Patents

Literature

63results about How to "Increase the number of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

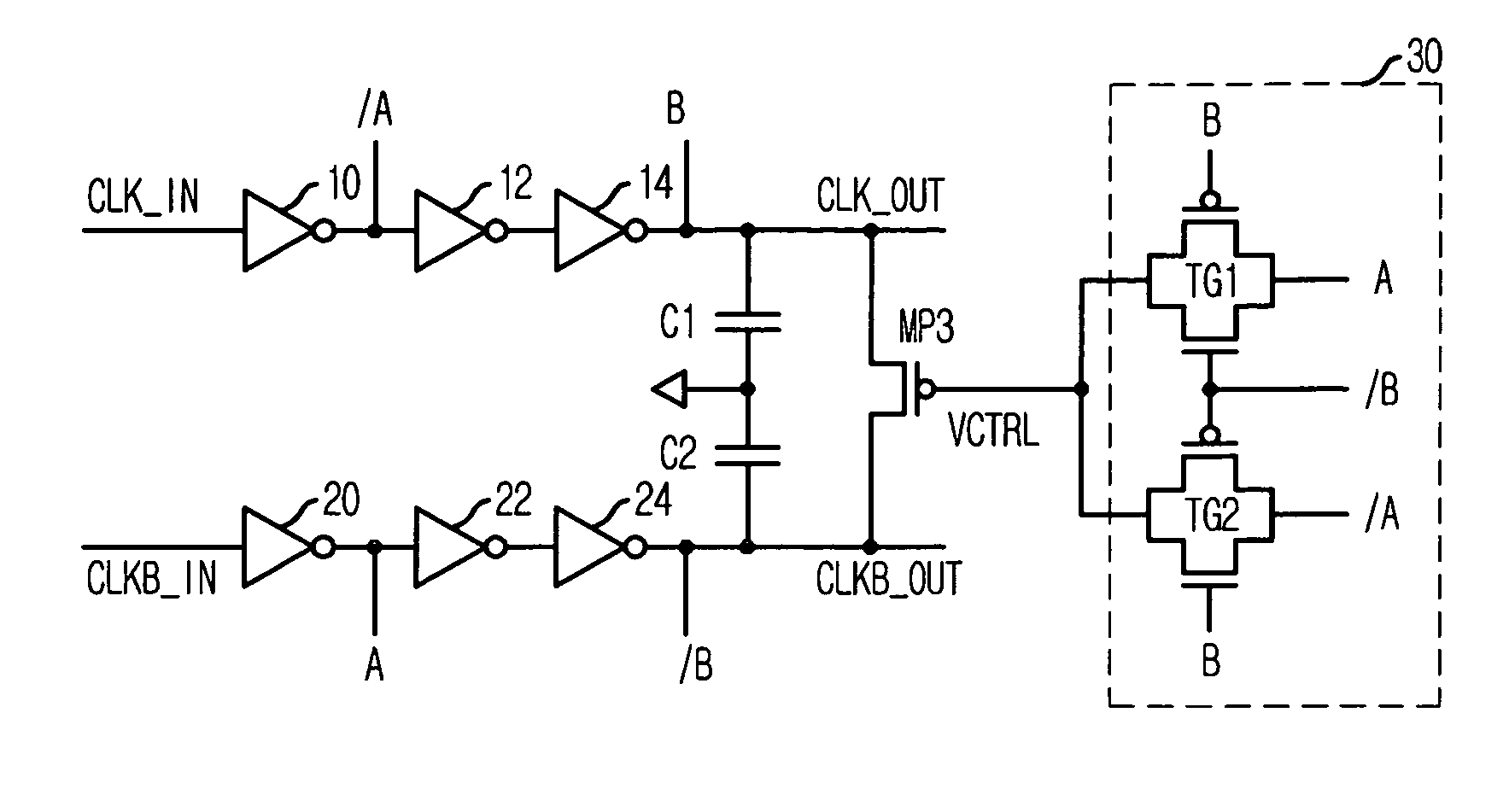

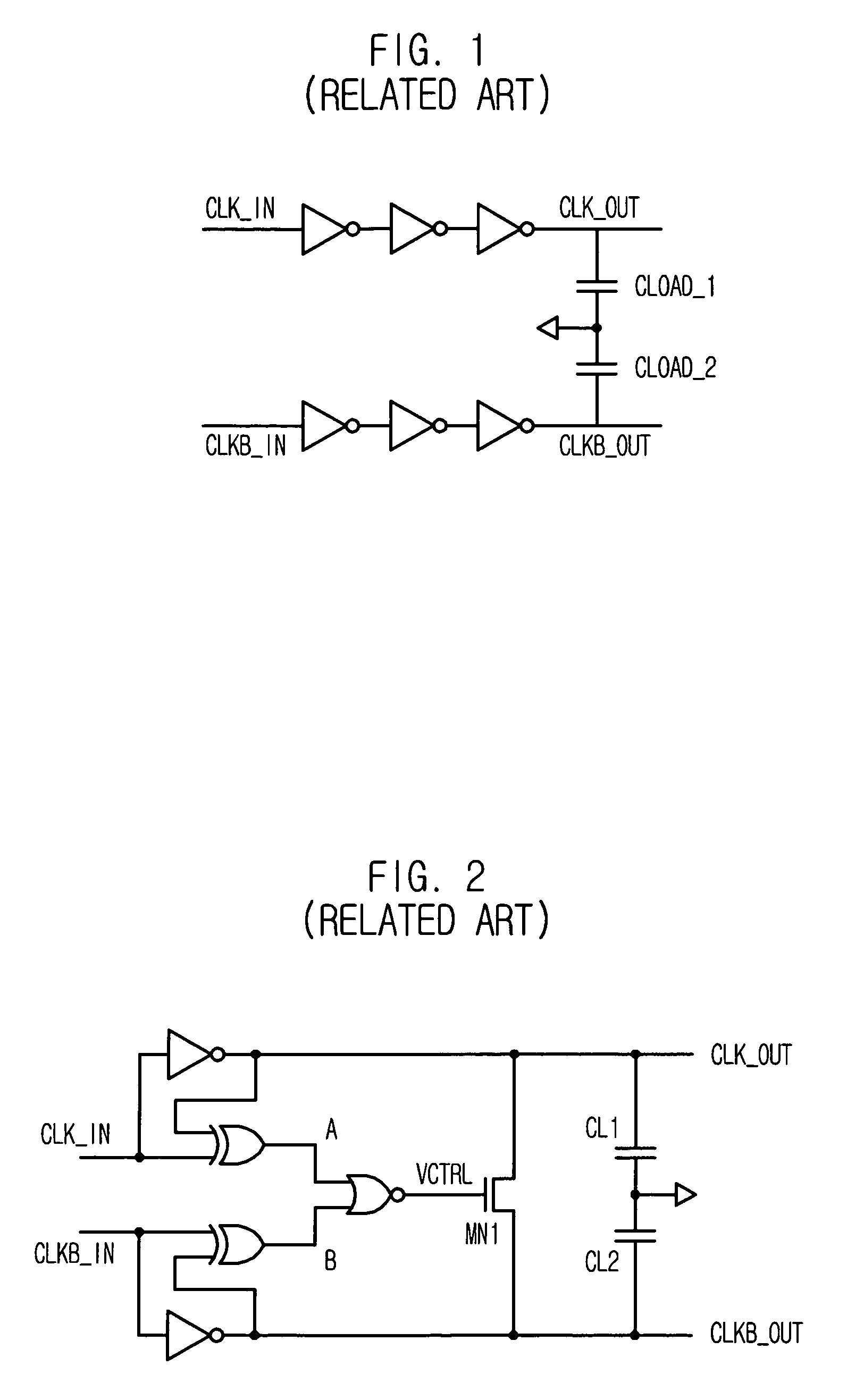

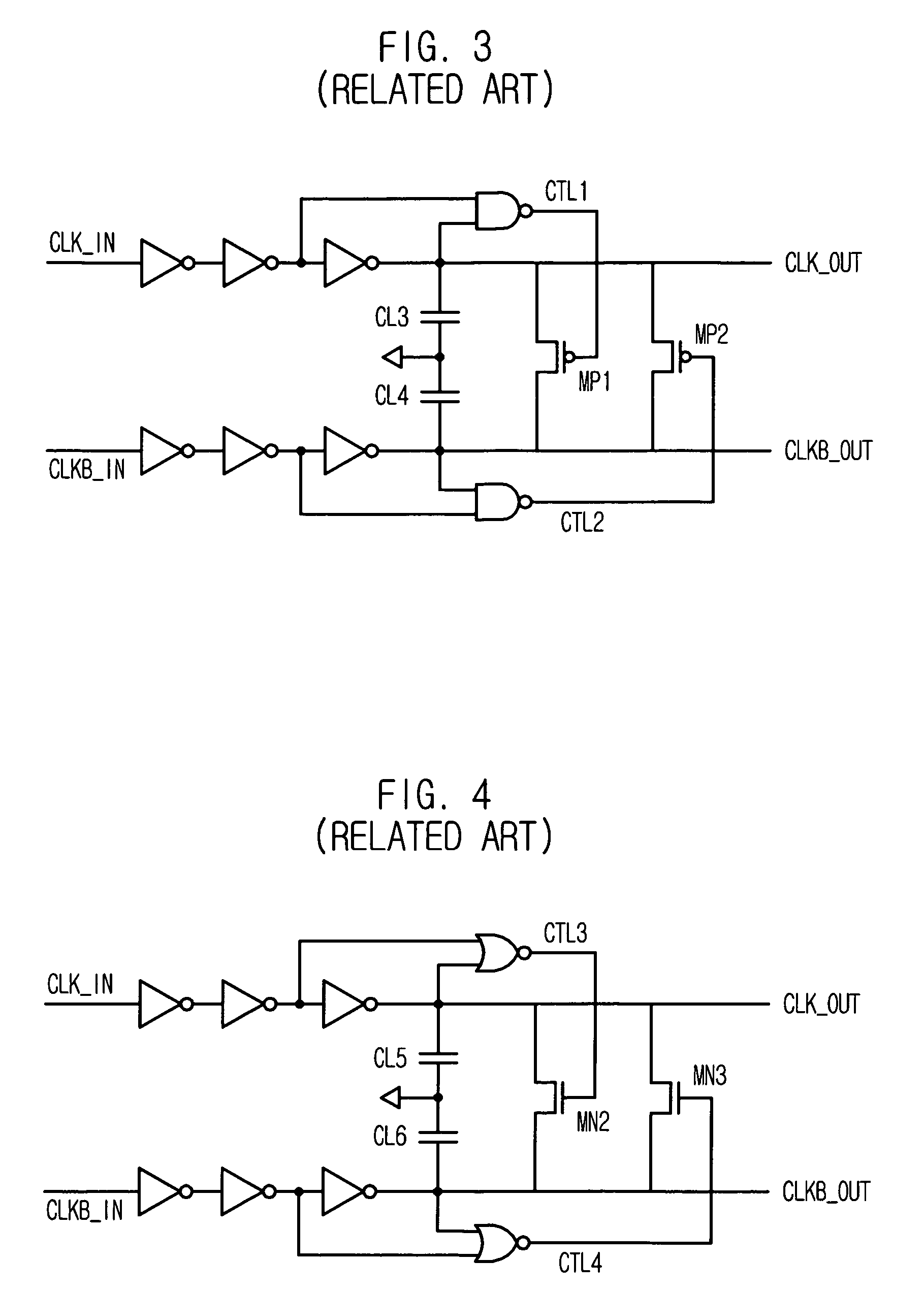

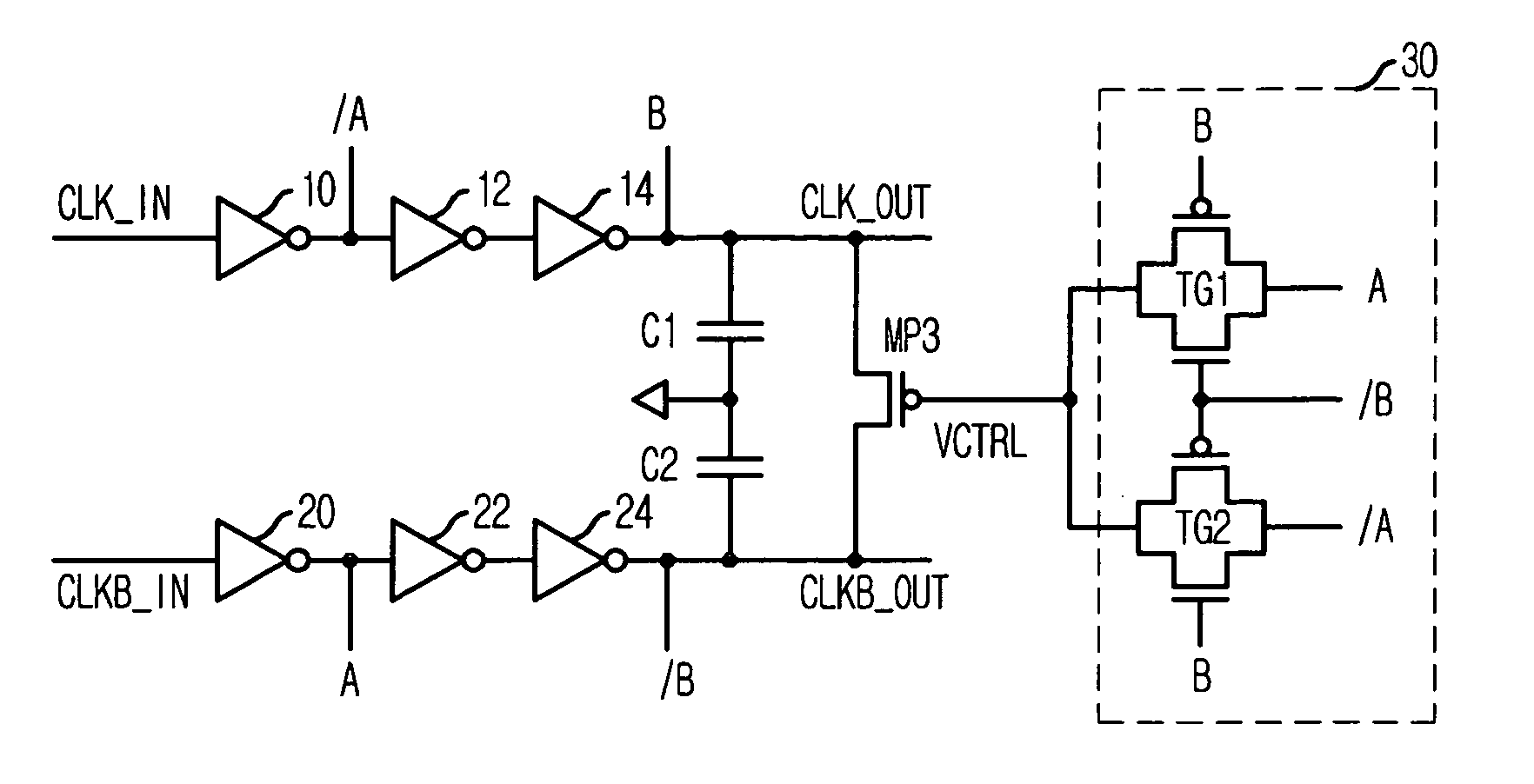

Clock driver

ActiveUS7521978B2Excellent charge recycling efficiencyReduced footprintDigital storageElectric pulse generatorEngineeringClock signal

