubber isolation agent is simple and feasible; the cost is low.

Owner:JIANGSU KAOU CHEM

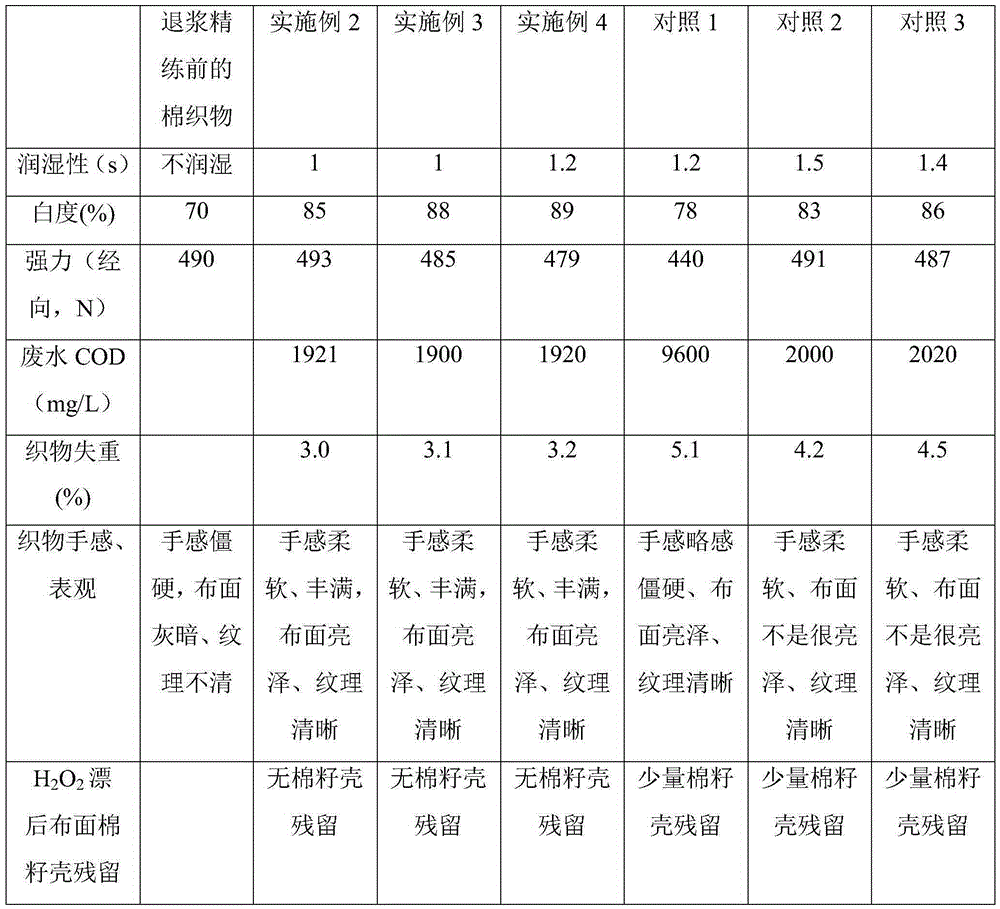

One-bath desizing and refining method of pure starch sizing cotton fabric

ActiveCN105369637AThe method is simpleGood effectBiochemical treatment with enzymes/microorganismsVegetal fibresChemistryLacquer

The invention discloses a one-bath desizing and refining method of pure starch sizing cotton fabric, and belongs to the technical field of textile dyeing and finishing pretreatment. According to the method, crude enzymes with various enzyme components such as laccase, cellulase, hemicellulase and pectinase produced by trametes Trametes sp.LEF01 are compounded with amylase, enzymic method one-bath desizing and refining pretreatment is conducted on PVA-free pure cotton fabric with starch slurry, starch slurry material is degraded through amylase, pectin, cottonseed hulls and other non-associated impurities are degraded through crude enzymes produced by trametes, and the removal of starch slurry material on fabric, the improvement of fabric wettability and the smoothness of surface are achieved. By means of the method, the pretreatment effect of cotton fabric can be comprehensively improved, the defects that during traditional alkali method desizing and refining, energy consumption, water consumption and waste water discharge are high, and environment pollution is severe are overcome, and the method is a green and environment-friendly cotton fabric short-process cleaning and producing process.

Owner:JIANGNAN UNIV

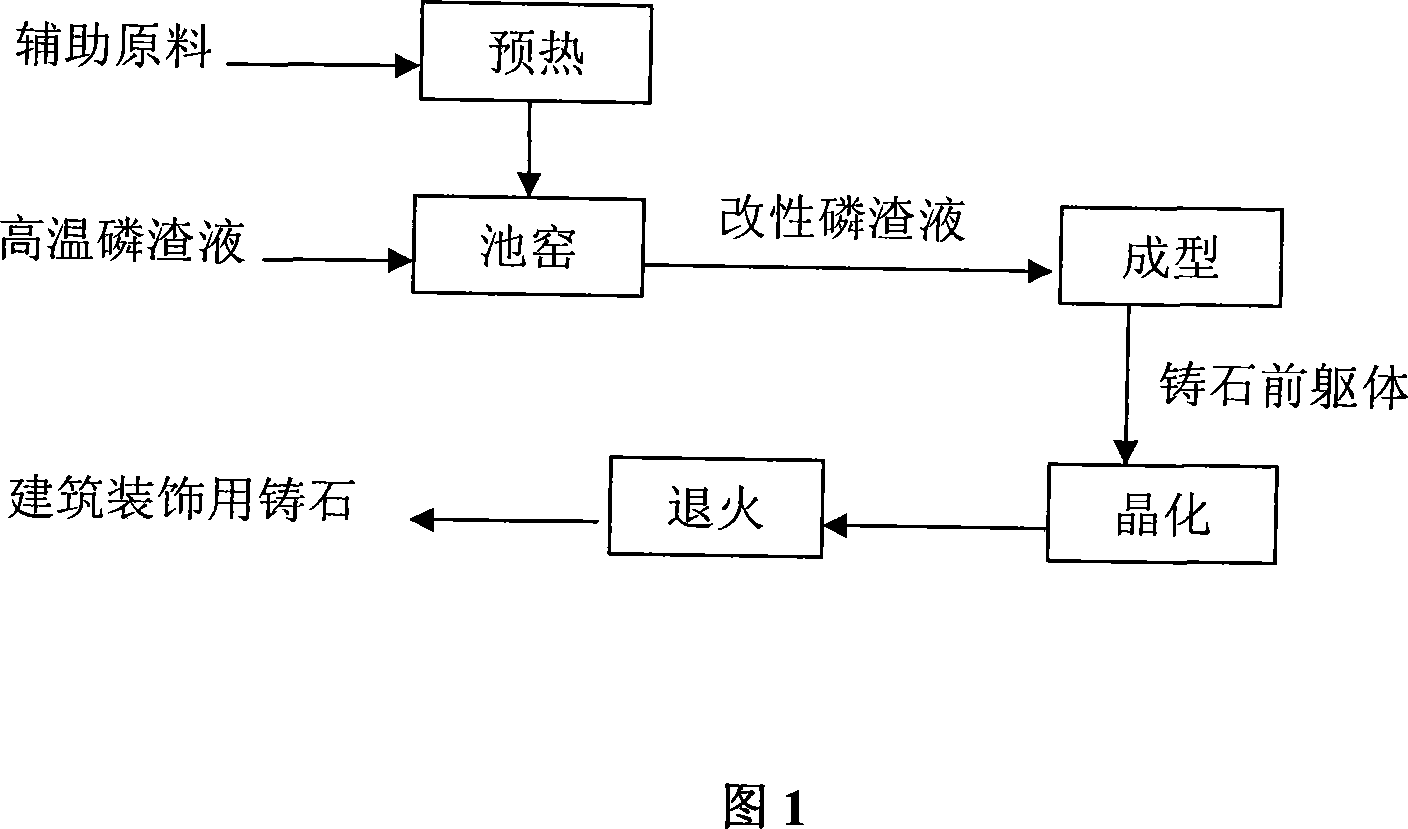

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

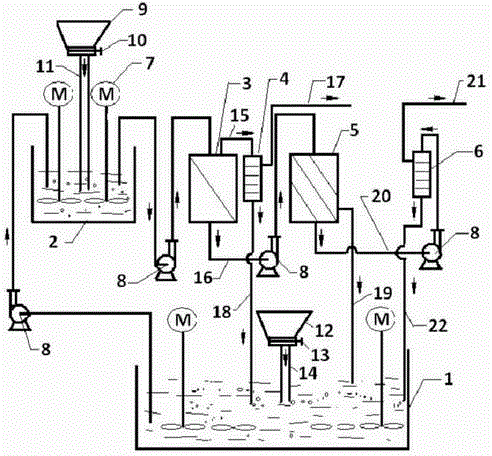

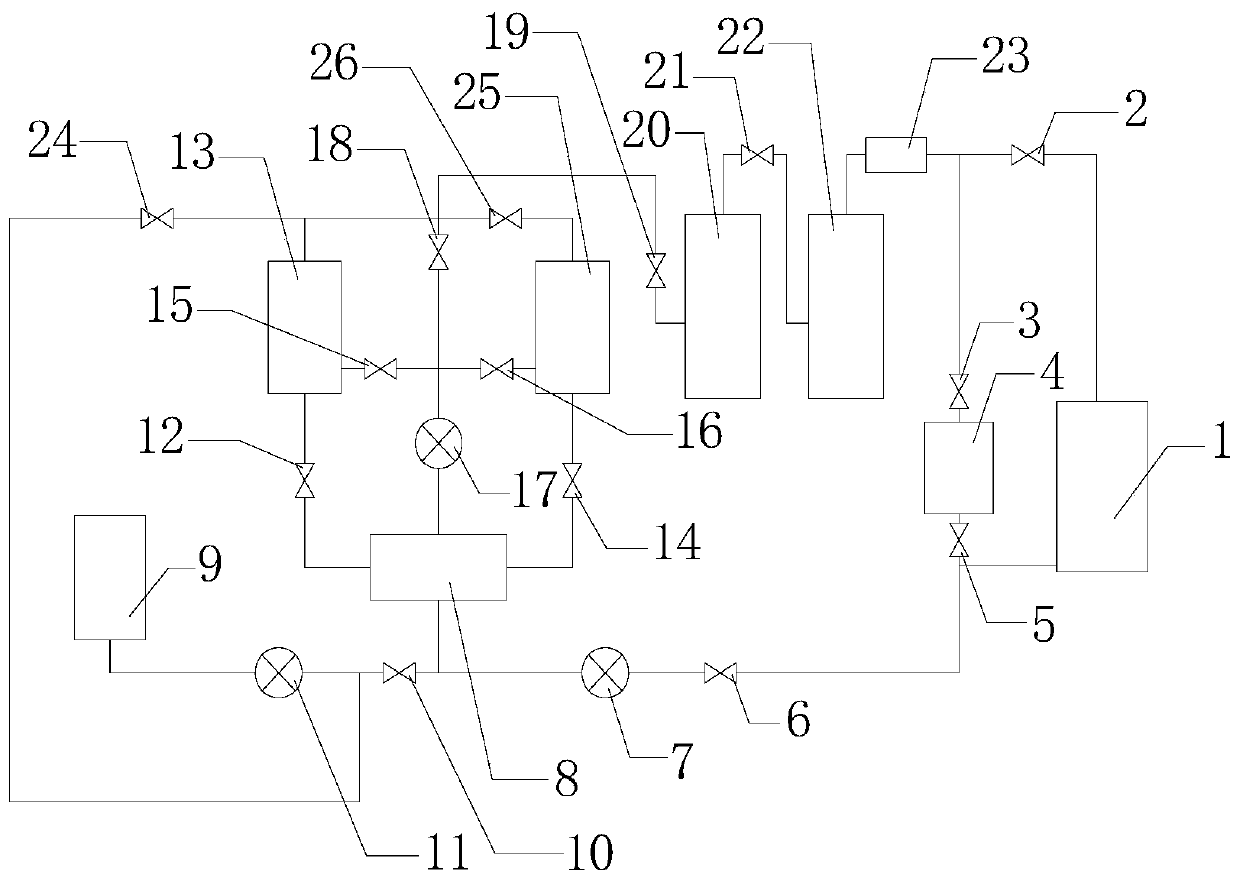

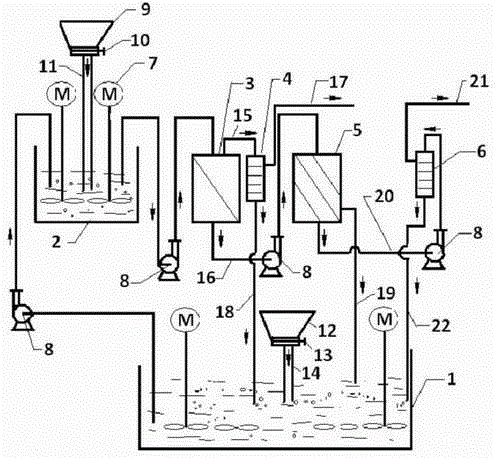

Device for realizing online cyclic utilization of rare earth polishing stock and method thereof