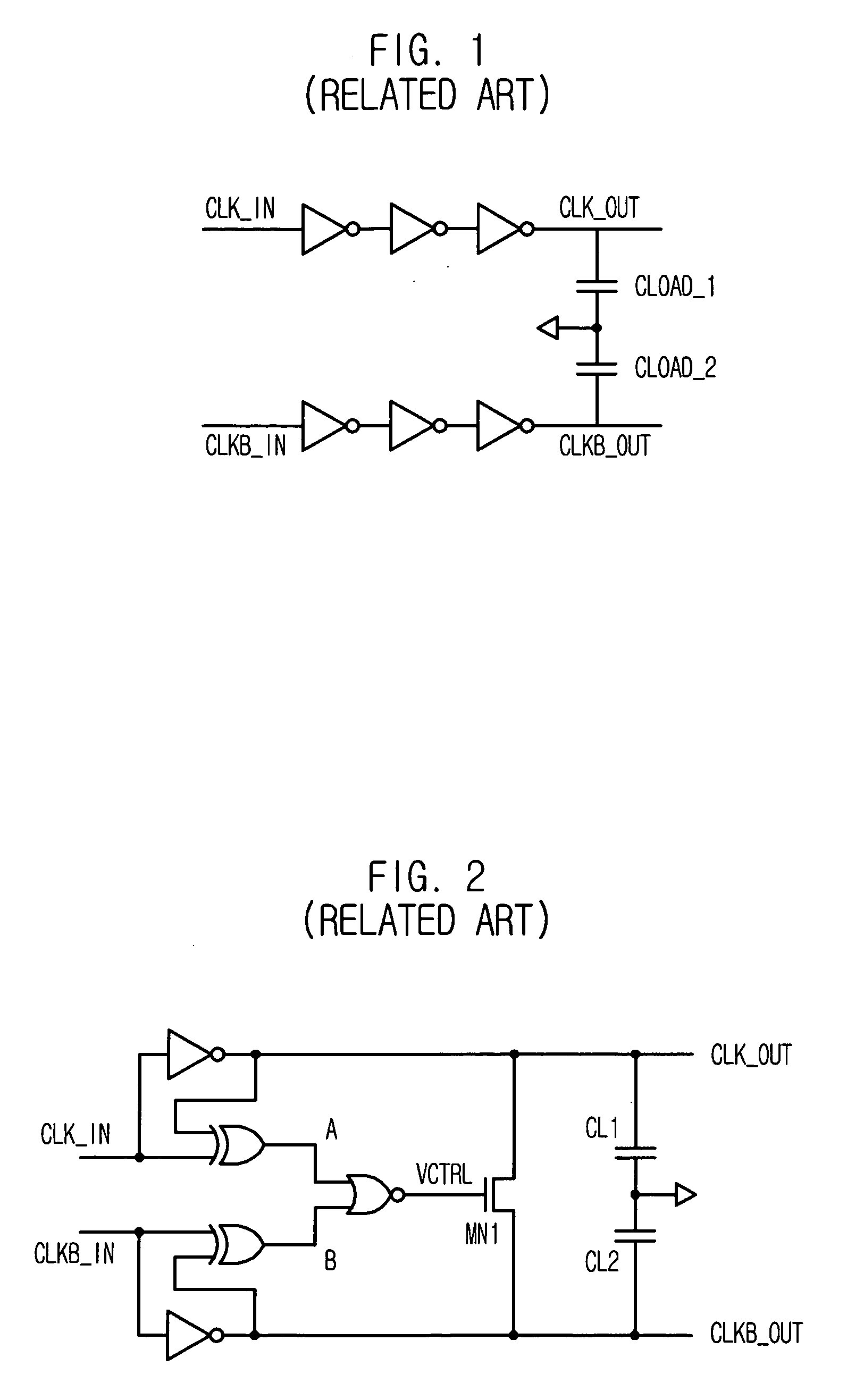

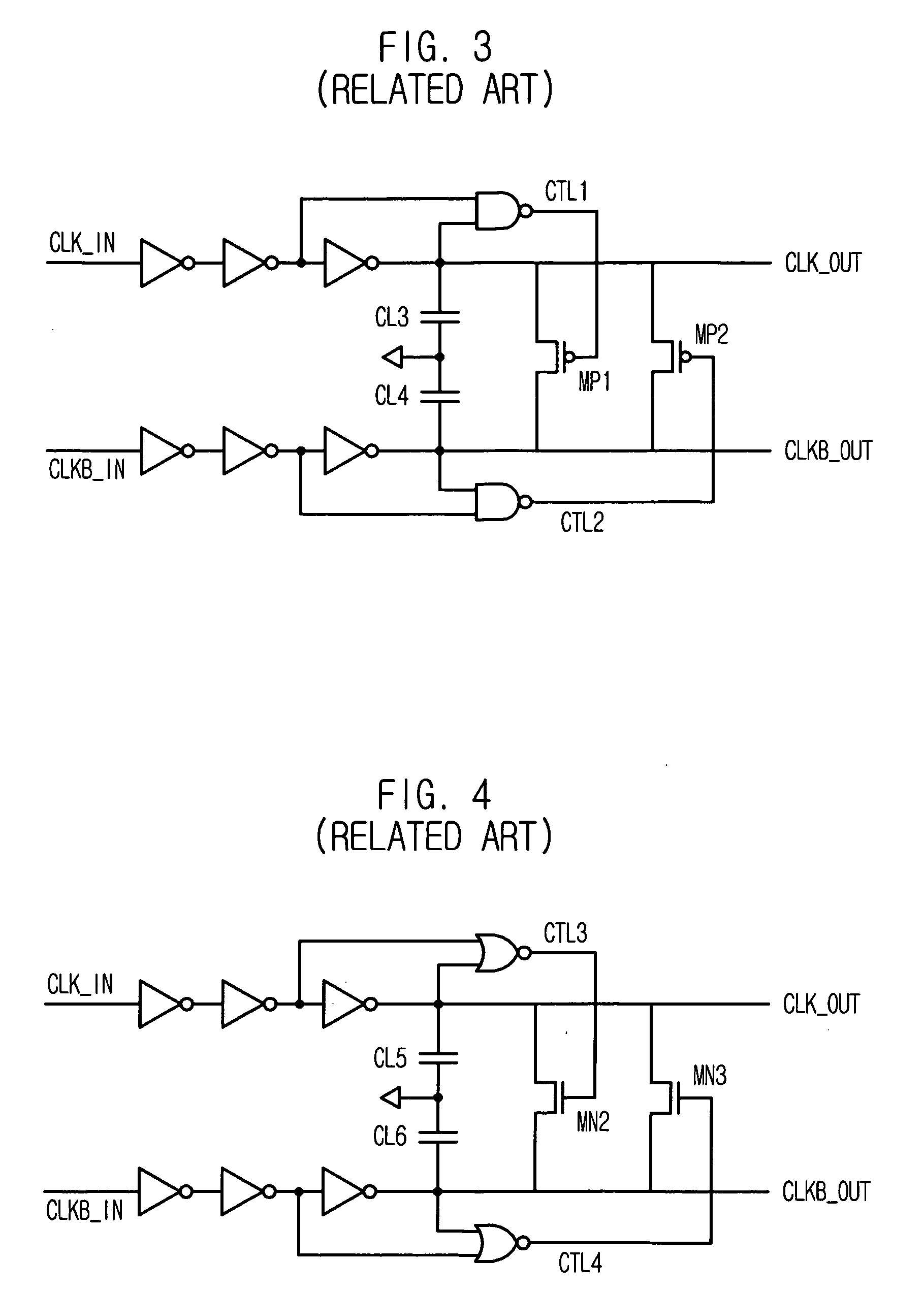

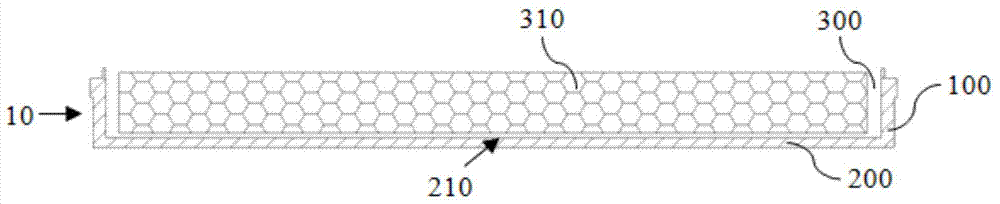

A clock driver is provided. A first driving unit is configured with a plurality of drivers and receives a first clock signal to drive a first pumping clock. A second driving unit is configured with a plurality of drivers and receives a second clock signal to drive a second pumping clock. A charge recycling switch is connected between an output terminal of the first driving unit and an output terminal of the second driving unit. A switch controller selectively transfers an input clock signal of the first or second driving unit to the charge recycling switch in response to the first and second pumping clock signals.

Owner:SK HYNIX INC

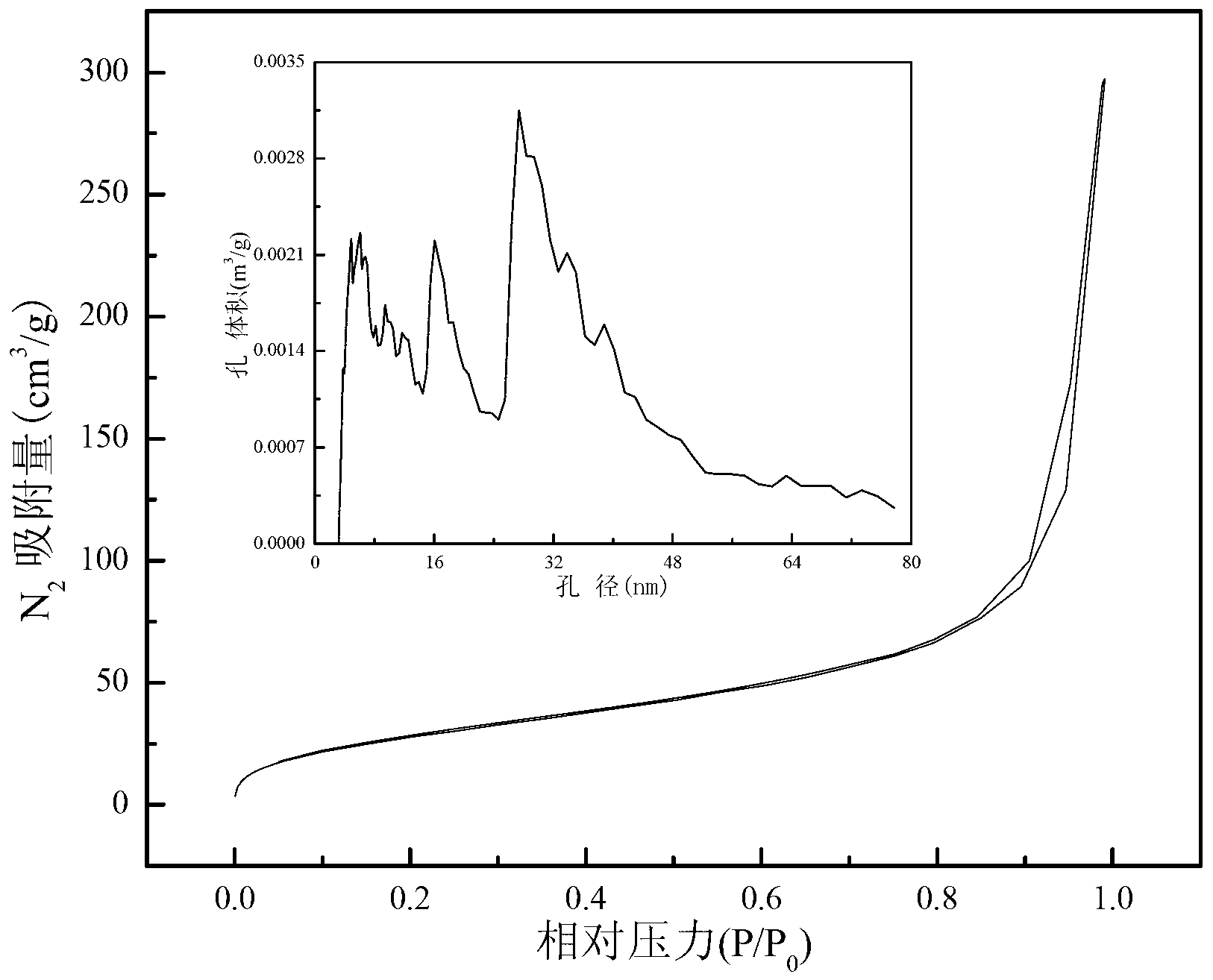

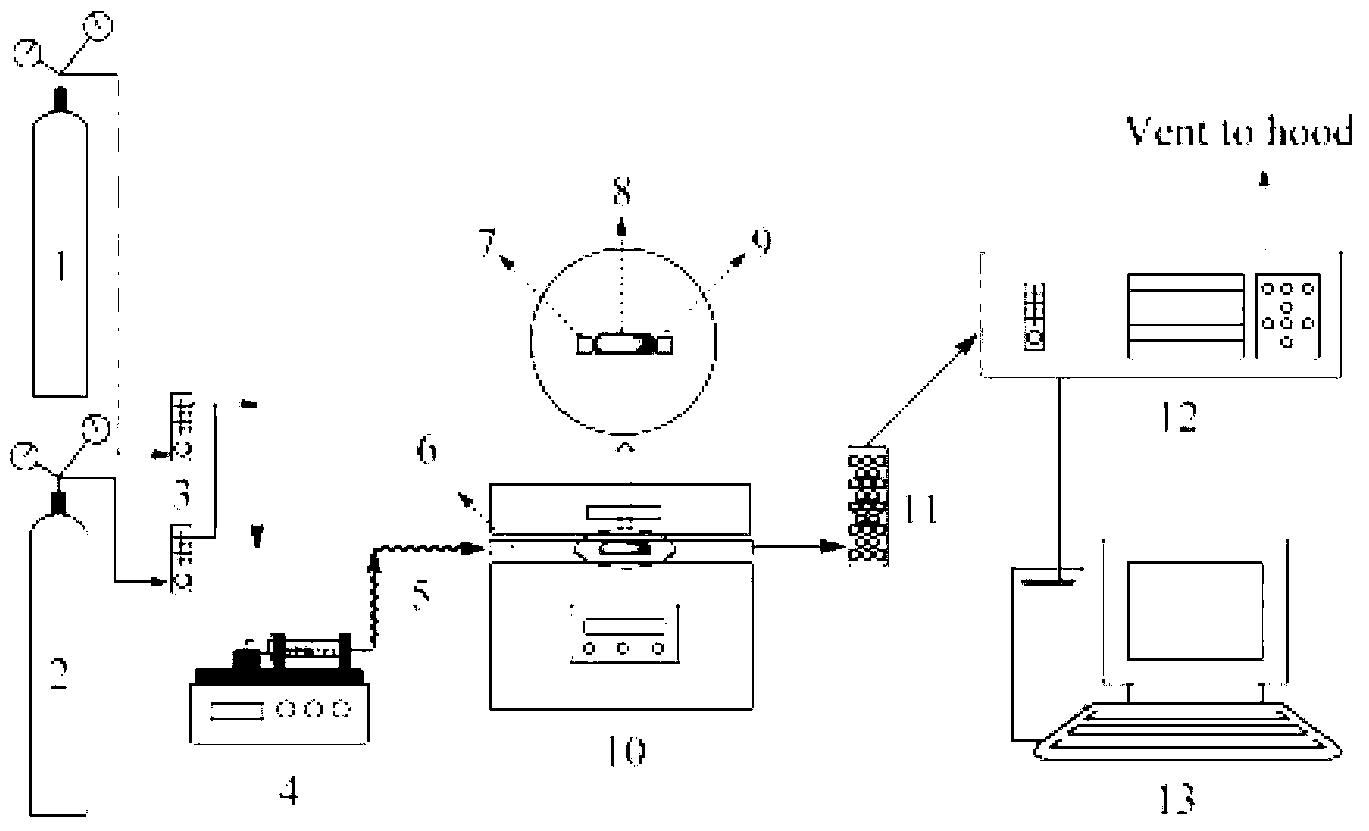

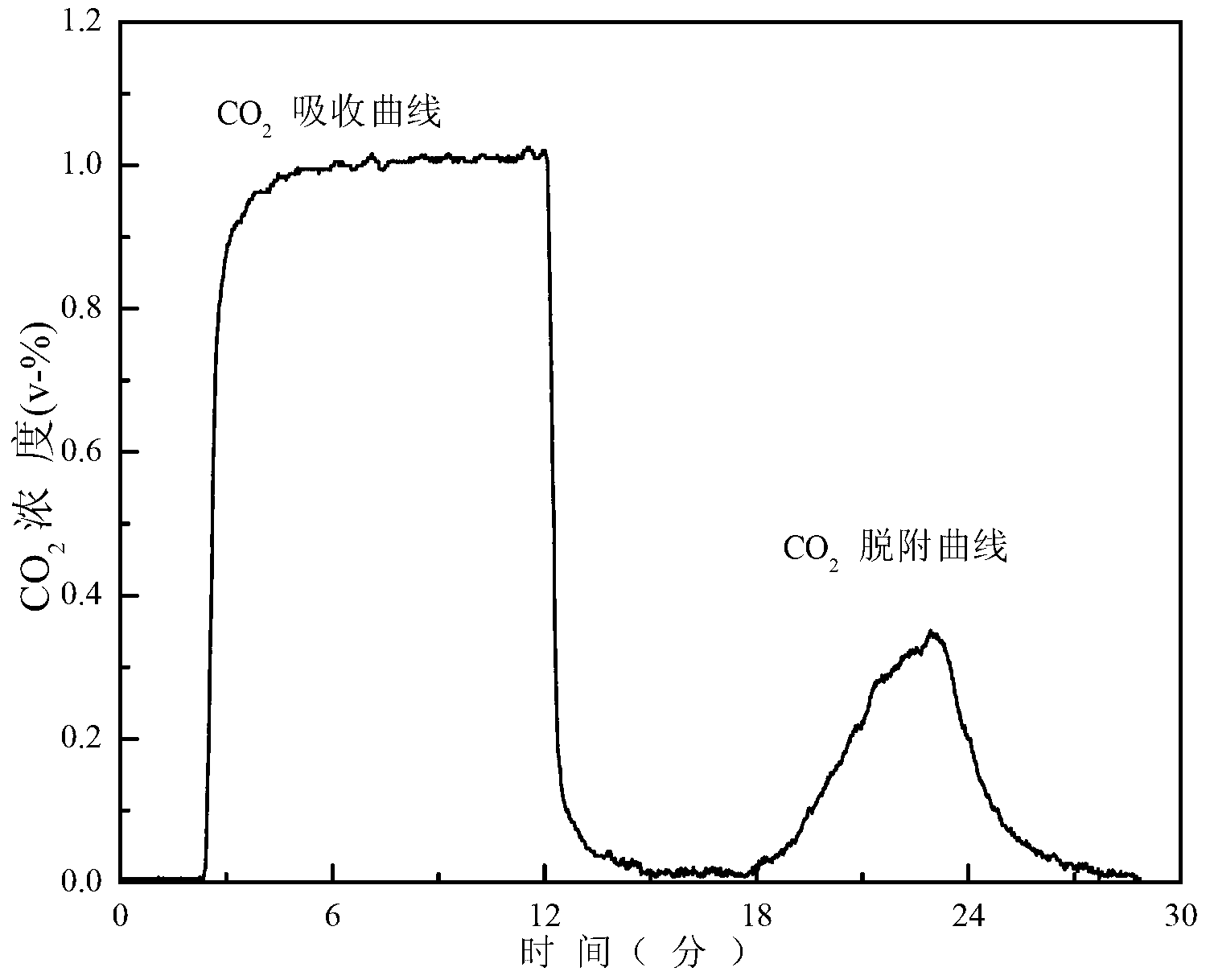

Solid absorbent with high CO2 adsorption capacity and preparation method thereof

InactiveCN103230778AFast decarbonizationFastOther chemical processesDispersed particle separationSupercritical dryingCorrosion

The invention discloses a solid absorbent with high CO2 adsorption capacity and a preparation method thereof. The solid absorbent comprises active components and a carrier; the active components are alkali carbonate and an amino group at the surface of the carrier, and are 15-60% of total quality of the solid absorbent; the molar ratio of the alkali carbonate and the amino group is 1 to (0.5-25); and the carrier is monox, and is 40-85% of total quality of the solid absorbent. The preparation method comprises the following steps of mixing and stirring the materials into emulsion; putting the emulsion into air to form cross-linking gel; putting the gel into a sealed dryer; soaking the gel by ethanol; and drying and screening the gel by a supercritical drying method, so as to prepare the solid absorbent with high CO2 adsorption capacity. The absorbent is low in price, stable in structure, high in carbonic acid conversion ratio, not easy to inactivate, and small in corrosion on equipment, and has certain mechanical strength, and high cyclic utilization rate; and the preparation method of the absorbent is convenient to operate, and low in expenses.