ActiveCN103978434AGood suspensionEliminate surface wrappingGrinding/polishing apparatusWastewaterRare earth

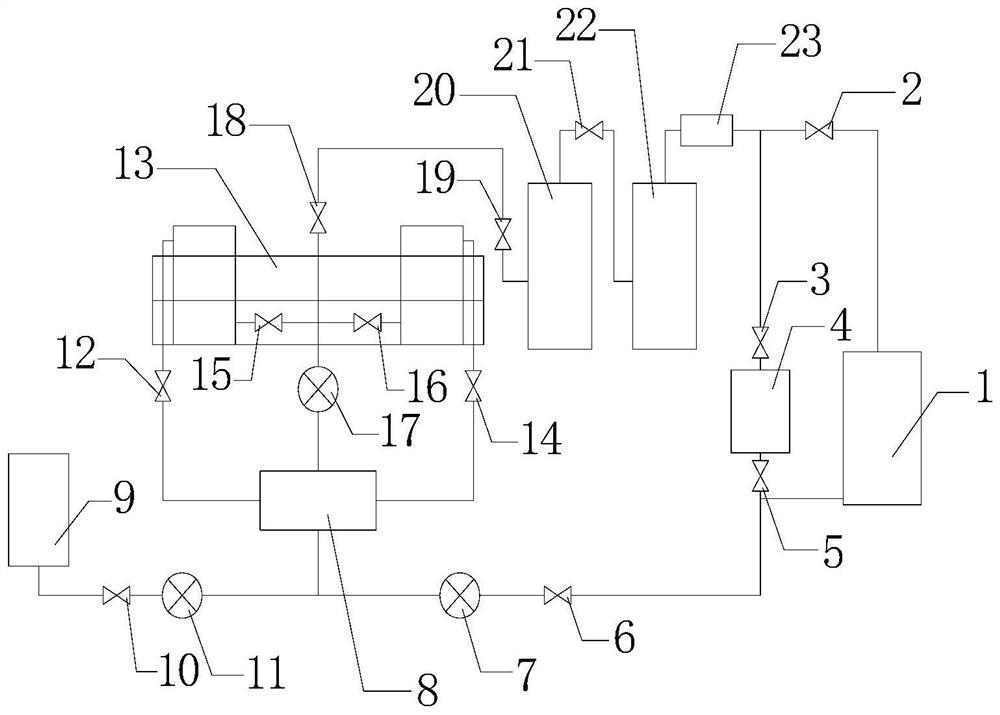

The invention discloses a device for realizing the online cyclic utilization of rare earth polishing stock. The device is composed of a stock tank (1), a stock mixing tank (2), a cyclone separator (3), a first press filter (4), a fine filter (5), a second press filter (6), a homogenizing agent hopper (9) and a powder adding head (12). The invention further discloses a method for using the device. The online cyclic utilization of the rare earth polishing stock can be directly realized by the device in the stock state, and the device can be directly used for matching with a polisher to recycle the polishing mortar, therefore the recycling times of a polishing mortar system can be greatly improved. According to the device, an aim of recycling the stock can be achieved by sectionally getting rid of invalid components and invalid particles in a stock system, and the device has the technical characteristics of high efficiency, quickness and low energy consumption; meanwhile, wastewater and effluent discharge can be avoided in the process of online cyclic utilization, and the production requirements on the clean whole process are met.