Owner:SOUTHEAST UNIV

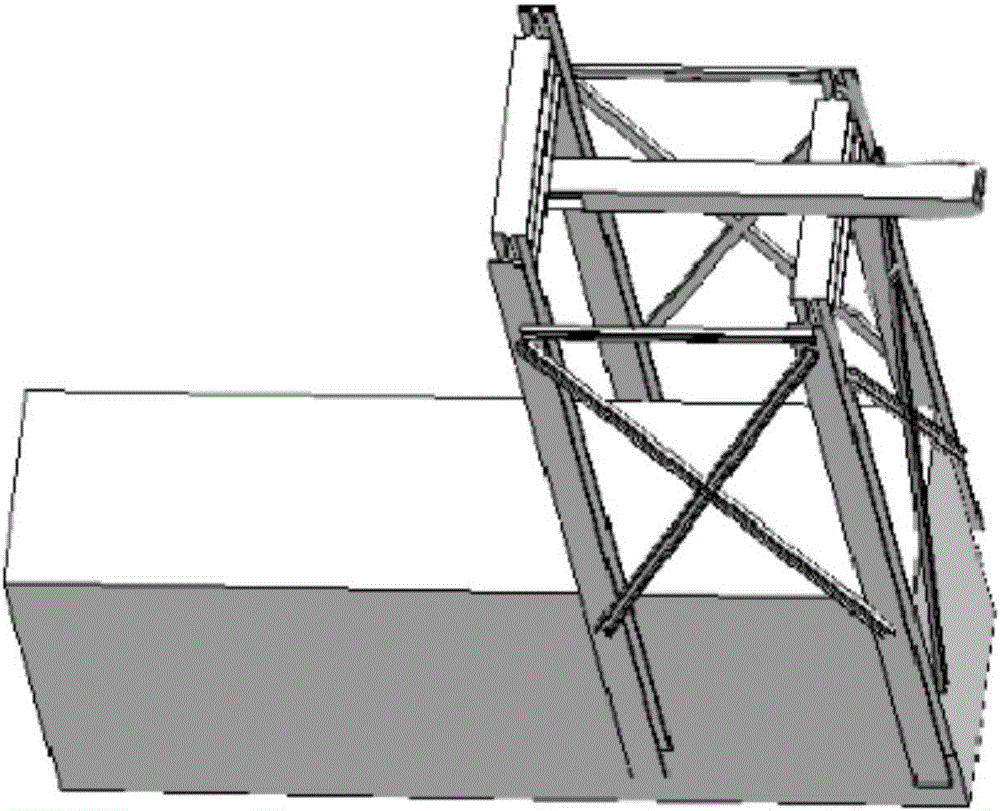

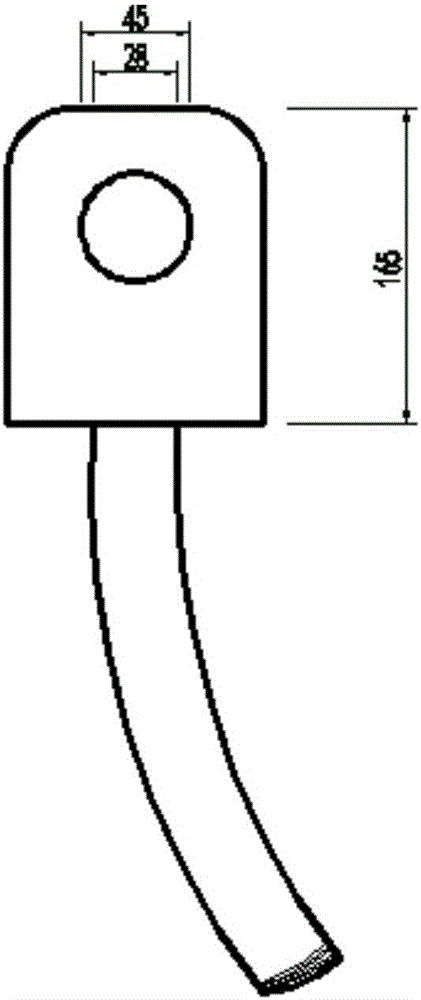

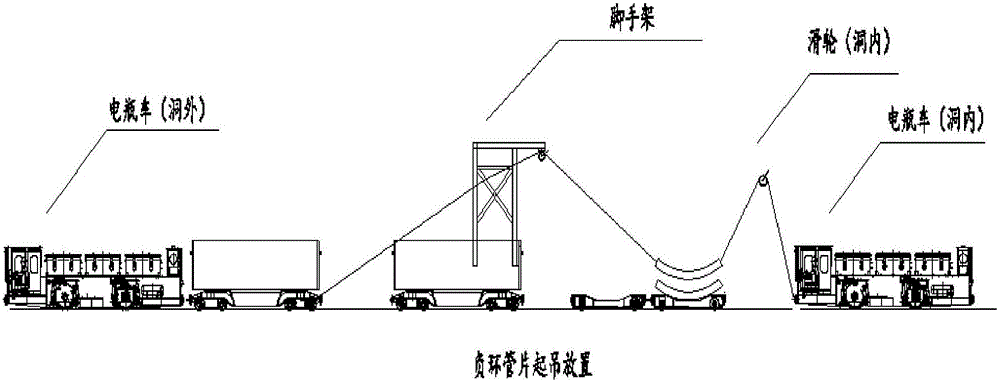

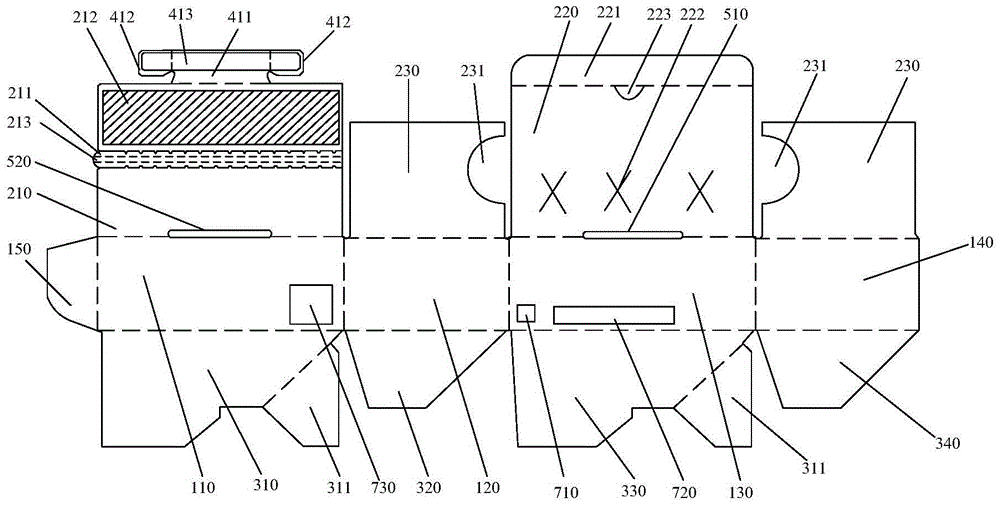

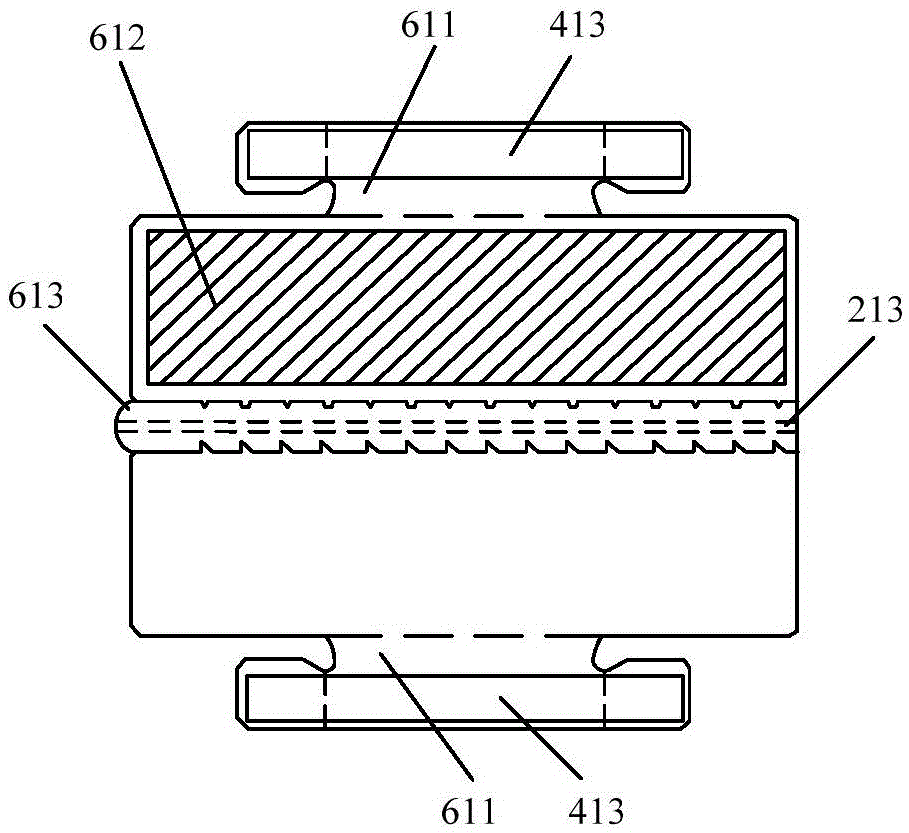

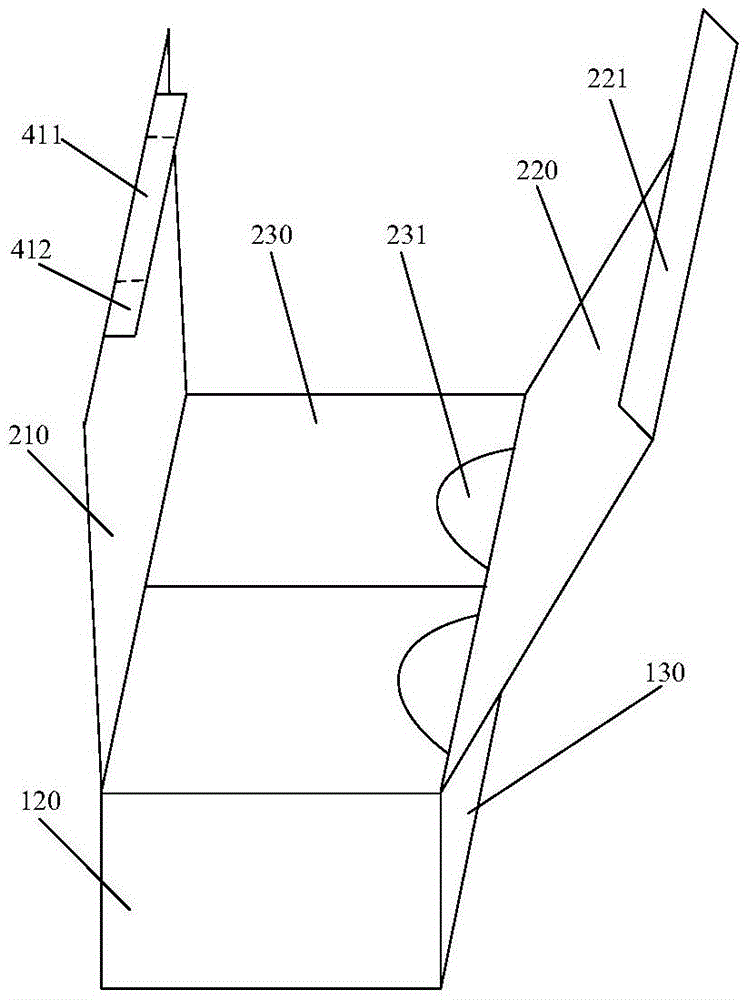

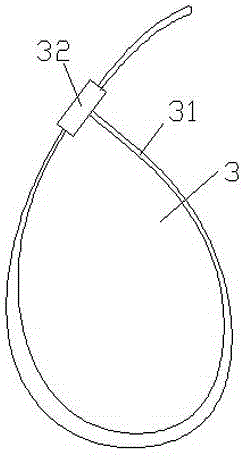

Technology for disassembling negative rings of TBM (tunnel boring machine) arrival hole

ActiveCN105781590AEasy to removeSafe dismantlingUnderground chambersTunnel liningShotcreteEngineering

The invention relates to a technology for disassembling negative rings of a TBM (tunnel boring machine) arrival hole. The technology is characterized in that firstly a set of complete negative ring disassembling and hoisting equipment is assembled, and is welded to form a steel bracket which is provided with a hoisting point; one steel rope is sequentially connected with a storage battery car outside the hole, penetrates through the hoisting point, and is used for hoisting pipe pieces through a hoisting bolt; a pulley inside the hole is fixed to the top of each of the pipe pieces through bolts; one end of another steel rope is connected with a storage battery car inside the hole and then goes around the pulley inside the hole, and the other end of the steel rope is used for hoisting the pipe pieces through hoisting bolts. The negative rings are disassembled through the following steps of (1) disassembling steel shotcrete; (2) assembling the hoisting equipment; (3) disassembling a reaction frame; (4) mounting the pulley inside the hole; and (5) disassembling the negative rings, wherein the negative rings are disassembled in a manner that the pipe pieces are separately disassembled, F pipe pieces and adjacent pipe pieces are disassembled at the same time, and the negative rings are disassembled in the disassembling sequence that the pipe pieces are sequentially and symmetrically disassembled from top to bottom. According to the technology disclosed by the invention, the pipe pieces are protected from being damaged in the disassembling process, so that the cyclic utilization number of times of the pipe pieces of the negative rings is increased; original construction machines and tools and original materials are utilized, the investment on the equipment and the materials is reduced, and the utilization rate of the negative rings is increased.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

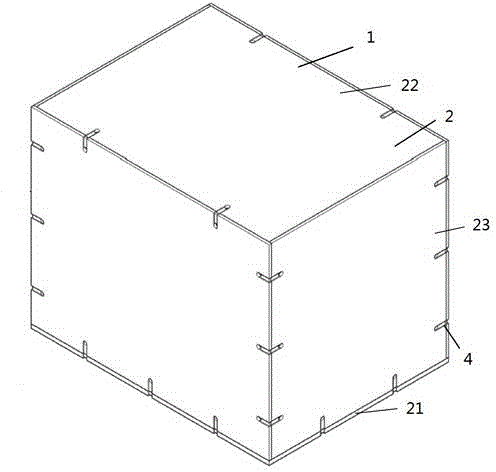

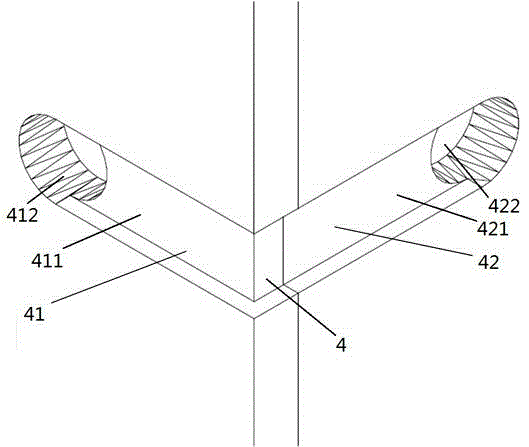

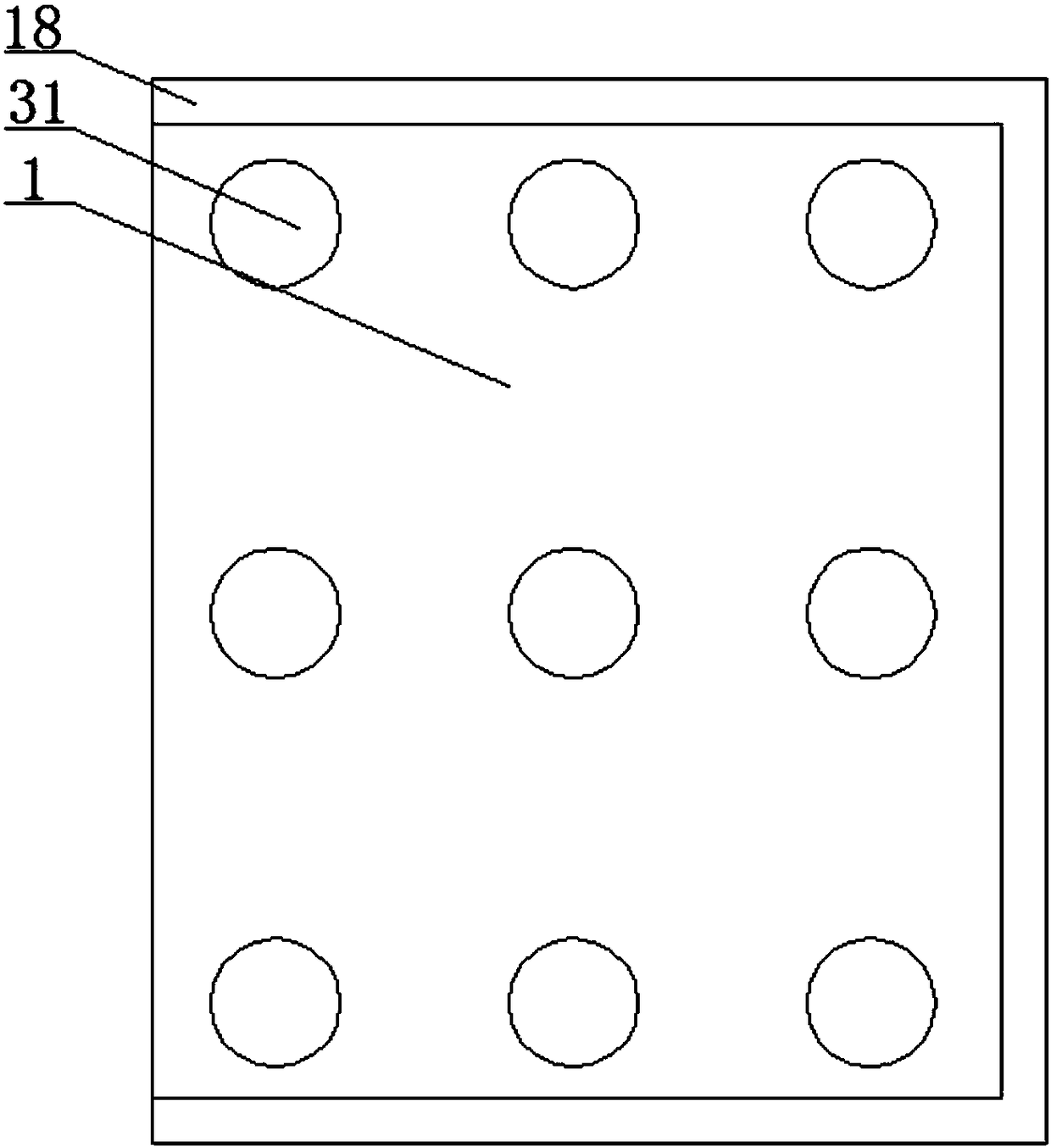

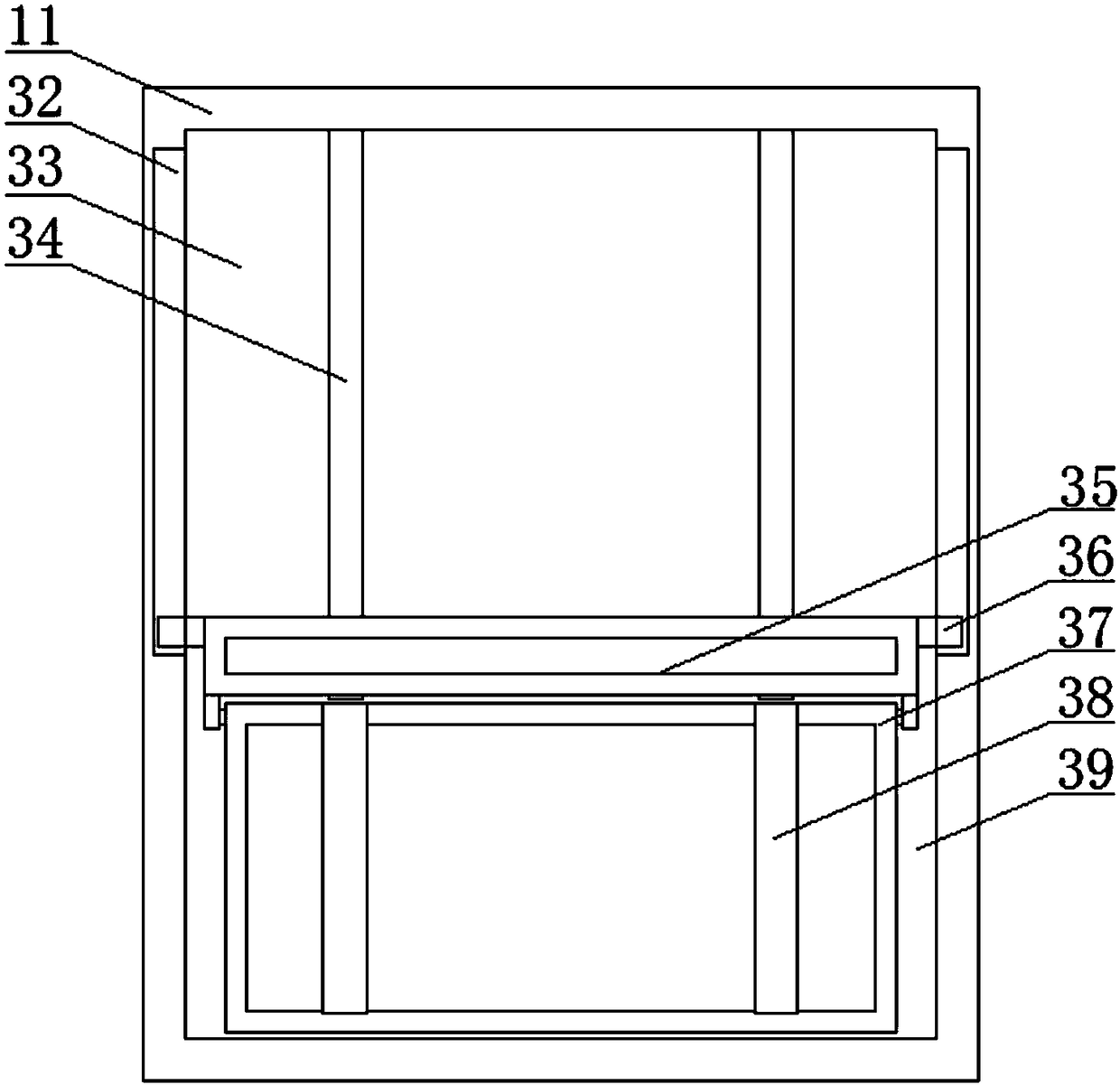

Digitalized antitheft compression-resistant reusable packaging box

ActiveCN105539978AHigh strengthIncrease the number of recyclingPackage recyclingRigid containersFirst insertionReusable packaging

The invention provides a digitalized antitheft compression-resistant reusable packaging box and relates to the technical field of packaging, aiming at solving the problems of the prior art that a packaging box cannot be reused, is relatively poor in safety and lacks digitalized application. The digitalized antitheft compression-resistant reusable packaging box comprises a box body, wherein the box body comprises a top cover part, a lateral side part, a bottom board part and a reinforcing board; the top cover part comprises an upper-layer top cover, a middle-layer top cover and a bottom-layer top cover; the upper-layer top cover is provided with a first double-wing insertion tongue and comprises a first tearing strip and a first adhesive area, a first insertion hole is formed at the connected part of the upper-layer top cover and a first side face; the reinforcing board is provided with two second double-wing insertion tongues; and the outer surface of the box body is provided with a two-dimension code, bar code and augmented reality recognition area. The digitalized antitheft compression-resistant reusable packaging box is high in safety performance, convenient to use, large in tensile strength, reusable and anti-counterfeiting, and is added with digitalized application, so that the user experience is higher.