Owner:江苏广晟健发再生资源股份有限公司

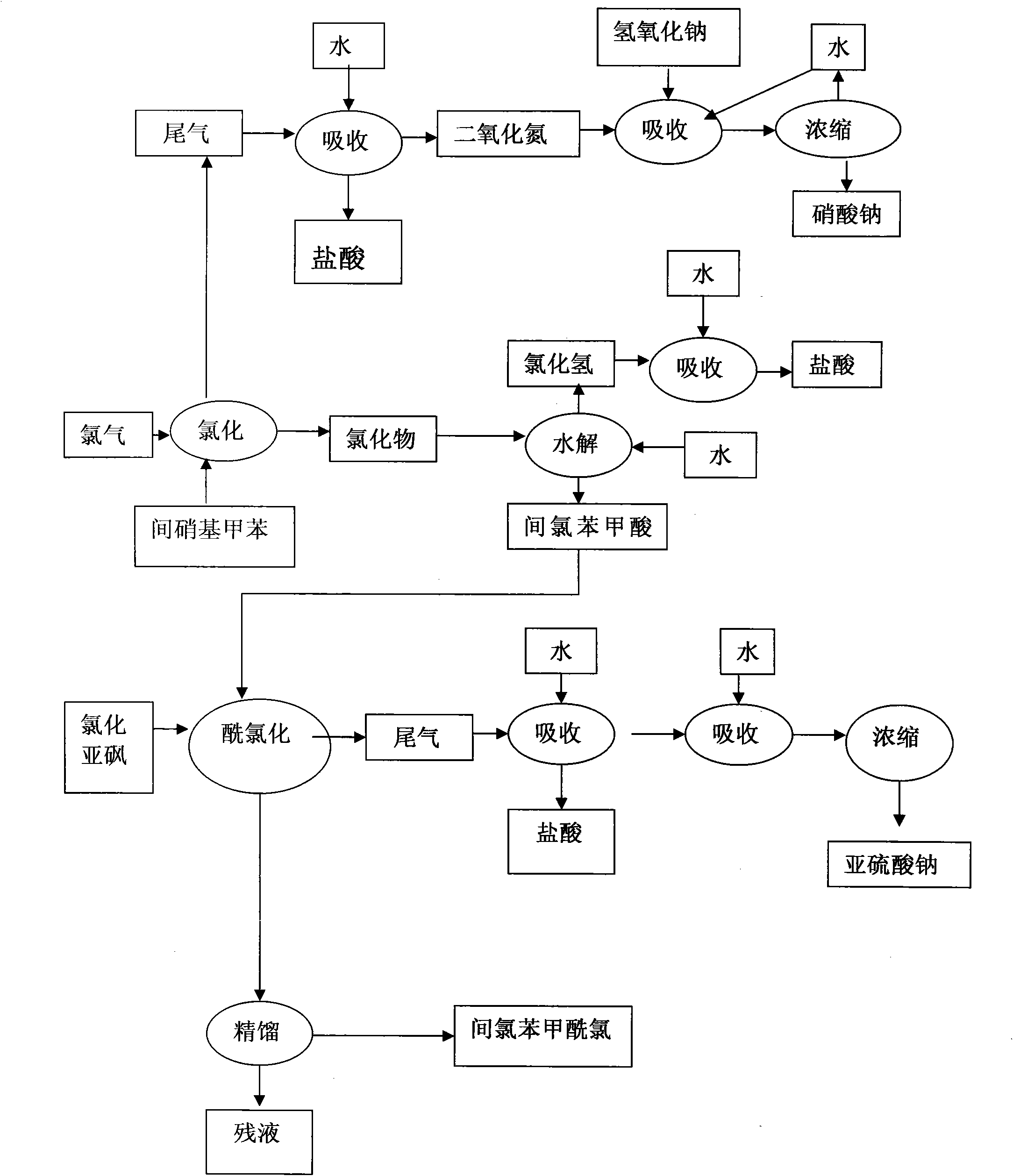

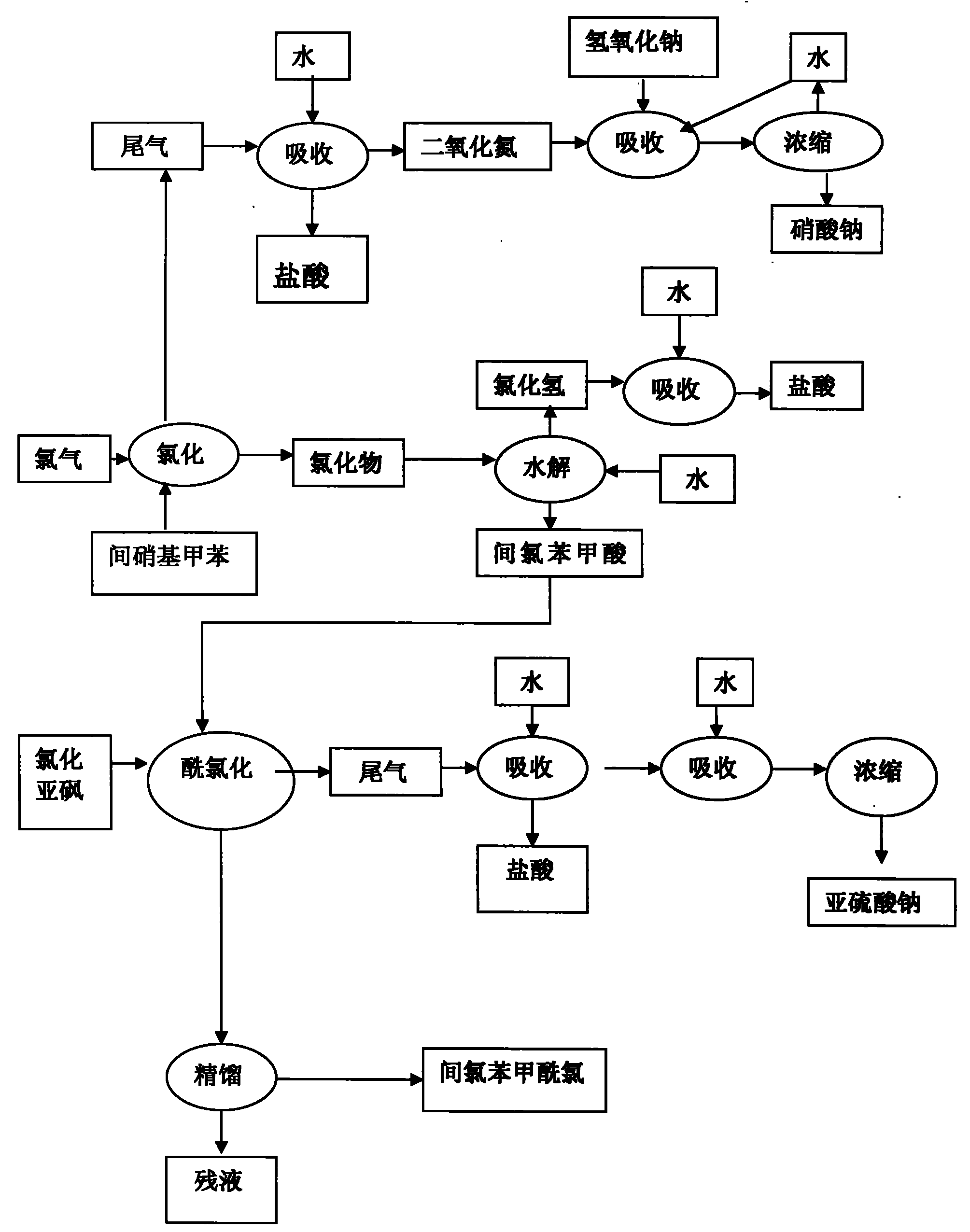

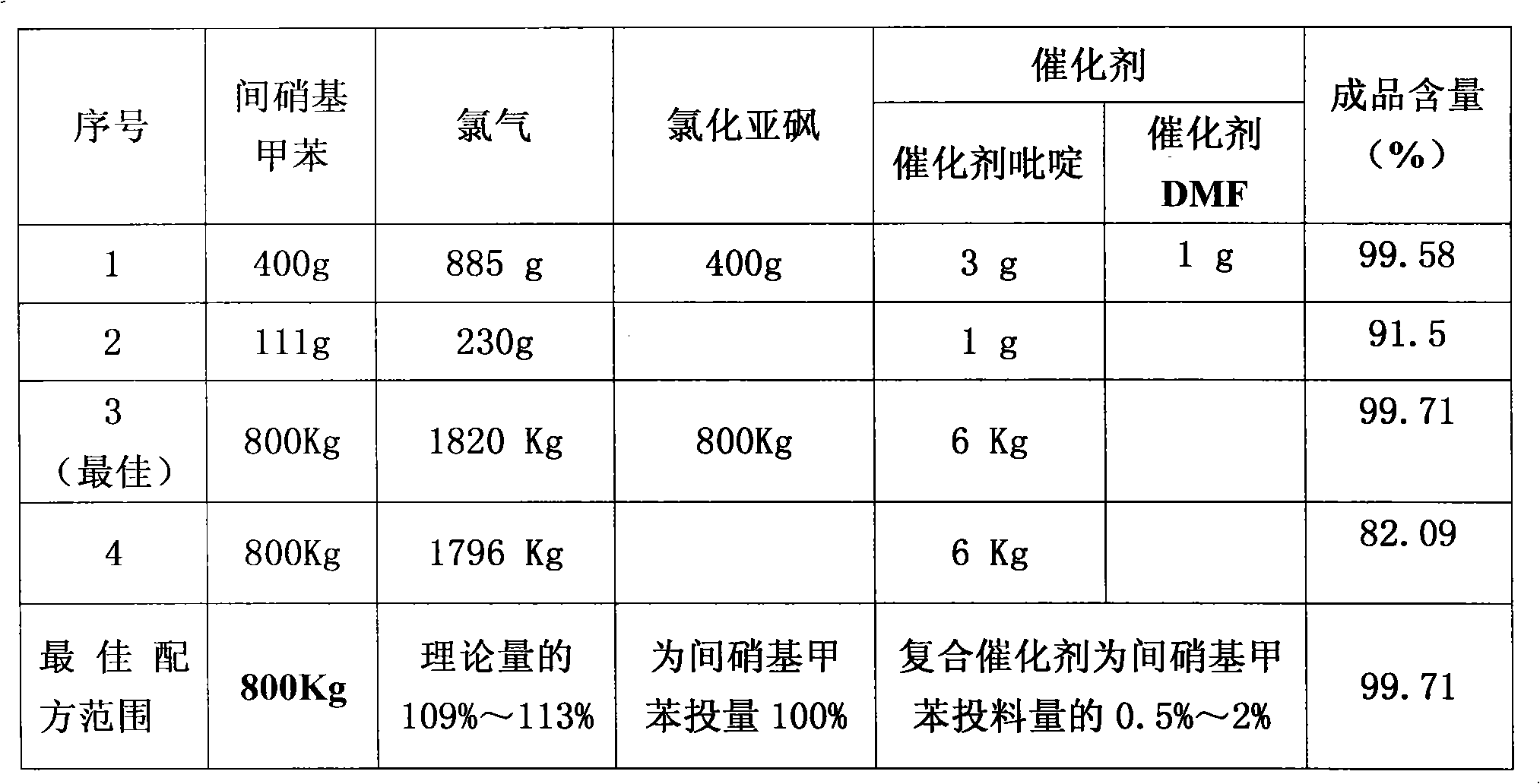

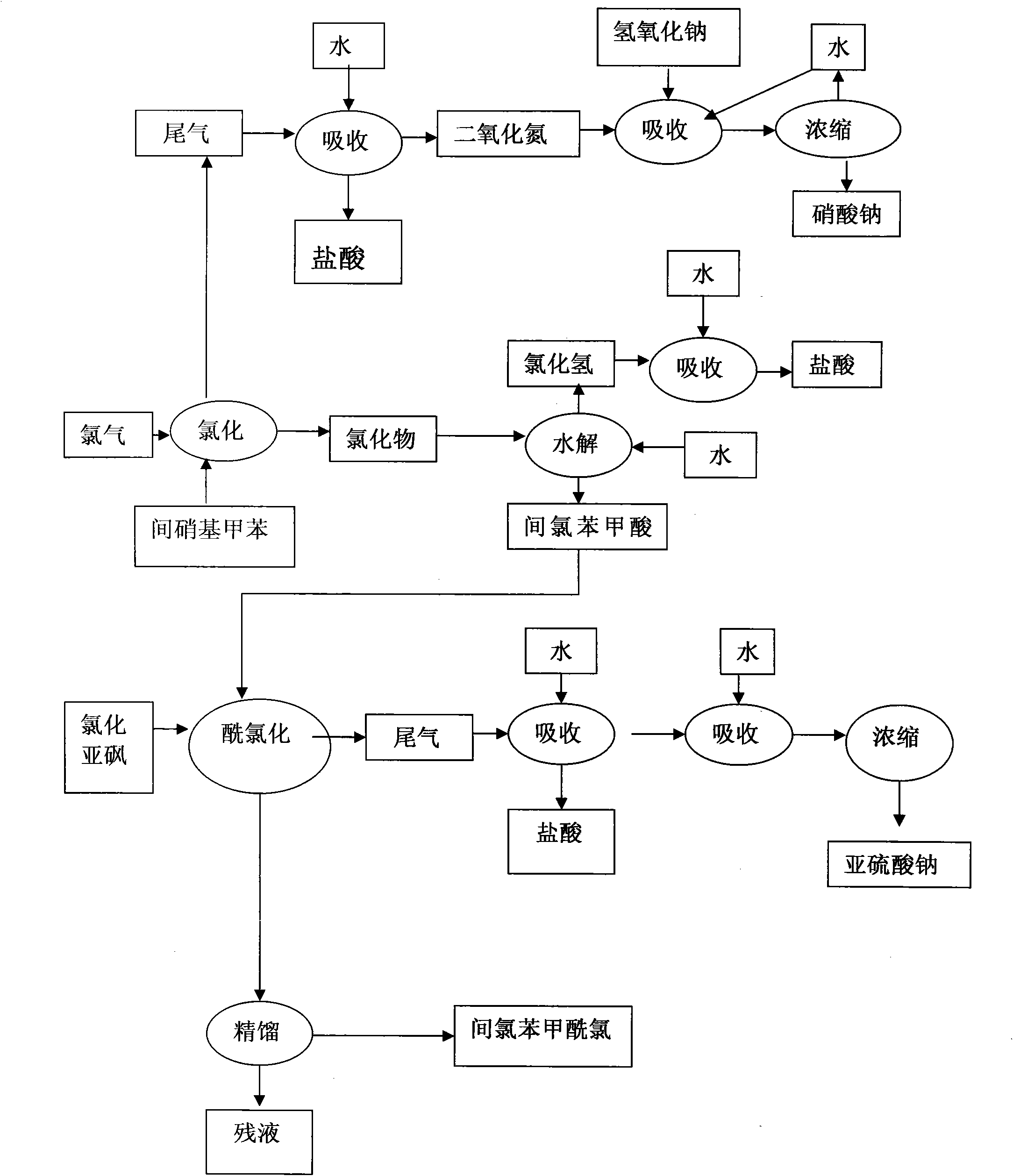

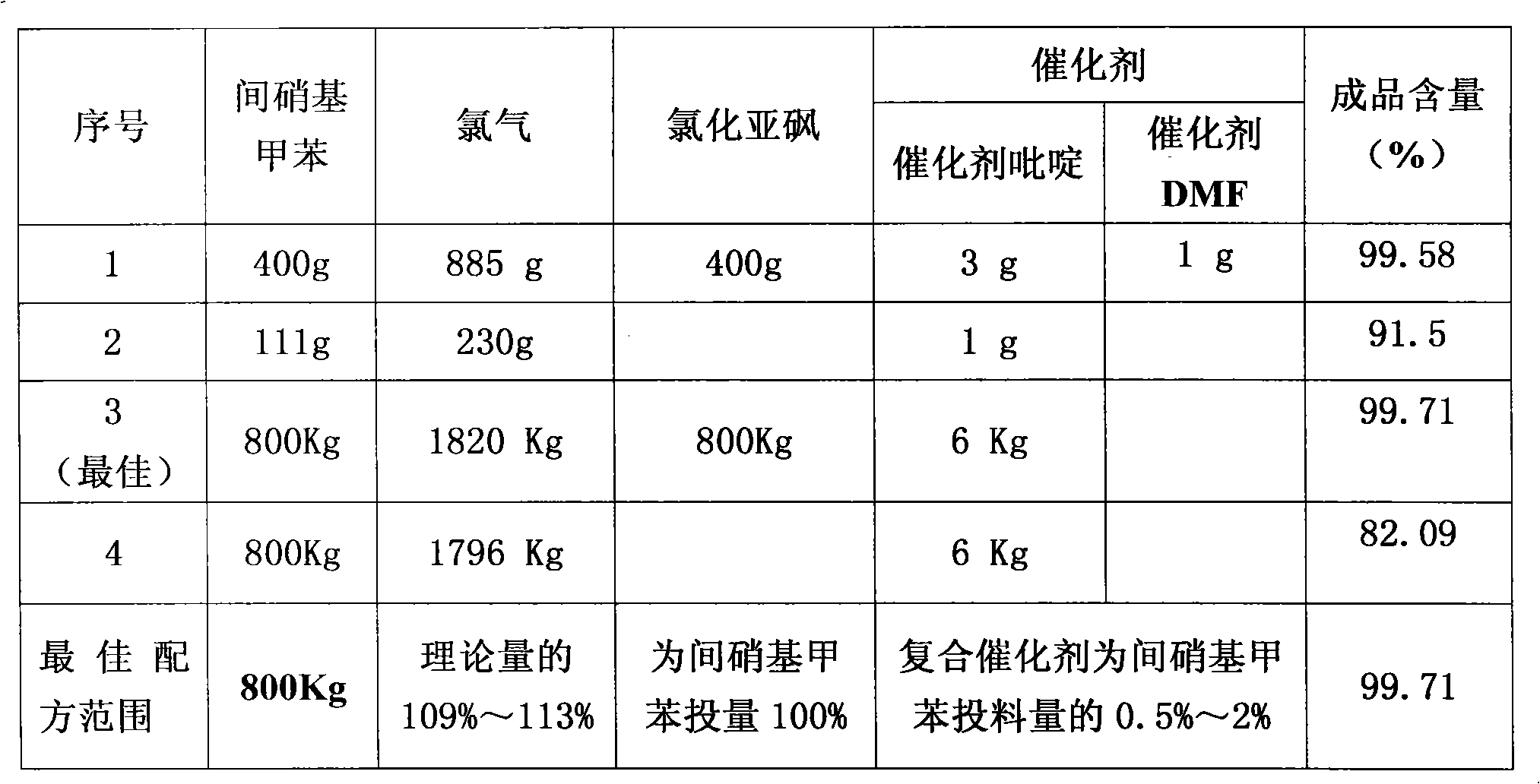

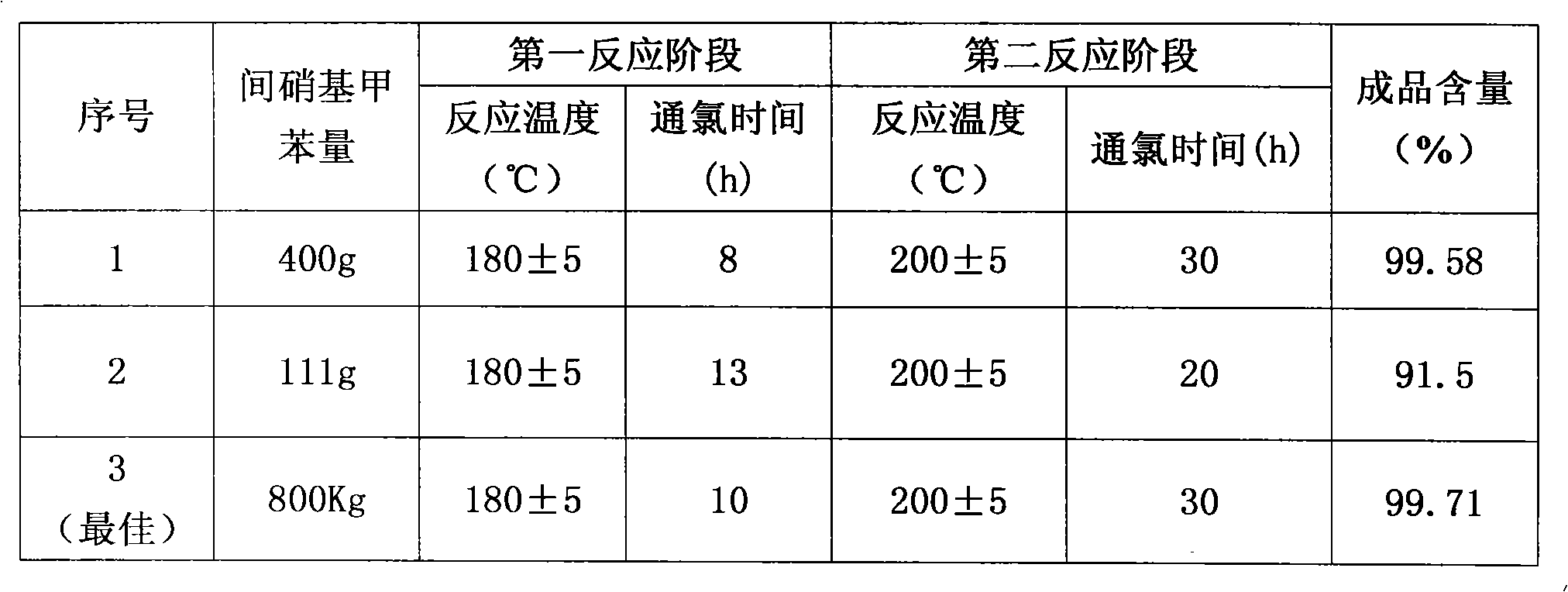

Method for producing m-chlorobenzoyl chloride

InactiveCN101774908ALow costHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsM-chlorobenzoic acidPyridinium

The invention relates to a method for producing m-chlorobenzoyl chloride, in which m-nitrotoluene is used as raw material, pyridine, pyridinium salt, pyridine derivative containing halogen and fat groups on a ring, salt thereof and N, N-dimethylformamide and salt thereof are used as catalysts, and substitution reaction between the m-nitrotoluene and chlorine is carried out at ordinary pressure and the temperature of 120-220 DEG C to obtain more than 90 percent m-chlorobenzoyl chloride crude. The chloride is directly hydrolyzed to obtain m-chlorobenzoic acid which is then reacted with thionyl chloride and rectified to obtain high-purity m-chlorobenzoyl chloride. The invention directly takes the m-nitrotoluene as the raw material, the m-chlorobenzoyl chloride is obtained via chlorination bychlorine with the catalysts under UV-irradiation, and hydrolysis is further carried out to obtain the m-chlorobenzoic acid. Each step of reaction is carried out under a relatively mild technological condition. The invention has the advantages of low cost and high yield and product purity, by-product hydrochloric acid and dilute nitric acid can both be used. Three wastes are not generated, energy is saved, and environment is protected.

Owner:YIXING BRANCH OF SHANDONG SHENGONG CHEM GROUPCO

Light organic matrix preparation method for strawberry cultivation frame and matching fertilizing method

InactiveCN103340141AMeet the characteristics of fertilizerHigh nutrient contentFertilising methodsCultivating equipmentsFragariaOrganic chemistry

The invention discloses a light organic matrix preparation method for a strawberry cultivation frame and a matching fertilizing method. The light organic matrix preparation method for the strawberry cultivation frame comprises the steps: mushroom dregs and vinegar residue matrix are mixed, wherein the volume ratio of the mushroom dregs and the vinegar residue matrixes is 3:2, the mixed material is stirred circularly, water is sprayed on the mixed material, the mixed material stands, and finally light organic matrix is obtained, wherein the volume weight of the light organic matrix is 0.25-0.28g / cm<3>, the total porosity of the light organic matrix is 65-79%, the content of available potassium is 9.8-10.2g / kg, the content of available nitrogen is 0.9-1.0g / kg, the content of available phosphorus is 0.29-0.32g / kg, the EC value of the light organic matrix is 1.0-1.3mS / cm, and the PH value of the light organic matrix is 6.7-7.0. By means of a matching fertilizing technology in the cultivation process of strawberries, 42.4kg strawberries can be harvested in total on one cultivation frame unit which occupies a 6 m<3> area place, the yield of the strawberries is increased greatly, and the light organic matrix preparation method and the matching fertilizing method can be applied to strawberry cultivation.