Owner:SHENZHEN YUTO PACKAGING TECH

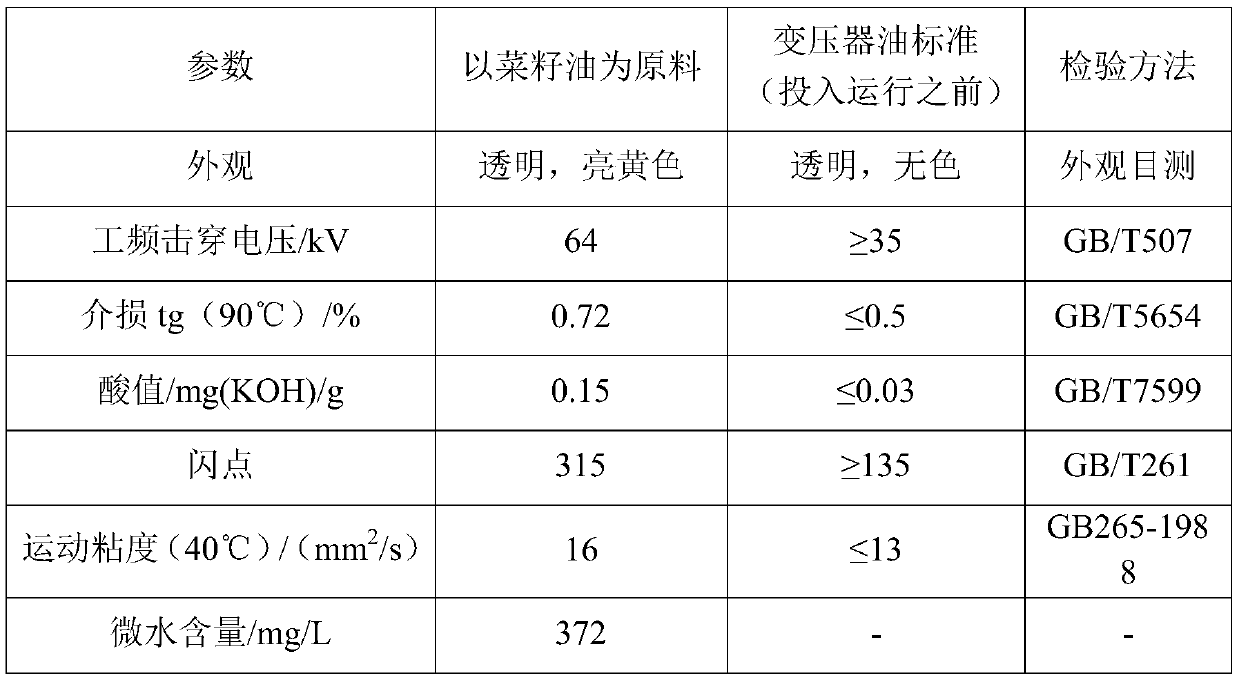

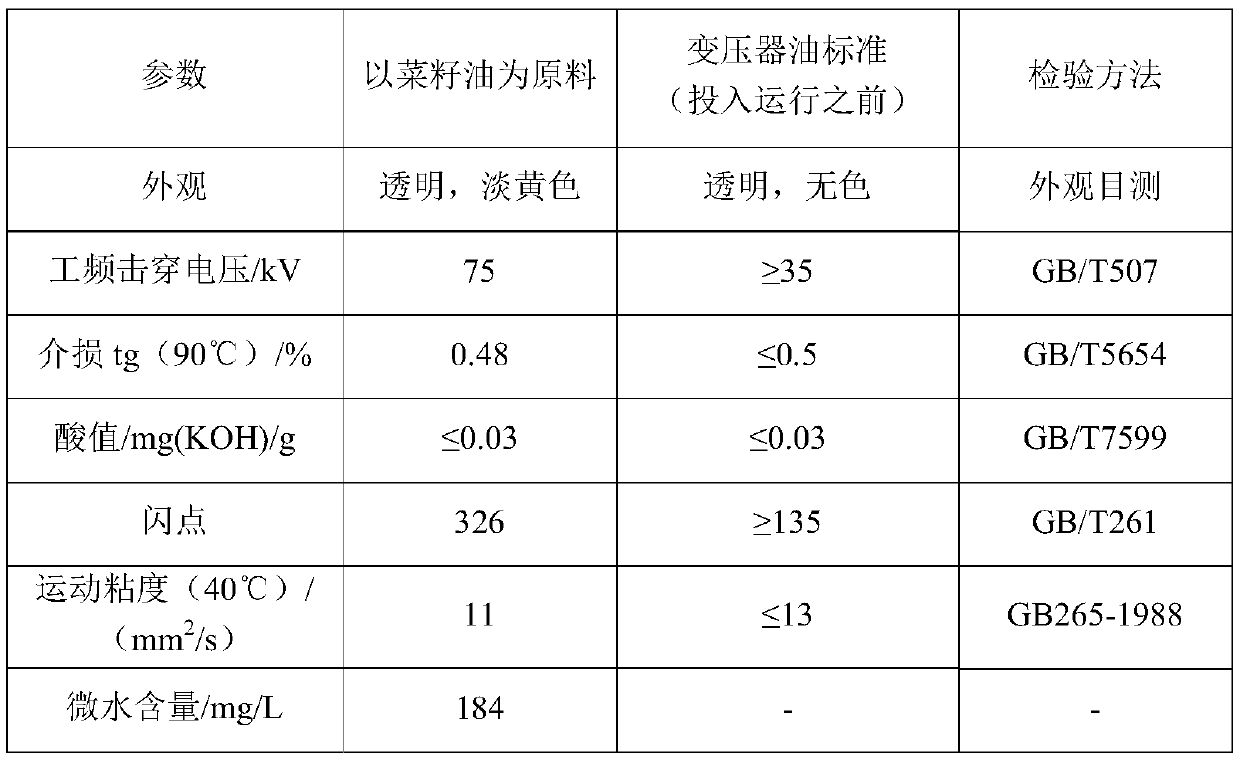

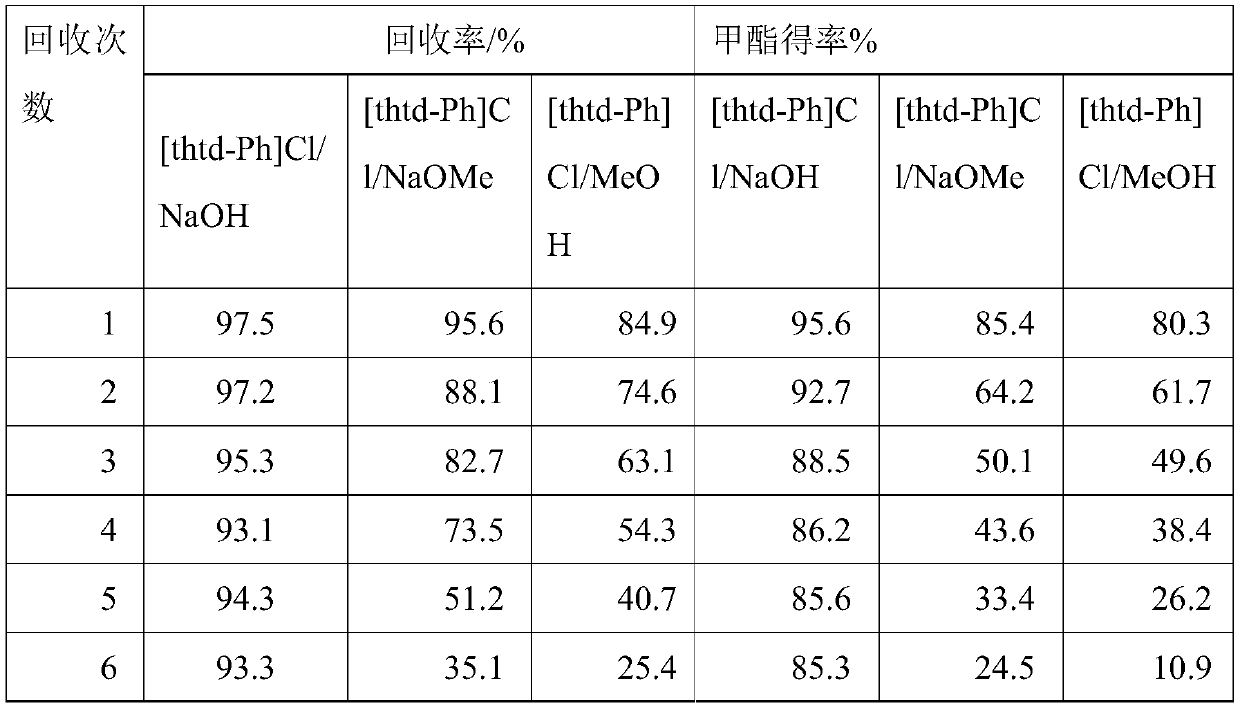

Vegetable insulating oil refining process taking rapeseed oil as raw material

ActiveCN110669583AHigh flash pointLow viscosityFatty acid esterificationLiquid organic insulatorsProcess engineeringRapeseed

The invention relates to a vegetable insulating oil refining process taking rapeseed oil as a raw material. The vegetable insulating oil refining process comprises the following steps: 1) selecting novel ionic liquid [thtd-Ph] Cl to carry out methyl esterification modification on rapeseed oil, and carrying out preliminary refining of degumming, washing, primary deacidification, reduced pressure distillation, normal pressure decoloration and deodorization on the rapeseed oil; 2) carrying out secondary alkali refining decolorization treatment and reduced pressure distillation on the rapeseed oilsubjected to primary refining to obtain refined rapeseed oil; 3) adding an antioxidant and an anticoagulant into the refined rapeseed oil to obtain modified rapeseed oil. The vegetable insulating oiltaking the rapeseed oil as a raw material has high flash point, low viscosity, low condensation point, low acid value and low water content, good physical and chemical properties and electrical properties, can meet the standard of transformer insulating oil, and can be widely popularized and used.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

Clock driver

ActiveUS20070103220A1Excellent charge recycling efficiencyReduced footprintDigital storageElectric pulse generatorEngineeringClock signal

A clock driver is provided. A first driving unit is configured with a plurality of drivers and receives a first clock signal to drive a first pumping clock. A second driving unit is configured with a plurality of drivers and receives a second clock signal to drive a second pumping clock. A charge recycling switch is connected between an output terminal of the first driving unit and an output terminal of the second driving unit. A switch controller selectively transfers an input clock signal of the first or second driving unit to the charge recycling switch in response to the first and second pumping clock signals.

Owner:SK HYNIX INC

Method for gasifying, dephosphorizing and steel-making in converter steel slag furnace

InactiveCN108754062AImprove dephosphorization efficiencyReduce phosphorus contentManufacturing convertersProcess efficiency improvementMaterial consumptionSemi-steel

The invention relates to a method for gasifying, dephosphorizing and steel-making in a converter steel slag furnace, and belongs to the technical field of metallurgy. The method comprises the following steps of: first furnace smelting: blowing gas, adding a slag-making material into a first furnace while starting to blow, controlling alkalinity of end-point slag until blowing is ended, adding first anthracite before tapping, splashing slag after tapping, gasifying, dephosphorizing and keeping all steel slag; second furnace smelting: reducing dosage of the slag-making material by one half, keeping one half of the slag after tapping, splashing the slag, and keeping the residual steel slag; and the rest of the steps which are the same with the first furnace smelting step; the third to the tenth furnace smelting: reducing 20-30wt% of the dosage of the slag-making material on the basis of the first furnace, keeping one half of the slag after tapping, and splashing the slag; and the rest ofthe steps which are the same with the first furnace smelting step. The method is simple, can reduce content of phosphor in steel slag, increases steel slag circulating times, reduces material consumption, improves converter dephosphorizing efficiency, relieves the problem that a semi-steel smelting heat source is insufficient, and reduces steel slag discharge amount.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

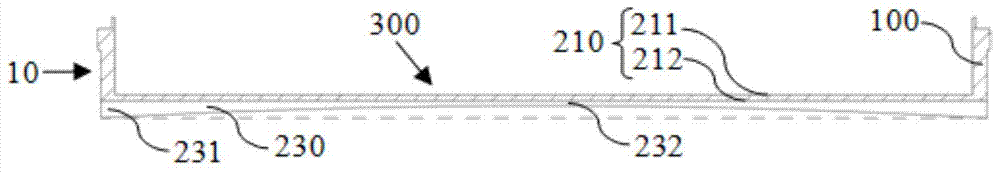

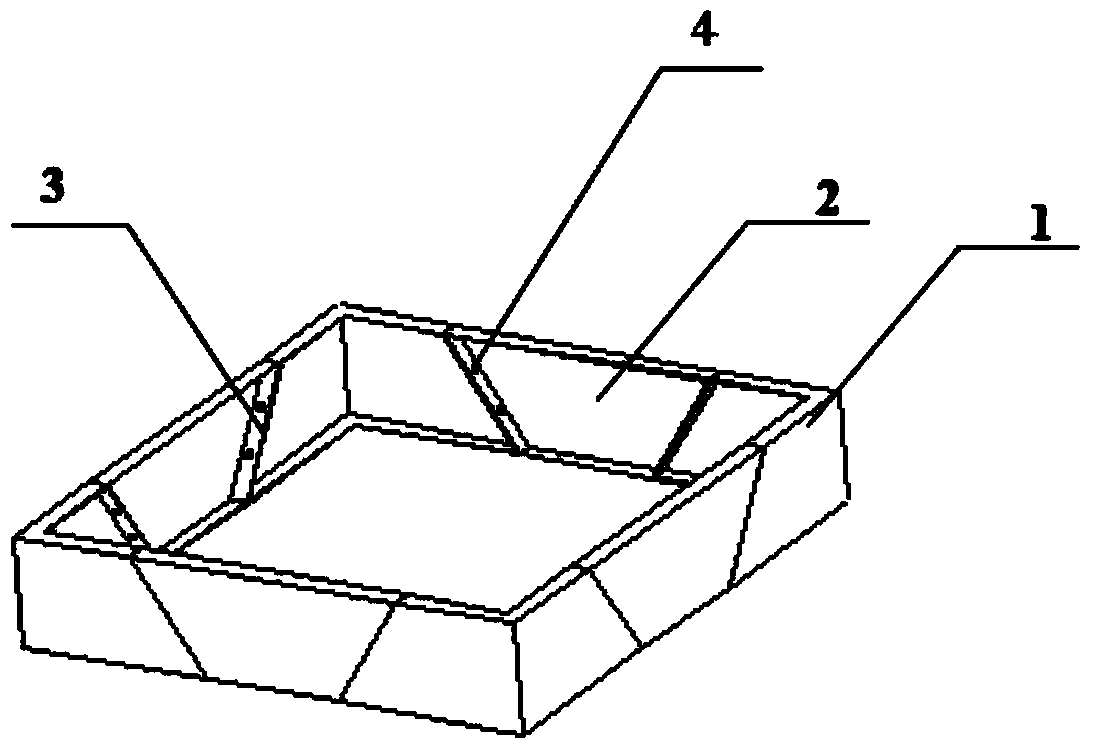

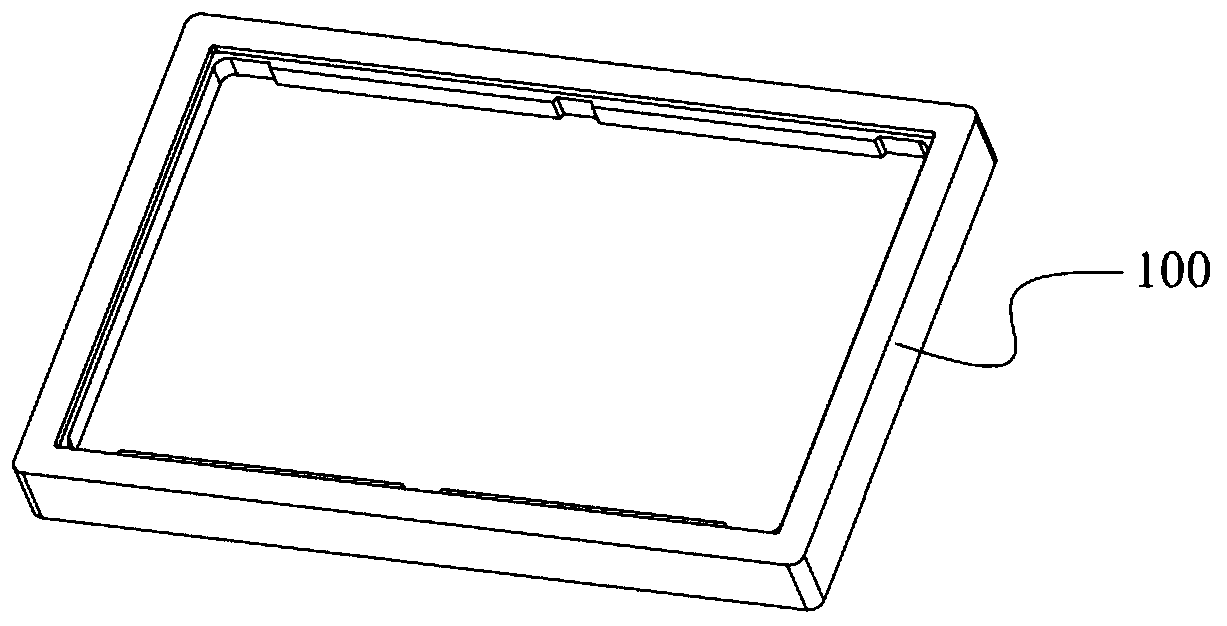

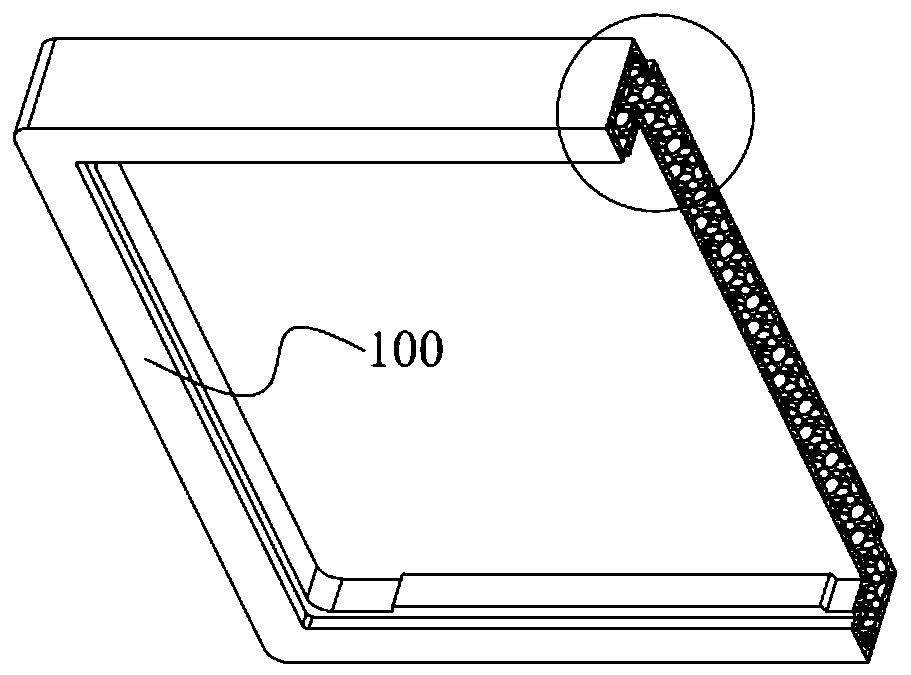

Injection-molded packing case for liquid crystal display panels

ActiveCN104495095ASimple structureImprove bending strengthTray containersDamagable goods packagingLiquid-crystal displayFlexural strength