Owner:JIANGSU UNIV

Anti-wet-slippery resin composite material

InactiveCN107603108AImprove wet skid resistanceImprove braking effectSpecial tyresArylAlicyclic Hydrocarbons

The invention discloses an anti-wet-slippery resin composite material including, by weight, 60-85 parts of modified terpene resin, 12-20 parts of aryl polysulfone resin, 10-20 parts of alicyclic hydrocarbon resin, and 4-10 parts of a compatibilizer. The composite material is a directly-inner-adding-type reagent and is used for overcoming problems in a scheme of using white carbon black and solution polymerized styrene-butadiene rubber, which needs a large number of adjustment operations and generates huge fluctuation. The composite material is added with other small materials during mixing andis free of adjustment on formula and process. The composite material can significantly increase the anti-wet-slippery performance of vulcanized rubber and improve driving safety of rubber products, especially tyres. In addition, a preparation method employs easy-to-obtained raw materials, has low cost and is simple in processes.

Owner:JIANGSU KAOU CHEM

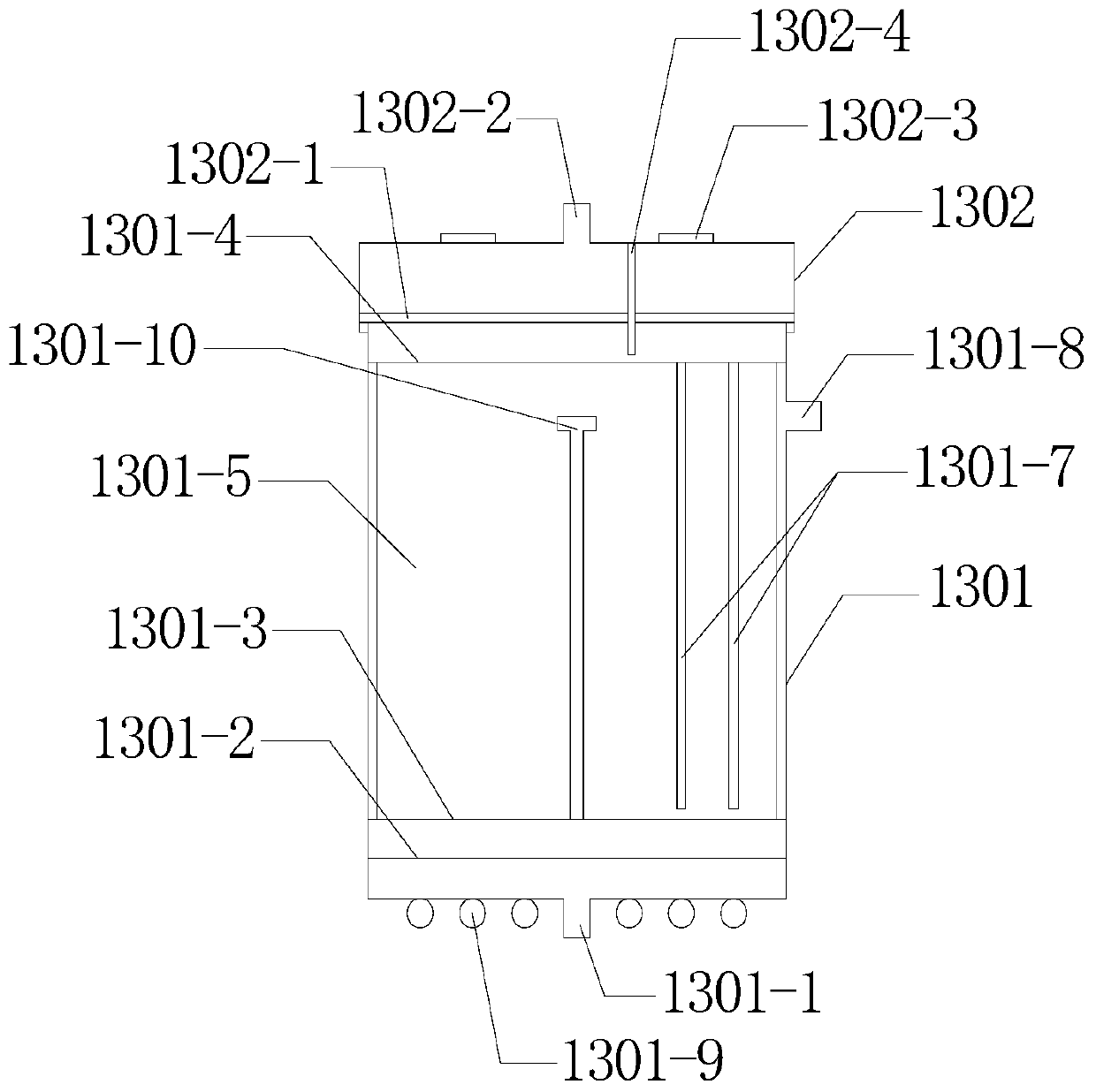

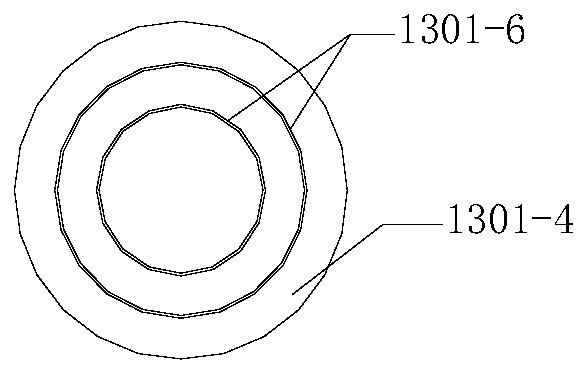

Super(sub)critical CO2 scouring device

ActiveCN110468457AEfficient recyclingSolve high water consumptionFatty substance recovery/refiningAnimal materialDistributorAqueous medium

The invention relates to a super(sub)critical CO2 scouring device, and belongs to the field of scouring equipment.The device includes a kettle body and a kettle lid of a super(sub)critical CO2 scouring kettle; a CO2 inlet is provided at the bottom of the kettle body, and a CO2 outlet is provided on the kettle body; the kettle body is internally provided with a water and purity separation membrane,a porous bottom plate, and a porous cover plate from bottom to top; a wool (velvet) bin is provided between the porous bottom plate and the porous cover plate; a co-solvent inlet is provided on the top of the kettle cover, and the kettle cover is internally provided with a distributor.When the kettle lid covers the kettle body, the CO2 outlet is located between the porous cover plate and the distributor.The device of the invention uses super(sub)critical CO2 instead of aqueous medium for chemical scouring, which solves the problem of high water consumption and high pollution during the scouring of the aqueous medium, and can realize the efficient recovery of oil and fat, which meets the clean production requirements of the washing scouring.

Owner:DALIAN POLYTECHNIC UNIVERSITY

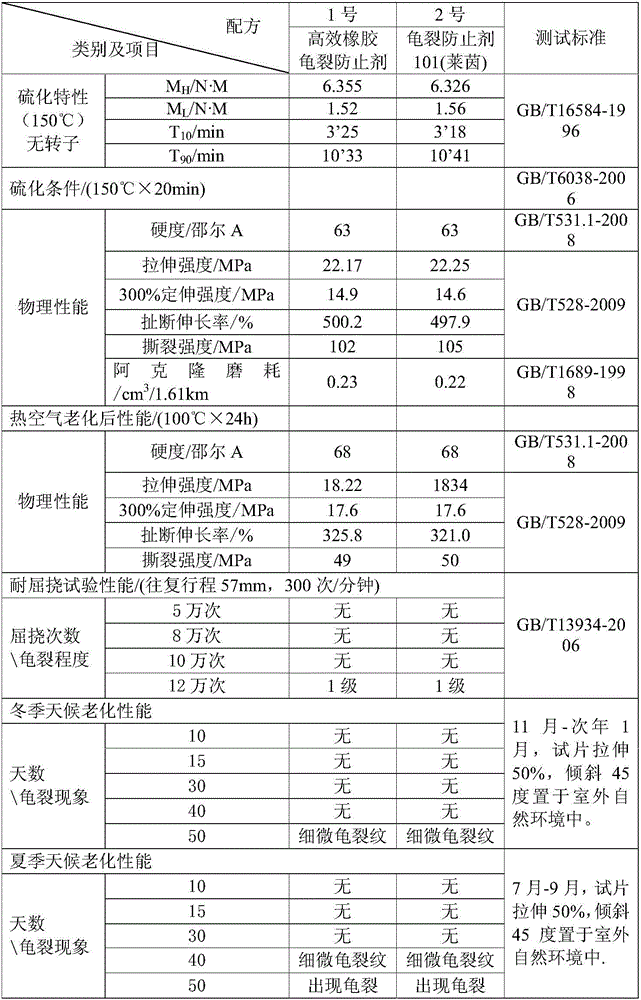

High-performance rubber cracking preventing agent

InactiveCN106751940AImprove crack resistanceImprove inner qualityMicrocrystalline waxHeat resistance

The invention discloses a high-performance rubber cracking preventing agent. The preventing agent is prepared from the following components in parts by weight: 20 to 30 parts of Number-58 completely-refined paraffin, 15 to 25 parts of number-58 semi-refined paraffin; 22 to 34 parts of number-70 microcrystalline wax, 18 to 30 parts of number-85 microcrystalline wax, 4 to 8 parts of oxidized polyethylene wax, and 2 to 5 parts of polyethylene wax. The preventing agent is smooth in surface, uniform in thickness, good in leakproofness, compact in structure, high in flexibility, heat resistance, elasticity and adhesive force, uneasy to drop, capable of playing a barrier role in preventing rubber from contacting ozone gas, and capable of effectively delaying the oxidization effect, delaying the cracking and prolonging the service life.

Owner:JIANGSU KAOU CHEM

Novel galvanizing and chrome-free passivating technology

InactiveCN103014688AEliminate pollution problemsGuaranteed corrosion resistanceMetallic material coating processesChromiumCorrosion

A novel galvanizing and chrome-free passivating technology is characterized in that passivating solution with the pH of 2.5 to 3.0 is used for passivating a zinc coating for 45 to 90 s at the temperature of 20 to 40 DEG C, so that a blue passive film can be obtained; and the corrosion resistance of the passive film is improved as the temperature (40 DEG C to 50 DEG C) of the passivating solution is increased and the processing time (100 s to 300 s) is prolonged. The novel galvanizing and chrome-free passivating technology can not only ensure the corrosion resistance of the surface coating of a product, but also solve the problem that the environment and operators are polluted by chrome during the galvanizing and passivating process.

Owner:ZUNYI CHANGZHENG ELECTRIC POWER EQUIP SURFACE TREATMENT CO LTD

A device and method for realizing online recycling of rare earth polishing slurry

ActiveCN103978434BIncrease the number of recyclingAvoid consumptionGrinding/polishing apparatusWastewaterRare earth

Owner:江苏广晟健发再生资源股份有限公司

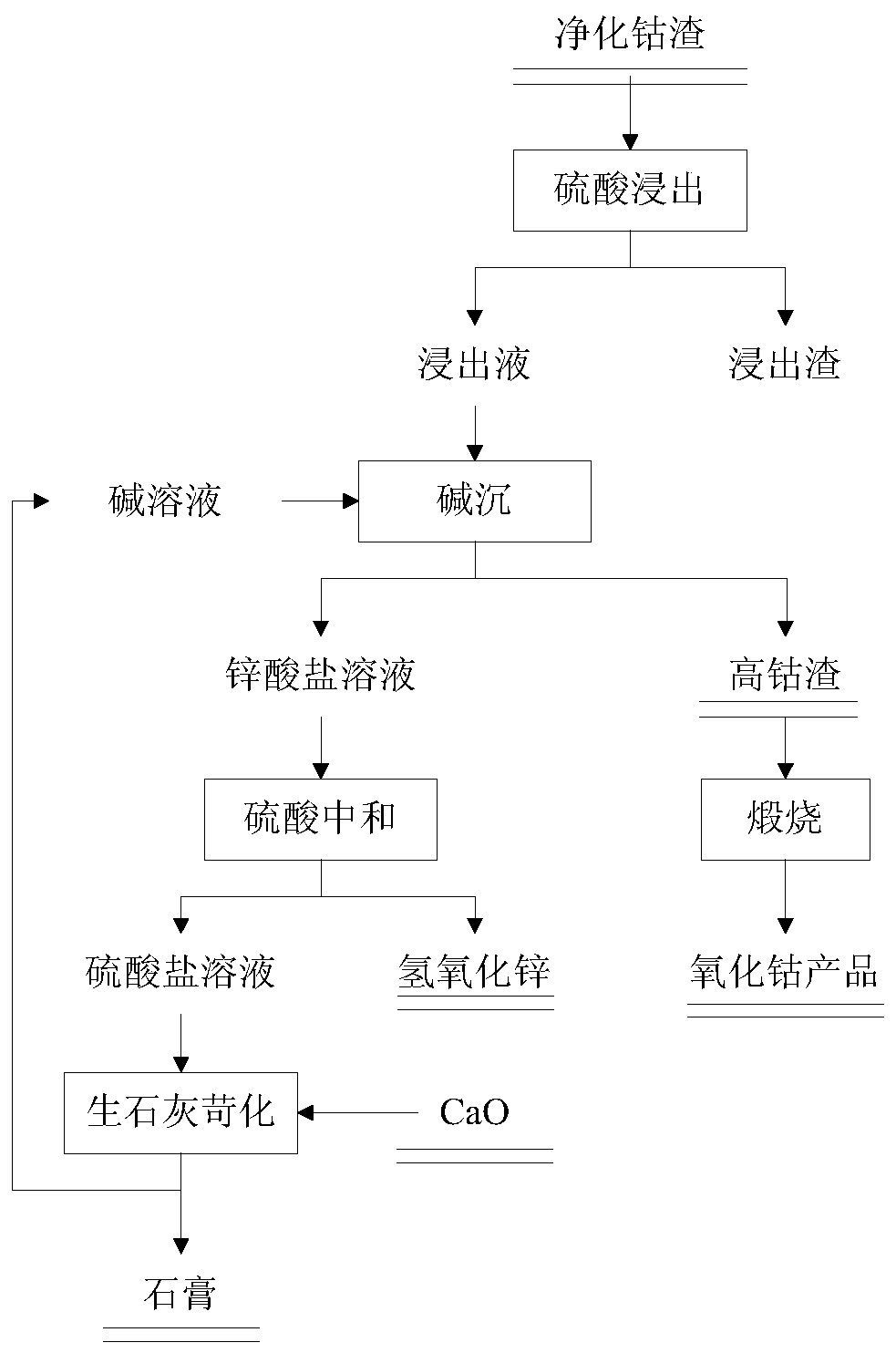

A method for efficiently separating and recovering zinc and cobalt from purified cobalt slag

ActiveCN108893617BEfficient separationImprove separation efficiencyProcess efficiency improvementZinc hydroxideSlag

The invention belongs to the technical field of hydrometallurgy comprehensive recycling and relates to a method of efficiently isolating and recycling zinc and cobalt from purified cobalt slag. The method herein comprises: 1) leaching out purified cobalt slag via sulfuric acid to obtain leached slag; 2) using an alkaline solution to neutralize leachate; 3) using sulfuric acid to neutralize zincatesolution to obtain sulfate solution and zinc hydroxide; calcining the cobalt slag under nitrogen protection to obtain finished high-purity cobalt oxide. Efficient separation of zinc and cobalt is achieved by making use of only the alkali solution PH difference of zinc hydroxide and cobalt hydroxide; the zincate solution and cobalt hydroxide slag attained from an alkali precipitation process are treated further respectively to recycle zinc and cobalt, operations are simple, the recycling efficiency is high; the sulfate solution attained herein can be returned to the alkali precipitating procedure, the material consumption and production cost are reduced, and the whole process has no emission of wastewater and waste gas, enables valuable metals to be comprehensively recycled and meets the requirement on clean production.

Owner:ZHENGZHOU UNIV

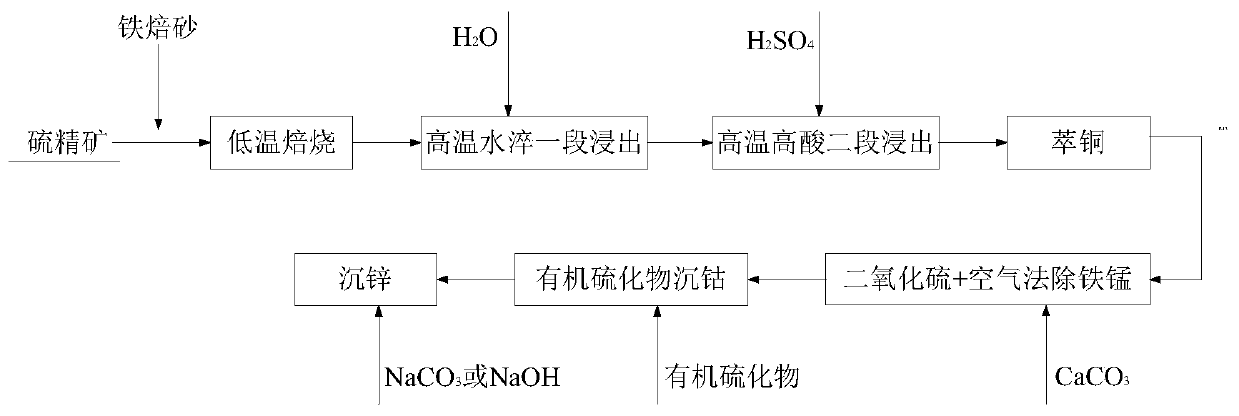

Method for gradient recovering of copper, cobalt and zinc from sulfur concentrate through low-temperature roasting

InactiveCN110229958AEasy to leachPromote maturityRotary drum furnacesCrucible furnacesOrganic sulfide compoundManganese

The invention discloses a method for gradient recovering of copper, cobalt and zinc from sulfur concentrate through low-temperature roasting. The method comprises the following steps of S1, carrying out low-temperature roasting on the sulfur concentrate; S2, carrying out high-temperature water quenching and one stage leaching; S3, carrying out high-temperature high-acid two-stage acid leaching; S4, extracting the copper; S5, removing iron and manganese by introducing mixed gas of sulfur dioxide and air; S6, selectively precipitating the cobalt by using organic sulfide; and S7, precipitating the zinc. According to the method, gradient recovery of the copper, the cobalt and the zinc in the sulfur concentrate can be realized.