An injection-molded packing case for liquid crystal display panels comprises a case body. The case body is composed of side wall panels and a bottom panel. The bottom panel is provided with a protrusion structure which protrudes towards the inside of the case body. The injection-molded packing case is simple in structure, bending strength of the injection-molded packing case is improved, the problem of downward concaving of the bottom of the injection-molded packing case is solved, meanwhile the problem that the injection-molded packing cases are mutually overlaid resulting in influence on the quality of liquid crystal display panels is avoided, recovery times of the injection-molded packing case are increased, and packing cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

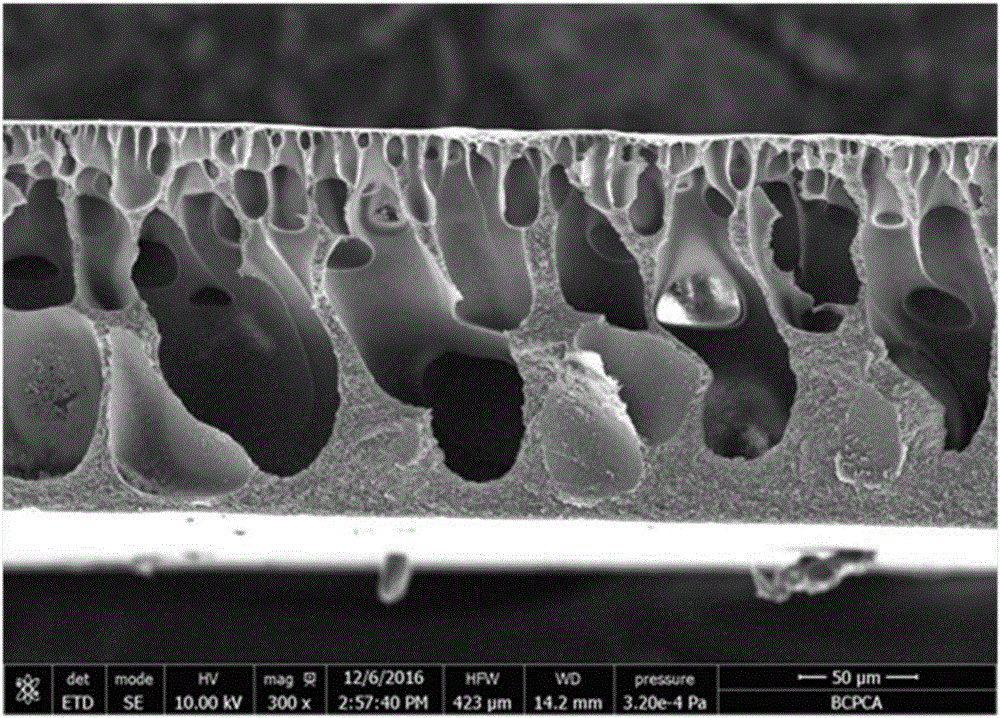

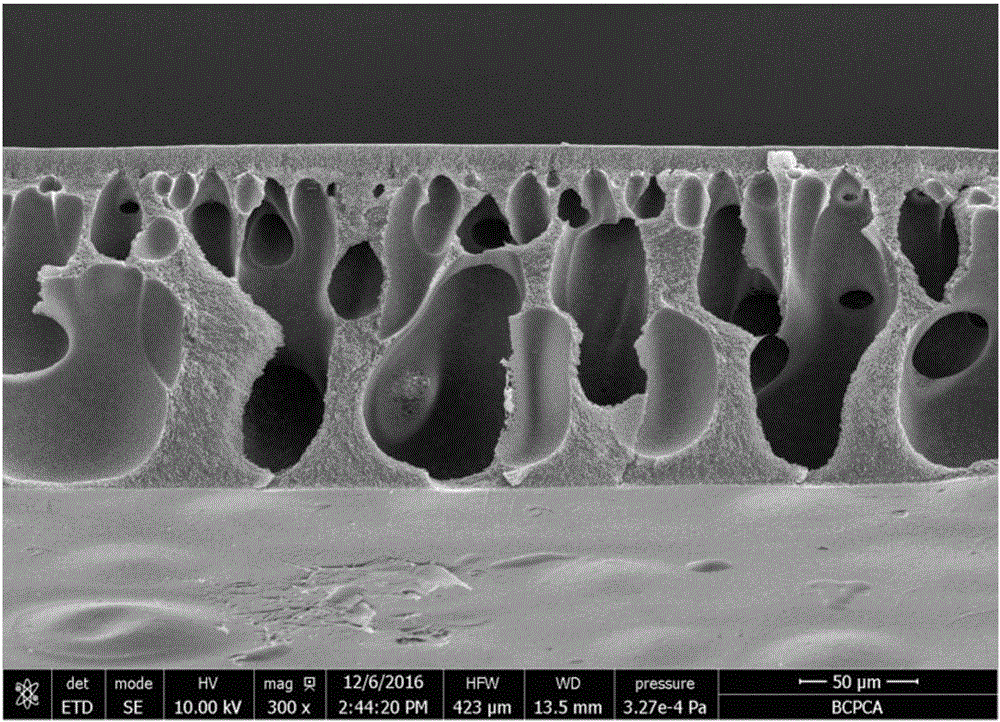

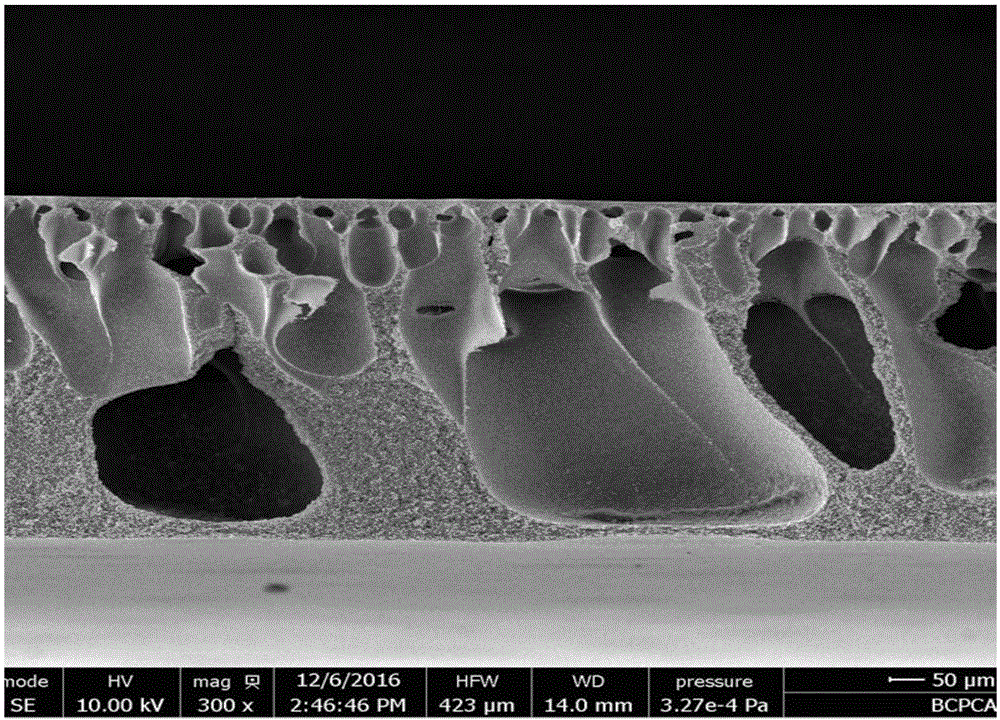

Cellulose acetate-based nano-material composite ultrafiltration membrane and preparation method thereof

InactiveCN106621857AHigh protein retentionHigh retention rateMembranesUltrafiltrationCoated membraneHalloysite

The invention relates to a cellulose acetate-based nano-material composite ultrafiltration membrane and a preparation method thereof. The cellulose acetate-based nano-material composite ultrafiltration membrane provided by the invention comprises two components including halloysite nanotubes and cellulose acetate, wherein levodopa is loaded on the halloysite nanotubes; after all the components are prepared into a membrane casting solution, a coated membrane is conveyed into a coagulation bath and is subjected to phase separation to form the membrane. According to the preparation method provided by the invention, the prepared ultrafiltration membrane has the advantages that the water flux is relatively high, the anti-pollution capability is relatively good, the membrane is relatively easy to wash and the like; the cellulose acetate and the halloysite nanotubes have the advantages of environment friendliness, relatively low price, wide source, degradability and the like. The cellulose acetate-based ultrafiltration membrane prepared by the method has very good market application prospect and industrial production value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

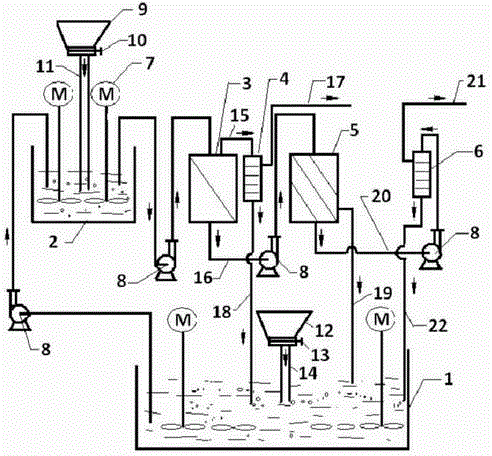

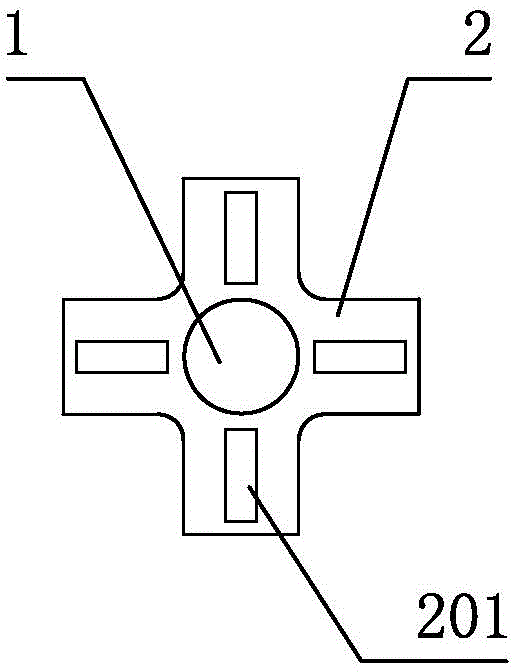

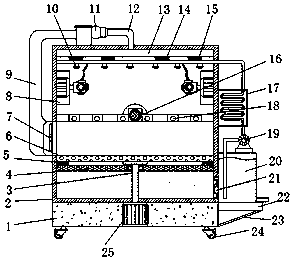

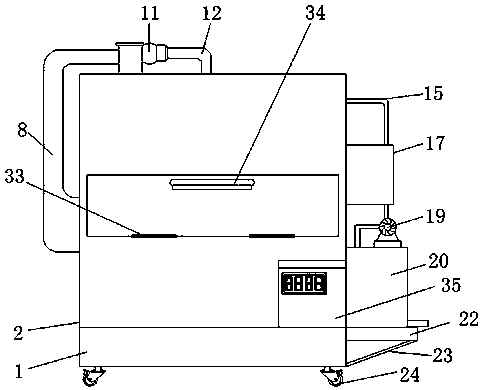

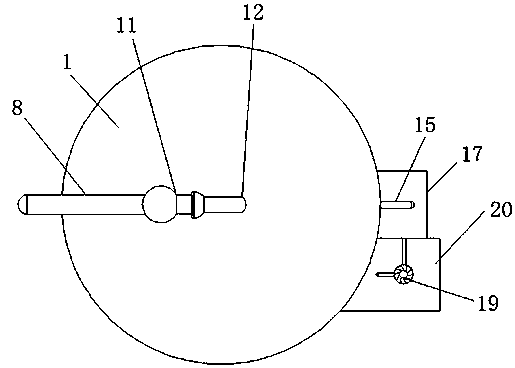

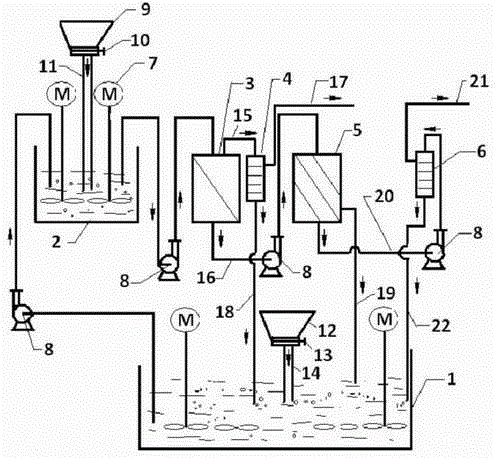

Device for realizing online cyclic utilization of rare earth polishing stock and method thereof

ActiveCN103978434AGood suspensionEliminate surface wrappingGrinding/polishing apparatusWastewaterRare earth

The invention discloses a device for realizing the online cyclic utilization of rare earth polishing stock. The device is composed of a stock tank (1), a stock mixing tank (2), a cyclone separator (3), a first press filter (4), a fine filter (5), a second press filter (6), a homogenizing agent hopper (9) and a powder adding head (12). The invention further discloses a method for using the device. The online cyclic utilization of the rare earth polishing stock can be directly realized by the device in the stock state, and the device can be directly used for matching with a polisher to recycle the polishing mortar, therefore the recycling times of a polishing mortar system can be greatly improved. According to the device, an aim of recycling the stock can be achieved by sectionally getting rid of invalid components and invalid particles in a stock system, and the device has the technical characteristics of high efficiency, quickness and low energy consumption; meanwhile, wastewater and effluent discharge can be avoided in the process of online cyclic utilization, and the production requirements on the clean whole process are met.