Owner:厦门紫金矿冶技术有限公司

Process for preparing disperse red 60

InactiveCN101343419BReduce dosageAvoid emissionsAmino-hydroxy-anthraquinone dyesHydroxyanthraquinoneDistillation

The invention relates to a producing method of disperse red 60. The producing method mainly comprises the steps that firstly, 1-anthraquinone is adopted as raw material to make 1-amino-2-bromine-4-hydroxyanthraquinone dry product; secondly, the 1-amino-2-bromine-4-hydroxyanthraquinone dry product reacts with phenol to perform condensation reaction under the existence of acid binding agent to generate 1-amino-2-phenoxy -4-hydroxyanthraquinone, in the second step, the condensation reaction is performed in inert solvent with a high boiling point, the mass ratio of the inert solvent with a high boiling point, the phenol and the 1-amino-2-bromine-4-hydroxyanthraquinone dry product is 2.5 to 3.5 : 1.7 to 1.05 : 1, the inert solvent with a high boiling point is organic solvent which is insolublein water and has a higher boiling point than that of the phenol, when the condensation reaction reaches the end, the phenol is removed through pressure reduction and distillation, 1-amino-2-phenoxy -4-hydroxyanthraquinone is separated through cooling, and the disperse red 60 is obtained through filtering. The producing method is simple, no wastewater is discharged, and the producing method can meet the requirement for clean production.

Owner:苏州市罗森助剂有限公司

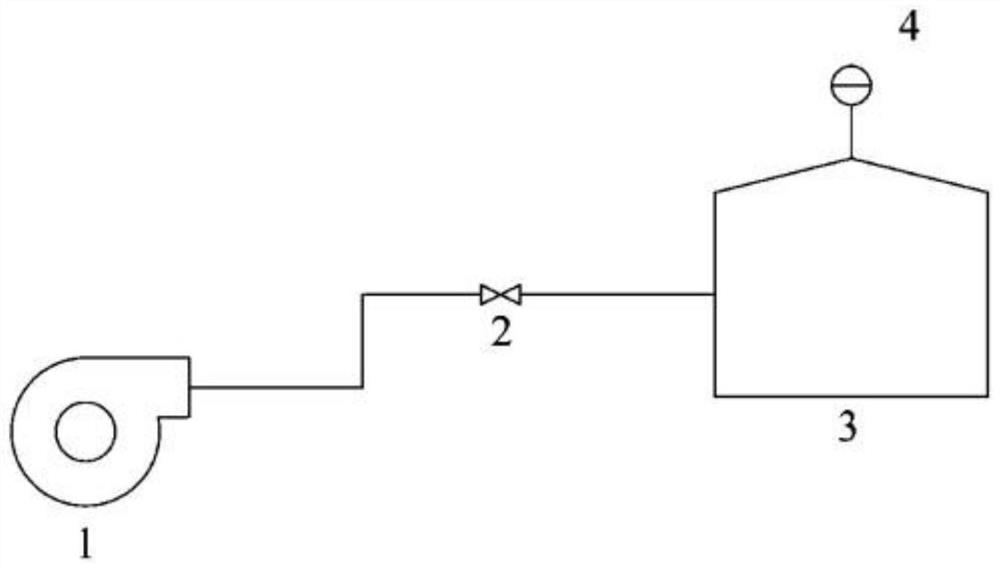

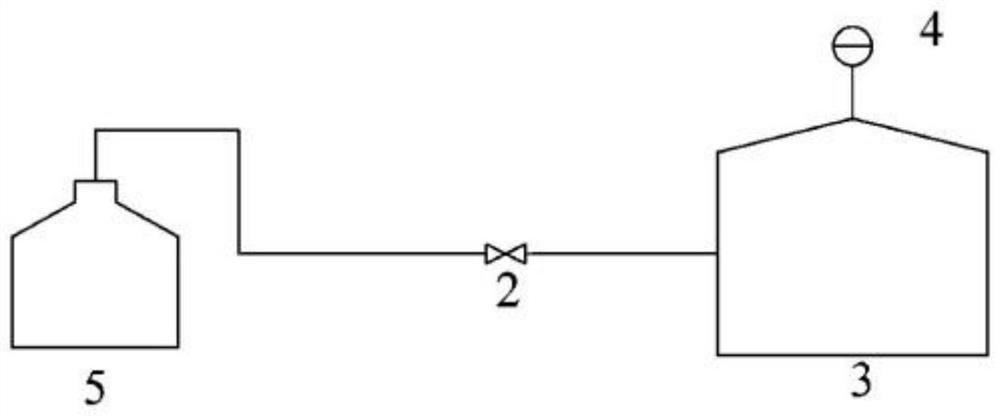

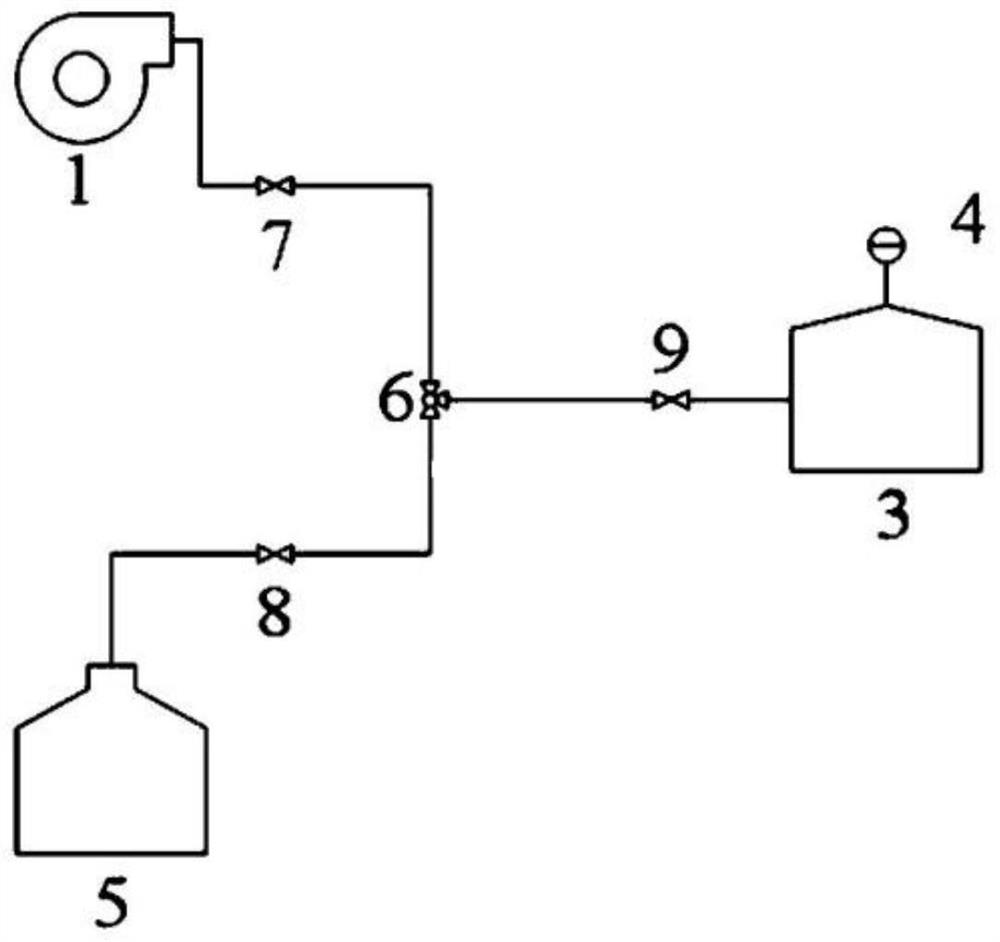

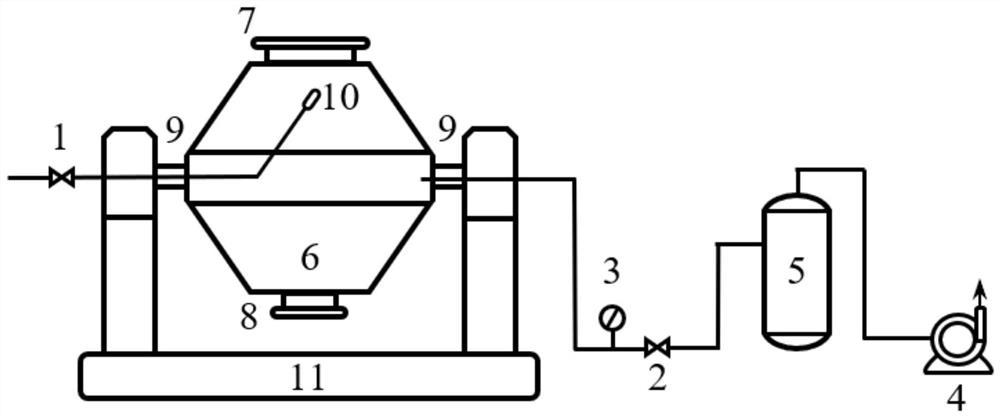

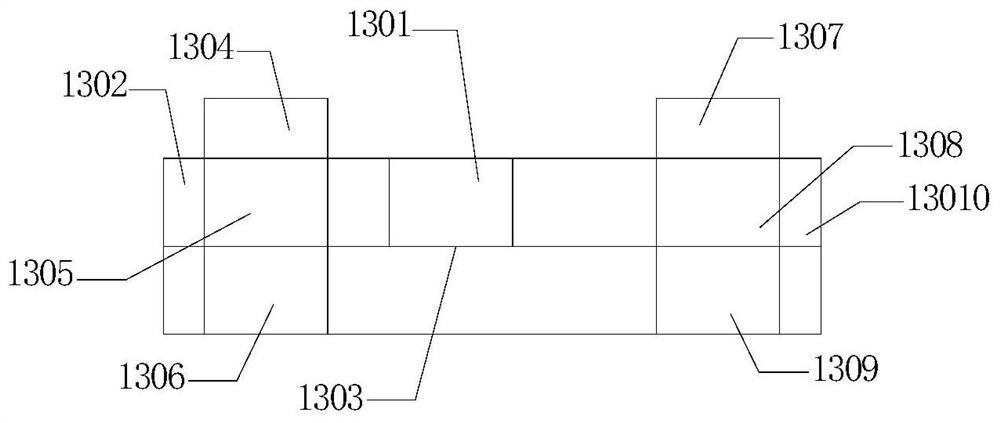

Loaded activated carbon, preparation method and device thereof

InactiveCN111686690AImprove performanceReduce air pressureOther chemical processesActivated carbonActivated charcoal powder

The invention relates to the technical field of activated carbon loading, in particular to a loaded activated carbon and a preparation method and device thereof. The preparation method of the loaded activated carbon comprises the following steps of: vacuumizing a reaction kettle filled with activated carbon, and then introducing an impregnation liquid into the reaction kettle for impregnation treatment to obtain the loaded activated carbon. According to the method, vacuumizing treatment is carried out on the reaction kettle filled with activated carbon, the air pressure in the activated carbonpore channels is reduced, so that a negative pressure environment is formed in the activated carbon pore channels, the mass transfer process of activated carbon impregnation is enhanced through differential pressure, active components in the impregnation liquid can be promoted to be uniformly adsorbed to adsorption sites on the surface of activated carbon, the loading capacity of the active components in the activated carbon is improved, and the obtained loaded activated carbon is good in performance; the method provided by the invention is simple to operate and high in production efficiency,the whole preparation process is carried out in a sealed environment, no activated carbon dust or chemicals escape, and the requirement of clean production is met.