Owner:江苏广晟健发再生资源股份有限公司

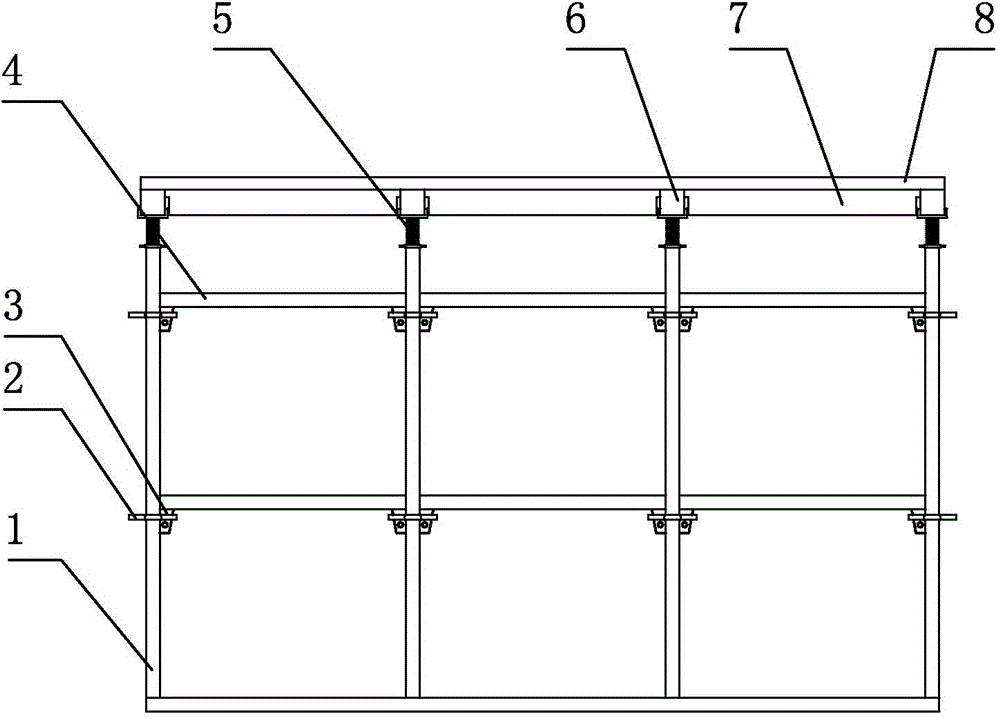

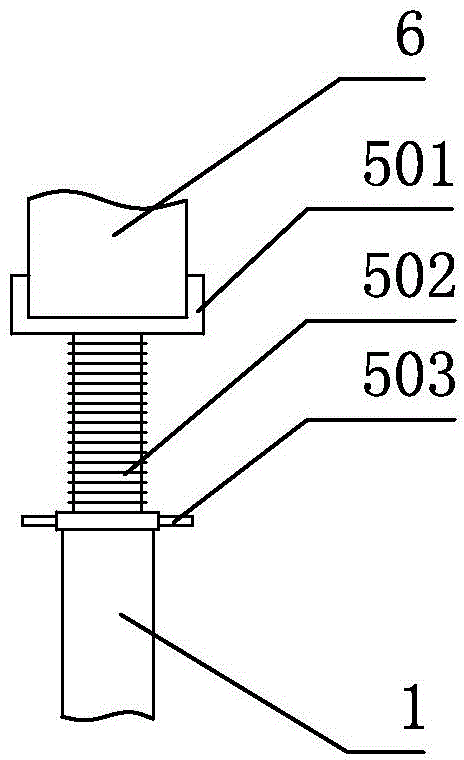

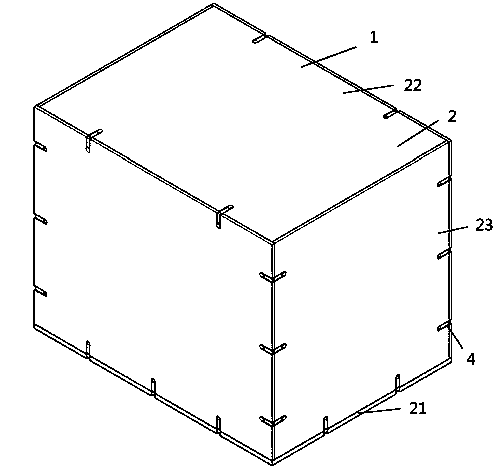

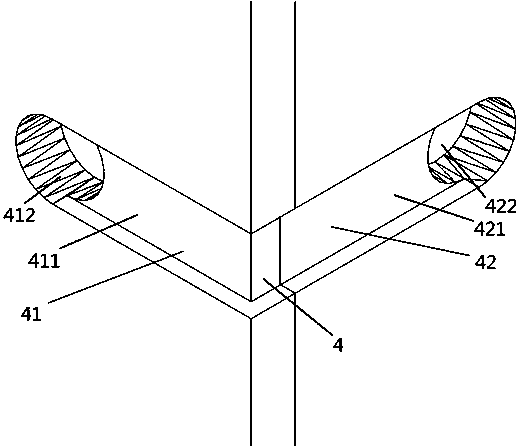

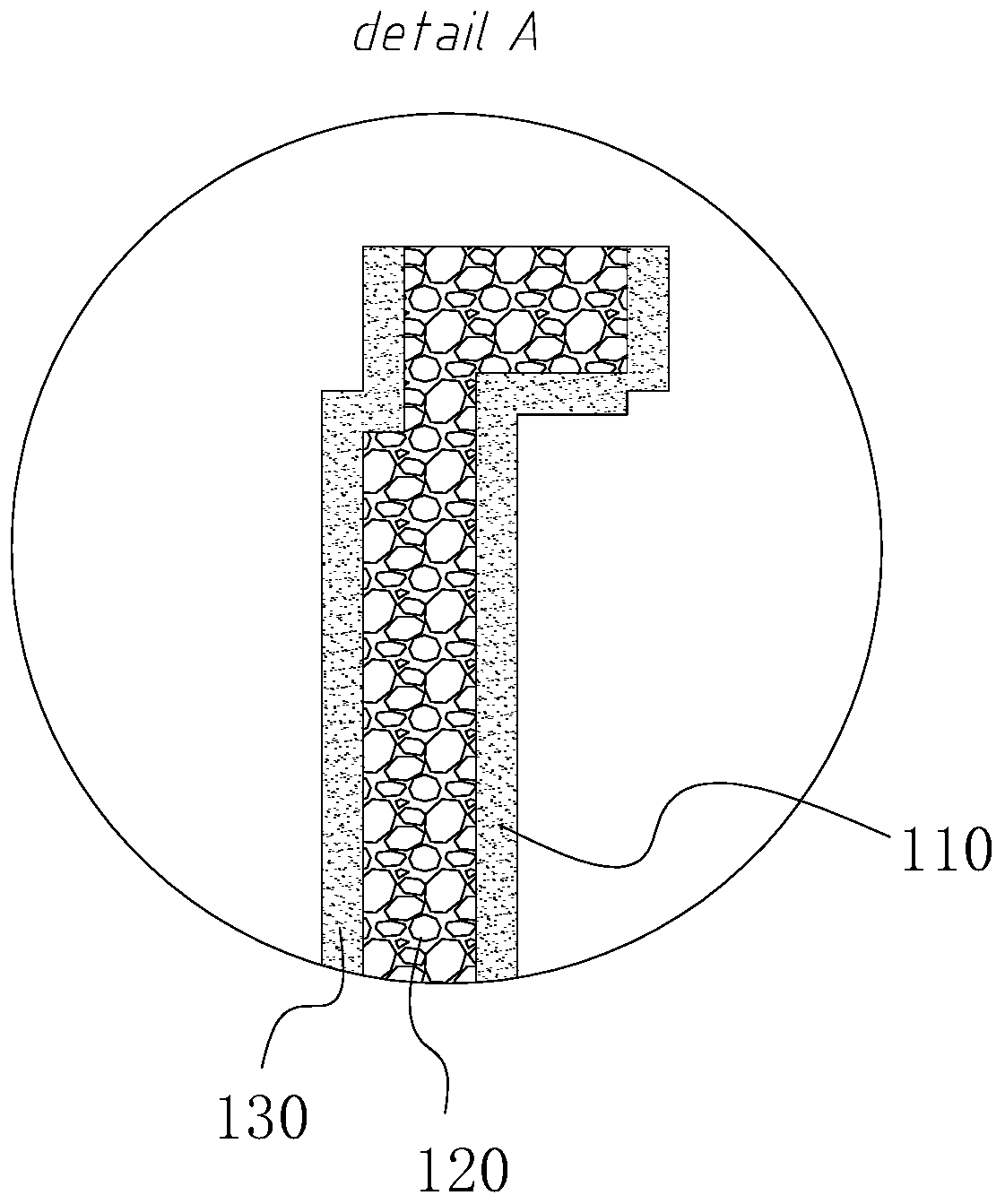

Normalized support system and construction method of weather-proof PVC (polyvinyl chloride) composite plastic template

InactiveCN104818844AIncrease the number of recyclingMeet the requirements of green constructionForms/shuttering/falseworksForming/stuttering elementsSupporting systemReinforced concrete

The invention relates to a normalized support system and construction method of a weather-proof PVC (polyvinyl chloride) composite plastic template, belonging to cast-in-place reinforced concrete structure beam and template support. According to the normalized support system of the weather-proof PVC composite plastic template, a vertical rod and a cross rod constitute a three-dimensional net-shaped structure, the top of the vertical rod is provided with an adjustable support, a lengthways main keel is erected at the top of the adjustable support, weather-proof PVC composite plastic templates are arranged above the main keel and a secondary keel. The construction method of the weather-proof PVC composite plastic template comprises the steps of: 1) designing the support system; 2) detecting a position line via flip; 3) designing the normalized support system of an erected template; 4) adjusting an elevation to install the plastic template; 5) strapping the reinforcing steel bars of the beam and a plate and pouring concrete; 6) lowering the main keel and the secondary keel; 7) dismantling the secondary keel; 8) dismantling the plastic template; 9) dismantling the main keel, the cross rod and the vertical rod successively. The normalized support system and construction method of the weather-proof PVC composite plastic template can save wood, and are simple to operate, and safe and reliable.

Owner:SHANDONG GOLDENCITY CONSTR

Modular recyclable wood beer case and manufacturing method thereof

ActiveCN104890980ASimple production processReduce production input costsPackage recyclingRigid containersManufacturing engineering

Owner:南平市华泰木竹有限公司

Chromatographic sheet with self-repairing function and preparation method thereof

InactiveCN103055827AWith self-healing functionRepair crackComponent separationOther chemical processesChromatographic separationCross-link

The invention discloses a chromatographic sheet with a self-repairing function and a preparation method thereof. A self-repaired modified silica gel with a hydrogen-bond interaction is served as an absorbing agent, a high molecular polymer which contains an amide or is liable to obtain a hydrogen-bond functional group is connected to the silica gel to obtain the modified silica gel, and the modified silica gel is aggregated to obtain a supramolecular structure in a reversible cross-linking state through multiple hydrogen-bond interactions among modified silica gel molecules, so that minor damages and microcracks of the chromatographic sheet can be self-inspected and self-repaired in process of placing the chromatographic sheet for a long time or carrying out activating, plate washing and plate running on an adsorbent, and the performance is stable and reliable; furthermore, a Rf value has a reproducibility that the general chromatographic sheet can not reach, so that the detection result is more accurate; and meanwhile, the chromatographic sheet can be self-repaired without outside intervention, so that the recycling times of the plate is increased greatly and the cost is saved.

Owner:CHONGQING UNIV OF TECH

Medical nursing disinfection device for intensive care

PendingCN108452335AIncrease contact areaImprove the bactericidal effectDrying gas arrangementsLavatory sanitoryDrive shaftIntensive care

The invention belongs to the technical field of medical equipment, in particular to a medical nursing disinfection device for intensive care. Aiming at the technical problems of simple design structure, single functions and inconvenience in use of the conventional nursing disinfection device, the following technical scheme is provided. The medical nursing disinfection device comprises a supportingtank, wherein a disinfection tank is welded to the top output wall of the supporting tank; in addition, a motor is fixed at the bottom inner wall of the supporting tank by bolts; a filtering plate iswelded to a position, close to the bottom end, of the inner wall of one side of the supporting tank; a circular through hole is formed in the central position of the top outer wall of the filtering plate; in addition, a bearing is welded to the inner wall of the circular through hole; a driving shaft is welded to the top end of a motor output shaft; in addition, one end, away from the motor, of the driving shaft, penetrates through the bottom inner wall of the disinfection tank and is welded with the inner wall of the bearing. The medical nursing disinfection device disclosed by the inventionhas the advantages that a contact area between a medical device and an ultraviolet disinfection lamp is increased; all-round temperature of the disinfection tank is instantly improved; the working efficiency is improved; the disinfected medical device is dried by hot air; residual heat energy is sufficiently utilized and further utilization rate of energy is improved.

Owner:王海霞

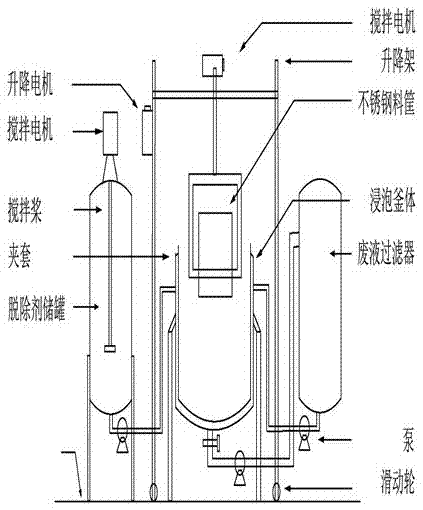

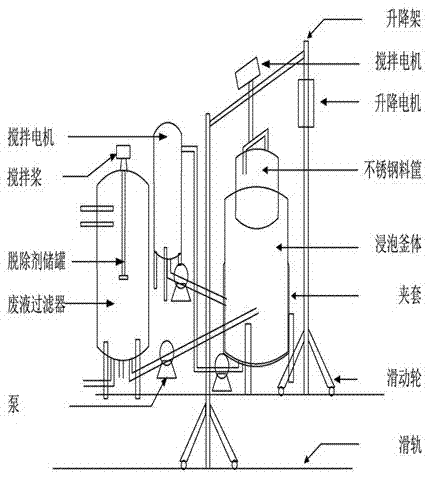

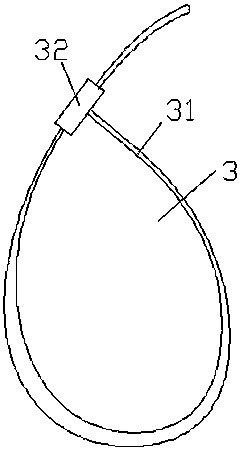

Apparatus for removing impregnating compound special for recovery of waste glass fiber

The invention belongs to the fields of removing of impregnating compound special for recovery of waste glass fiber. An apparatus mainly comprises an immersion kettle body (4), a stainless steel charging basket (3), a waste liquid filter (5), and a removing agent storage tank (12). The apparatus mainly solves the problem that a surface impregnating compound is removed before glass fiber waste filaments return to a kiln and are refined again for ensuring that the discharge standards of calcination flue gas are reached is solved. Compared with the prior art, the product has the beneficial effectsthat integral design of immersion and removing reduces equipment investment, improves recovery rate and cyclic utilization frequencies of the removing agent, and improves removing efficiency of the glass fiber impregnating compound; centrifugal type impregnating compound removing greatly improves working efficiency, and large scale industrial production demands are satisfied; treatment difficultyof waste water is reduced.

Owner:JINAN HANGCHEN BIOTECHNOLOGY CO LTD

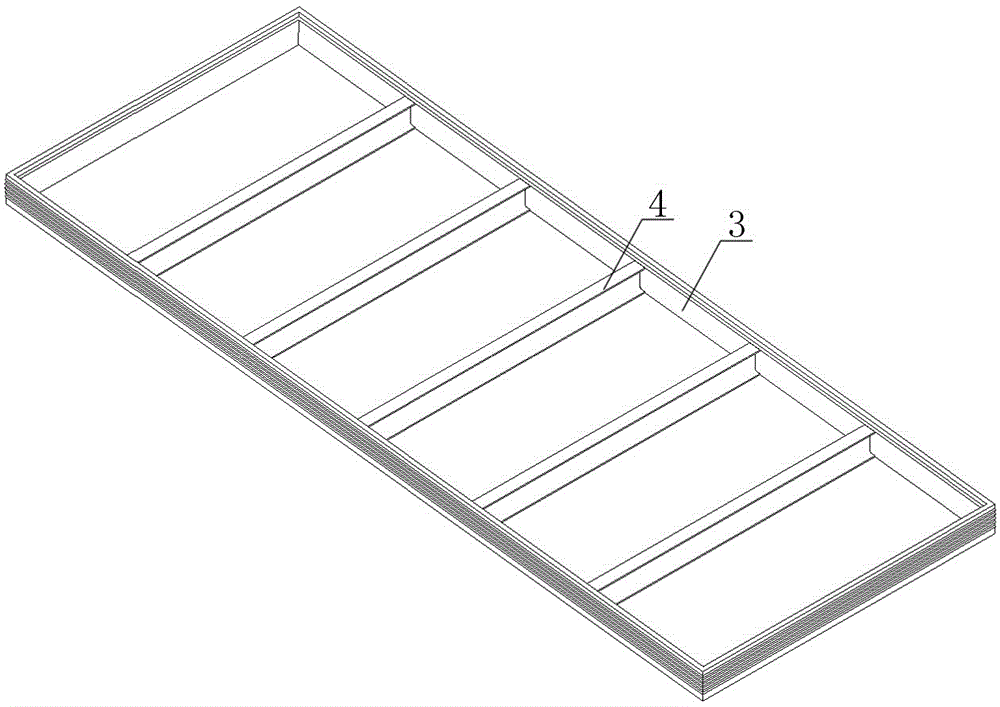

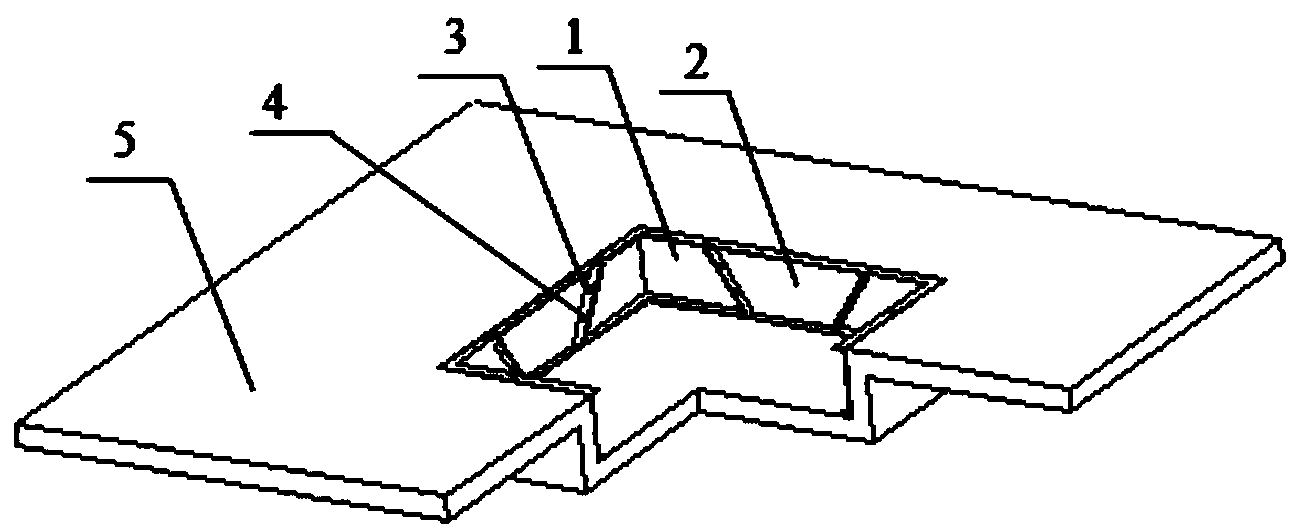

Plastic formwork which is provided with frame and used repeatedly and circularly and construction method of plastic formwork

InactiveCN105735632APromote repairEasy to replaceForming/stuttering elementsForm treatmentSupporting systemResource utilization

A framed plastic formwork used for multiple turnovers and its construction method. The formwork includes a panel, the panel is embedded in the upper end of the frame, and the upper end of the outer side of the frame has a horizontally convex flange. Tightly covered with a plastic skin, the upper surface of the panel is flush with the upper end of the frame, the lower port of the skin is flush with the lower end of the frame, the side of the skin matches the shape of the side of the frame, and the frame is connected with reinforcing ribs. The present invention is an integrated product composed of skins, panels, and frames, and the number of times of use is significantly increased, which is conducive to improving resource utilization, effectively solving the waste of resources in formwork engineering in the construction industry, and reducing construction environmental costs, economic costs, and labor costs; the present invention It can replace bamboo and wood plywood, wooden squares, secondary beams and other products, and it can be used in conjunction with an independent support system to simplify the construction process of concrete engineering, improve construction efficiency, and improve construction quality. It can be widely used in concrete pouring formwork system.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

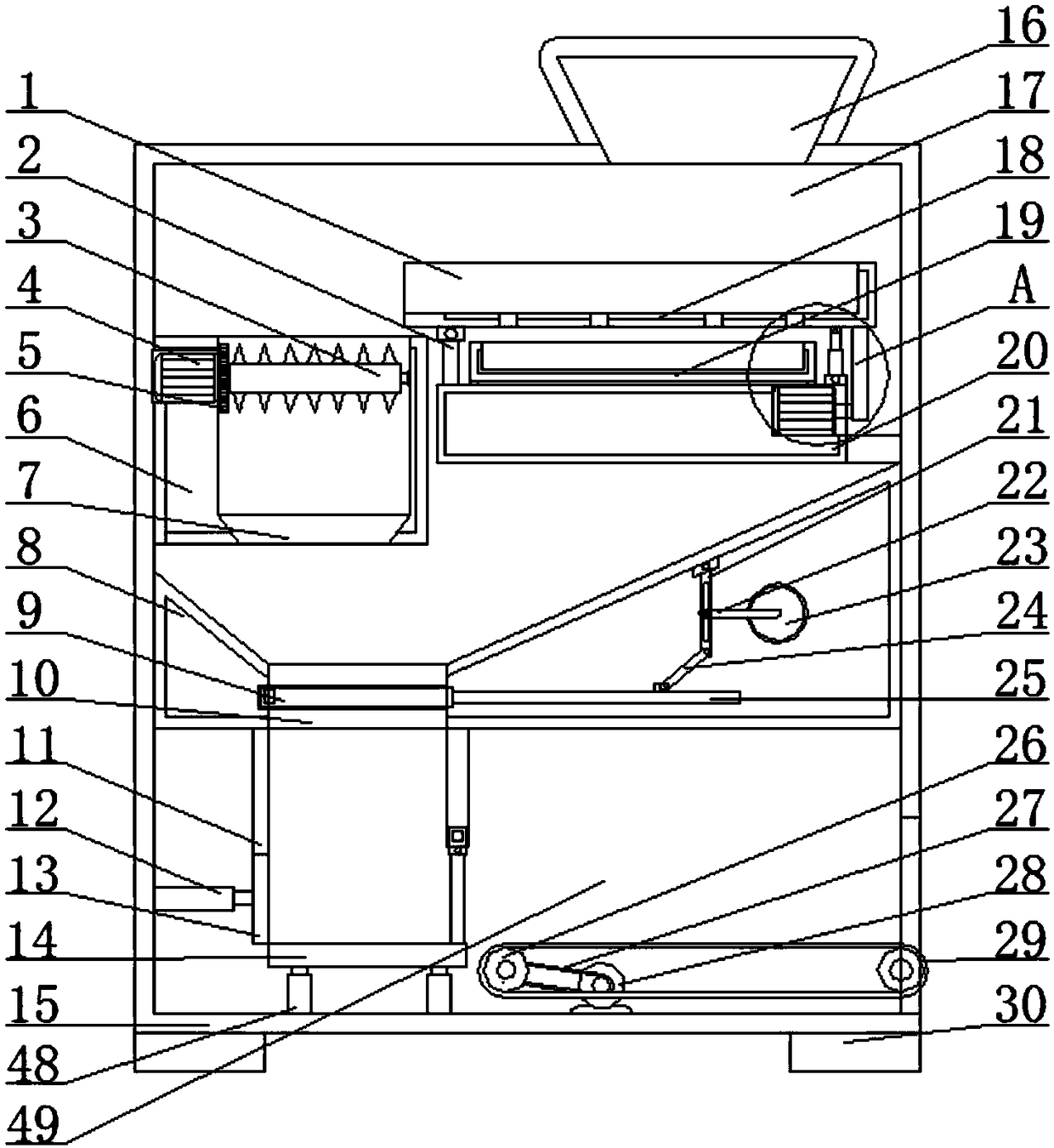

Environment-friendly energy-saving garbage classifying, treating and compressing device

The invention discloses an environment-friendly energy-saving garbage classifying, treating and compressing device. The environment-friendly energy-saving garbage classifying, treating and compressingdevice comprises a housing, wherein a charge hole is fixedly formed in one side of the upper end of the housing; a partition is arranged in the housing for dividing the housing into a bearing cavityand a mobile cavity from up to bottom; a classifying device is fixedly arranged on the side wall of one end in the bearing cavity; and the classifying device corresponds to the charge hole. The environment-friendly energy-saving garbage classifying, treating and compressing device realizes garbage classifying, and crushes garbage with a relatively large size, so that oversized space is not occupied; then, garbage is compressed, so that occupied space of garbage is further reduced, and therefore, transportation is convenient; a drive device, an oil cylinder, a crushing roller and a movable plate are combined, so that the problems that garbage recycling efficiency is affected, the recycling frequency is increased, time and labor are wasted, and labor intensity of a worker is increased as garbage of different sizes appears, some garbage materials, such as a packaging box, are small in quantity, but are relatively great in size are solved; and the environment-friendly energy-saving garbageclassifying, treating and compressing device is simple in structure, convenient to operate, and suitable for being popularized.