Owner:SHUNDE APOLLO AIR CLEANER +1

Compound fertilizer production technology

InactiveCN103539496BWide variety of sourcesMeet production requirementsFertilizer mixturesPotassiumPulverized fuel ash

The invention discloses a compound fertilizer production technology. The technology comprises the following steps: (1) selecting organic raw materials, namely by weight percent, respectively selecting 35-45% of crop straws, 25%-30% of pig manure and 25%-40% of organic household garbage as the raw materials, wherein the organic household garbage comprises 55wt% of leftover, 15wt% of fruit peels and 30wt% of waste paper; (2) crushing and drying; (3) preparing inorganic fertilizer, namely fully mixing and stirring ordinary superphosphate, urea and potassium chloride, then adding zeolite powder and pulverized fuel ash, and continuously and uniformly mixing, wherein the mass ratio of the superphosphate, the urea and the potassium chloride is (1-2):1:(1-1.5), and the usage amounts of the zeolite powder and the pulverized fuel ash respectively account for 5-8% and 3-5%; (4) metering and mixing; (5) granulating the fertilizer; (6) packaging a product, namely packaging the produced granulated fertilizer with a polypropylene woven bag with a lining, wherein each bag contains 20-25Kg of the fertilizer, and putting the packaged fertilizer in a cool, dry and ventilated storehouse to store. The technology is reasonable and simple, and the raw materials can be widely obtained; in addition, the fertilizer can make the soil bulked, so that the air permeability of the soil is increased; moreover, the fertilizer has a long fertilizer effect period and strong water adsorption capability.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Horizontal centrifugal equipment for separating pectins

InactiveCN103008119AReduce labor intensityAvoid enteringRotary centrifugesEngineeringCentrifugal force

The invention discloses horizontal centrifugal equipment for separating pectins. A rotating drum is divided into a settlement area and a drying area from left to right in an axial direction; a spiral material pusher is arranged in a cavity of the rotating drum; the spiral material pusher comprises a spindle and spiral pushing sheets; the spindle is coaxial with the rotating drum; with equal leads, the spiral pushing sheets are fixedly distributed on the external circumferential surface of the spindle in an axial direction of the spindle; the spiral pushing sheets in the settlement area are distributed with equal circles; a material outlet is formed in the spindle of the settlement area; a liquid phase outlet is formed at the leftmost end of the settlement area; the spiral pushing sheets of the drying area are conically distributed in an axial direction; a solid phase outlet is formed at the right end of the drying area; the ratio between the effective working length and the radius of the rotating drum is more than 4.5; pectin and fruit residue suspension is placed in a centrifugal force field of the rotating drum; the solid phase is settled on the inner wall of the rotating drum and conveyed to the material outlet by the spiral material pusher; the liquid phase overflows out via a spiral passage; and the solid phase and the liquid phase are separated; therefore, a better separating effect is obtained.

Owner:CHANGZHOU UNIV

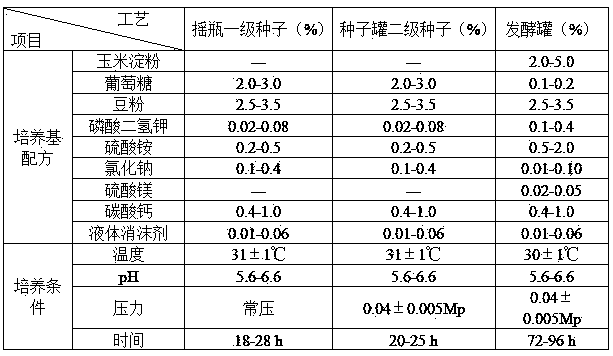

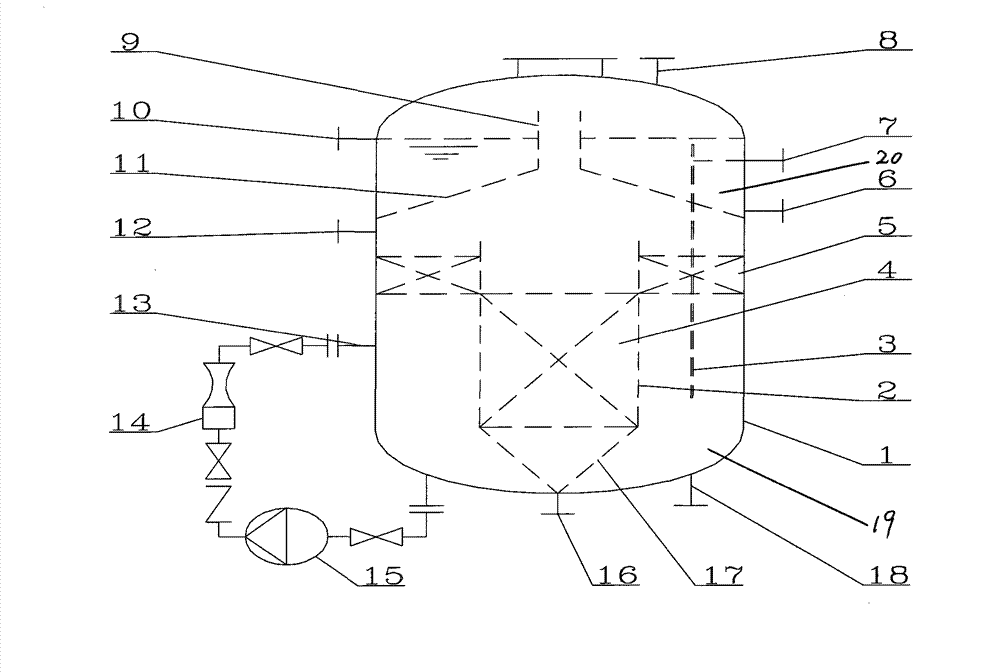

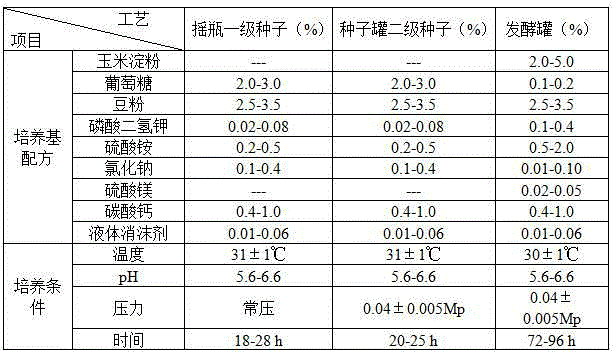

Method for reducing ammonia nitrogen content in polymyxin E fermentation liquor

ActiveCN103509839AMeet clean production requirementsReduce difficultyMicroorganism based processesFermentationBiotechnologyAmmoniacal nitrogen

The invention discloses a method for reducing the ammonia nitrogen content in polymyxin E fermentation liquor. The method comprises the step of dropwise adding an alkaline substance during the fermentation process of polymyxin E to control the pH value of the fermentation liquor. The key point is that the method is to feed ammonia water and sodium hydroxide sequentially at the beginning of fermentation to control the pH value of the fermentation liquor. The beneficial effects are as follows: when the polymyxin E is fermented for a certain time, the sodium hydroxide is fed to replace the ammonia water to maintain the pH value, so that the nitrogen source is supplemented, the pH value is controlled, and the ammonia nitrogen content in the polymyxin E waste fermentation liquor can be reduced by more than 40%. Therefore, the difficulty of sewage treatment is reduced from the source, and the clean production requirement of polymyxin E fermentation can be met.

Owner:HEBEI SHENGXUE DACHENG PHARMA

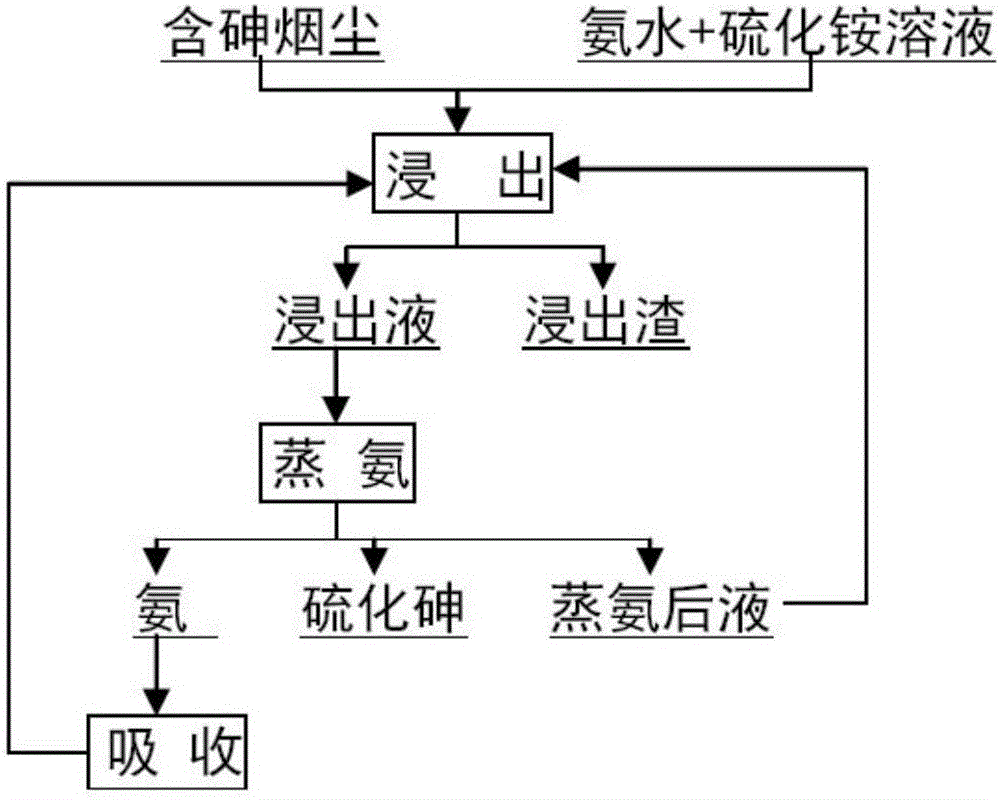

Method for removing arsenic from arsenic-contained smoke

ActiveCN105907982ALow toxicityAchieve selective removalProcess efficiency improvementAmmonium sulfideEvaporation

The invention provides a method for removing arsenic from arsenic-contained smoke, and belongs to the technical field of wet metallurgy. According to the method, arsenic is selectively leached out of the arsenic-contained smoke through ammonia and an ammonium sulfide solution, the arsenic is leached out to enter the solution, and valuable metal stays in residue; arsenic leaching liquid is subject to evaporation and deamination, and arsenic sulfide precipitation is obtained; ammonia generated through evaporation is absorbed and returns to leaching of the arsenic-contained smoke, and liquid obtained after ammonia evaporation returns to the leached-out arsenic-contained smoke; and according to the process, selective removing of arsenic is achieved, white arsenic obtained through volatizing of arsenic sulfide residue relative to the pyrogenic process is low in virulence, a reagent for leaching out is circularly used, and the method has the beneficial effects of being short in process flow and small in number of working procedures and can meet the clean production requirement.