Owner:姚福泉

A method for manufacturing modular recyclable wooden beer boxes

ActiveCN104890980BSimple production processReduce production input costsPackage recyclingRigid containersManufacturing engineering

Owner:南平市华泰木竹有限公司

Removable adhesive formula

InactiveCN110684488AIncrease the number of recyclingStickyPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer sciencePolymer chemistry

The invention discloses a removable adhesive formula which is used on a bubble bag or an express bag. The removable adhesive formula comprises the following components in parts by weight: 80-200 partsof a waterborne polyurethane resin dispersion and 800-900 parts of waterborne polyacrylic resin. The preparation method of the movable adhesive formula comprises the following steps: adding the waterborne polyurethane resin dispersion and the waterborne polyacrylic resin into a stirrer according to a ratio, and performing stirring for 5-10 minutes at a first rotation speed so as to form a first intermediate; adding a water-based thickener drop by drop into the first intermediate until the amount is exhausted so as to form a second intermediate; continuously stirring the second intermediate for 40-60 minutes at a second rotation speed, so as to form the removable adhesive formula. The removable adhesive formula disclosed by the invention is still remarkably sticky after being pasted for multiple times, and can be applied to the bubble bag or the express bag which is used for multiple times, and thus the recycling times of the bubble bag or the express bag can be increased.

Owner:浙江天之元物流科技有限公司

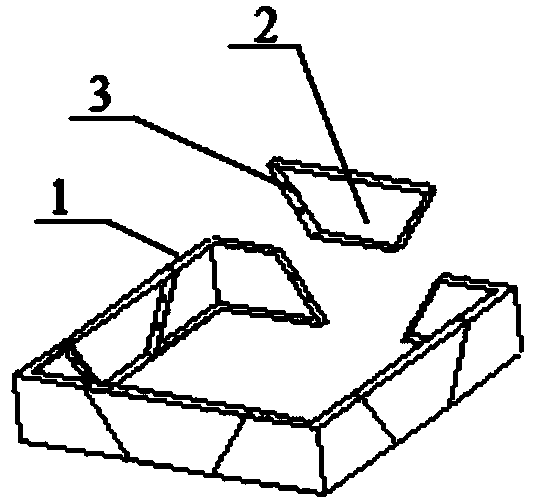

Steel wedge hang mould convenient to demount

InactiveCN103835498AIncrease the number of recyclingFirmly connectedForms/shuttering/falseworksMetallurgyUltimate tensile strength

The invention discloses a steel wedge hang mould convenient to demount. The steel wedge hang mould comprises a plurality of steel corner moulds and side moulds, edges of face plates of the corner moulds and the side moulds are mutually spliced, edges of the inner sides of the face plates of the corner moulds and the side moulds extend inwardly to form rib plates, and a plurality of connection bolts are penetratingly arranged between each rib plate of each corner mould and the rib plate of the adjacent side mould. The corner moulds and the side moulds are made of steel materials and in spliced connection, and the adjacent rib plates are penetratingly provided with the connection bolts to firmly connect the corner moulds with the side moulds. The steel wedge hang mould convenient to demount has the advantages of energy saving, environment friendliness, low cost, high strength and more convenience in assembly and disassembly.

Owner:ZHONGTIAN CONSTR GROUP

Method for pretreatment of sulfur-containing wastewater after refinery gas extraction by using activated refinery coke

InactiveCN101434422AReduce processing costsMild activation treatmentWater/sewage treatment by sorptionPretreatment methodAlkaline activation

The invention provides an activation and regeneration method of petroleum coke, and a pre-treatment method for applying active petroleum coke to refinery waste water, particularly a method for reducing COD in sulfur-bearing waste water after the air lift of the refinery. The method comprises the following steps: carrying out alkaline activation treatment to petroleum coke in an alkaline aqueous solution, roasting the petroleum coke at 200-350 DEG C to prepare the active petroleum coke, using the prepared active petroleum coke to absorb organic containments in the water, and oxidizing the absorbed petroleum coke material at 200-350 DEG C so as to regenerate the active petroleum coke to be reused. The method provided by the invention can reduce the COD of waste water after the air-lift of the refinery by 60-90 percent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

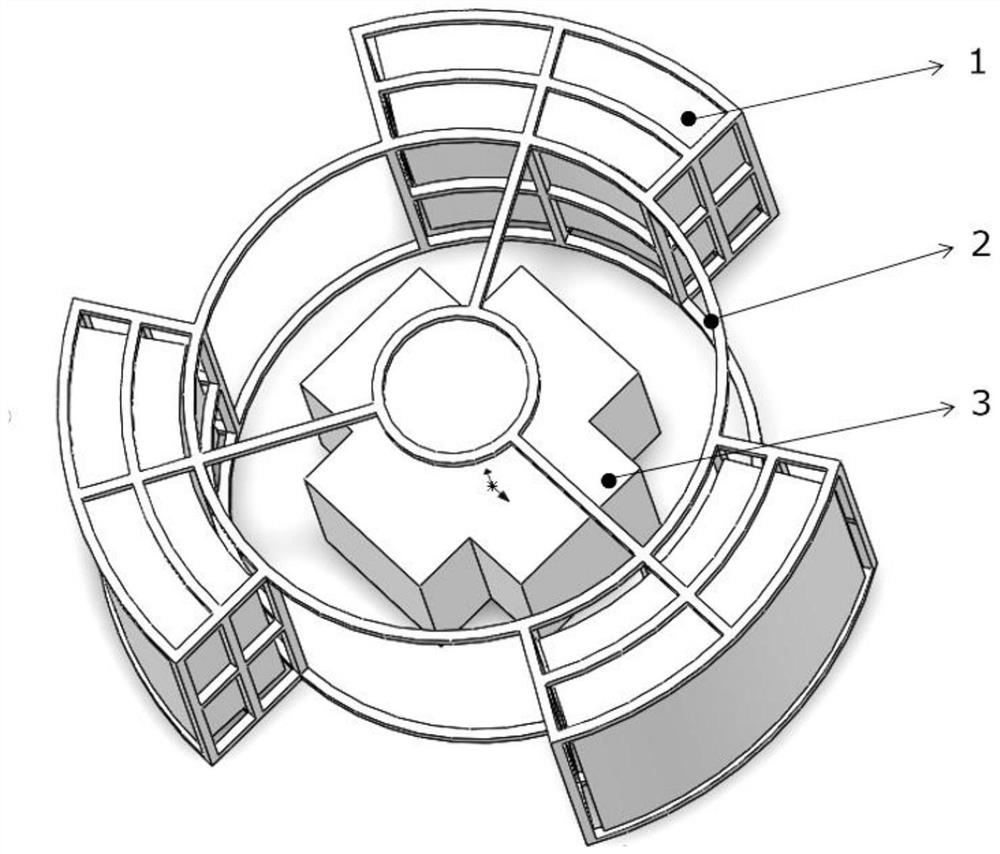

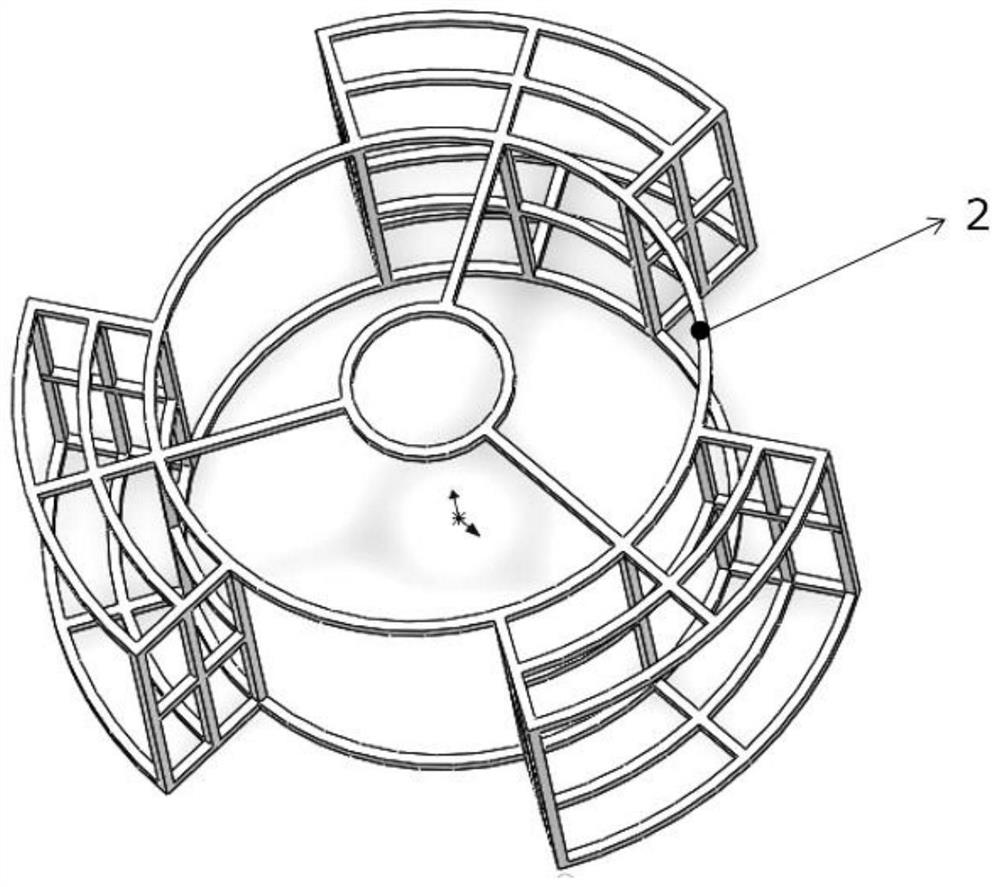

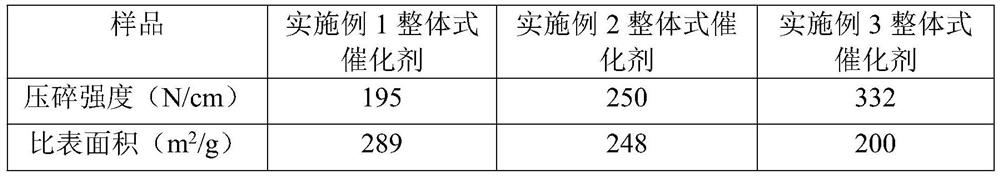

3D printing assembled monolithic catalyst and preparation method thereof

ActiveCN113716946AHigh mechanical strengthSimple structurePreparation by oxidation reactionsAdditive manufacturing apparatus3d printPtru catalyst

The invention discloses a 3D printing assembled monolithic catalyst and a preparation method thereof. The assembled monolithic catalyst comprises a cage type catalyst protection frame mounted on a rotor, and a monolithic catalyst is mounted on the cage type catalyst protection frame. The preparation method comprises the following steps of: designing a cage-type catalyst protection frame and a monolithic catalyst according to the structure of a reaction kettle, and performing 3D printing of the cage-type catalyst protection frame by adopting a powder bed melting technology; then mechanically stirring and mixing a catalytic active agent and a ceramic carrier material to obtain catalyst 3D printing slurry, and carrying out 3D printing of an initial monolithic catalyst blank through direct-writing forming equipment; naturally drying the initial monolithic catalyst blank, and then carrying out a high-temperature sintering process to obtain monolithic catalysts; and finally, uniformly inserting a plurality of monolithic catalysts into the cage type catalyst protection frame to assemble a monolithic catalyst structure. According to the invention, the mechanical strength of the monolithic catalyst is enhanced, the damage of the monolithic catalyst in the reaction process is reduced, and the cyclic utilization function of the monolithic catalyst is fully exerted.

Owner:XI AN JIAOTONG UNIV

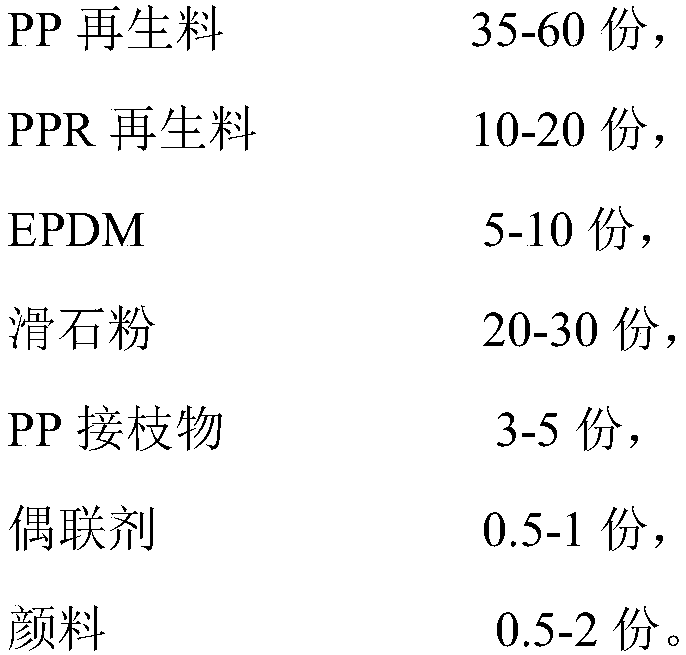

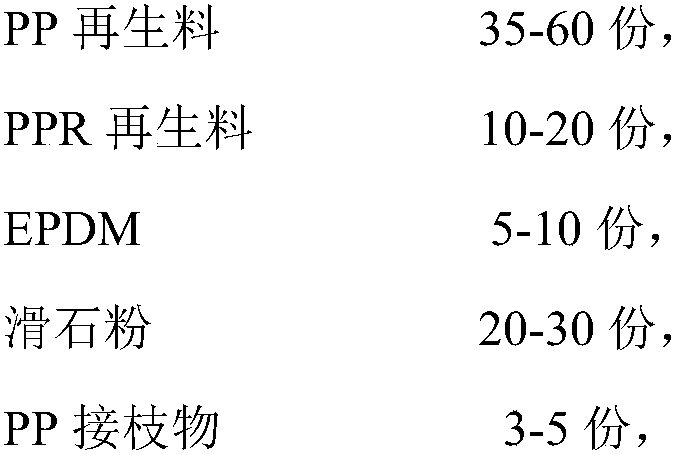

High-elongation low-temperature-resistant special material for PP building formwork and preparation method of special material

The invention discloses a high-elongation low-temperature-resistant special material for a PP building formwork. The special material comprises the following components, in parts by weight: 35-60 parts of a PP regenerated material, 10-20 parts of a PPR regenerated material, 5-10 parts of EPDM, 20-30 parts of talc powder, 3-5 parts of a PP graft, 0.5-1 part of a coupling agent and 0.5-2 parts of apigment. The special material for the PP building formwork provided by the invention has excellent low-temperature impact resistance and can be used at minus 20 DEG C, the flexural modulus is >= 1500MPa, the elongation is >= 350%, the melt flow velocity is 3-4 g / 10min, and the special material is suitable for direct extrusion preparation of the PP building formwork; the prepared PP building formwork is easy to form, can be coated with different colors by using different color powder and be recycled, has high recycling frequency, a light mass of a product and convenient construction, and guarantees safety in the construction process; and the special material is prepared by using the recycled PP material, so that the production costs are greatly reduced, and the purpose of turning waste into treasure is achieved.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

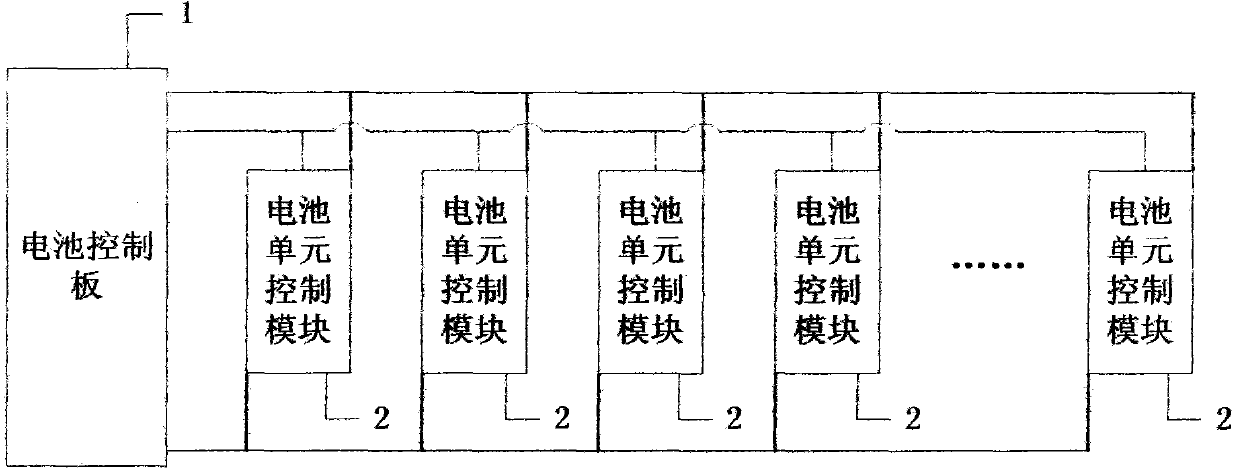

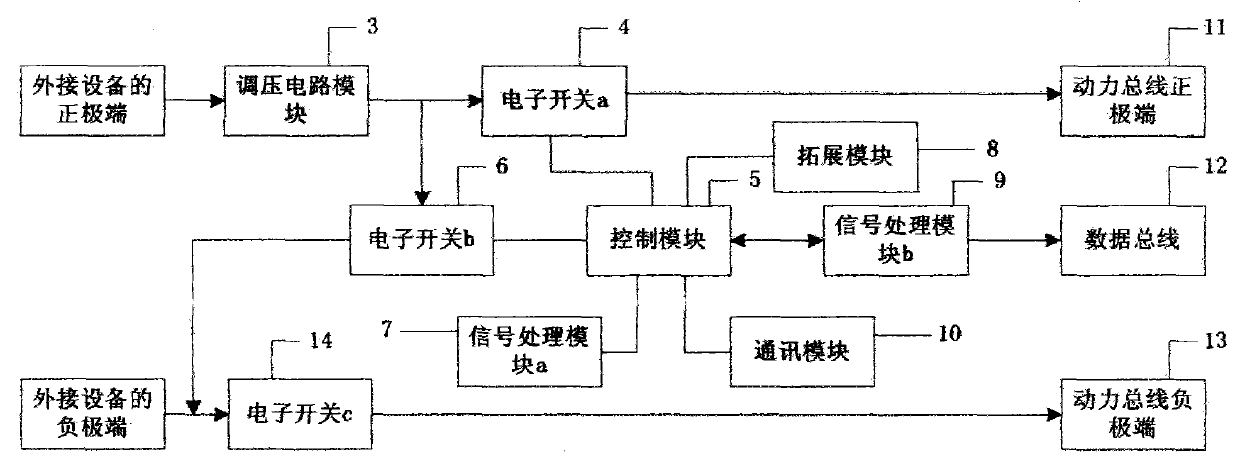

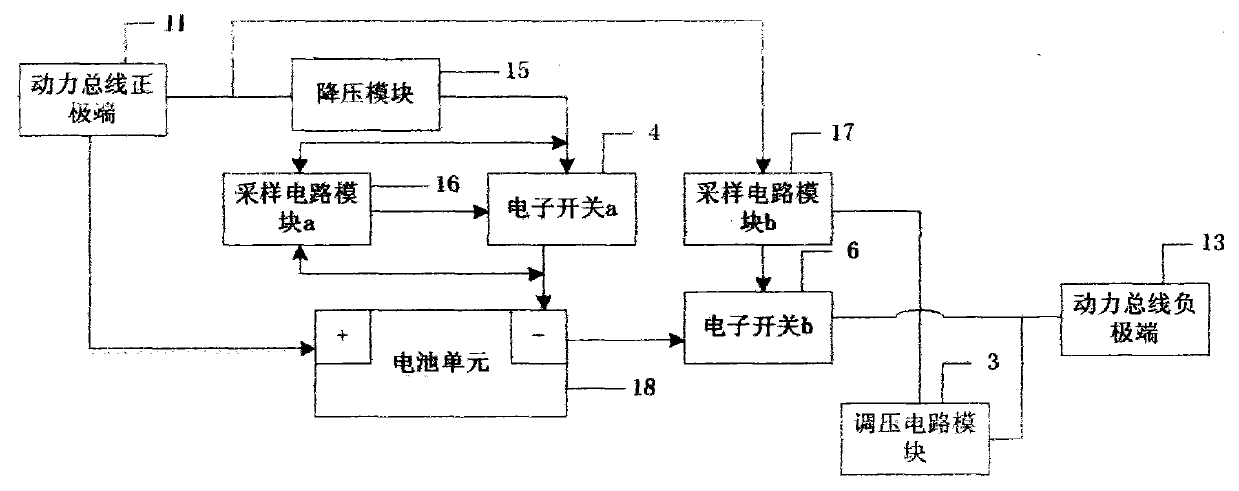

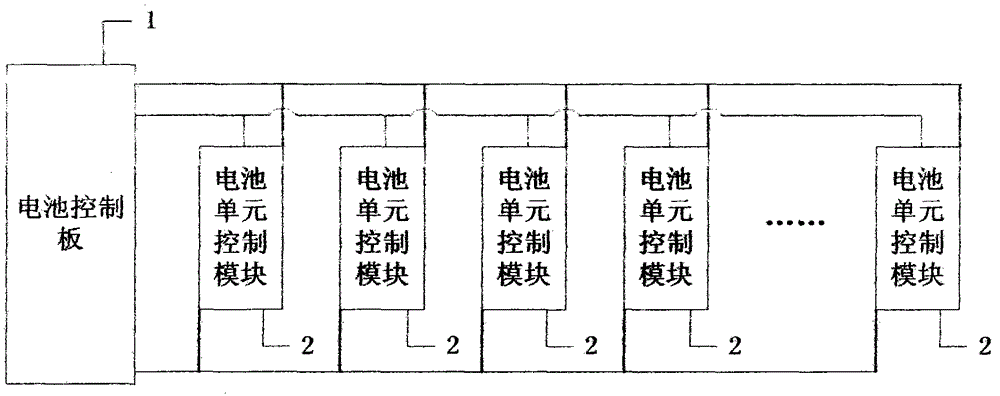

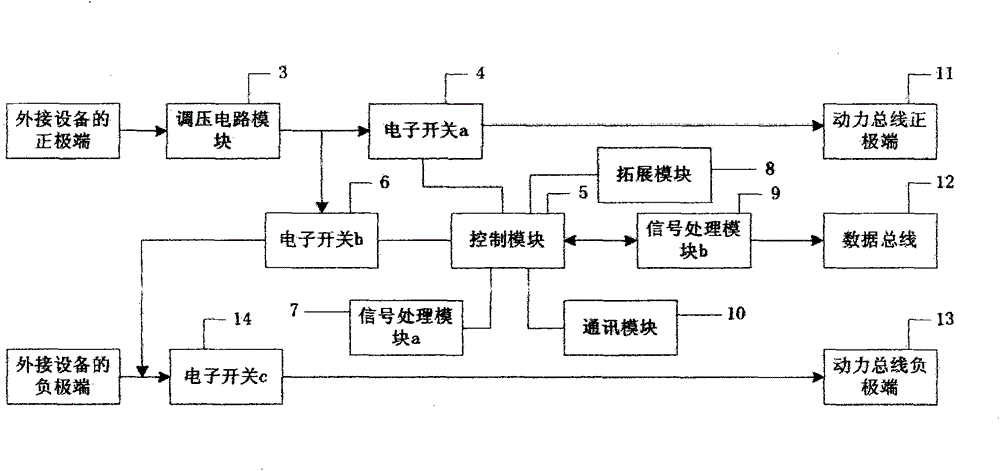

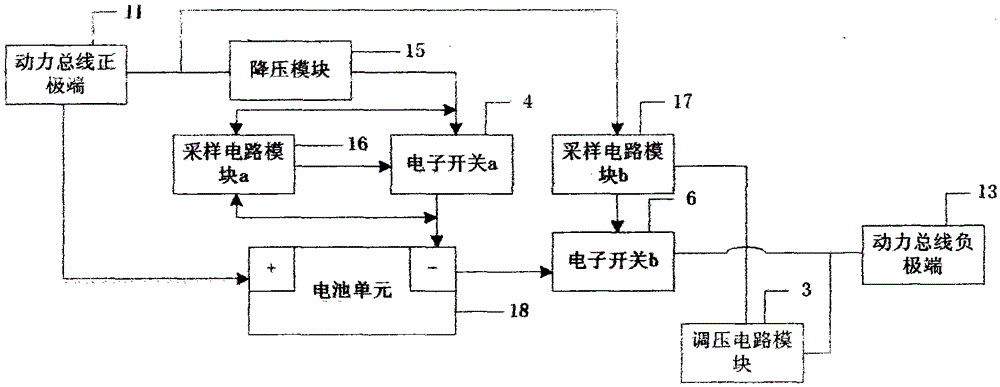

Intelligent communication type battery charge and discharge optimization control system and method

InactiveCN104009525AImprove securityImprove stabilityBatteries circuit arrangementsElectric powerElectricityBattery charge

The invention provides an intelligent communication type battery charge and discharge optimization control system. The system is composed of battery control panels and at least one battery unit control module set connected with the battery control panels, wherein the battery unit control module set is composed of a plurality of battery unit control modules which are electrically connected with the battery control panels in parallel. Each battery control panel comprises a signal processing module a, a signal processing module b, a voltage adjusting circuit module, a communication module, a power bus and a data bus which are all connected with the corresponding control module. The method for implementing the system includes the steps that when the current input voltage is larger than a preset norminal voltage, the multiple battery control panels are connected with the power buses in parallel so that charging can be performed; otherwise, the multiple battery unit control modules are connected with the power buses in series, and the multiple battery unit control modules are controlled to perform discharging. Due to the intelligent communication type battery charge and discharge optimization control system, safety and stability of battery packs can be improved, the charging speed of the battery packs is increased, and the service life of the battery packs is prolonged as a whole.

Owner:徐宪华

A device and method for realizing online recycling of rare earth polishing slurry

ActiveCN103978434BIncrease the number of recyclingAvoid consumptionGrinding/polishing apparatusWastewaterRare earth

Owner:江苏广晟健发再生资源股份有限公司

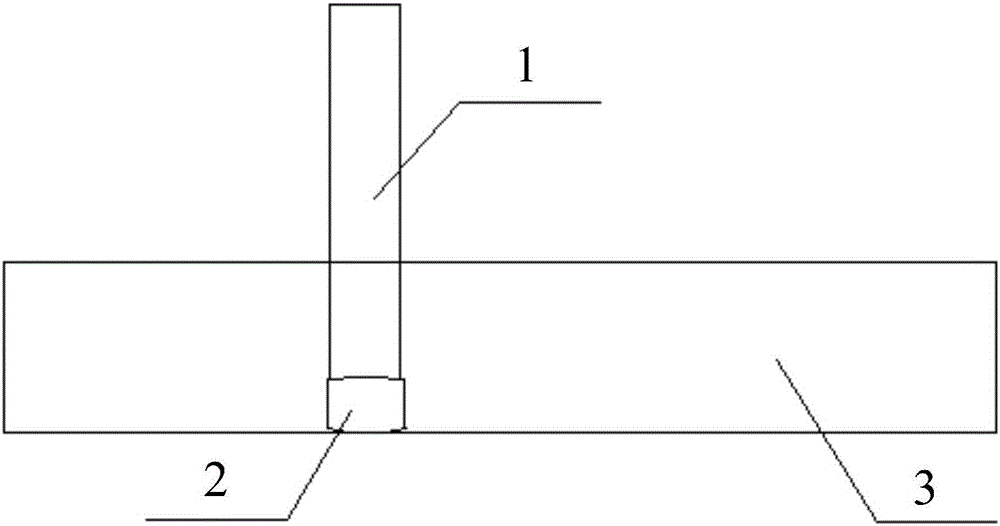

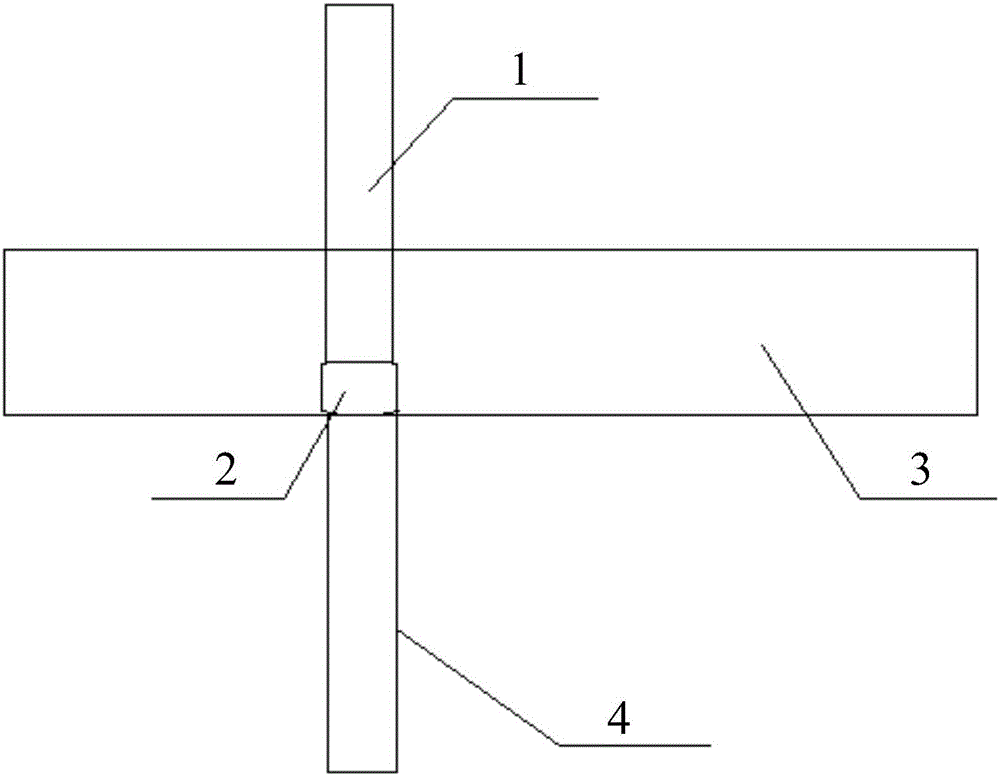

Construction method during beam penetrating of spool

InactiveCN106401182AWill not flowAvoid quality defectsForms/shuttering/falseworksArchitectural engineeringBuilding construction

The invention discloses a construction method during beam penetrating of a spool. The construction method comprises the steps that the bottom of the embedded spool (1) is blocked; and the embedded spool (1) is abutted against a beam bottom template, and concrete is poured on the periphery of the embedded spool so as to form a beam body (3). Through the construction method during beam penetrating of the spool, the defect of construction quality is overcome effectively, and the mechanical and electrical installation and construction efficiency is improved.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

Thermoplastic polyurethane elastomer and preparation method thereof

The invention relates to a thermoplastic polyurethane elastomer and a preparation method thereof. The preparation method comprises the following steps of: mixing polyester polyol, polyether polyol or a mixture of polyester polyol and polyether polyol, organic diisocyanate and micromolecular diol, inputting into a twin-screw premixing unit, shearing and dispersing in axial and radial directions ata high speed for 1 to 2 minutes to make the polymer have certain viscosity and molecular weight, pressing into a co-rotating reactive twin-screw extruder at the temperature of between 180 and 240DEG C, reacting for 2 to 3 minutes, and performing underwater granulation by using a granulator to obtain thermoplastic polyurethane elastomer particles. Compared with the prior art, the invention has a series of advantages that: production equipment investment is small, the process is simple, the process is controlled stably, and the prepared polyurethane elastomer has a few gel points, good appearance and color, good physical and mechanical properties, uniform molecular weight distribution and wide application prospect.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

Foam box

InactiveCN110641808AImprove stiffnessHigh strengthPackage recyclingContainers to prevent mechanical damageEngineeringMechanical engineering

The invention provides a foam box which sequentially comprises an outer layer, a middle layer and an inner layer. The material of the outer layer is EPP or EPO; the material of the middle layer is EPS; and the material of the inner layer is EPS. The foam box solves the problem that the inner layer does not drop chips, so that the cleanliness of glass products is ensured; the impact resistance of the outer layer of the reinforced foam box is strong, the outer layer of the reinforced foam box is not prone to being damaged in the packaging and transportation processes, and the recovery times areincreased; the stiffness and strength of the foam box are improved, and the foam box is not prone to being bent in transportation; and the packaging cost is reduced.

Owner:NANJING CEC PANDA LCD TECH

Intelligent communication battery charge and discharge optimization control system

InactiveCN104009525BImprove securityImprove stabilityBatteries circuit arrangementsElectric powerElectricityBattery charge

Owner:徐宪华

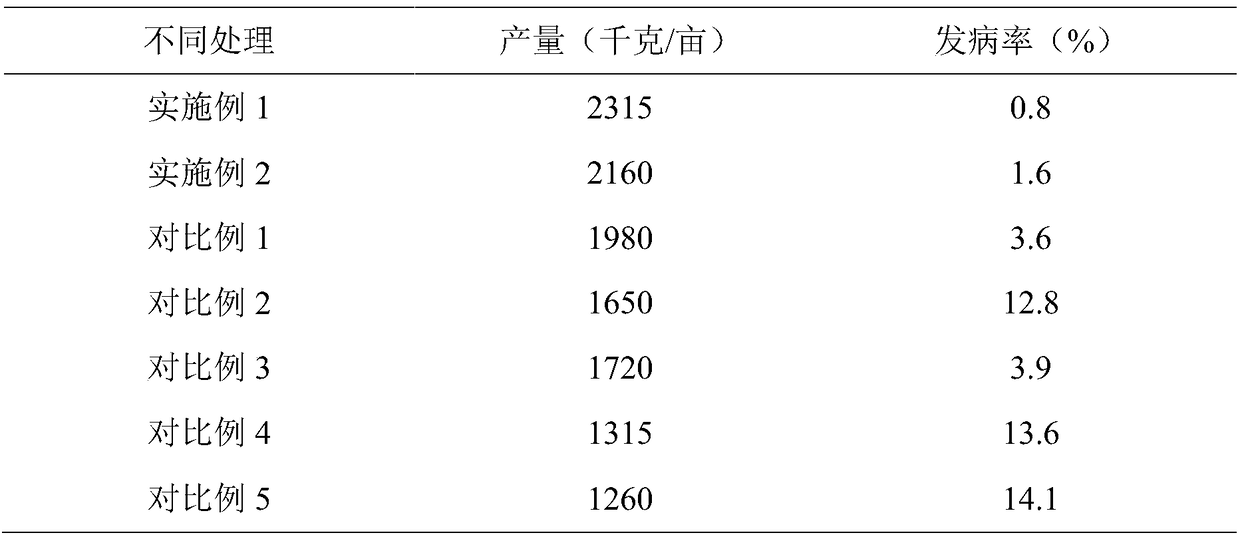

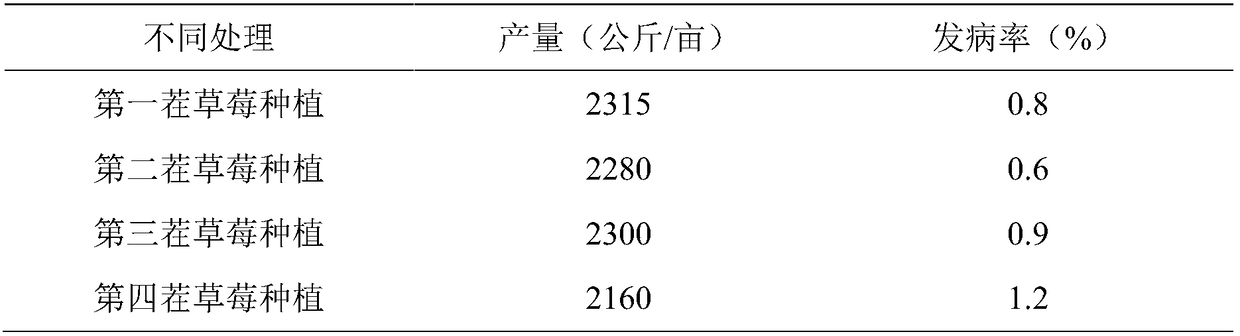

High-efficiency disinfection treatment method for strawberry elevated cultivation substrate

InactiveCN108934916AImprove disinfection efficiencyImprove physical and chemical propertiesGrowth substratesCulture mediaContinuous croppingDisease

The invention discloses a high-efficiency disinfection treatment method for a strawberry elevated cultivation substrate. The method comprises the following steps: (1) pulling up strawberries in an elevated substrate in late April, removing a cultivation trough mulch, deeply ploughing the cultivation trough substrate, and pulling out strawberry plant root systems; (2) in early May, adding a bactericide to the substrate, turning over the bactericide and the substrate for uniform mixing, and thoroughly watering the substrate to make the water content of the substrate at 70-80%; (3) covering a cultivation trough with a film with a matched width immediately, after the covering for 25 to 30 days, revealing the film for deflating for 15 to 20 days; and (4) spreading a microbial agent and an organic fertilizer to the substrate, performing uniform mixing, thoroughly watering the substrate, allowing the watered substrate to stand for 10-15 days. The method disclosed by the invention solves the problem that an elevated cultivation substrate has heavy pests and diseases during continuous cropping and disinfection is time-consuming and labor-intensive, enables the cultivation substrate to be recyclable and improves physical and chemical properties of the substrate, and also the application scale of elevated substrate cultivation can be expanded, and the planting efficiency is improved.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com