Owner:UNIV OF SCI & TECH BEIJING

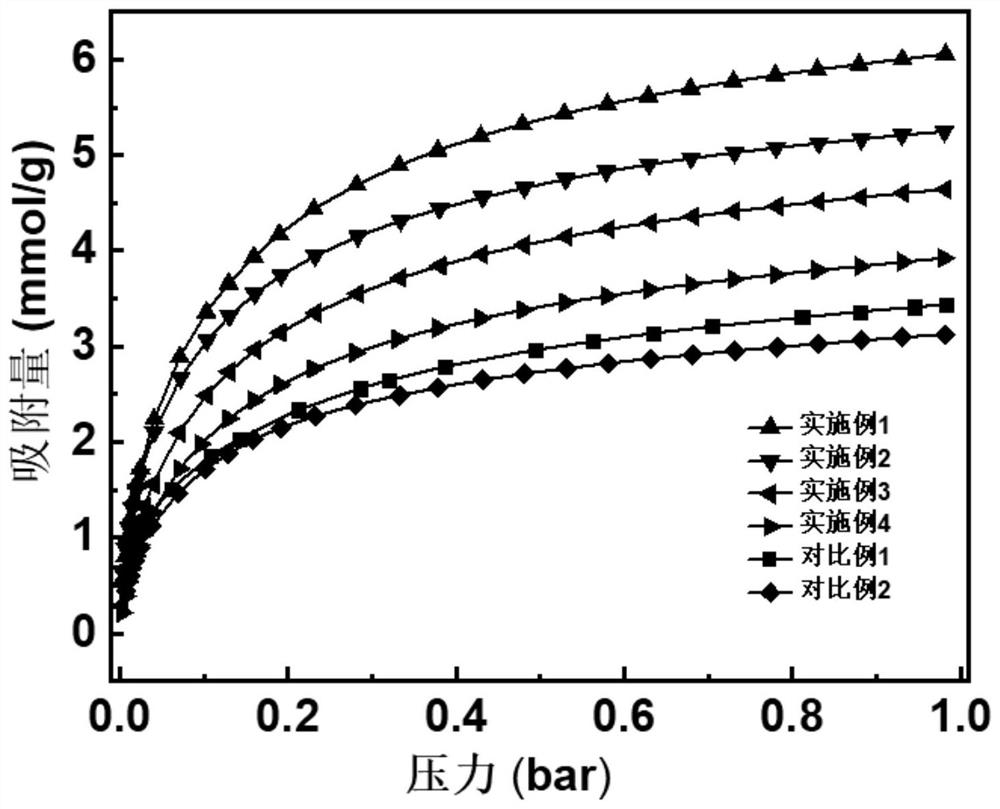

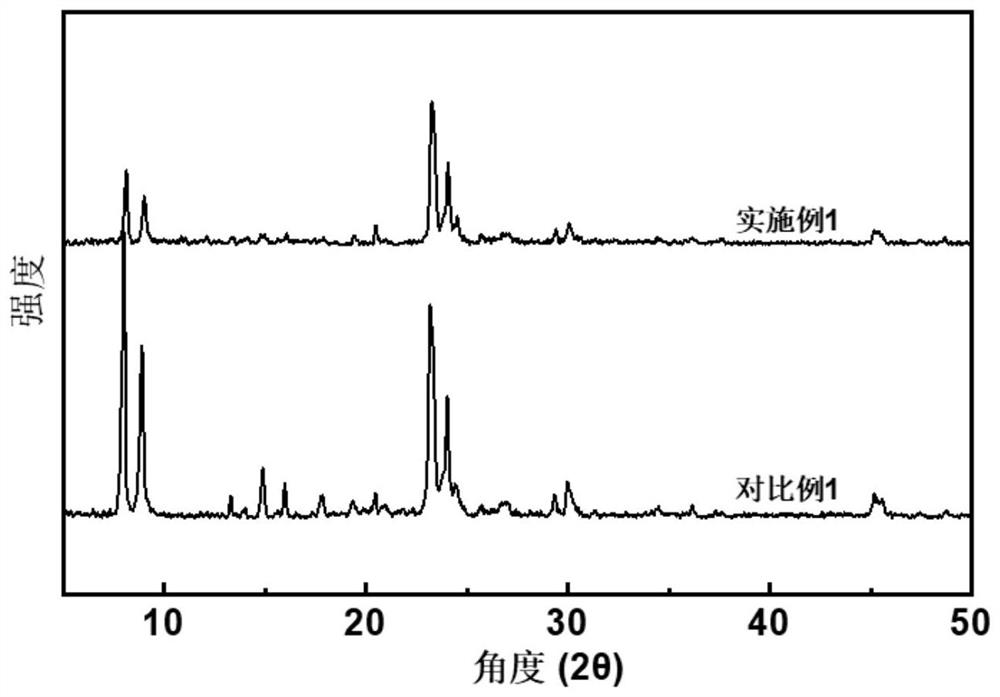

Modified molecular sieve for CO2 adsorption separation and preparation method and device thereof

ActiveCN114713186AEnhance chemical adsorption forceImprove adsorption capacityGas treatmentOther chemical processesMolecular sievePhysical chemistry

The invention discloses a modified molecular sieve for CO2 adsorption separation and a preparation method and device thereof, and relates to the technical field of carbon capture. The method comprises the following steps: (1) carrying out vacuum degassing activation on a molecular sieve to obtain a product A; (2) depositing organic amine on the product A to obtain a product B; the deposition is step-by-step deposition; and (3) carrying out vacuum degassing on the product B to obtain the modified molecular sieve. According to the method, vacuum gas phase step-by-step dynamic deposition is adopted, the defects that a traditional organic amine impregnation method is uneven in loading and prone to causing pore channel blockage are overcome, waste liquid is not generated, and industrial batch production is easy to achieve. The molecular sieve provided by the invention has high CO2 adsorption capacity at low pressure, the maximum CO2 adsorption capacity is measured to be 3.35 mmol g <-1 > at 25 DEG C and 0.1 bar, the low-pressure adsorption capacity is improved by more than 50% compared with that of an original sample, and a device for preparing the modified molecular sieve provided by the invention has a very good industrial application prospect.

Owner:SOUTH CHINA UNIV OF TECH

A tunnel type super (sub) critical CO 2 Waterless scouring device

ActiveCN110468458BEfficient recyclingSolve pollutionFatty substance recovery/refiningWool fibre washing/scouringProcess engineeringMechanical engineering

The invention relates to a tunnel type super (sub)critical CO 2 A waterless wool washing device belongs to the field of wool washing equipment. The device of the present invention includes a tunnel-type wool scouring warehouse; the tunnel-type wool scouring warehouse includes a wool washing car, a wool washing car locator I, a guide rail, a wetting pool, a cleaning pool, and a wool washing car locator II; the guide rail Pass through the scouring car locator I, the wetting pool, the cleaning pool, and the scouring car locator II in sequence; the scouring car slides on the guide rail; when the wool scouring car enters the wetting pool along the guide rail, the The wool washing car is sealed with the wetting pool; when the wool washing car enters the washing pool along the guide rail, the wool washing car is sealed with the washing pool.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for producing m-chlorobenzoyl chloride

InactiveCN101774908BLow costHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsM-chlorobenzoic acidN dimethylformamide

The invention relates to a method for producing m-chlorobenzoyl chloride, in which m-nitrotoluene is used as raw material, pyridine, pyridinium salt, pyridine derivative containing halogen and fat groups on a ring, salt thereof and N, N-dimethylformamide and salt thereof are used as catalysts, and substitution reaction between the m-nitrotoluene and chlorine is carried out at ordinary pressure and the temperature of 120-220 DEG C to obtain more than 90 percent m-chlorobenzoyl chloride crude. The chloride is directly hydrolyzed to obtain m-chlorobenzoic acid which is then reacted with thionyl chloride and rectified to obtain high-purity m-chlorobenzoyl chloride. The invention directly takes the m-nitrotoluene as the raw material, the m-chlorobenzoyl chloride is obtained via chlorination bychlorine with the catalysts under UV-irradiation, and hydrolysis is further carried out to obtain the m-chlorobenzoic acid. Each step of reaction is carried out under a relatively mild technological condition. The invention has the advantages of low cost and high yield and product purity, by-product hydrochloric acid and dilute nitric acid can both be used. Three wastes are not generated, energy is saved, and environment is protected.

Owner:YIXING BRANCH OF SHANDONG SHENGONG CHEM GROUPCO

Novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification

ActiveCN101994008BEliminate the effects of pollutionRealize closed-loop operationProcess efficiency improvementBiological activationCobalt

The invention relates to a process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification, which comprises: separating cobalt from lixivium of nickel and cobalt slag by using a cobalt activation inorganic flocculation method, enriching the cobalt, recovering cobalt, removing cadmium from the cobalt-free lixivium by using the conventional zinc replacement method, obtaining sponge metal cadmium, delivering the sponge metal cadmium to a zinc smelting copper and cadmium processing step to recover metal cadmium. After cobalt and cadmium are removed, the lixivium is returned to a leaching step in a main zinc smelting system for recovering zinc. Thus, metals such as zinc, cobalt, cadmium and the like are recovered from the nickel and cobalt slag; meanwhile, the environmental pollution influence of the long-term piled up slag and the risk of irregular transfer of heavy metal pollutants such as cadmium in the zinc industry are eliminated, the closed-circuit operation of the recycling of the slag is realized, discharge of waste water and gas is avoided, valuable metals are comprehensively recovered, the requirement on pollution-free production is met and the problem of the industry is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

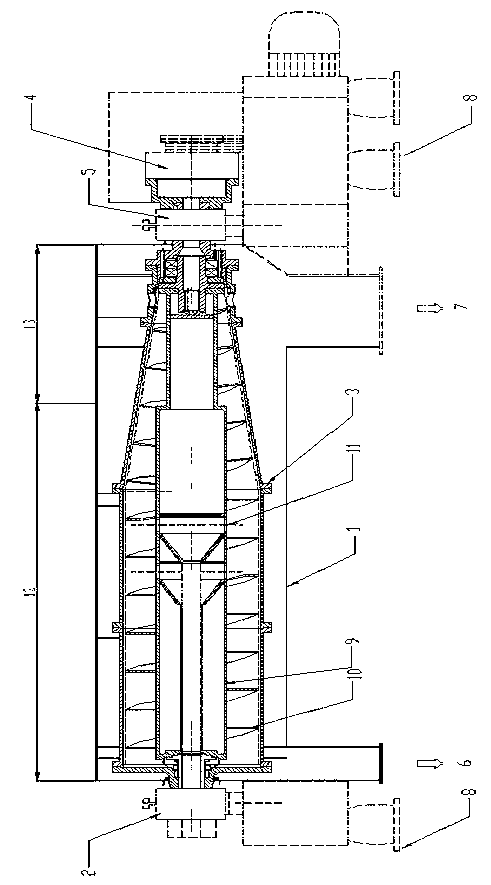

Integrated multifunctional air-floatation water purifier

InactiveCN101993126BMeet clean production requirementsReduce volumeWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationEngineeringVertical cylinder

The invention discloses an integrated multifunctional air-floatation water purifier, and belongs to the technical field of water treatment. The integrated multifunctional air-floatation water purifier comprises a vertical cylinder; the side face of the vertical cylinder is provided with a water inlet, a dissolved air inlet, a water outlet, a residue discharge hole, an overflow gate, an air outlet and an emptying port; an concentric inner cylinder is arranged on the middle lower part of the vertical cylinder; an air-liquid mixing device is arranged in the inner cylinder; the water inlet extends into the inner cylinder; the upper opening of the inner cylinder is open; an obconical floating residue collecting cover is arranged in the vertical cylinder above the inner cylinder; a floating residue concentrator on the top of the floating residue collecting cover is communicated with the residue discharge hole; a mud and sand collecting concentrator is arranged on the bottom of the inner cylinder, and is communicated with a mud discharge pipe on the bottom of the vertical cylinder; a space between the upper part of the inner cylinder and the vertical cylinder is designed to be a filter area; a space between the middle lower part of the inner cylinder and the vertical cylinder is designed to be a purified water area; a space at the upper end of the floating residue collecting cover is designed to be a water outlet area; the dissolved air inlet is connected with a plurality of groups of Venturi pipes and then is communicated with the purified water area on the lower part of the vertical cylinder through an external water pump; and a water communicating built-in flow transfer pipe is arranged between the purified water area and the water outlet area. The integrated multifunctional air-floatation water purifier has long service life, high automation degree, low operating cost without secondary pollution, is easy and convenient to operate and runs in a closed mode.

Owner:YAZHOU ENVIRONMENTAL PROTECTION YIXING CITY

Method for reducing ammonia nitrogen content in polymyxin E fermentation liquor

ActiveCN103509839BMeet clean production requirementsReduce difficultyMicroorganism based processesFermentationBiotechnologyAmmoniacal nitrogen

A method for reducing the ammonia nitrogen content in the polymyxin E fermentation liquid, comprising the step of controlling the pH of the fermentation liquid by dropping alkaline substances during the fermentation of the polymyxin E, the key is: the method is in After the fermentation starts, ammonia water and sodium hydroxide are used to feed successively to control the pH of the fermentation liquid. The beneficial effect of the present invention is that, after fermentation reaches a certain period of time, the pH can be maintained by feeding sodium hydroxide solution instead of ammonia water, which can not only achieve The purpose of supplementing nitrogen source and controlling pH can also reduce the content of ammonia nitrogen in polymyxin E fermentation waste liquid by more than 40%, which reduces the difficulty of sewage treatment from the source and achieves the cleanliness of polymyxin E fermentation. Production requirements.

Owner:HEBEI SHENGXUE DACHENG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com